Iron-based amorphous alloy, its preparation method and use in electric heating material

An iron-based amorphous alloy and electric heating technology, which is applied in the field of electric heating materials, can solve the problems of electrothermal film substrate shedding and power instability, and achieve the effects of stable power, high electrothermal conversion efficiency, and short thermal response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

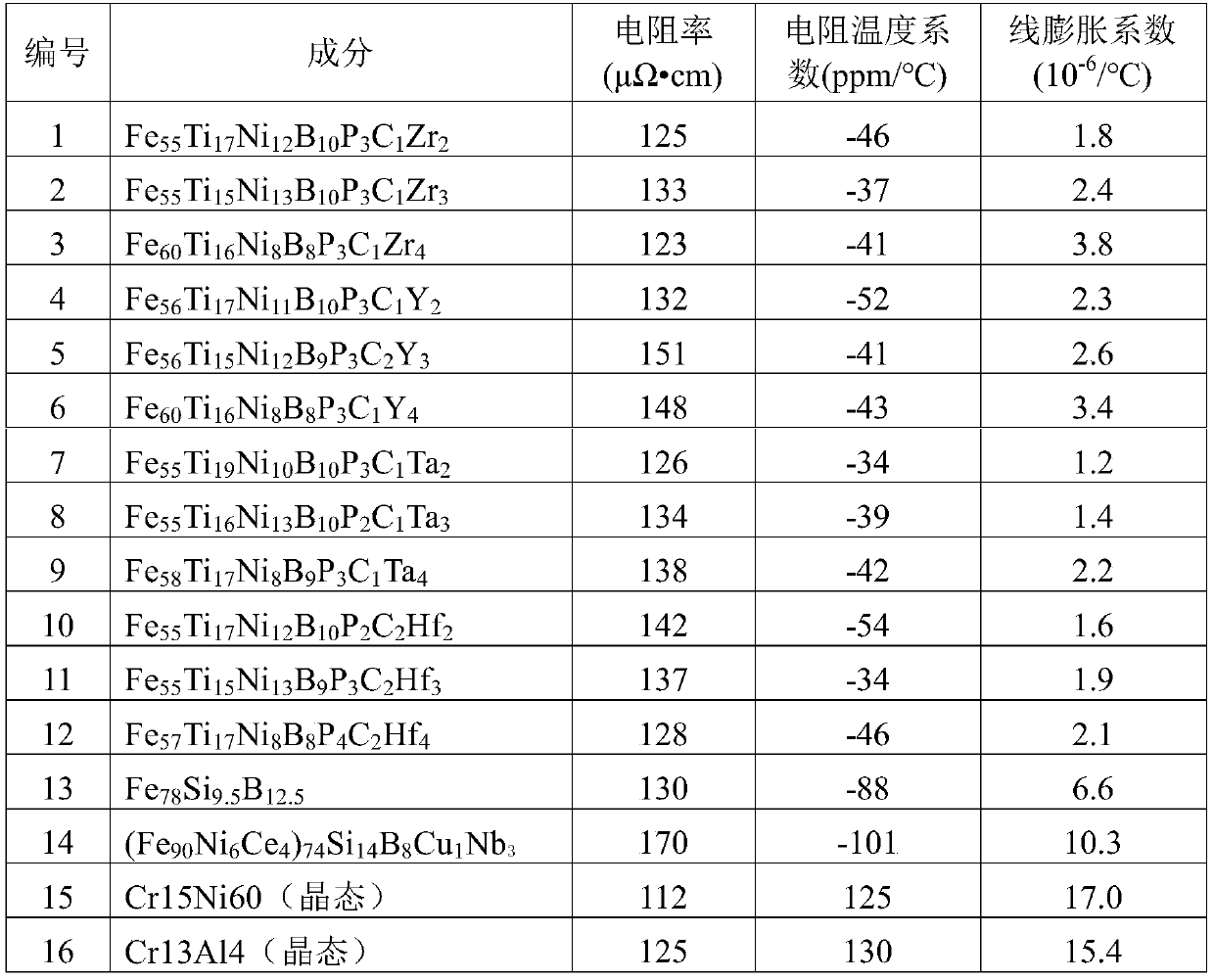

[0029] According to the iron-based amorphous alloy electric heating material composition Fe of the present invention a Ti b Ni c B d P e C f m g , prepare a series of amorphous alloy strips, wherein M is an element in Zr, Y, Ta, Hf, the specific composition and atomic percentage content are shown in Table 1, numbers 1-12 are examples, and numbers 13-16 are comparisons example.

[0030] According to the ingredients and atomic percentages of the alloys listed in Table 1, put the proportioned raw materials in a high-vacuum induction melting furnace and vacuumize to 5×10 -3 Pa, fill the argon protective gas to 0.5MPa, then turn on the melting power supply to start melting, the melting temperature is 1500-1600°C, after the raw materials are completely melted into molten steel, use magnetic stirring to mix the molten steel evenly, and keep it warm for 15 minutes; then melt The good molten steel is poured into a device with a nozzle, and the molten steel is sprayed on a rotati...

Embodiment 2

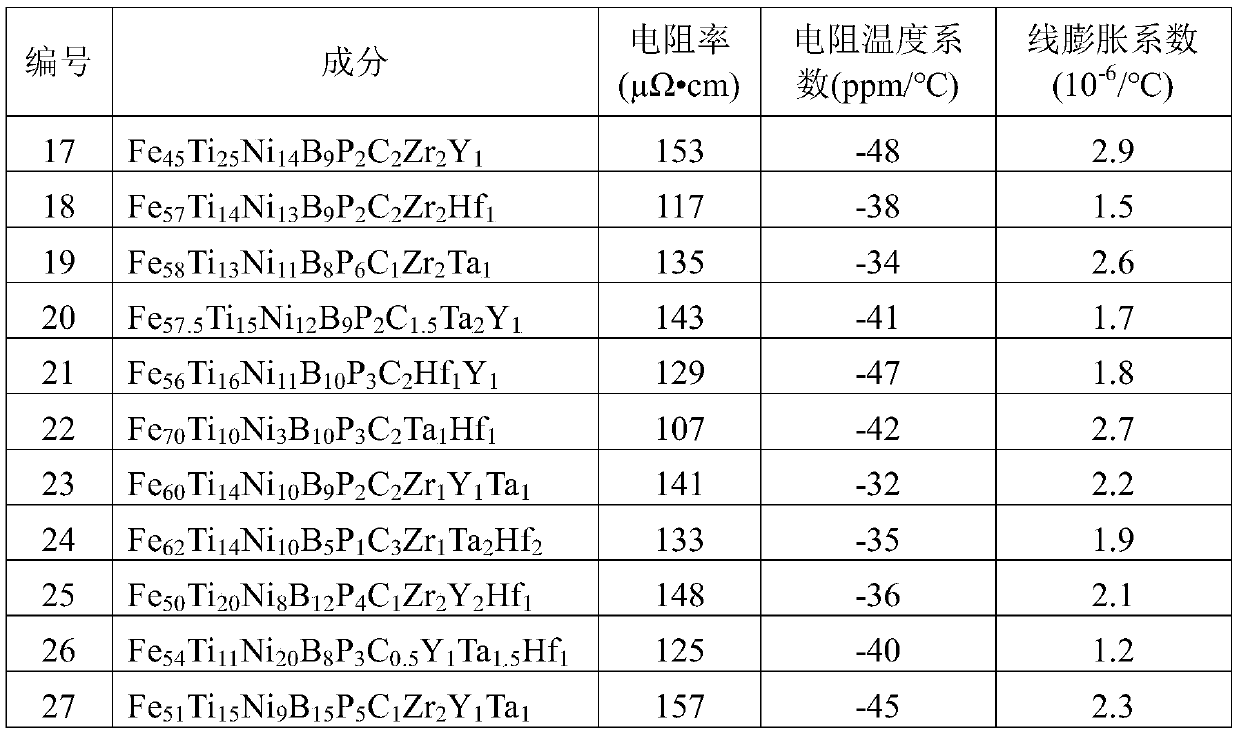

[0036] According to the iron-based amorphous alloy electric heating material composition Fe of the present invention aTi b Ni c B d P e C f m g , to prepare a series of amorphous alloy strips, wherein M is two or three elements in Zr, Y, Ta, Hf, the specific composition and atomic percentage content are shown in Table 2, and numbers 17-27 are examples.

[0037] According to the ingredients and atomic percentages of the alloys listed in Table 2, put the proportioned raw materials in a high-vacuum induction melting furnace and vacuumize to 5×10 -3 Pa, fill the argon protective gas to 0.5MPa, then turn on the melting power supply to start melting, the melting temperature is 1550-1650°C, after the raw materials are completely melted into molten steel, use magnetic stirring to mix the molten steel evenly, and keep it warm for 15 minutes; then melt The good molten steel is poured into the device with a nozzle, and the molten steel is sprayed on the rotating cooling roll with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com