Method for splicing plates

A technology for plates and joints, applied in covering/lining, construction, building construction, etc., can solve problems such as easy loosening, insufficient connection at splicing joints, inconvenient disassembly, etc., to enhance hardness and strength, and improve production efficiency , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

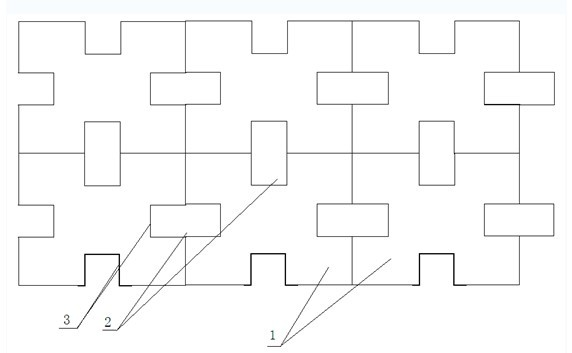

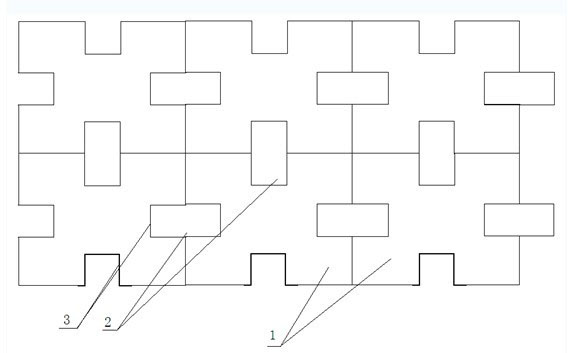

[0014] see figure 1 , a splicing method for plates, comprising at least two plate blocks, 1 and at least one connecting piece 2, comprising the following steps: firstly, opening a concave connection opening 3 on each edge of the two plate blocks 1; secondly, forming a shape The two ends of the connector 2 whose size is suitable for the above-mentioned concave connection opening 3 are respectively inserted into the concave connection opening 3 until the edges of two adjacent plate blocks are in close contact. The edge of the concave connection port 3 or the edge of the plate block 1 can also be covered with a hard sheath to increase strength and prevent breakage. Comes in a hard sheath. The plate block 1 is rectangular. During application, according to the size of the demand, the number of plate blocks and connectors can be flexibly set to match the actual shape and size.

[0015] When the present invention is implemented, the in-line connector is just inserted into the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com