Soft fast recovery diode of multi-mixture structure and preparation method thereof

A recovery diode and hybrid structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of increasing low-concentration P-type impurity injection, weakening Schottky junction shielding effect, and increasing reverse leakage current, etc. problem, achieve the effect of reducing the hole injection efficiency, avoiding the reduction of the barrier height, and reducing the reverse recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

[0016] 0014 embodiment

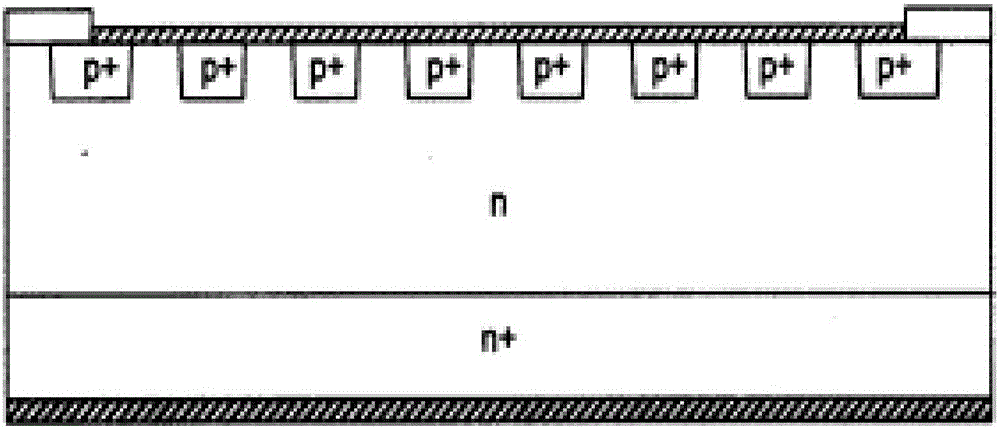

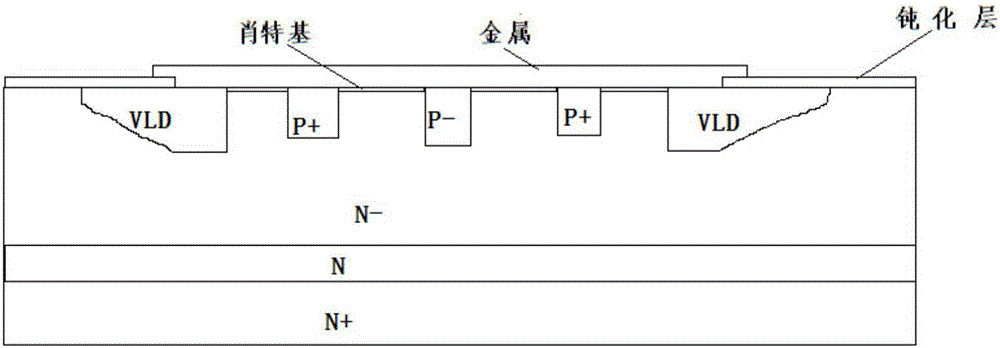

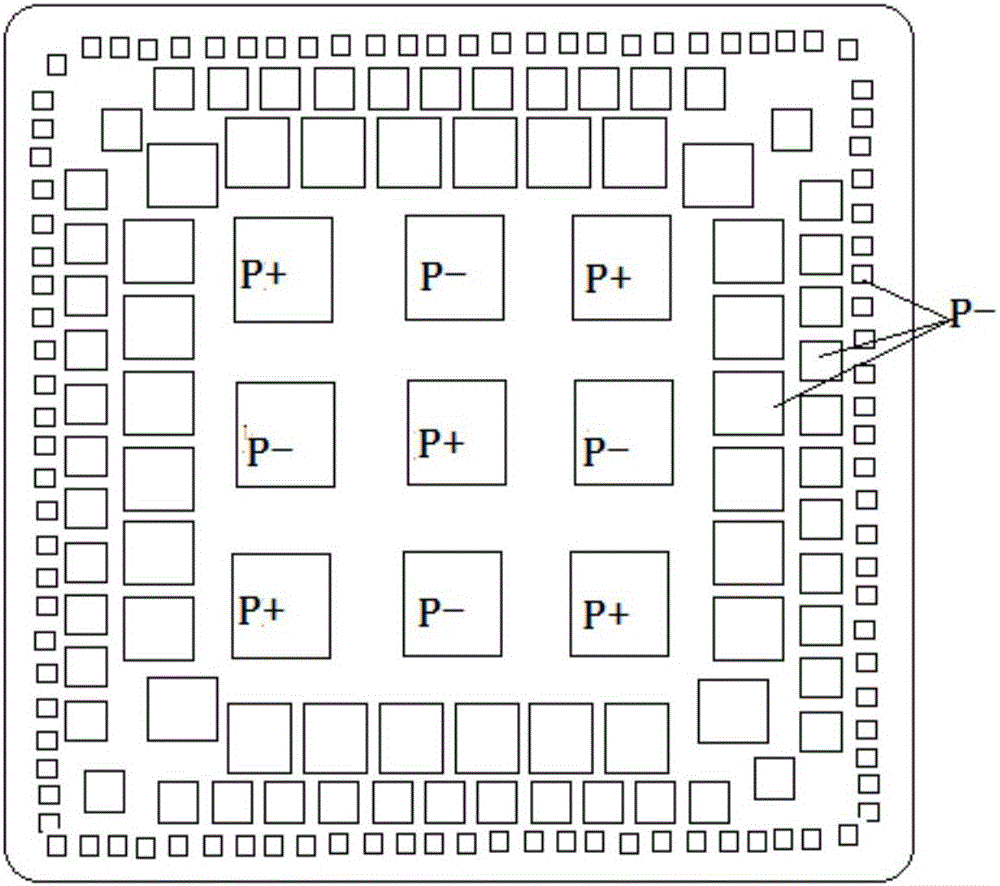

[0017] Grow an oxide layer of 1um on a silicon epitaxial wafer (N-region thickness 45um), lithography the P-region, and implant B11 (1E13cm 2 ), pushing the junction (junction depth 4um), photolithography P+ area, implanting B11 (2E15 / cm 2 ), push junction (6um), lithography active area, sputtering metal Pt, alloy at 450°C, removing Pt, evaporating metal AL, lithography corroding metal, backside thinning 250um, evaporating TiNiAg metal, P+ area and P- area All adopt a square shape with a side spacing of 18um. The VLD terminal is divided into three areas, and the duty cycles are 75%, 50%, and 25%.

[0018] The obtained diode reverse cut-off (breakdown) voltage is 720V, T rr : 30ns, reverse leakage current 2uA, VF: 1.7V, softness 1.1.

[0019] Of course, those of ordinary skill in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com