Inverted type organic electroluminescence structure

An inverted, electroluminescent technology, used in organic semiconductor devices, circuits, electrical components, etc., can solve the problems of difficult electron injection and high device driving voltage, achieve good conductivity and flexibility, and reduce the hole injection barrier. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

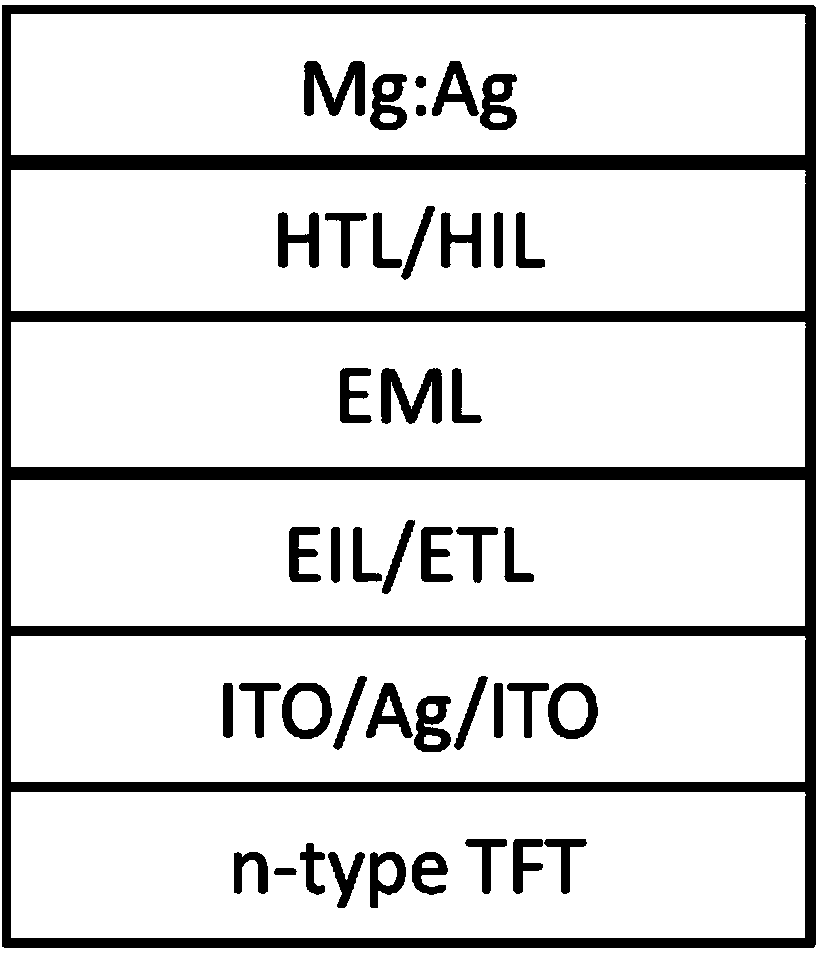

[0047] refer to image 3 , for the figure 2 On the basis of the structural schematic diagram of Embodiment 1, such as image 3 As shown, the first form of the inverted organic electroluminescence structure of the present invention is a bottom emission structure, including: a substrate 6 and a cathode layer 1 arranged on the substrate 6 from bottom to top, an electron injection transport layer 2, and a light emitting layer 3 , a hole injection transport layer 4 and an anode layer 5 . Wherein, the cathode layer 1 is a translucent, 25nm-thick Mg:Ag alloy, and the ratio of Mg:Ag is 1:9, 5:5 or 7:3, so that the transmittance of the cathode layer 1 is controlled at 21%; And anode layer 5 is ITO, Ag double-layer structure (without the second conductive layer), and promptly the first conductive layer is the thick ITO of 15nm, and its transmittance is greater than 85%, because the metal layer is the thick Ag of 150nm, with this, The reflectivity of the anode layer 5 is controlled a...

Embodiment 2

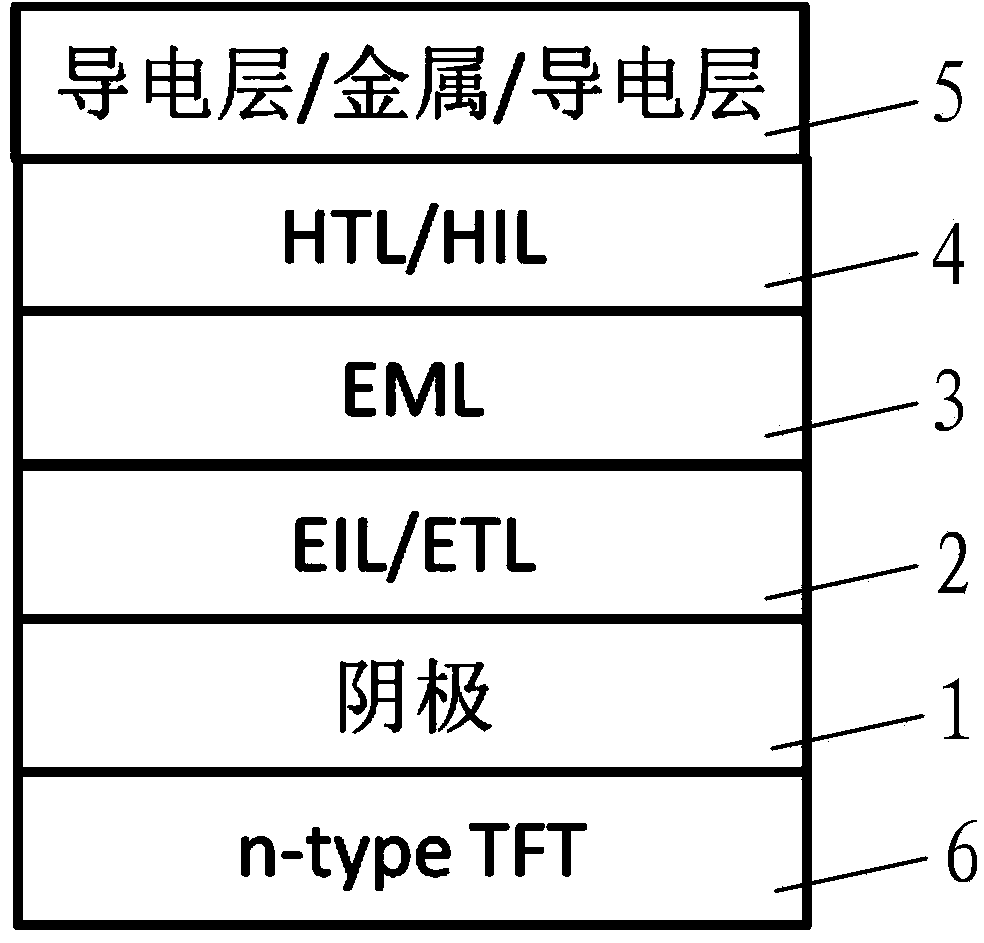

[0050] refer to Figure 6 ,exist figure 2 On the basis of the structural schematic diagram of embodiment two, as Figure 6 As shown, the second form of the inverted organic electroluminescence structure of the present invention: top emission structure,

[0051] 1) The device structure of the top emission structure is:

[0052] Substrate / Ag / Al / Alq3 / Bebq2: Ir(MDQ)2(acac) / NPB / HAT-CN / Ag / ITO.

[0053] 2) Preparation of cathode layer 1

[0054] Under the condition that the pressure of the vacuum chamber is 10-4Pa, a layer of metallic silver is first coated on the substrate 6, and then annealed at a high temperature of 400°C, and the self-aggregation of silver is used to form silver nanoparticles, and the height of the nanoparticles is 30- 50nm, and then coated with a layer of metal aluminum with a thickness of 150nm, at this time, the cathode has a high reflectivity.

[0055] 3) Preparation of organic light-emitting layer

[0056] Keeping the pressure of the vacuum chamber co...

Embodiment 3

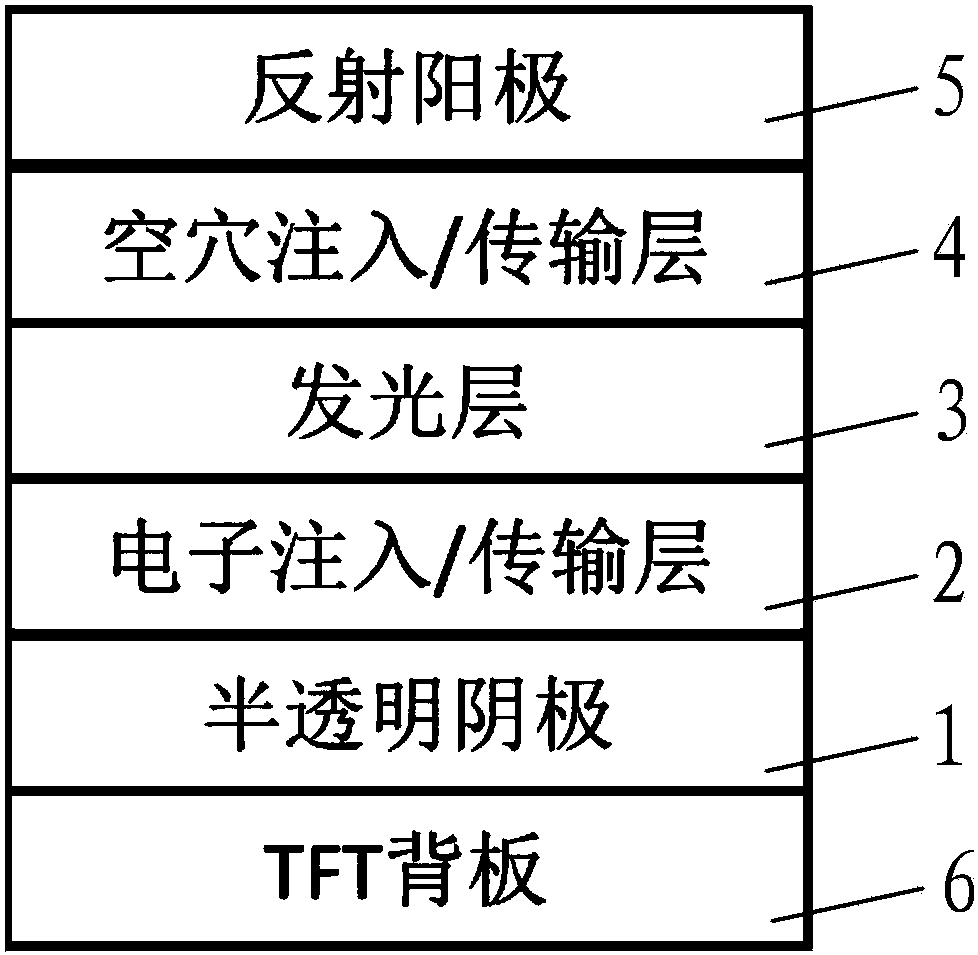

[0060] refer to Figure 7 ,exist figure 2 On the basis of the structural schematic diagram of embodiment three, as Figure 7 As shown, the third form of the inverted organic electroluminescent structure of the present invention: a double-sided light emitting structure,

[0061] 1) The device structure of the double-sided light emitting structure is:

[0062] Substrate / Al / Alq3 / Bebq2: Ir(MDQ)2(acac) / NPB / CuPc / ITO.

[0063] 2) Preparation of cathode structure

[0064] Under the condition that the pressure of the vacuum chamber is 10-4Pa, a layer of metal aluminum with a thickness of 15nm is plated on the substrate 6, and the cathode has a high transmittance because the thickness is very thin.

[0065] 3) Preparation of organic light-emitting layer

[0066] Keeping the pressure of the vacuum chamber constant, the electron injection transport layer 2, the light emitting layer 3, and the hole injection transport layer 4 were successively evaporated. In this embodiment, the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com