Profile control-unplugging combining technique for water injection well

A process method and technology for water injection wells, which are applied in chemical instruments and methods, earth-moving drilling and production, wellbore/well components, etc. To meet production needs and other issues, to achieve the effect of plugging high-permeability layers, improving water injection efficiency, and reducing construction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

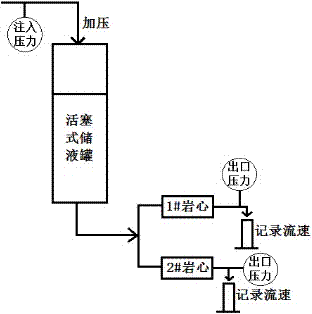

[0058] Using the reservoir core of Bohai BZ34-1 oilfield as the experimental material, a double core flow experimental device was used for indoor experimental simulation. The experimental procedure is shown in figure 2 .

[0059] First select two cores with different permeability: 1# (565md) and 2# (89md), put the two cores into the core holder, then connect the experimental pipeline and configure the experimental samples. The temperature of the Bohai Sea reservoir is simulated by the experiment at 65°C.

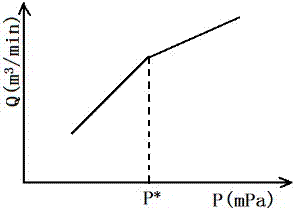

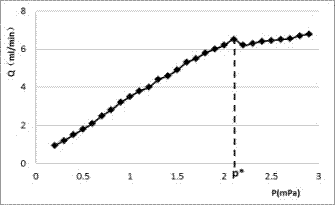

[0060] Experimental process: The first step is to obtain the pressure test curve through the experiment. The displacement pressure difference starts from 0.2mPa and increases by 0.1mPa. The simulated formation water is injected into the double core flow device, and the flow velocity of the formation water when the two cores flow stably under different pressures is recorded. The pressure test curve of the displacement process is drawn according to the experimental data, th...

Embodiment 2

[0074] The reservoir cores of Bohai PL19-3 oilfield were used as experimental materials, and the double core flow experimental device was used for indoor experimental simulation. The experimental procedure is shown in figure 2 .

[0075] First select two cores with different permeability: 3# (862md) and 4# (226md), put the two cores into the core holder, then connect the experimental pipeline and configure the experimental samples. The temperature of the Bohai Sea reservoir is simulated by the experiment at 65°C.

[0076] Experimental process: The first step is to obtain the pressure test curve through the experiment. The displacement pressure difference starts from 0.1mPa and increases by 0.1mPa. Simulated formation water is injected into the double core flow device, and the flow rate of the formation water when the two cores flow stably under different pressures is recorded. The pressure test curve of the displacement process is drawn according to the experimental data, t...

Embodiment 3

[0090] Using the reservoir core of Bohai BZ34-1 oilfield as the experimental material, a double core flow experimental device was used for indoor experimental simulation. The experimental procedure is shown in figure 2 .

[0091] First select two cores with different permeability: 5# (356md) and 6# (287md), put the two cores into the core holder, then connect the experimental pipeline and configure the experimental samples. The temperature of the Bohai Sea reservoir is simulated by the experiment at 65°C.

[0092] Experimental process: The first step is to obtain the pressure test curve through the experiment. The displacement pressure difference starts from 0.2mPa and increases by 0.1mPa. The simulated formation water is injected into the double core flow device, and the flow velocity of the formation water when the two cores flow stably under different pressures is recorded. The pressure test curve of the displacement process is drawn according to the experimental data, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com