Small-size high-efficiency electric heating device with waste heat recovery function

An electric heating device and waste heat recovery technology, applied in fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems of small volume and high power density components that are easy to burn out, and achieve excellent electric heating performance and low shell temperature , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

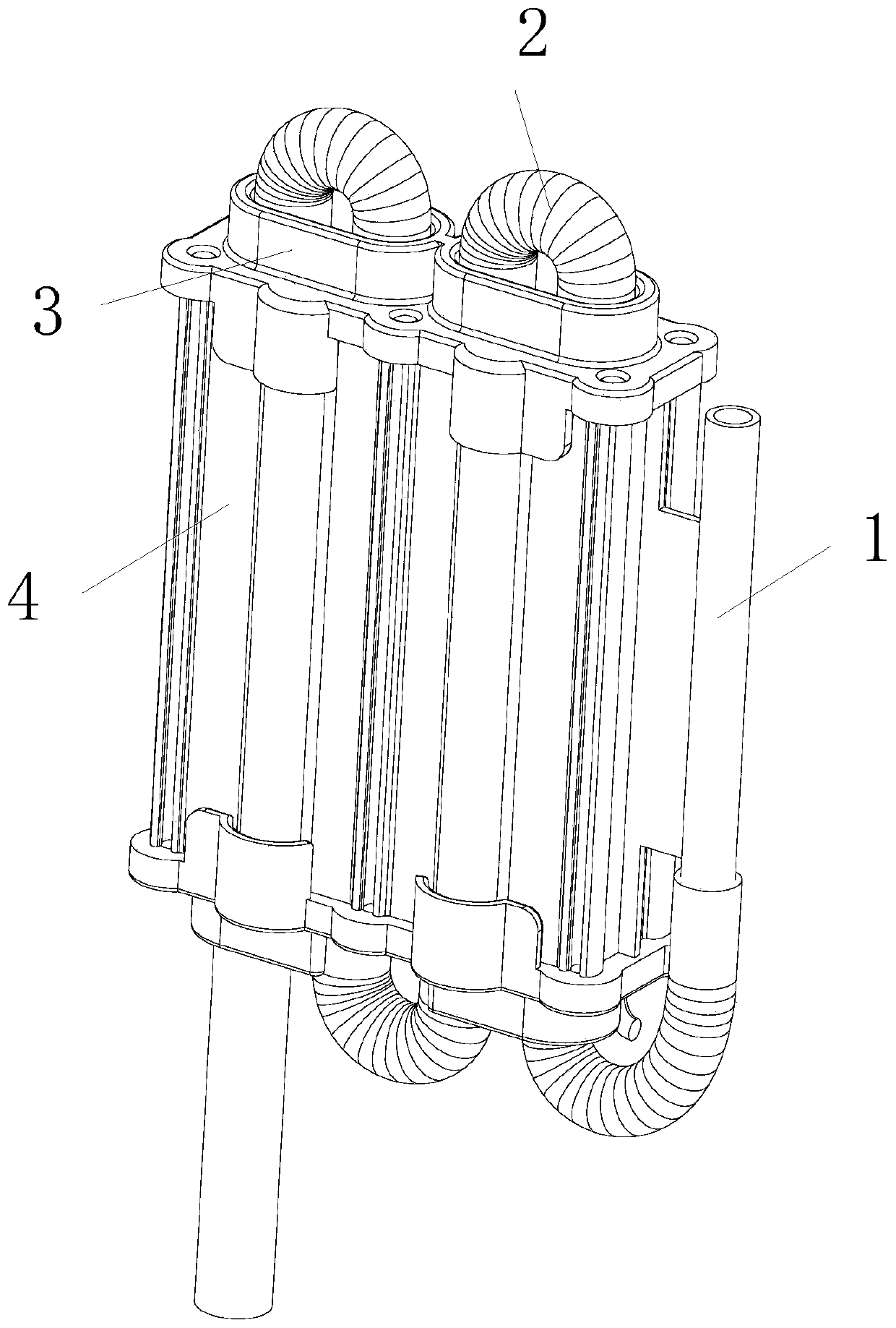

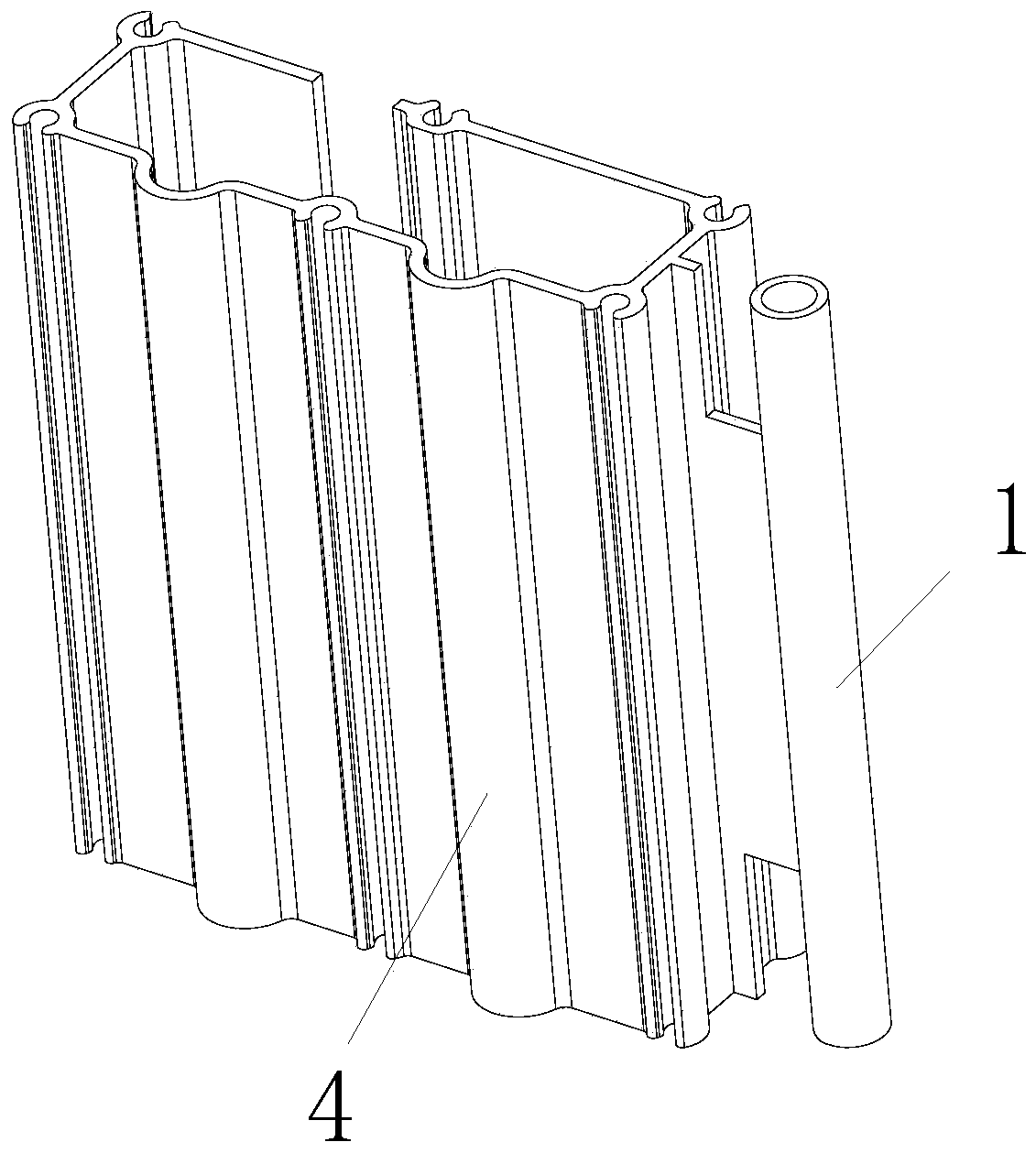

[0024] refer to Figure 1-3 , a small-volume high-efficiency electric heating device with a waste heat recovery function, including a plurality of electric heating tubes 5, the electric heating tube 5 is a nano-film electric heating tube based on a heat-conducting tube, and the nano-electric heating film has a high thermal efficiency High environmental protection heating film, the heat conduction tube is one of inorganic tubes, quartz tubes, ceramic tubes, high borosilicate glass tubes, and metal tubes with insulating coatings. Multiple electric heating tubes 5 are connected through the connecting tube 2 to form a liquid Electric heating passage, a plurality of electric heating tubes 5 are provided with a heat conduction shell 4, the heat conduction shell 4 is made of a material with good thermal conductivity, preferably the heat conduction shell 4 is aluminum, stainless steel, carbon steel, copper, alloy, and the electric heating tube 5 The upper and lower ends are fixed toge...

Embodiment 2

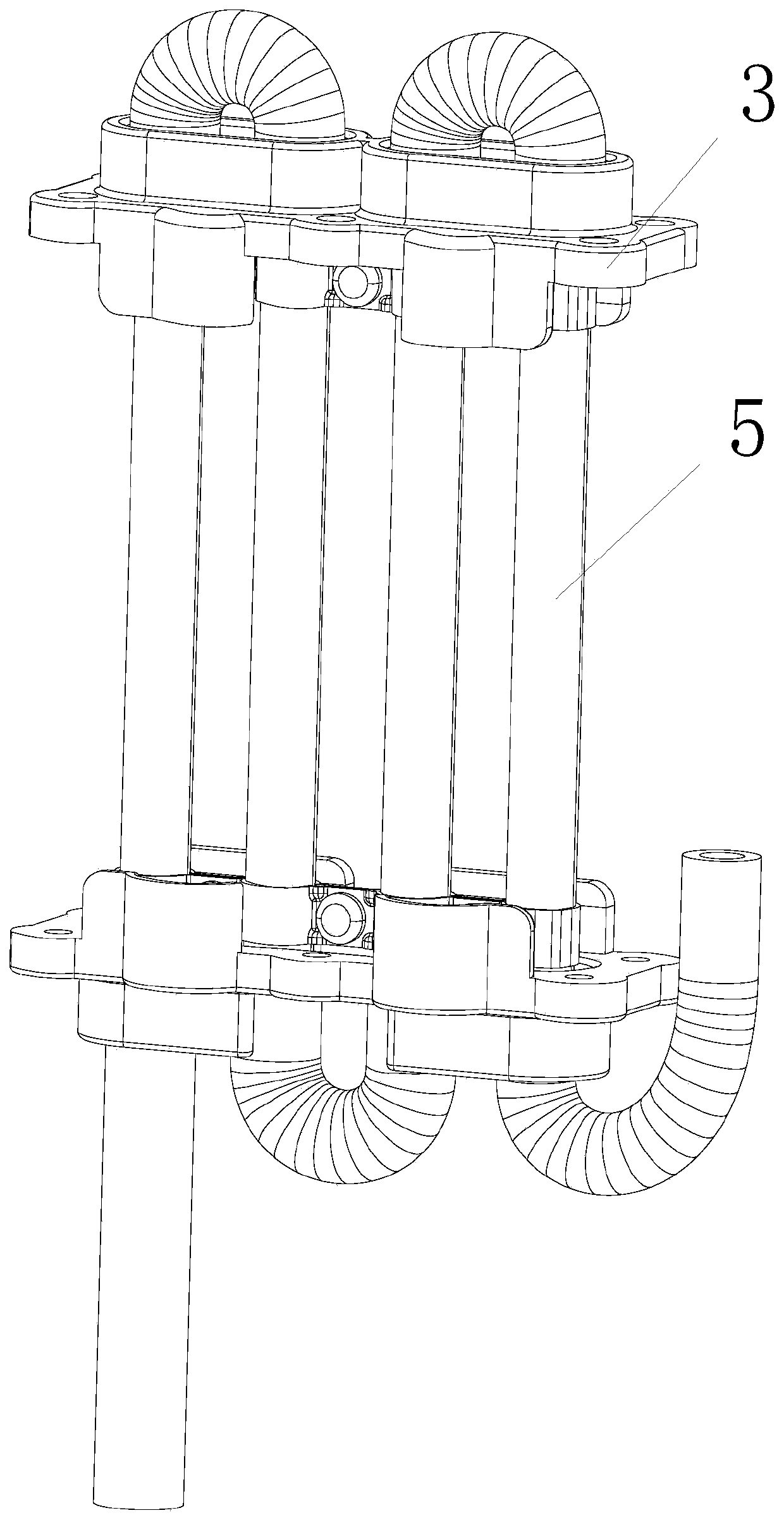

[0028] refer to Figure 4-5 , a small-volume high-efficiency electric heating device with a waste heat recovery function, including a plurality of electric heating tubes 5, the electric heating tube 5 is a nano-film electric heating tube based on a heat-conducting tube, and the heat-conducting tube is an inorganic tube, quartz One of tubes, ceramic tubes, high borosilicate glass tubes, and metal tubes with insulating coatings. Multiple electric heating tubes 5 are connected through the connecting tube 2 to form a liquid electric heating path. Multiple electric heating tubes 5 are sleeved outside There is a heat conduction shell 4, and the upper and lower ends of the electric heating tube 5 are fixed together with the heat conduction shell 4 through the fixing piece 3. The heat conduction shell 4 is integrally formed with a water inlet pipe 1, and the water inlet pipe 1 communicates with the water inlet end of the liquid electric heating channel. The water inlet pipe 1 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com