PEIE intervention standard inverted QLED device and preparation method thereof

A device and standard technology, applied in the field of PEIE intervening standard inverted QLED devices and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Using ITO as a substrate, a method for preparing PEIE intervening standard inverted QLED devices,

[0043] Weigh a certain amount of ethoxylated polyethyleneimine, put it in a vacuum drying oven for 24 hours, and prepare it into 0.4 mg / ml ethanol solution and 0.5 mg / ml ethylene glycol methyl ether solution respectively, and place it on a magnetic bar to stir Stir continuously on the mixer for 24 h and wait for the device to be used.

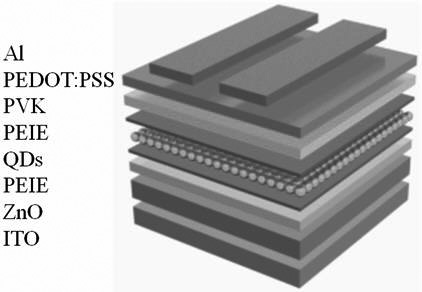

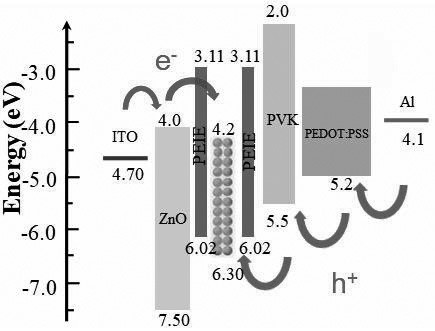

[0044] Such as figure 1 As shown, the specific process is as follows

[0045] a. Spin-coating an electron injection layer on a substrate containing a bottom electrode;

[0046] The substrate containing the bottom electrode of the present invention is an ITO substrate, and the electron injection layer is ZnO, and the ZnO with a particle diameter of 3-4 nm is dissolved in ethanol to prepare a solution with a concentration of 30 mg / ml, 2000 Spin coating at rpm for 45 s, anneal at 80 °C for 30 min, and then anneal at 60 °C for 30 min to obt...

Embodiment 2

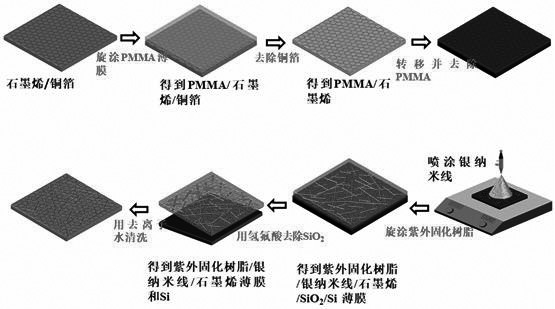

[0056] Through the above method, the manufactured device has high luminous efficiency and excellent electrical transmission performance. On this basis, it was prepared on the single crystal graphene / silver nanowire composite flexible transparent electrode. The preparation method of the flexible electrode is as follows: image 3 As shown, the specific process is as follows:

[0057] a. Transfer of single crystal graphene

[0058] Spin-coat PMMA photoresist at 600 rpm / 6 s and 1500 rpm / 15 s on the surface of copper foil (copper foil thickness 0.5 μm) grown with 0.5 nm-1 nm thick graphene, and anneal at 180 °C for 5 min; then PMMA / Graphene / copper foil was placed in FeCl with a concentration of 2 mol / mL 3 solution, remove the copper foil by etching; then transfer the PMMA / graphene to concentrated hydrochloric acid: deionized water = 1:1 solution for immersion for 30 min, concentrated hydrochloric acid is 36-38wt%; continue to transfer the film cycle to the washed three times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com