CYLINDRICAL Cu-Ga ALLOY SPUTTERING TARGET AND PRODUCTION METHOD THEREFOR

A sputtering target, cylindrical technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the problems of difficult manufacturing methods, cracking, etc., and achieve small fluctuation and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] In Example 1, the powder manufacturing process was performed first. In the powder production process, in order to produce a cylindrical Cu-Ga alloy sputtering target, Ga as a starting material is 25% by mass and the balance is Cu, which is blended, melted and cast to obtain a Cu-Ga alloy Ingot. Thereafter, the ingot was pulverized and classified by a disc mill to obtain Cu—Ga alloy powder. The average particle size of the classified Cu-Ga alloy powder is 90μm, and the tap density is 5.0g / cm 3 .

[0104] Next, a molding process is performed. In the forming process, in order to form the produced Cu-Ga alloy powder by CIP, the Cu-Ga alloy powder was filled in a rubber mold and processed at a pressure of 250 MPa to obtain a Cu-Ga alloy formed body.

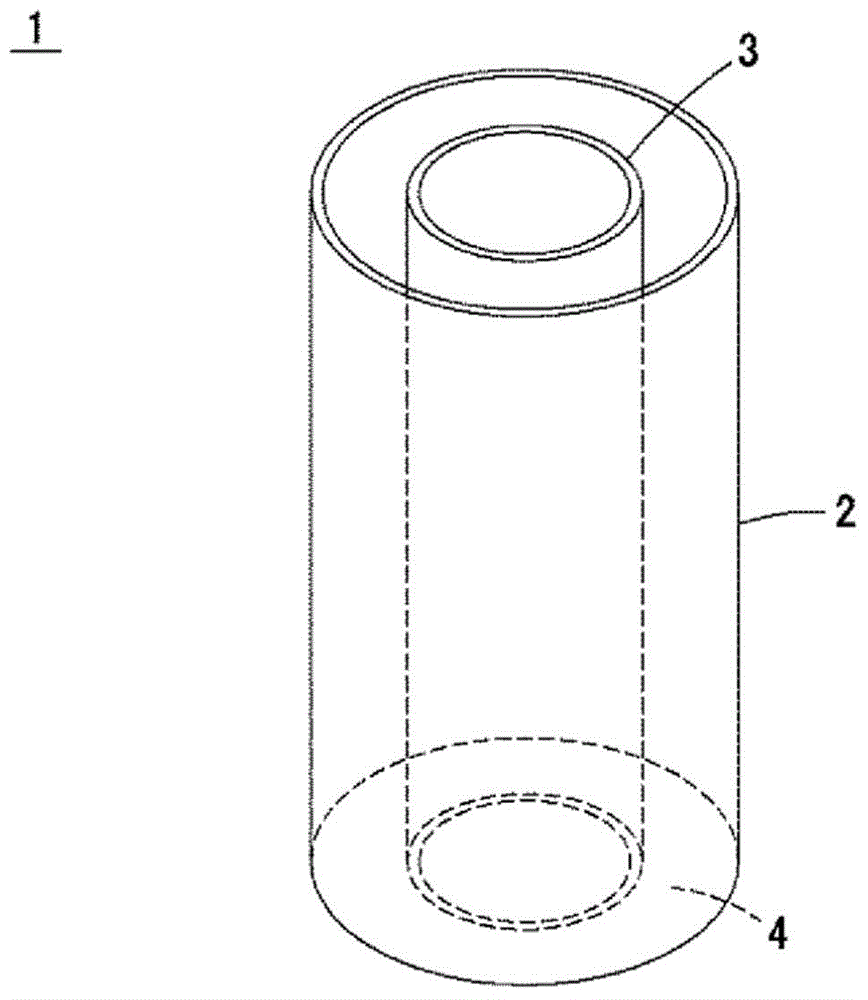

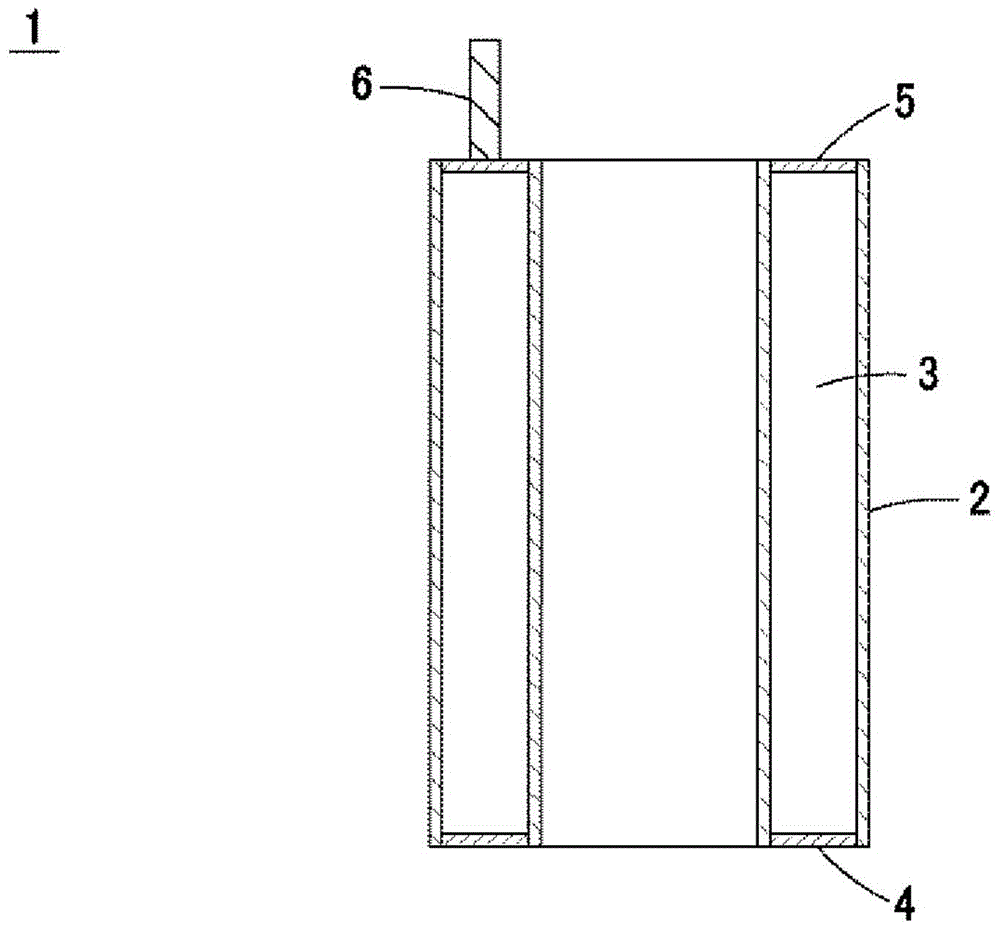

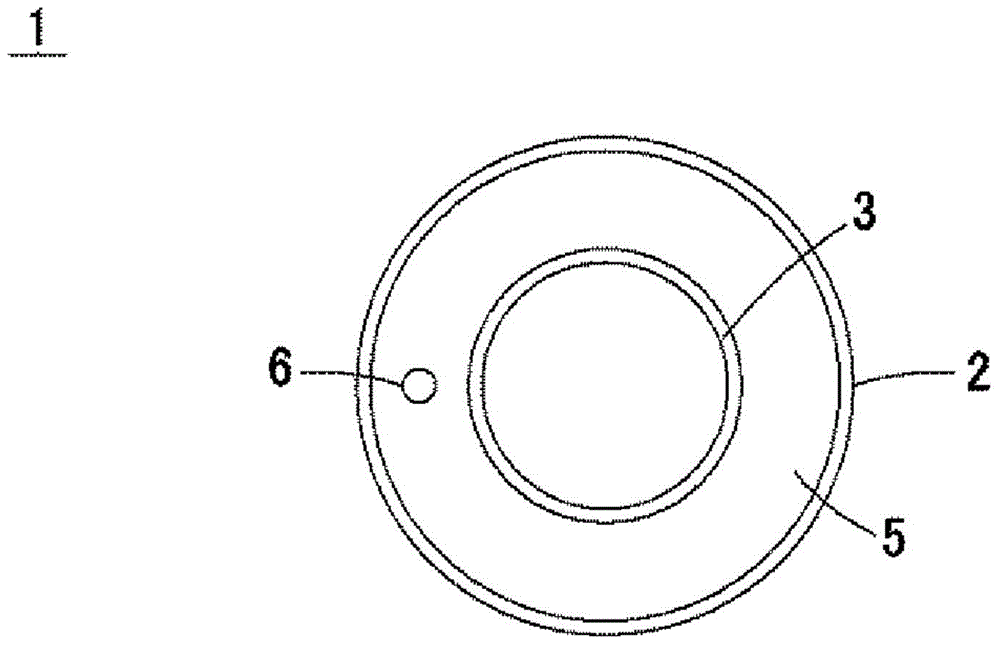

[0105] Next, a HIP process is performed. In the HIP process, first, in order to sinter the Cu-Ga alloy molded body by hot isostatic pressing (HIP), the upper and lower covers, the outer frame, and the hollow middle cylinde...

Embodiment 2

[0114] In Example 2, in the powder production process, Ga as a starting material was blended and melted so that 25% by mass and the balance was Cu, produced by gas atomization, and classified to obtain Cu-Ga alloy powder. The average particle size of the classified Cu-Ga alloy powder is 45μm, and the tap density is 6.2g / cm 3 .

[0115] Next, in the HIP process, Cu-Ga alloy powder was filled between the middle cylinder and the outer frame of the sheath produced in the same manner as in Example 1. As a result, the filling density relative to the specific gravity of the Cu-Ga alloy was 8.6 g / cm 3 was 71.8%. After that, degas from the degassing pipe while heating, crimp and weld the upper cover to seal the sheath (refer to figure 2 ).

[0116] Next, HIP treatment was performed in the same manner as in Example 1 to obtain a Cu—Ga alloy sintered body. Then, in order to confirm the occurrence of cracks and cracks caused by the HIP treatment, radiation transmission inspection w...

Embodiment 3

[0120] In Example 3, in the powder production process, Ga as a starting material was blended so that 25% by mass and the balance was Cu, and melted and casted to obtain a Cu—Ga alloy ingot. Thereafter, the ingot was pulverized and classified with a disc mill to obtain Cu—Ga alloy powder. The average particle size of the classified Cu-Ga alloy powder is 90μm, and the tap density is 5.0g / cm 3 .

[0121] Next, in the molding step, a Cu—Ga alloy molded body was obtained in the same manner as in Example 1.

[0122] Next, in the HIP process, a sheath was produced in the same manner as in Example 1 using a steel plate with a thickness of 1.0 mm.

[0123] Next, the Cu-Ga alloy molded body was filled between the middle cylinder and the outer frame of the sheath, and the Cu-Ga alloy powder was further filled while tapping. As a result, the filling density relative to the specific gravity of the Cu-Ga alloy was 8.6g / cm 3 was 65.2%. After that, degassing is performed from the degassin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com