Composite hole transport layer with multi-layer periodic doping structure, LED device structure and application and preparation method of LED device structure

A technology of hole transport layer and LED device, applied in semiconductor/solid-state device manufacturing, electric solid-state device, semiconductor device, etc., can solve the problems of unbalanced carrier injection, high color purity, narrow half-peak width, etc., and achieve improved Hole injection ability, high color purity, effect of improving injection balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

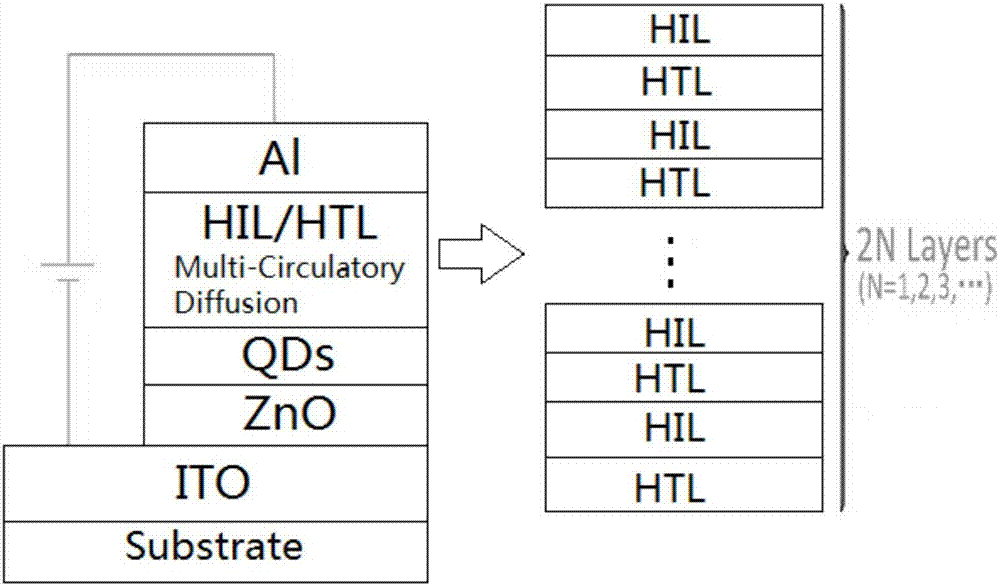

[0030] In this embodiment, see figure 1 , A composite hole transport layer with a multilayer periodic doping structure, the composite hole transport layer has a multilayer composite structure, and the composite hole transport layer is made of MoO 3 Inorganic materials are used as doping materials. The composite hole transport layer is composed of N layers of doped organic layered structural units sequentially stacked, N=10, and each layer of doped organic layered structural units consists of a hole transport layer and doped materials The layer composition is such that a doped material layer is arranged between any adjacent hole transport layers as a hole injection layer to form a 10-period sequence with the combination of this doped material layer and CBP hole transport layer as a structural unit A 20-layer composite hole transport layer structure, in which the first hole transport layer and the first hole injection layer constitute the first doped organic layered structural unit...

Embodiment 2

[0057] This embodiment is basically the same as the first embodiment, and the special features are:

[0058] In this embodiment, a method for manufacturing the LED device structure of this embodiment includes the following steps:

[0059] a. This step is the same as the first embodiment;

[0060] b. This step is the same as the first embodiment;

[0061] c. This step is the same as the first embodiment;

[0062] d. Then transfer the substrate assembly with the light-emitting layer prepared in the step c to the cavity of the thermal evaporation device, and control the cavity pressure of the thermal evaporation device to be not higher than 2×10 -4 Pa, then adjust the temperature of the evaporation heat source so that the evaporation source medicine reaches the sublimation point, and the evaporation source medicine is deposited on the surface of the light-emitting layer in a gas state to form a composite hole transport layer capable of solid-gas-solid three-phase conversion , The composit...

Embodiment 3

[0069] This embodiment is basically the same as the previous embodiment, and the special features are:

[0070] In this embodiment, a method for manufacturing the LED device structure of this embodiment includes the following steps:

[0071] a. This step is the same as the first embodiment;

[0072] b. This step is the same as the first embodiment;

[0073] c. This step is the same as the first embodiment;

[0074] d. Then transfer the substrate assembly with the light-emitting layer prepared in the step c to the cavity of the thermal evaporation device, and control the cavity pressure of the thermal evaporation device to be not higher than 2×10 -4 Pa, then adjust the temperature of the evaporation heat source to make the evaporation source medicine reach the sublimation point, and deposit the evaporation source medicine in a gas state on the surface of the light-emitting layer to form a composite hole transport layer capable of solid-gas-solid three-phase conversion , The composite ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com