Carbon dioxide acidification blocking remover and process of not reversely discharging raffinate after acidification

A technology of carbon dioxide and blocking agent, which is applied in chemical instruments and methods, cleaning equipment, and production fluids, etc., can solve the problems of poor blocking effect and single effect of blocking agent, and achieves simple construction, remarkable effect, promotion prospects, adaptability The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

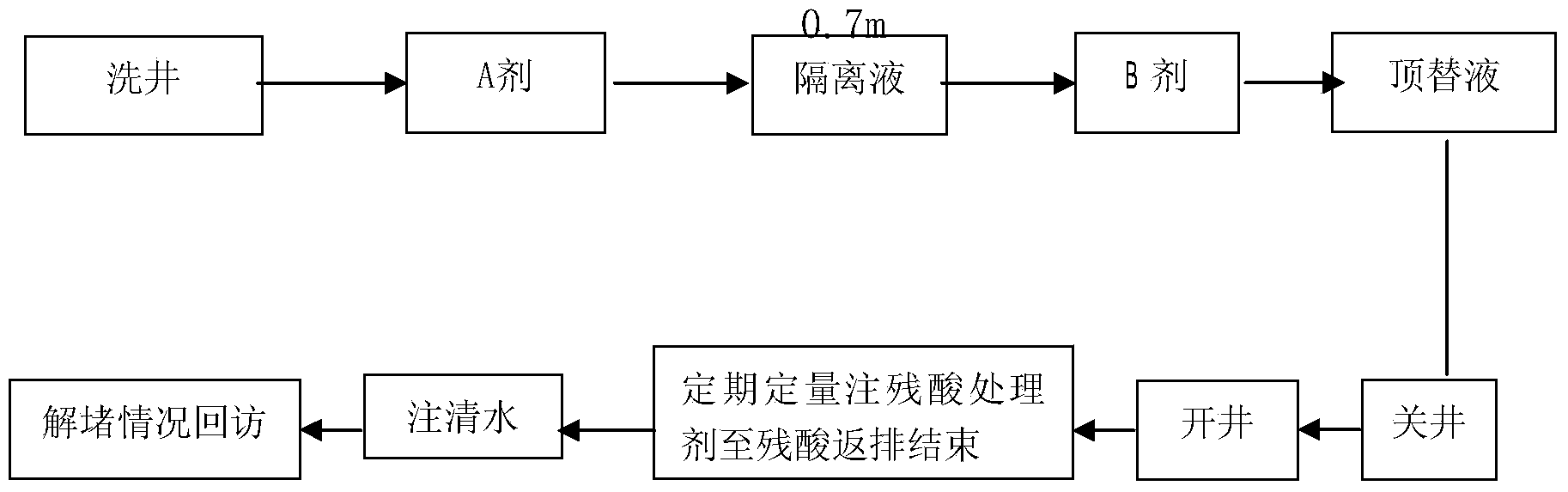

Method used

Image

Examples

Embodiment 1

[0030] The present invention is a segmented injection composite plugging remover, which includes A component and B component, and the mass ratio of A component and B component is 2:1.

[0031] The A component consists of the following raw materials in weight percentage.

[0032] Group A: 8% hydrochloric acid, 4% hydrofluoric acid, 2% acetic acid, 0.25% polyoxyethylene alkylphenol ether, 1% citric acid, 1% corrosion inhibitor, 1% mutual solvent, 1% clay stabilizer, clear water 62.05%.

[0033] The present invention also provides a preparation method of the above-mentioned composite plugging remover, which comprises the following steps: hydrochloric acid, hydrofluoric acid, glacial acetic acid, polyoxyethylene alkylphenol ether, citric acid, corrosion inhibitor, mutual solvent, clay stabilizer , water mixed with each other, stirring at room temperature for 1 hour to form A agent.

[0034] The B component consists of the following raw materials in weight percentage.

[0035] G...

Embodiment 2

[0038] The present invention is a segmented injection composite plugging remover, which includes A component and B component, and the mass ratio of A component and B component is 2:1.

[0039] The A component consists of the following raw materials in weight percentage.

[0040] Group A: hydrochloric acid 12%, hydrofluoric acid 2%, glacial acetic acid 2%, polyoxyethylene alkylphenol ether 0.5%, citric acid 2%, corrosion inhibitor 2%, mutual solvent 3%, clay stabilizer 2%, Clear water 74.5%.

[0041] The present invention also provides a preparation method of the above-mentioned composite plugging remover, which comprises the following steps: hydrochloric acid, hydrofluoric acid, glacial acetic acid, polyoxyethylene alkylphenol ether, citric acid, corrosion inhibitor, mutual solvent, clay stabilizer , water mixed with each other, stirring at room temperature for 1 hour to form A agent.

[0042] The B component consists of the following raw materials in weight percentage.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com