Electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings

A technology for pretreatment devices and spare parts, applied in electrophoretic plating, electrolytic coatings, coatings, etc., can solve problems such as insufficiency of electrophoresis devices, and achieve the effects of improving aesthetics, avoiding damage, and improving work efficiency

Active Publication Date: 2018-04-13

ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

View PDF11 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to solve the problem of incomplete function of the electrophoretic device in the prior art, and propose a pretreatment device for electrophoretic painting on the surface of mechanical parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

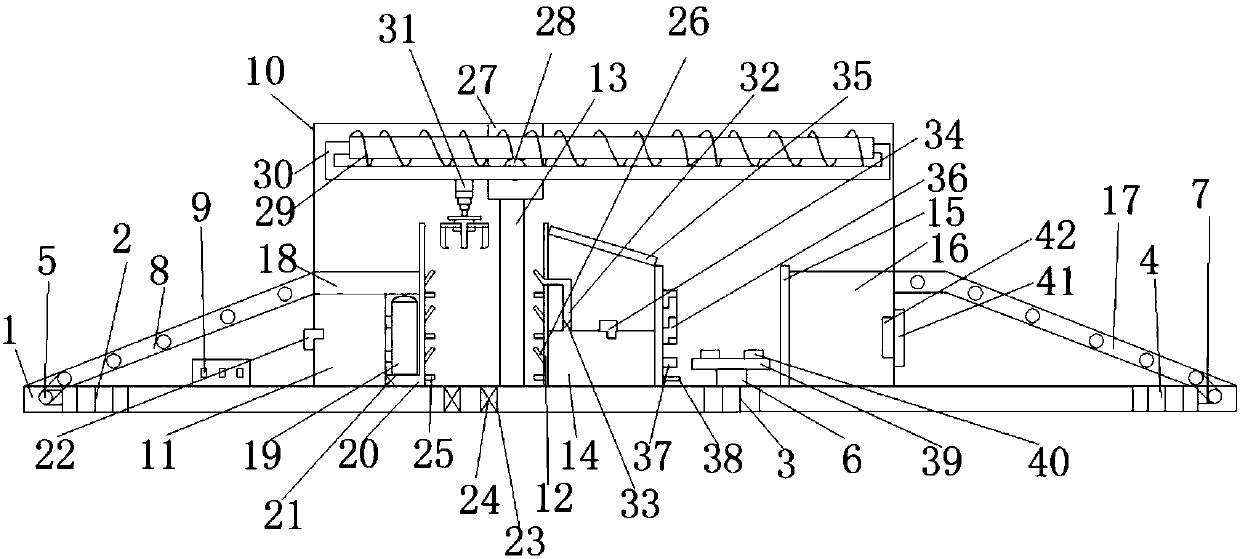

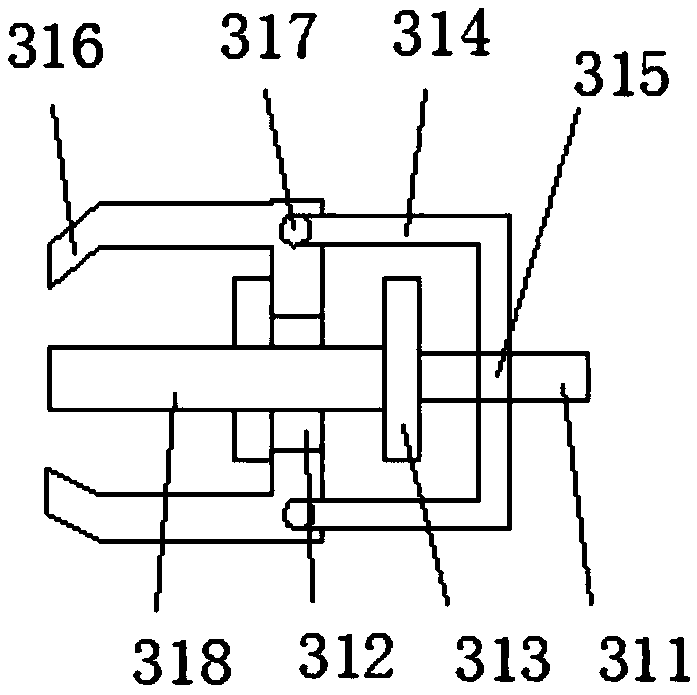

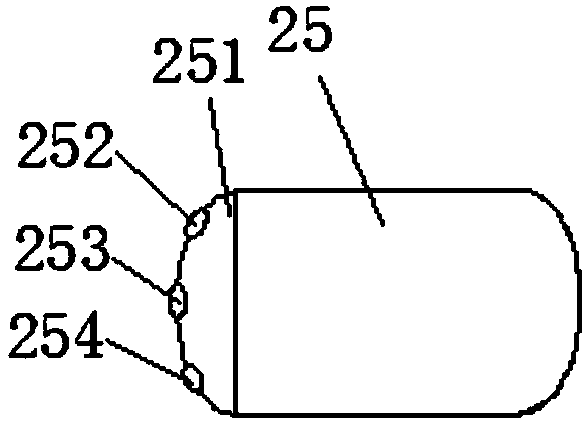

The invention discloses an electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings. The electrophoresis paint-spraying pretreatment device comprises a housingI, wherein an inner cavity of the housing I is hollow; the bottom wall of the housing I is sequentially connected with a motor I, a motor II and a motor III in the horizontal direction; one end of themotor I, one end of the motor II and one end of the motor III are separately connected with a rotary shaft I, a rotary shaft II and a rotary shaft III; the top of the housing I is sequentially connected with a conveyor belt I, a controller, a frame body, a water tank, a barrel body, a supporting rod, a booster pump, a housing II, an electrophoresis slot and a conveyor belt II in the horizontal direction; one end, away from the housing I, of the conveyor belt I is fixedly connected with a placing plate; the placing plate is positioned on the top of the water tank; and the side wall of one side, away from the conveyor belt, of the water tank is sequentially connected with a water pump and a water introducing tube in the vertical direction. The electrophoresis paint-spraying pretreatment device is simple in structure, is convenient to operate, realizes pretreatment for electrophoresis parts and fittings and a treatment function after electrophoresis is completed, and improves electrophoresis quality.

Description

technical field [0001] The invention relates to the technical field of mechanical production equipment, in particular to a pretreatment device for electrophoretic paint spraying on the surface of mechanical parts. Background technique [0002] The electrophoretic coating has the advantages of fullness, uniformity, smoothness and smoothness. The hardness, adhesion, impact performance and permeability of the electrophoretic coating film are significantly better than other processes, while reducing pollution. The traditional electrophoretic spraying technology is harmful to automobiles Parts are sprayed, and the parts that the spraying device clamps during work are separated separately, which greatly reduces the work efficiency for the same type of parts, and when clamping irregular parts, it is easy to cause problems caused by insecure clamping. The accessories fell, causing damage to the spraying device and causing great losses. Moreover, the paint film was not cured after th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D13/22C25D13/20

Inventor 陈玉何宏颖陈运洲郝声远李敏

Owner ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com