Oil-containing sludge profile-control plugging agent and preparation method thereof

A profile control plugging agent, oil sludge technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of unstable profile control agent, poor profile control plugging effect, etc., to improve stability, Improve the effect of profile control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

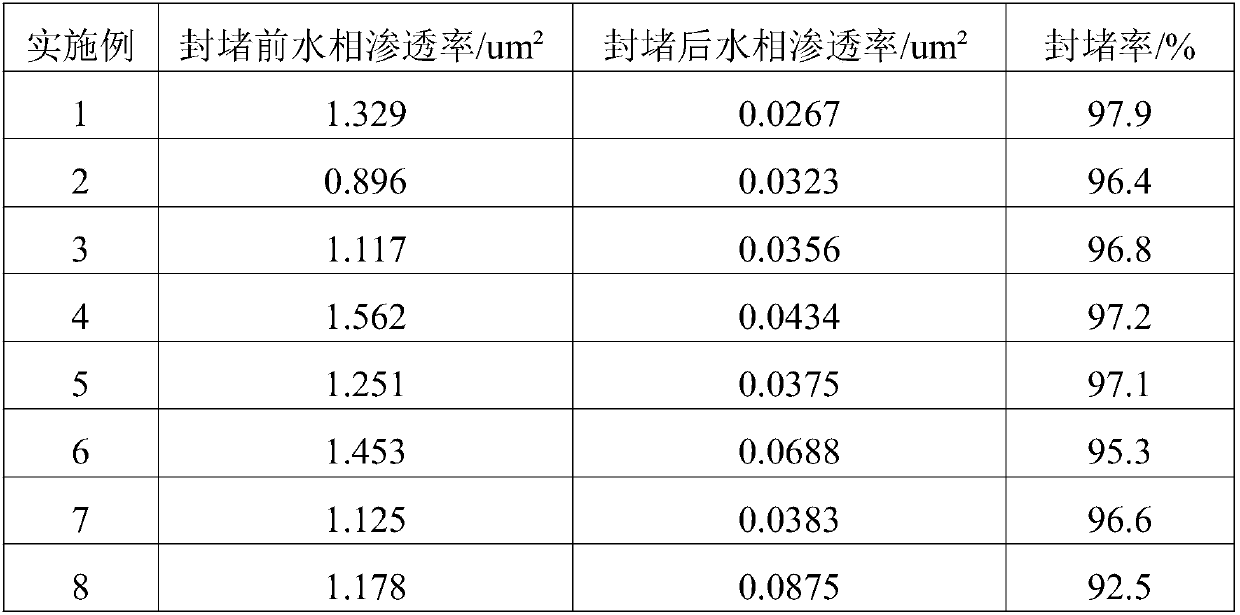

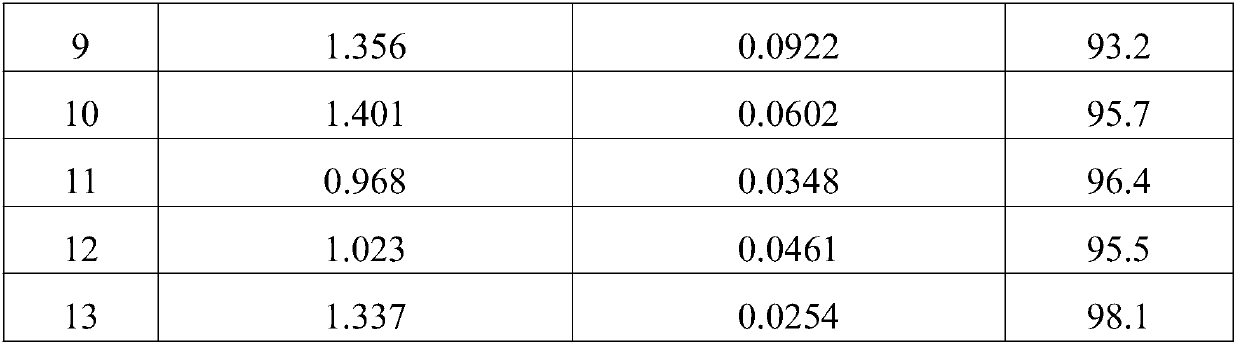

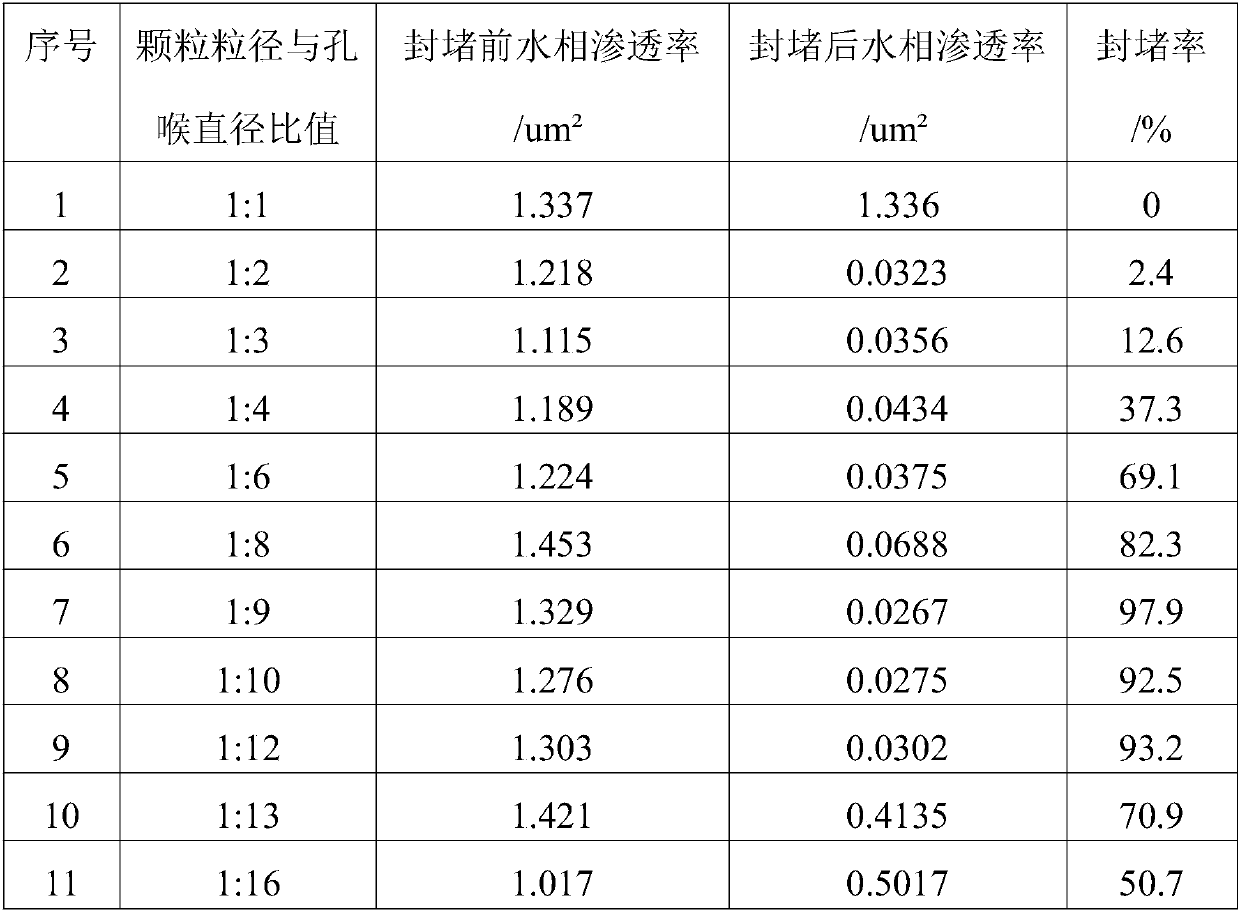

Examples

Embodiment 1

[0051] This embodiment provides a profile control and plugging agent for oily sludge. The profile control and plugging agent is made of the following raw materials: 3 kg of oily sludge, which is produced by the second joint station of Gudong Oil Production Plant in Shengli Oilfield Subsidence output, its water content is 70wt%, oil content is 10wt%, mud content is 20wt%;

[0052] Dispersant 1.0kg, described dispersant is sodium lauryl sulfate;

[0053] Suspension stabilizer 0.2kg, described suspension stabilizer is amphiphilic block T type polymer A;

[0054] 95.5kg of water.

[0055] This embodiment also provides a method for preparing the oily sludge profile control and plugging agent, comprising the following steps:

[0056] (1) Take the oily sludge according to the above selected parts by weight, pump it to the oily sludge dispersion tank through the solid sludge feeding pump, add water and dispersant in the selected parts by weight, and disperse through stirring;

[00...

Embodiment 2

[0060] This embodiment provides a profile control and plugging agent for oily sludge. The profile control and plugging agent is made of the following raw materials: 5 kg of oily sludge, which is produced by the second joint station of Gudong Oil Production Plant in Shengli Oilfield Subsidence output, its water content is 61.99wt%, oil content is 13.01wt%, mud content is 25wt%;

[0061] Dispersant 0.6kg, described dispersant is the sodium perfluoroalkyl sulfonate of C5-C10;

[0062] Suspension stabilizer 0.2kg, described suspension stabilizer is amphiphilic block T type polymer B;

[0063] 94.5kg of water.

[0064] This embodiment also provides a method for preparing the oily sludge profile control and plugging agent, comprising the following steps:

[0065] (1) Take the oily sludge according to the above selected parts by weight, pump it to the oily sludge dispersion tank through the solid sludge feeding pump, add water and dispersant in the selected parts by weight, and dis...

Embodiment 3

[0069] This embodiment provides a profile control and plugging agent for oily sludge. The profile control and plugging agent is made of the following raw materials: 7kg of oily sludge, which is produced by the second joint station of Gudong Oil Production Plant in Shengli Oilfield Subsidence output, its water content is 69.54wt%, oil content is 15.46wt%, mud content is 15wt%;

[0070] Dispersant 0.5kg, described dispersant is sodium alkylsulfonate;

[0071] Suspension stabilizer 0.2kg, described suspension stabilizer is amphiphilic block T type polymer C;

[0072] 92.3kg of water.

[0073] This embodiment also provides a method for preparing the oily sludge profile control and plugging agent, comprising the following steps:

[0074] (1) Take the oily sludge according to the above selected parts by weight, pump it to the oily sludge dispersion tank through the solid sludge feeding pump, add water and dispersant in the selected parts by weight, and disperse through stirring; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com