Drilling sample plate with positioning and supplementing functions

A kind of template and supplementary technology, applied in the direction of the drilling mold used for the workpiece, etc., can solve the problems of taking up a lot of working time, not very convenient to use, and cumbersome design process, so as to shorten the working time, avoid deviation, and reduce working steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

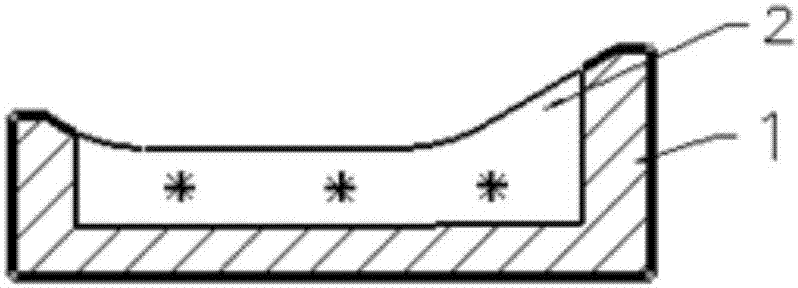

[0019] (1) Design a drilling template at the rib, and the upper surface shape of the rib and the required hole position are given on the drilling template.

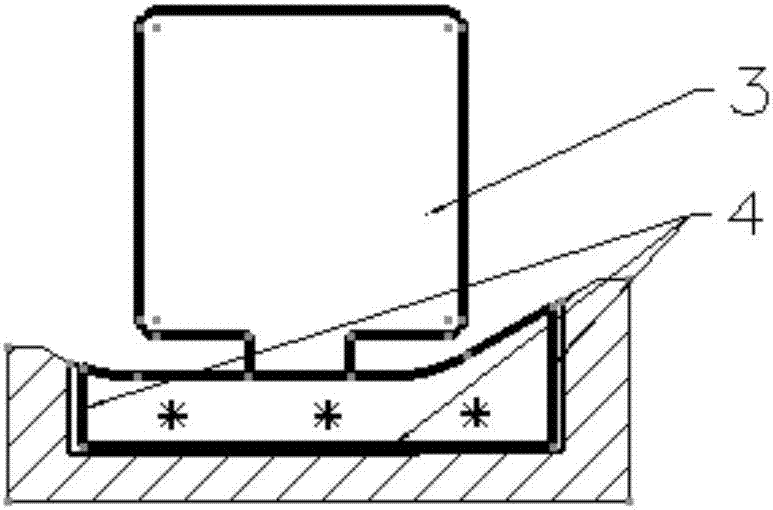

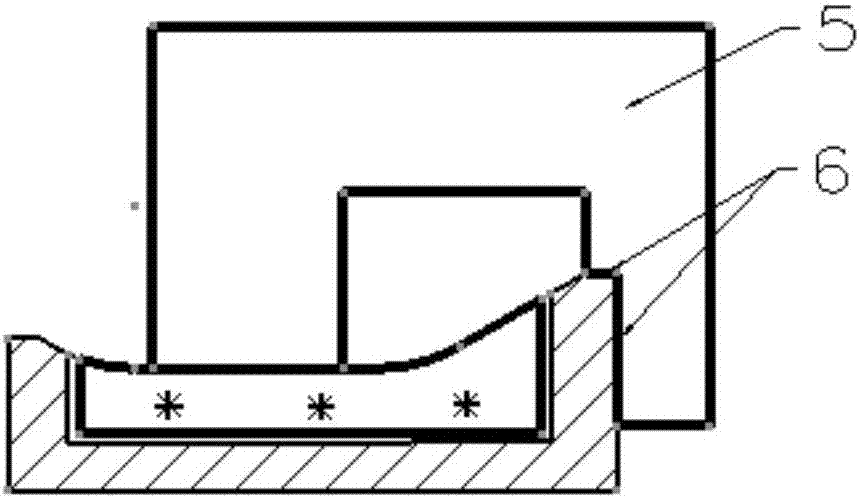

[0020] (2) Select the top surface and side surface of the side edge of the part as the supplementary outer edge shape as the positioning reference, and design a drilling template with positioning supplementation, such as image 3 .

[0021] (3) The drilling template with positioning addition is directly attached to the rib, and the added positioning edge is directly attached to the part to complete the drilling and inspection work at the rib of the part, which meets the needs of rapid positioning of the template .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com