Organic light-emitting diode and preparation method thereof

A light-emitting diode, organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as reducing the performance of OLED devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the organic light emitting diode, comprising the following steps:

[0041] After the PEDOT:PSS solution is spin-coated on the surface of the ITO substrate, the first annealing is carried out to obtain the PEDOT:PSS layer; the solvent of the PEDOT:PSS solution is water;

[0042] MoS 2 After the quantum dot solution is spin-coated on the surface of the PEDOT:PSS layer, the second annealing is performed to obtain MoS 2 quantum dot layer;

[0043] In the MoS 2 On the surface of the quantum dot layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injection layer and an electrode layer are vapor-deposited in sequence to obtain an organic light-emitting diode.

[0044] In the present invention, after the PEDOT:PSS solution is spin-coated on the surface of the ITO substrate, the first annealing is performed to obtain the PEDOT:PSS layer; the solvent of the PEDOT:PSS solution...

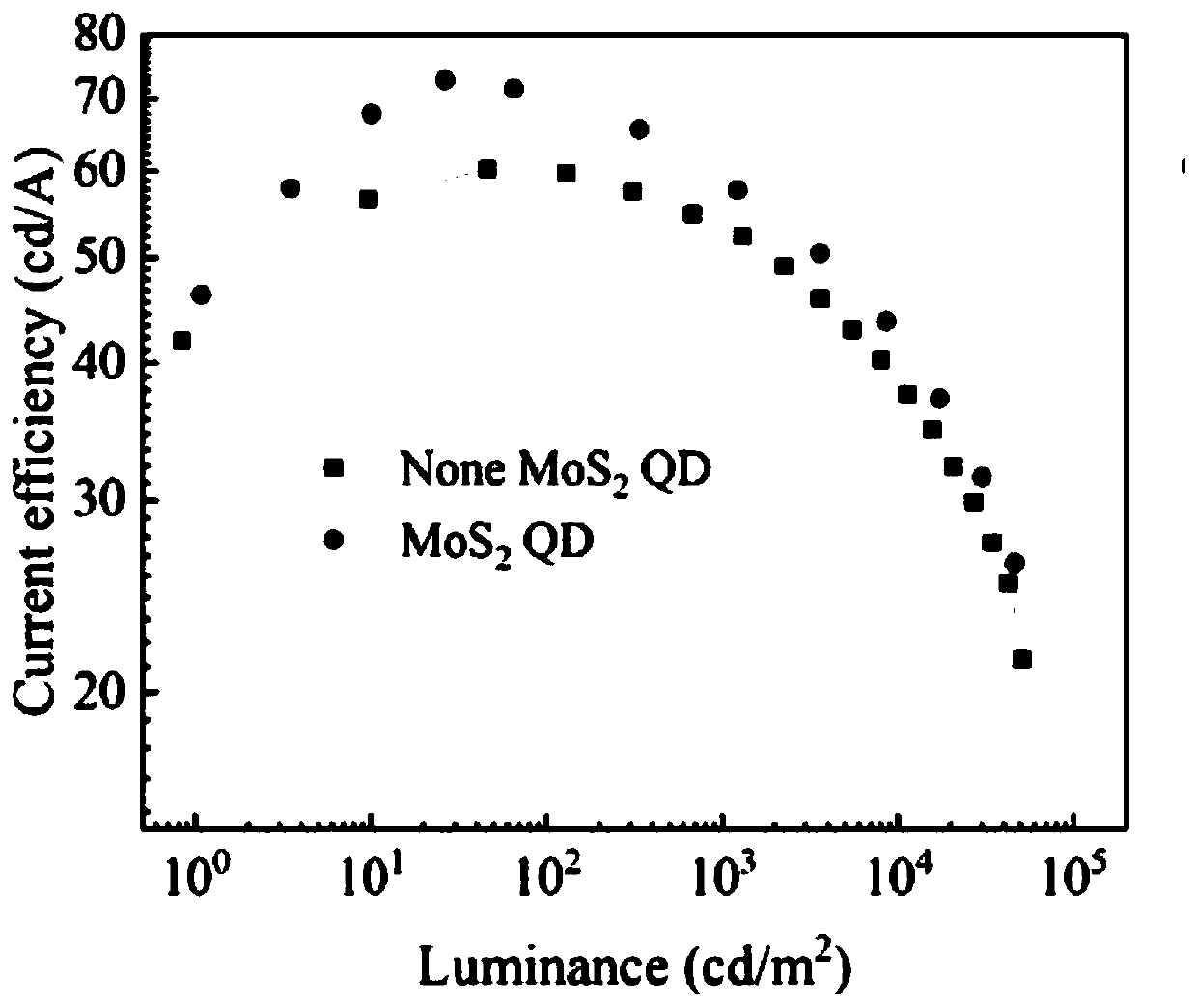

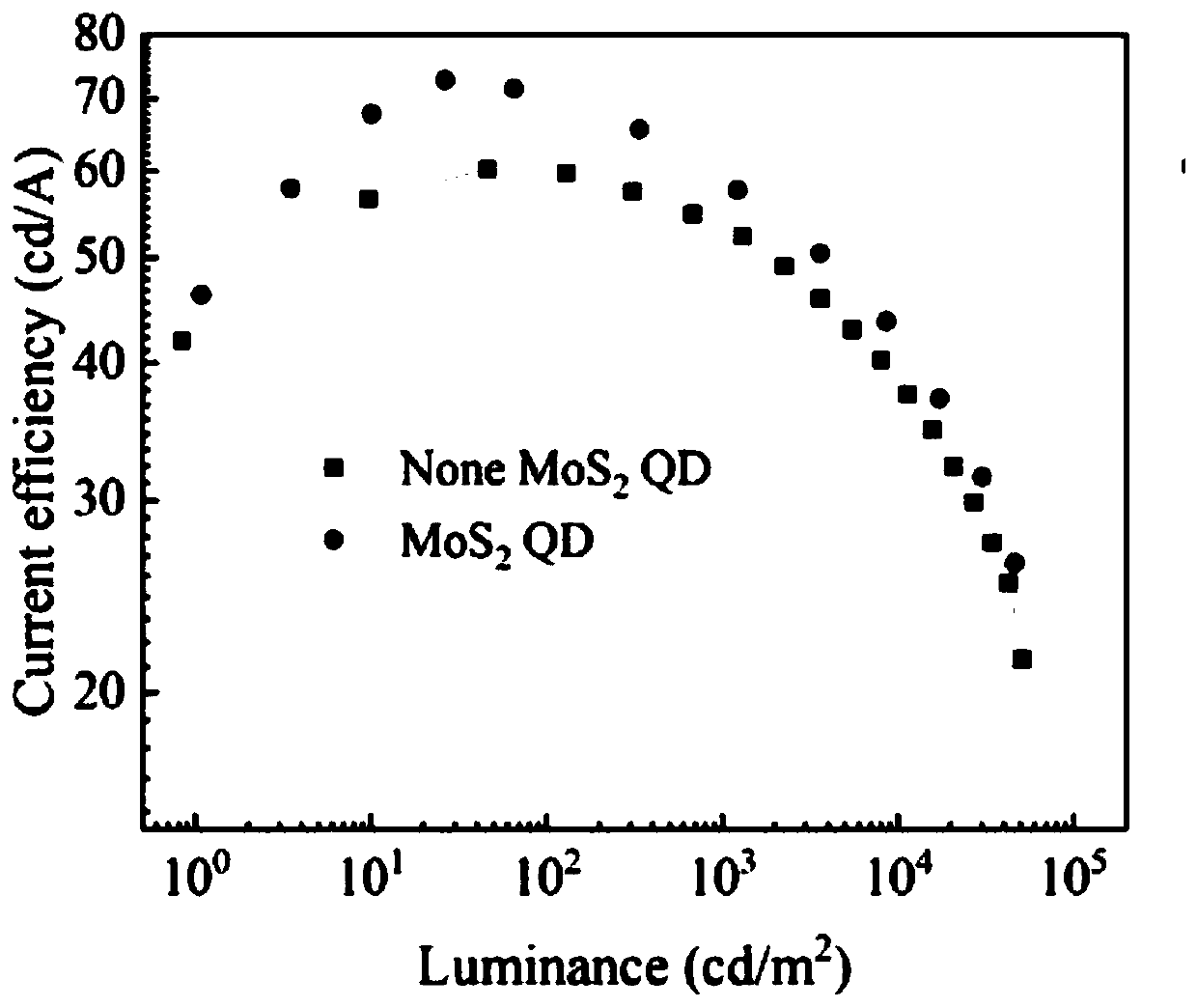

Embodiment 1

[0067] After the 150nm thick ITO substrate is cleaned and dried, it is treated with ultraviolet light for 5 minutes, and then left to stand for 10 minutes to obtain a pretreated ITO substrate;

[0068] Adjust the working parameters of the KW-4 spin coater (rotating speed is 3000rpm, time is 60s), place the ITO substrate on the sheet holder of the KW-4 spin coater, fix the ITO substrate by vacuum suction, and pipette The gun sucks the PEDOT:PSS solution, and the tip of the gun is about 3cm away from the ITO substrate. After dropping the PEDOT:PSS solution on the ITO substrate, quickly start the KW-4 spin coater for spin coating; after the spin coating is completed, at 130°C Anneal for 15 minutes, cool to get PEDOT:PSS layer (30nm);

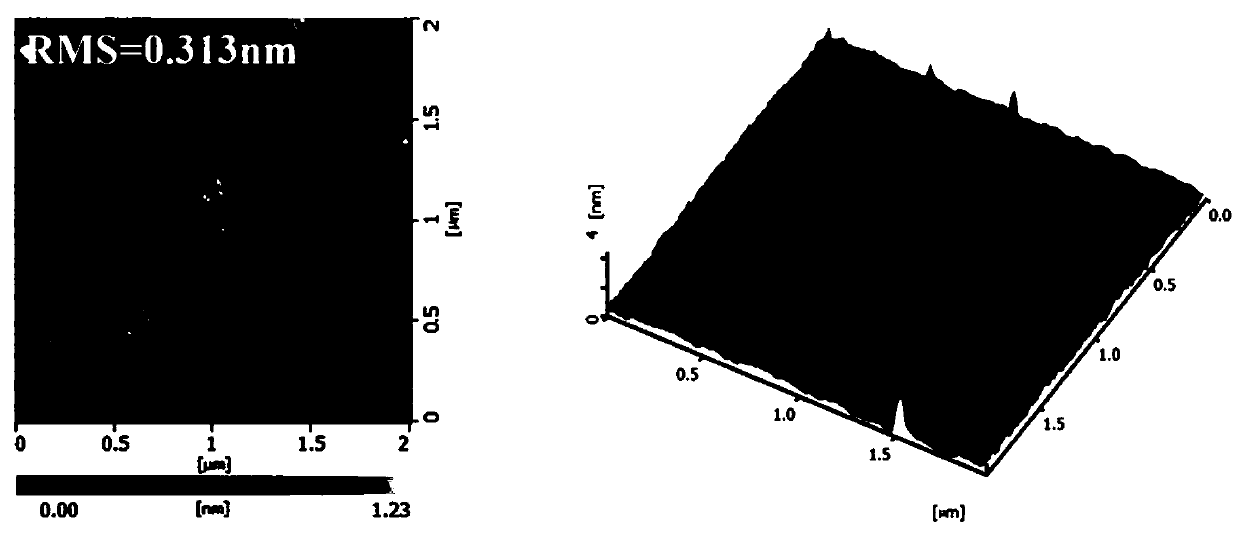

[0069] According to the above spin-coating and annealing process, MoS was prepared on the surface of PEDOT:PSS layer 2 Quantum dot layer (20nm) (the difference is: MoS 2 The concentration of the quantum dot solution is 12mg / mL, and the annealing ...

Embodiment 2

[0073] After the 150nm thick ITO substrate is cleaned and dried, it is treated with ultraviolet light for 5 minutes, and then left to stand for 10 minutes to obtain a pretreated ITO substrate;

[0074] Adjust the working parameters of the KW-4 spin coater (rotating speed is 3000rpm, time is 60s), place the ITO substrate on the sheet holder of the KW-4 spin coater, fix the ITO substrate by vacuum suction, and pipette The gun sucks the PEDOT:PSS solution, and the tip of the gun is about 3cm away from the ITO substrate. After dropping the PEDOT:PSS solution on the ITO substrate, quickly start the KW-4 spin coater for spin coating; after the spin coating is completed, at 130°C Anneal for 15 minutes, cool to get PEDOT:PSS layer (30nm);

[0075] According to the above spin-coating and annealing process, MoS was prepared on the surface of PEDOT:PSS layer 2Quantum dot layer (25nm) (the difference is: MoS 2 The concentration of the quantum dot solution is 15mg / mL, and the annealing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com