Wear-resistant quick temperature measuring platinum resistance thermometer

A platinum thermal resistance, wear-resistant technology, applied in the field of platinum thermal resistance temperature measuring elements, can solve the problem of thermal response time lag of platinum thermal resistance temperature sensors, wear resistance and corrosion resistance, and the thermal response time of temperature sensors is not significantly reduced , short service life and other issues, to speed up the thermal response time, the method is convenient and practical, and meet the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

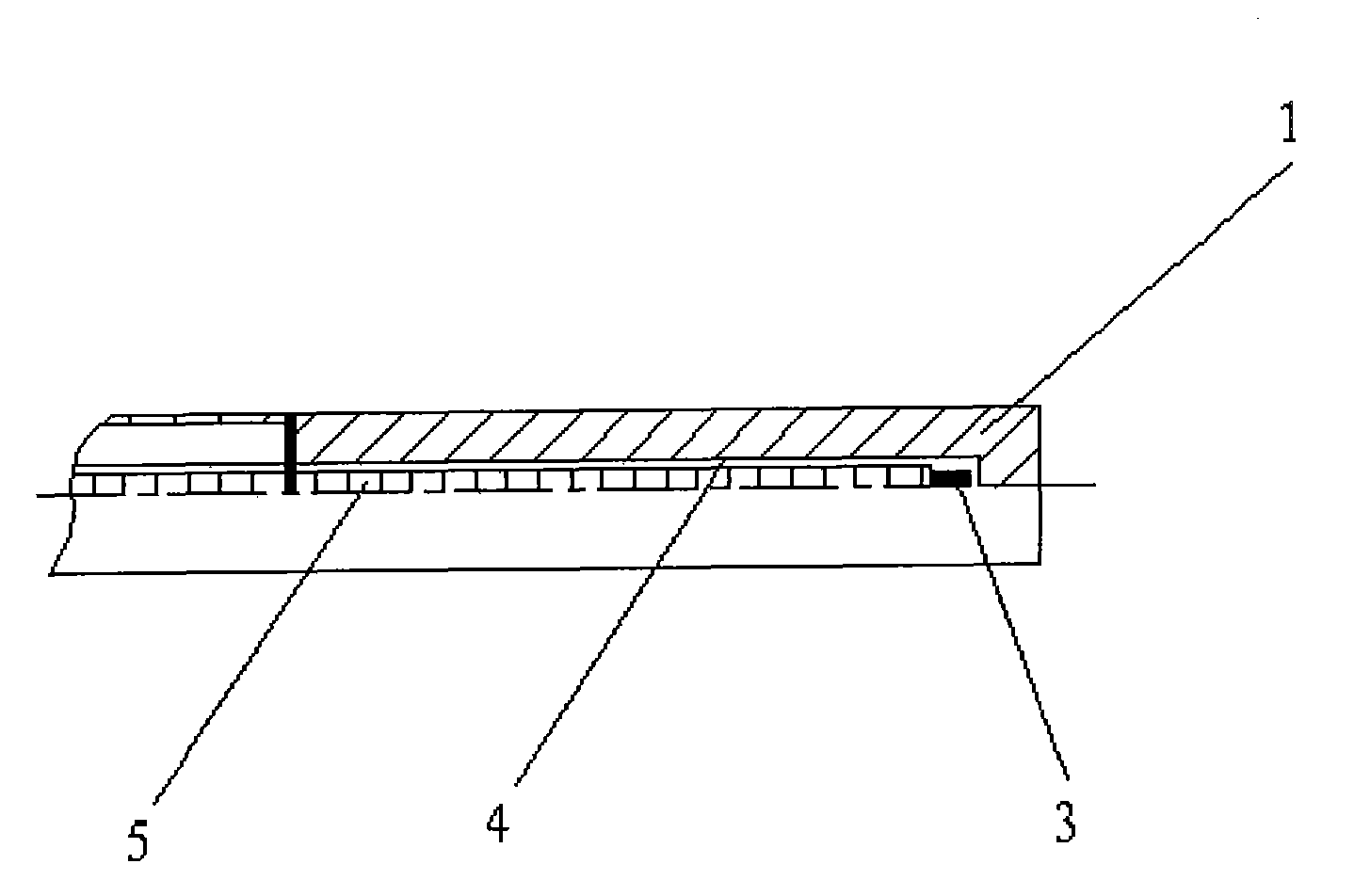

[0014] figure 1 It is a schematic diagram of the structure of the prior art, and there is no fast heat conductor in the figure, figure 1 The medium heat conducting material 4 is magnesium oxide or air, and the insulator 5 is ceramics to ensure good insulation.

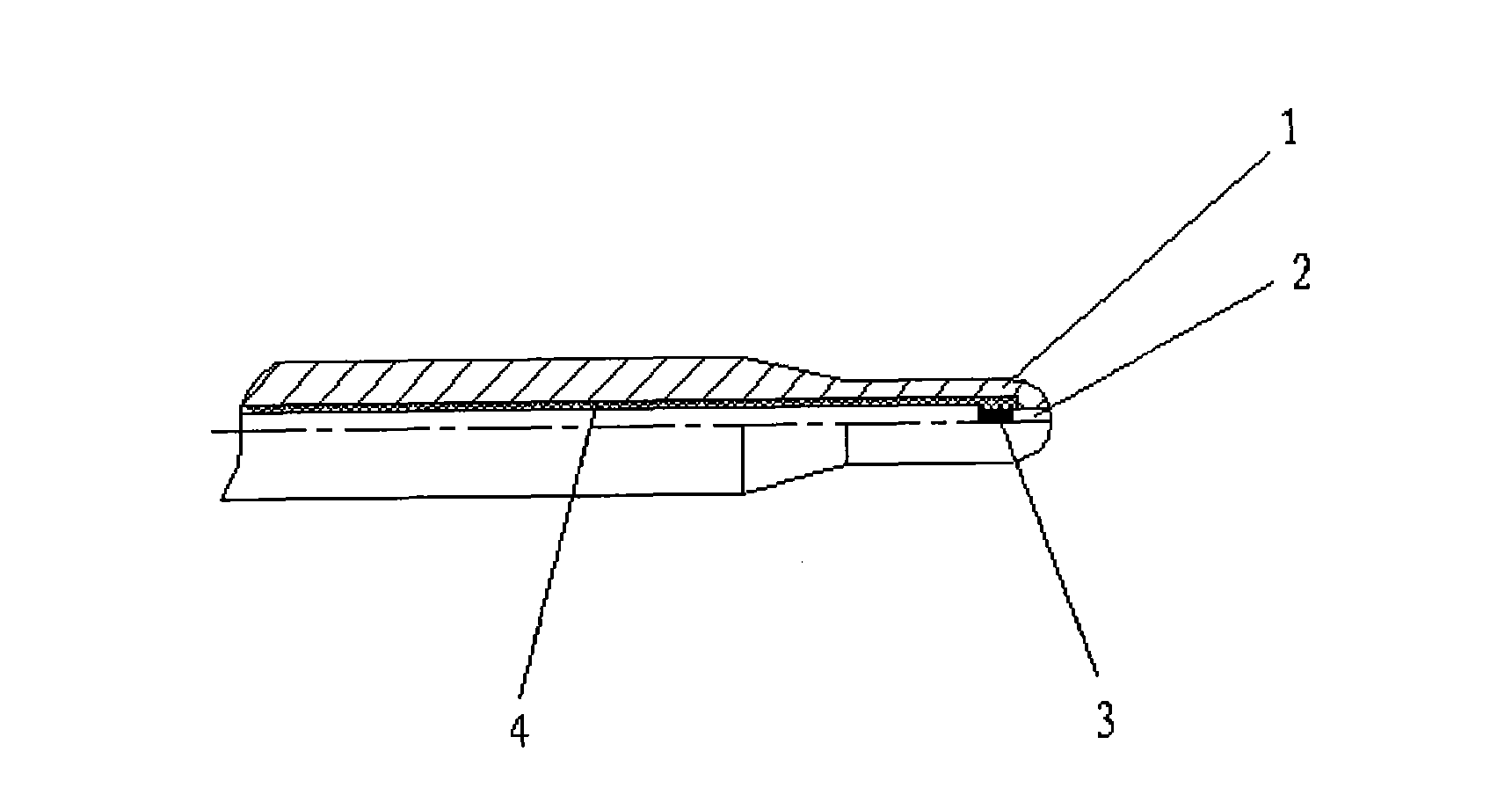

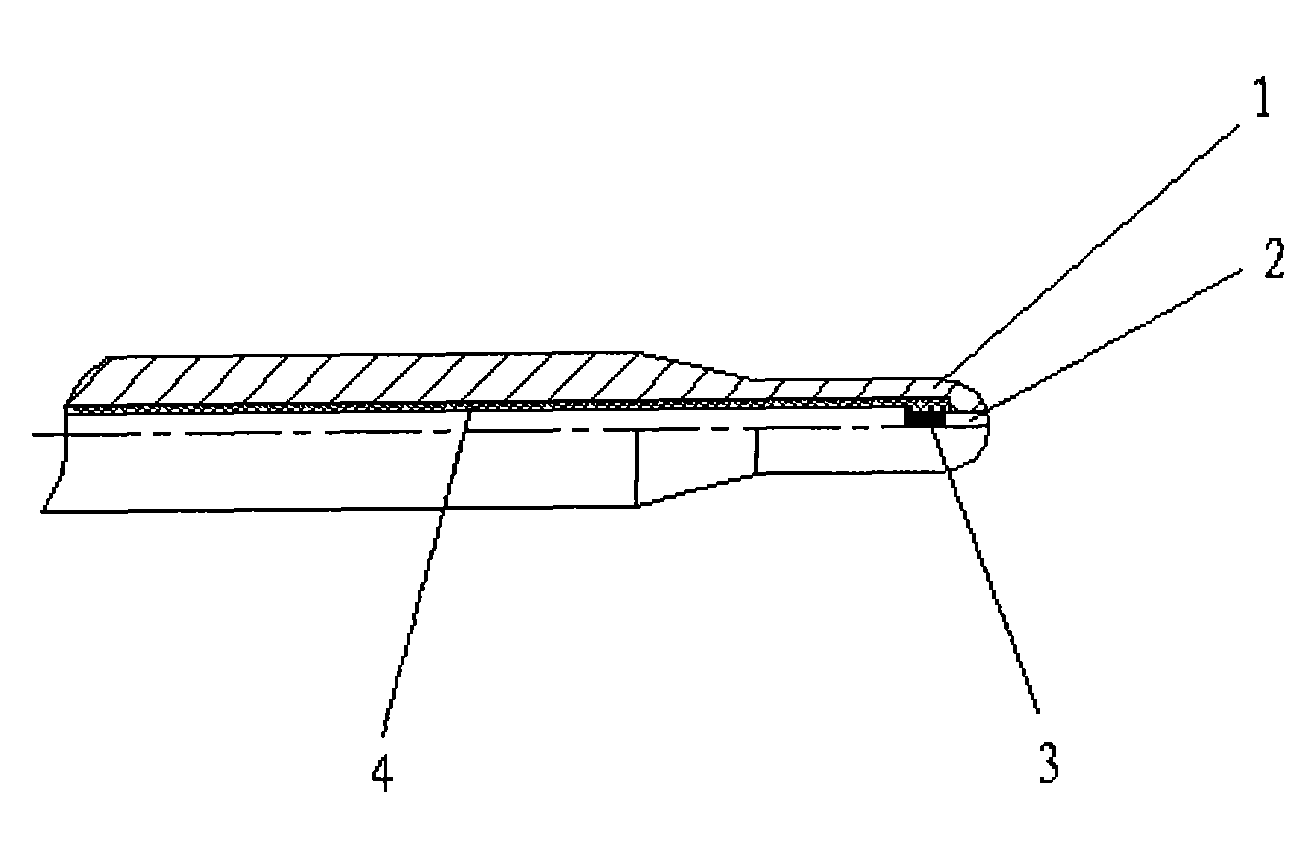

[0015] figure 2 It is a schematic diagram of the structure of the present invention after adding a fast heat conduction element. It can be seen in the figure that a wear-resistant platinum thermal resistor for rapid temperature measurement includes a wear-resistant protective tube 1 and a platinum thermal resistor 3 placed in the protective tube 1, and is characterized in that: inside the protective tube 1, the temperature-sensing end A fast heat conduction element 2 connected to the platinum thermal resistance 3 is installed, and the platinum thermal resistance 3 is closely matched with the inner wall of the protection tube 1, and a very small gap between them is filled with a heat-conducting material 4 .

[0016]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com