Silicon carbide Trench MOS device and manufacturing method thereof

A silicon carbide and device technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high power loss, low work efficiency, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

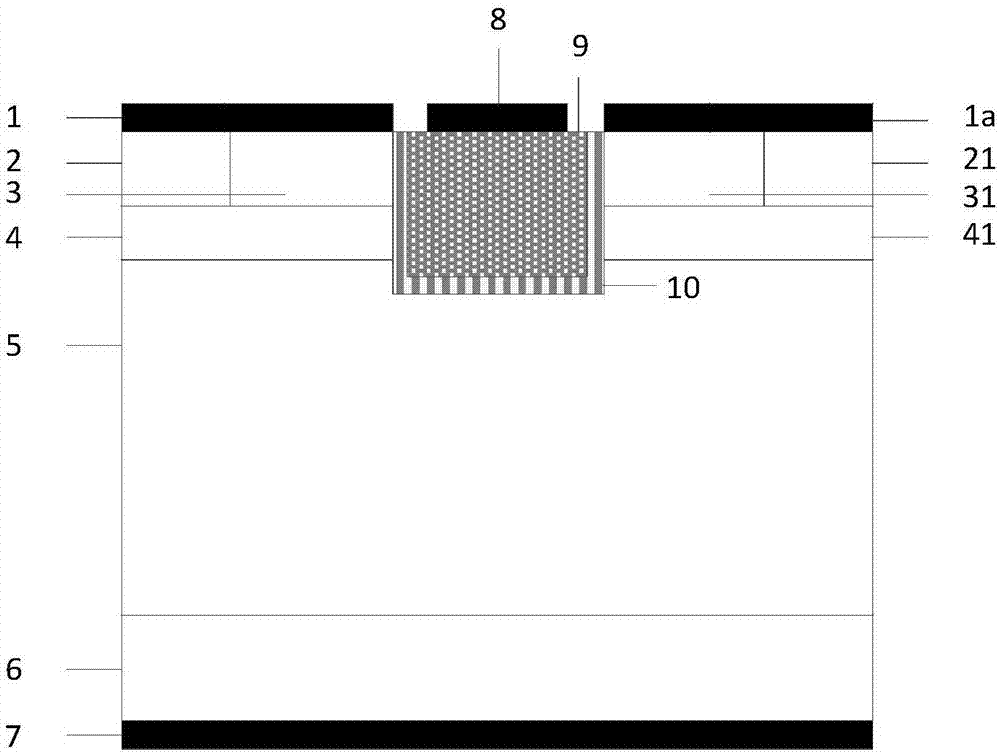

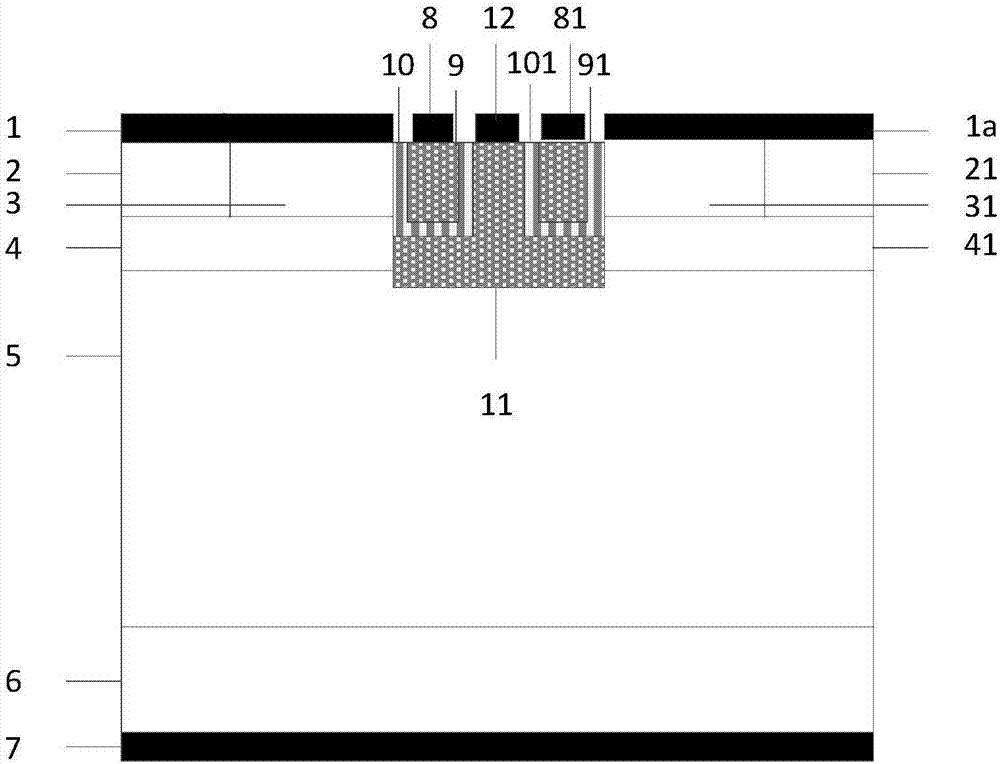

[0099] A silicon carbide Trench MOS device, its cell structure is as follows figure 2 Shown includes: metal drain electrodes 7, N + Substrate 6 and N - epitaxial layer 5; the N - One end of the upper layer of the epitaxial layer 5 has a first Pbase region 4, the N - The other end of the upper layer of the epitaxial layer 5 has a second Pbase region 41; the first Pbase region 4 has mutually independent first N + source region 3 and the first P + Contact region 2; the second Pbase region 41 has second N independent of each other + source region 31 and the second P + Contact area 21; the first P + contact zone 2 and the first N + The upper surface of the source region 3 has a first metal source electrode 1; the second P + contact region 21 and the second N + The upper surface of the source region 31 has a second metal source electrode 1a; it is characterized in that: the N under the middle position of the two Pbase regions 4, 41 - There is a convex P-type polysilicon re...

Embodiment 2

[0102] In this implementation, on the basis of Embodiment 1, there is also a P+ silicon carbide region 13 in contact with it below the P-type polysilicon region 11; the width of the P+ silicon carbide region 13 is the same as that of the P-type polysilicon region 11 .

[0103] The P+ silicon carbide region 13 added in this embodiment can shield the P+ polysilicon region 11 and the MOS trench gate from the electric field, thereby improving the withstand voltage of the device, and has a certain effect on suppressing the reverse leakage current.

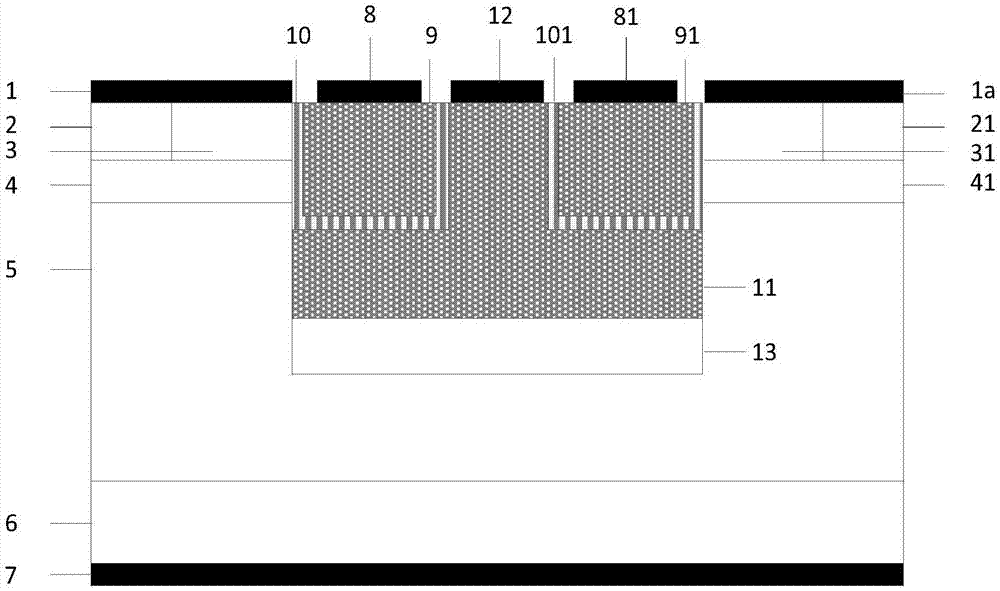

Embodiment 3

[0105] In this implementation, on the basis of Embodiment 1, there is also a P + SiC region 13; the P + The width of the silicon carbide region 13 is greater than the width of the P-type polysilicon region 11, the P + The width of the silicon carbide region 13 ranges from 1.0 to 2.6 μm.

[0106] In this example, P + The lateral dimension (i.e. width) of the silicon carbide region 13 is enlarged, and compared with the embodiment 2, it has a stronger electric field shielding effect on the P+ polysilicon region 11 and the MOS trench gate, further improves the withstand voltage of the device, and further suppresses the reverse leakage current.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com