SiC vertical double diffused metal-oxide-semiconductor (VDMOS) device and fabrication method thereof

A technology of silicon carbide and silicon carbide area, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as rising system cost, low working speed, and increased volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

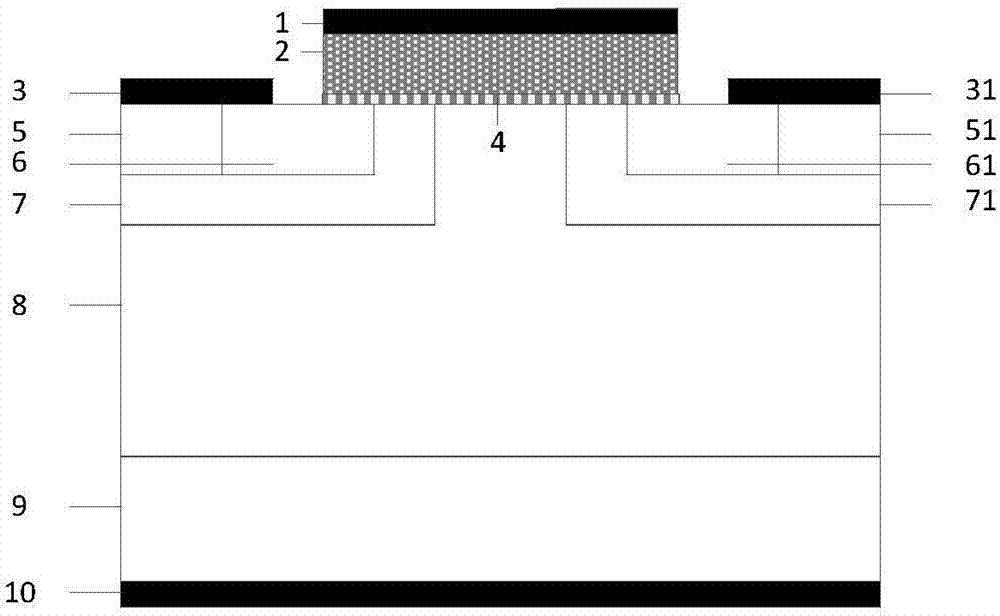

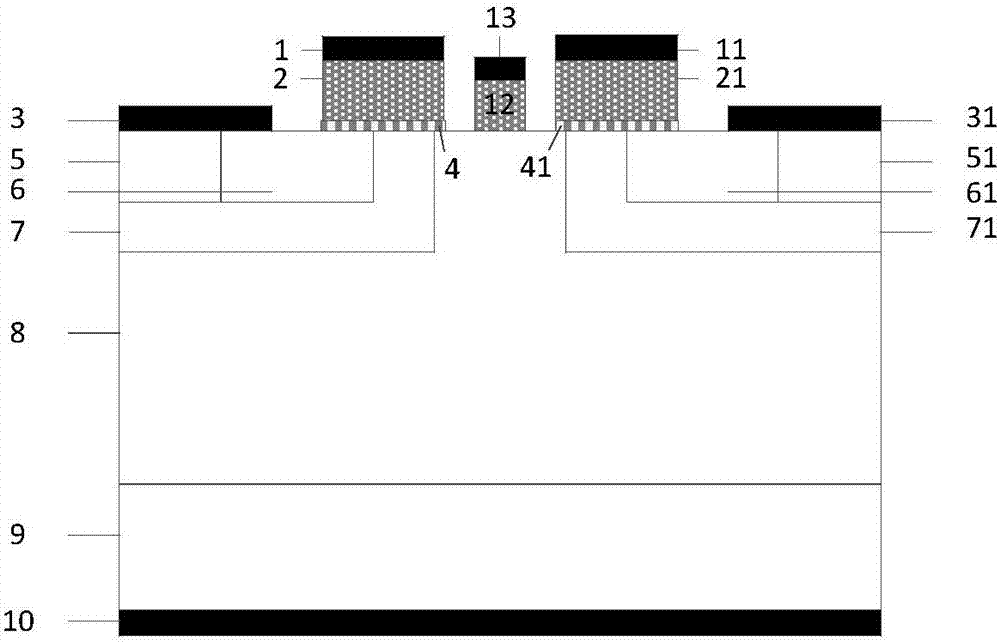

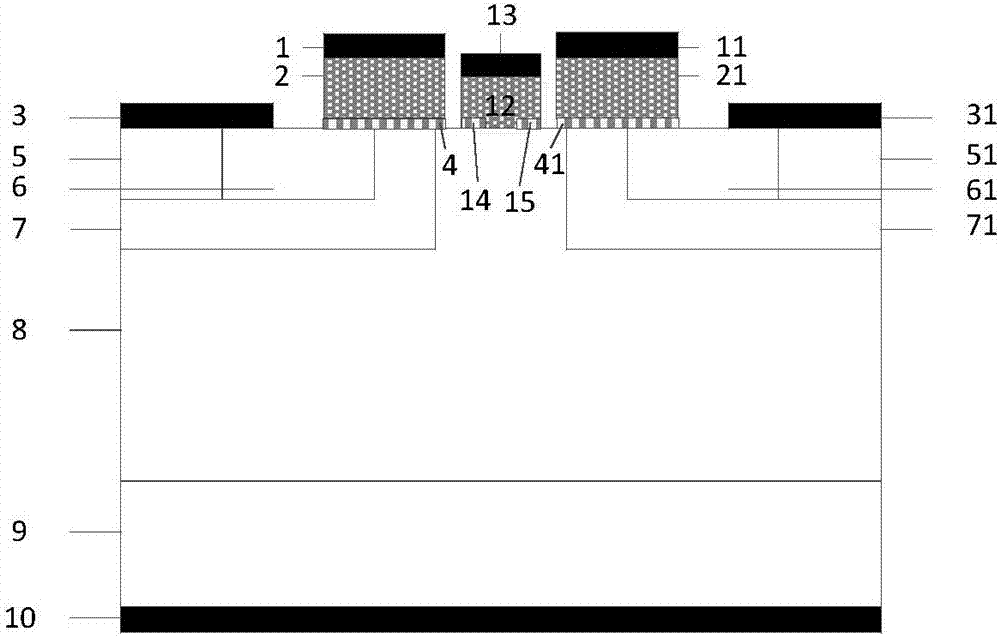

[0062] A kind of silicon carbide VDMOS device provided by the present invention, the cell structure of its basic structure is as follows figure 2 shown. It includes a metal drain electrode 10 arranged sequentially from bottom to top with a thickness of about 0.5-6 μm and a doping concentration of 1×10 18 cm -3 ~1×10 19 cm -3 , N with a thickness of 50-200 μm + The substrate 9 has a thickness of 15-18 μm and a doping concentration of about 1×10 15 cm -3 ~5×10 16 cm -3 N - Epitaxial layer 8; above the N- epitaxial layer 8 has a doping concentration of 1×10 17 ~7×10 17 cm -3 1. Implant the first Pbase region 7 with a depth of about 0.5-1 μm, and the other end of the upper layer has a second Pbase region 71 with the same parameters; the first Pbase region 7 has mutually independent doping concentrations of 1×10 19 ~1×10 20 cm -3 , implanting the first N with a depth of about 0.3-0.5 μm + The source region 6 and the doping concentration are about 3×10 19 ~1×10 20 ...

Embodiment 2

[0064] except P + Both sides below the polysilicon layer 12 also have N - The first dielectric layer 14 and the second dielectric layer 15 in direct contact with the epitaxial layer 8 are the same as the first embodiment in the rest of the structure of this embodiment.

[0065] In diode application, the first dielectric layer 14 and the second dielectric layer 15 are at P + The electron accumulation layer formed under the polysilicon layer 12 can further reduce the drift region resistance of the device, thereby reducing the forward conduction voltage drop of the device.

Embodiment 3

[0067] divide by N - In the epitaxial layer 8 and under the first Pbase region 7, there is also a first P-type silicon carbide region 16 forming a super junction or semi-super junction structure, and the N - In the epitaxial layer 8 and below the first Pbase region 7 there is also a second P-type silicon carbide region 161 forming a superjunction or semi-superjunction structure, and the rest of the structure of this embodiment is the same as that of Embodiment 1.

[0068] The formation of a superjunction or semi-superjunction structure can further reduce the drift region resistance of the device in diode applications and MOS applications, thereby reducing the forward conduction voltage drop of the device.

[0069] and figure 1 Compared with the cell structure of the traditional silicon carbide VDMOS device shown, the present invention deposits a polysilicon layer on the surface of the JFET region of the silicon carbide VDMOS device to form a Si / SiC heterojunction. Applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com