Punching device for bridge plate production line

A punching device and production line technology, applied in stripping devices, punching tools, metal processing equipment, etc., can solve the problems of economic loss of production units, difficulty in second alignment, and no blanking, etc., and achieve high production efficiency. Compact structure and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

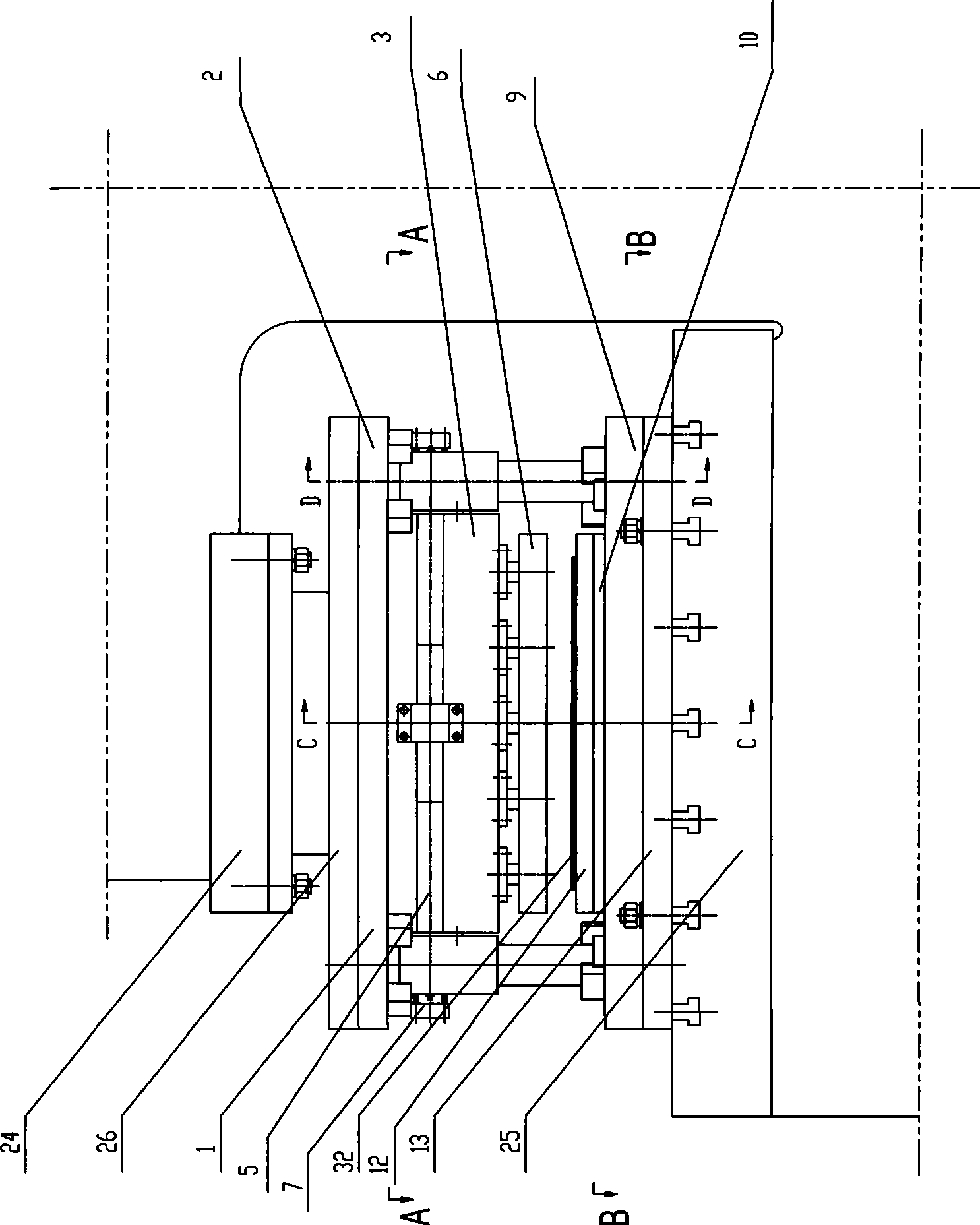

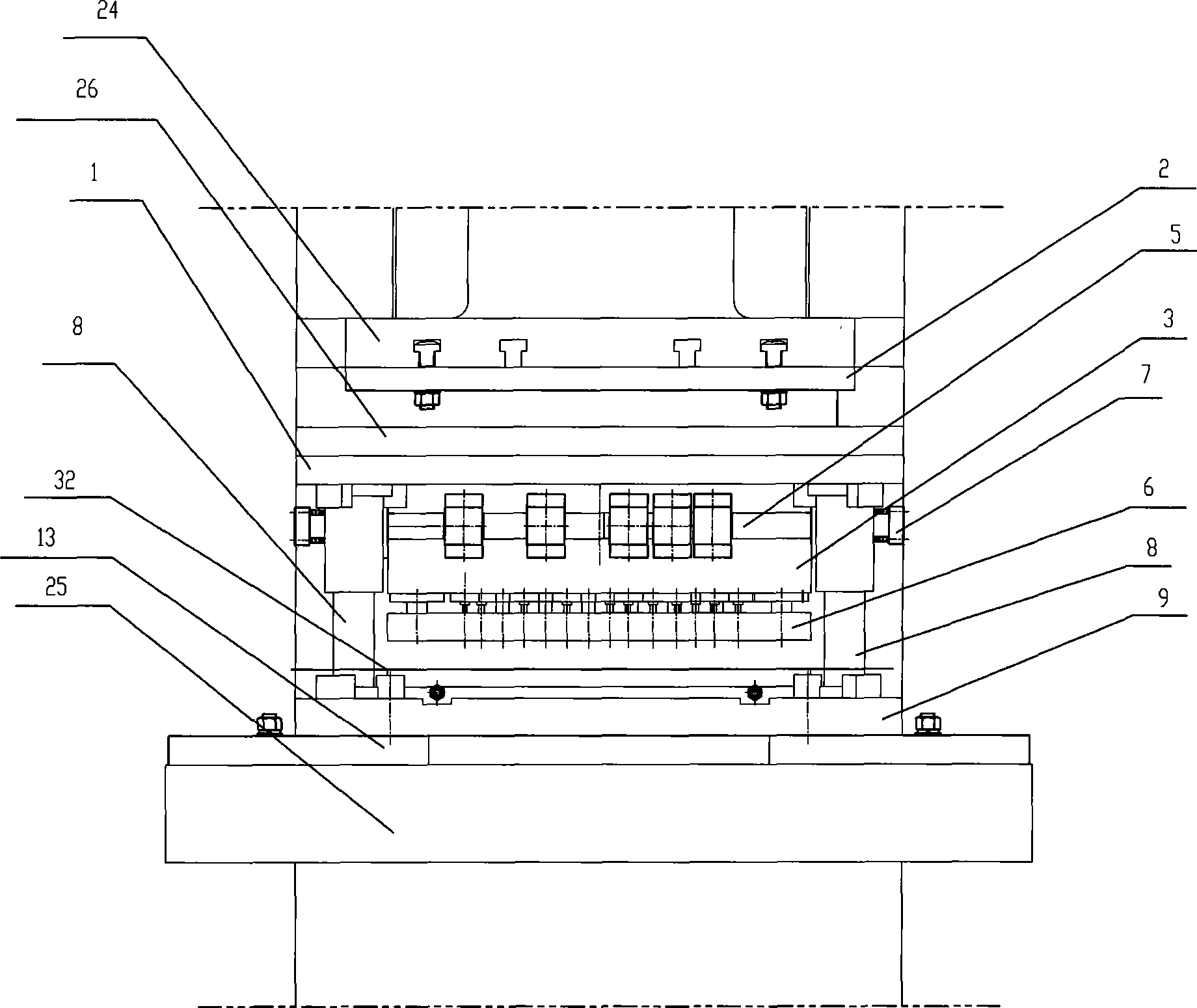

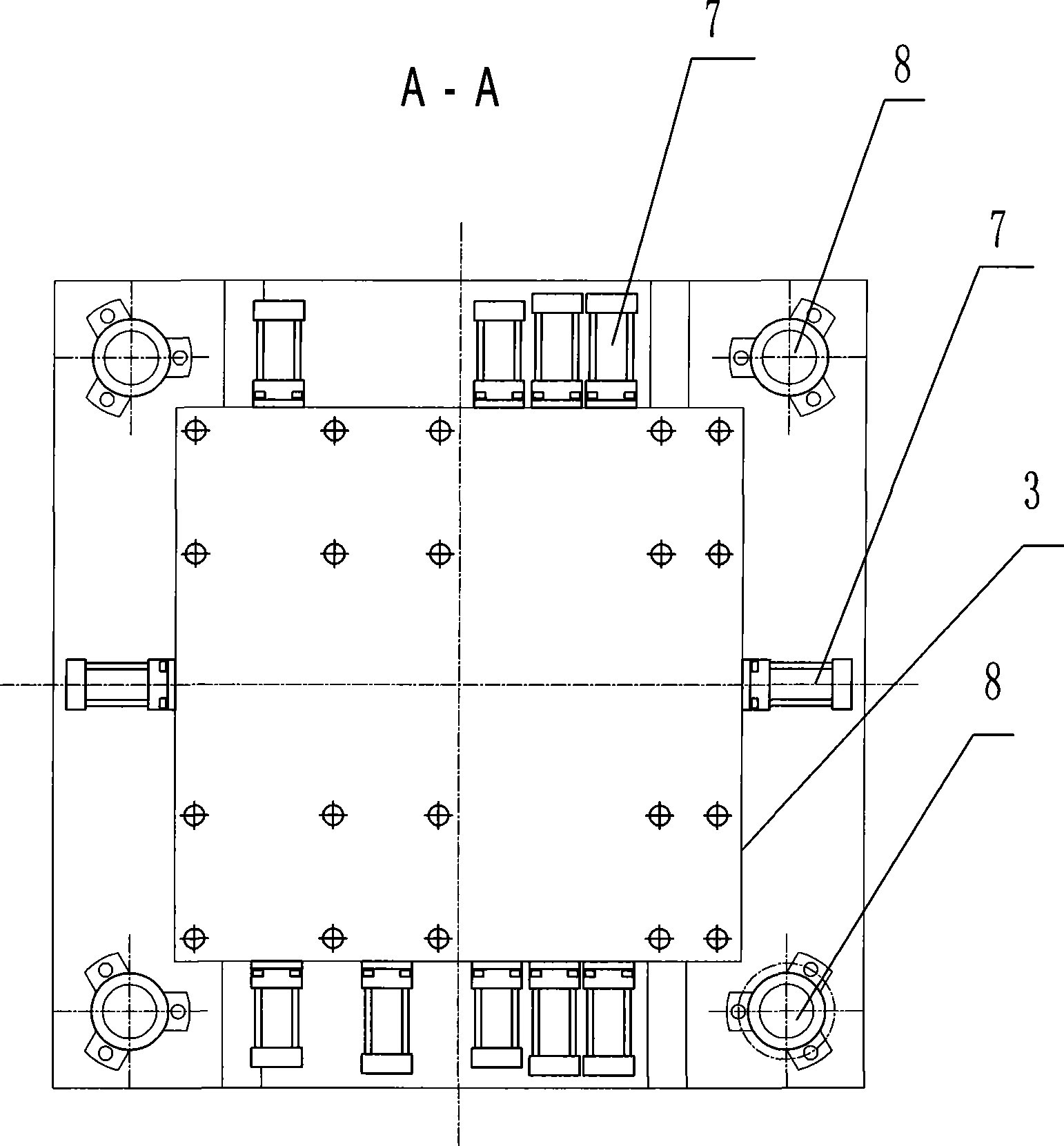

[0028] figure 1 , 2 , 3, 4, and 5 show a specific embodiment of the present invention, which is a punching device installed on the bridge plate production line for construction engineering; it is characterized in that: the upper workbench 24 and the lower workbench of the mechanical press 25 is connected with a transition bracket 26 composed of longitudinal and beam connections, and a punching device is installed in the transition bracket 26. The punching device is composed of a square frame body, convex template 3, II# upper connecting plate 2, and inserting plate 5 , cylinder 7, stripper plate 6, concave template 12, lower template 9 and backing plate 13, are assembled into a square frame body by I# upper connecting plate 1, lower template 9 and four movable guide columns, each of the Square active guide pillars (such as Image 6 shown) is made up of guide post 8 and guide post cover 18; the lower template 9 in the frame body sits on the backing plate 13; the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com