Simulation experiment device system for porous medium microscopic seepage

A technology for simulating experimental devices and microscopic seepage. It is used in measurement devices, suspension and porous material analysis, permeability/surface area analysis, etc. It can solve problems such as insufficient injection capacity, complex structure, and inaccurate data, and improve injection capacity. , the effect of accurate calculation data and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

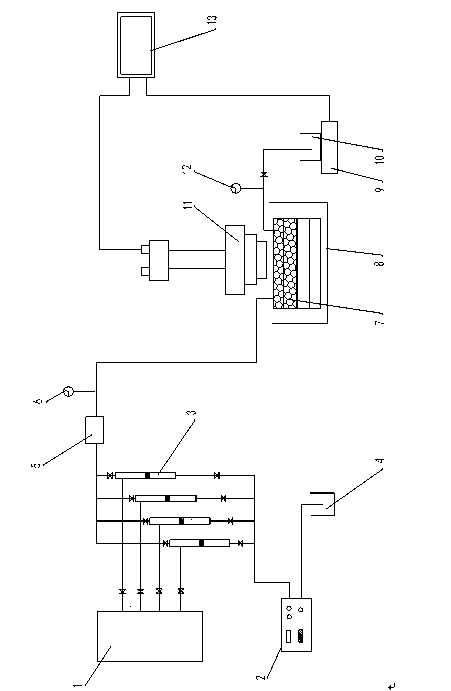

[0017] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0018] Refer to attached figure 1 , the porous medium microscopic seepage simulation experimental device system includes a multi-media mixing device 1, a precision metering injection pump 2, a displacement hydraulic piston cylinder 3, a pump working fluid container 4, a high-pressure container 5, pressure gauges 6, 12, and a microscopic model simulation device 7. Constant temperature control system 8. Precision electronic balance 9. Displacement medium recovery container 10. Microscopic camera information collection system 11. Computer information processing system 13.

[0019] Among them, the multi-media mixing device 1, precision metering injection pump 2, displacement hydraulic piston cylinder 3, pump working flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com