Making process of fast recovery chip

A manufacturing process and chip technology, which is applied to the manufacturing process of fast recovery chips, can solve the problems of high failure rate and low reliability, and achieve the effects of low failure rate, high reliability and improved functional characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

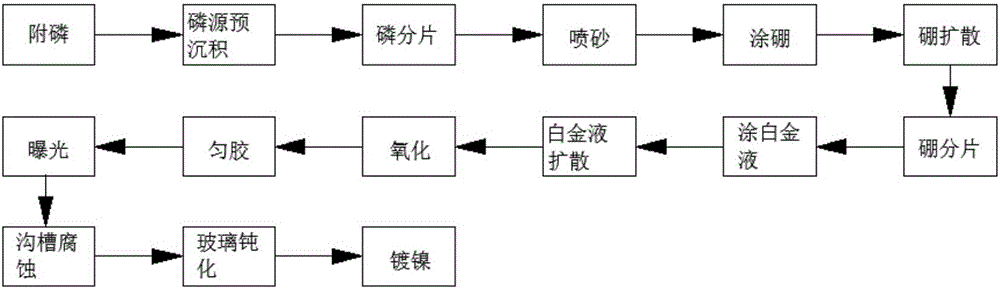

[0037] Such as figure 1 A fast recovery type chip fabrication process shown includes the following steps:

[0038] (1) Phosphorous attachment: first clean the silicon wafers, then sandwich the paper-like phosphorus source with a concentration of not less than 70% between adjacent silicon wafers, and place them on the quartz boat in turn; the silicon wafer cleaning steps are: First put the silicon wafer into the HF solution and soak for 2 minutes, wherein the ratio of the HF solution is HF:H2O=1000ml:8500ml, the temperature is 35°C, and then use the Harmo solution and hot pure water for ultrasonic vibration, the Harmo solution ratio is Harmo powder: H2O=200g: 18000ml, temperature: 85°C, time 20min, finally flushing, shaking with running water, flushing, drying, silicon wafers are cleaned;

[0039] (2) Phosphorus source pre-deposition: send the quartz boat equipped with silicon wafers into a diffusion furnace with a temperature of 600°C to decompose the phosphorus source for 2 ...

Embodiment 2

[0055] Such as figure 1 A fast recovery type chip fabrication process shown includes the following steps:

[0056] (1) Phosphorous attachment: first clean the silicon wafers, then sandwich the paper-like phosphorus source with a concentration of not less than 70% between adjacent silicon wafers, and place them on the quartz boat in turn; the silicon wafer cleaning steps are: First put the silicon chip into the HF solution and soak for 1min, wherein the ratio of the HF solution is HF:H2O=1000ml:8500ml, the temperature is 25°C, and then use the Harmo solution and hot pure water for ultrasonic vibration, the Harmo solution ratio is Harmo powder: H2O=200g: 18000ml, temperature: 75°C, time 10min, finally flushing, shaking with running water, flushing, drying, silicon wafers are cleaned;

[0057] (2) Phosphorus source pre-deposition: send the quartz boat equipped with silicon wafers into a diffusion furnace with a temperature of 550°C to decompose the phosphorus source for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com