Small-sized material carrying device

A technology for handling devices and materials, applied in the field of machinery, can solve the problems of inflexible use, difficult to meet the needs of use, simple structure, etc., and achieve the effect of flexible use, suitable for popularization and use, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

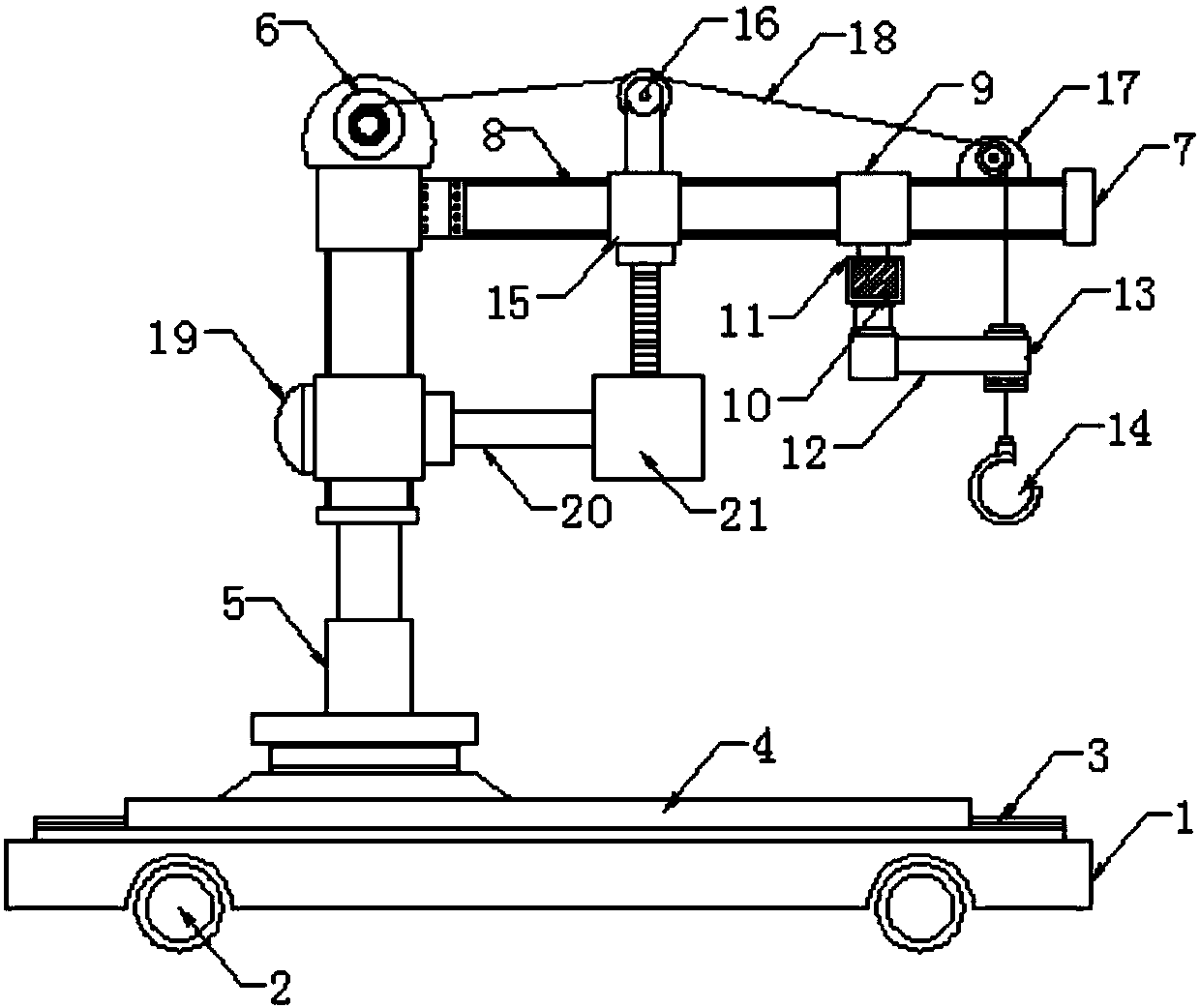

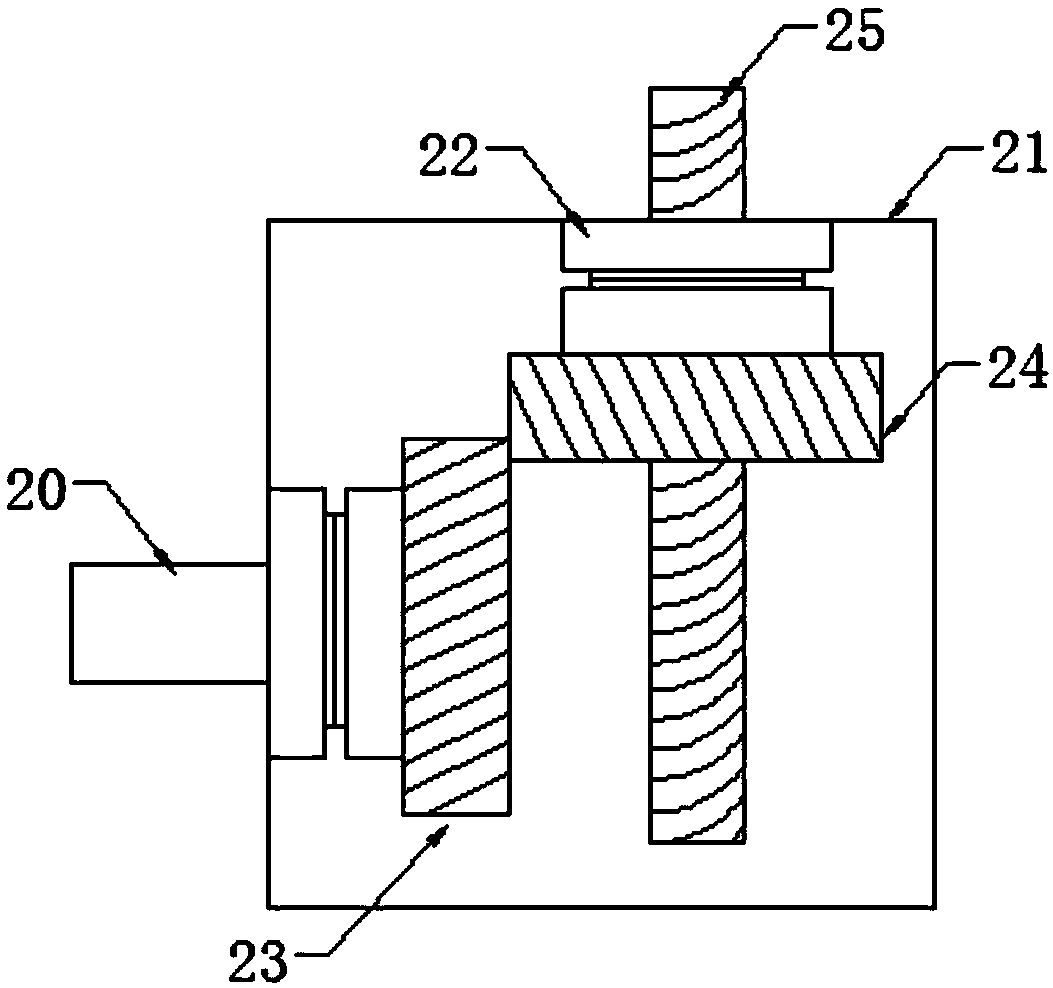

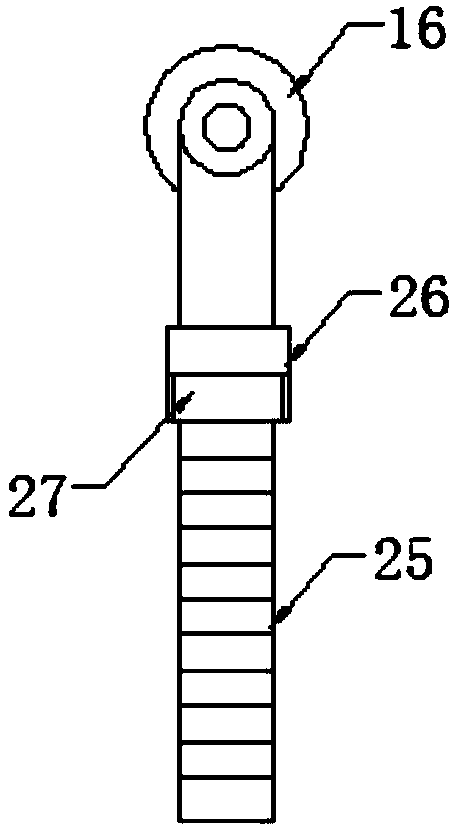

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a small material handling device, including a base 1, a roller 2, a chute 3, a bottom plate 4, a lifting column 5, a pay-off roller 6, a first beam 7, and a slide rail 8 , the first slider 9, the second beam 10, the second slider 11, the rocker arm 12, the limit joint 13, the hook 14, the sleeve 15, the ejector 16, the pulley 17, the pull wire 18, the servo motor 19, the output Shaft 20, steering gear box 21, swivel seat 22, first steering gear 23, second steering gear 24, screw mandrel 25, positioning joint 26 and movable bushing 27, base 1 is provided with chute 3, and base 1 passes through The chute 3 is slidably installed with a bottom plate 4, the bottom plate 4 is fixed with a lifting column 5, the lifting column 5 is fixedly connected with a first crossbeam 7, the first crossbeam 7 is provided with a slide rail 8, and the first crossbeam 7 passes through the slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com