Light emitting diode including quantum dots and energy transfer molecules and fabrication method and display device thereof

A technology of light-emitting diodes and energy transfer, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of difficult carrier injection into quantum dots, low internal quantum efficiency, limiting the development and application of QLEDs, large-scale commercialization and Industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

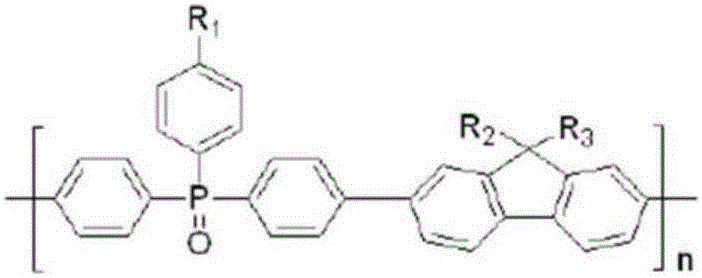

[0130] Synthesis of P8 molecule:

[0131] Under an argon atmosphere, 3.29g (6mmol) of 2,7-dibromo-9,9-dioctylfluorene was dissolved in 80ml of anhydrous tetrahydrofuran, and the temperature was lowered to -78°C (dry ice-acetone bath). 5.1 ml of n-butyl lithium (2.5M in hexane; 12.75 mmol) was slowly added dropwise to give a thick bright yellow solution. Stirring was continued at -70°C for 20 min, then the temperature of the reaction mixture was raised to 0°C. Then the temperature was raised to normal temperature, and 2.8 g (12.75 mmol) of diphenylphosphine chloride were added. The reaction was stirred at -70°C for an additional 3 hours before quenching with 2 ml of degassed methanol. The volatiles were removed under reduced pressure to leave an oily liquid. The crude material was purified by column chromatography on silica (R f =0.29), with chloroform / n-hexane (2:8) as the mobile phase, and finally 3.50 g (77%) of chemically pure P8 was obtained.

Embodiment 2

[0133] Synthesis of PO8 molecules:

[0134] Mix 3.03 g (4 mmol) of P8, 50 ml of dichloromethane and 10 ml of 30% hydrogen peroxide solution, and mix and stir overnight at room temperature. The organic layer was separated and washed successively with water and brine. The product was evaporated to dryness to give a white solid, which was further purified by recrystallization from toluene / n-hexane to give 2.7 g (85%) of chemically pure PO8.

Embodiment 3

[0136] Pre-treatment and cleaning of pre-patterned ITO flakes:

[0137] Set 12 pre-patterned ITO chips covered with polymer on the glass substrate, and immerse in 5% sodium hydroxide aqueous solution at 80° C. for 5 min. Repeat the above steps, and then wash the chip with nanopure water and 20% ethanolamine aqueous solution, and sonicate for 15 minutes, then wash and dry with sufficient nanopure water. Finally, load the ITO chip into the plasma cleaning chamber to clean the surface of the ITO-coated device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com