Patents

Literature

106results about How to "Uniform heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

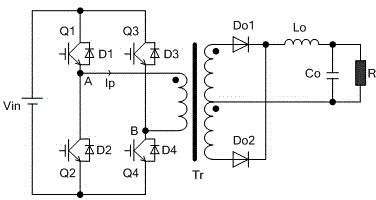

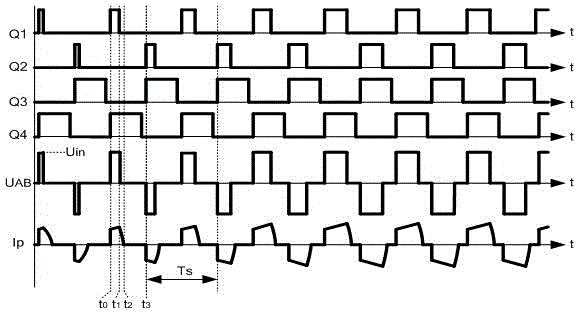

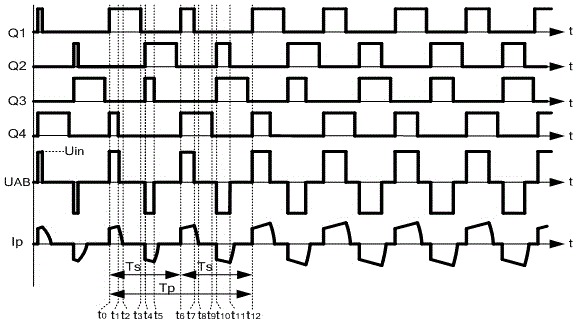

Method for controlling uniform heating of switch device of switch power source

InactiveCN104600998AUniform heatingExtend your lifeDc-dc conversionElectric variable regulationPhysicsFull bridge converter

The invention relates to the field of switch power source control, in particular to a method for controlling uniform heating of switch devices of a switch power source. The switch power source comprises a full bridge converter, the switch devices in the full bridge converter are switch tubes, the sequence of the switch devices in the full bridge converter alternately changes periodically, and the alternating period is N times of the switch control period of the switch devices, wherein N refers to a natural number larger than 2. Alternate soft turnoff of the switch devices is realized by alternately changing turnoff sequence of the switch devices composed of the switch tubes of the full bridge converter in the switch power source, so that the switch devices are uniform in heating within a long time period, and service life of the whole switch power source is prolonged.

Owner:SICHUAN INJET ELECTRIC CO LTD +1

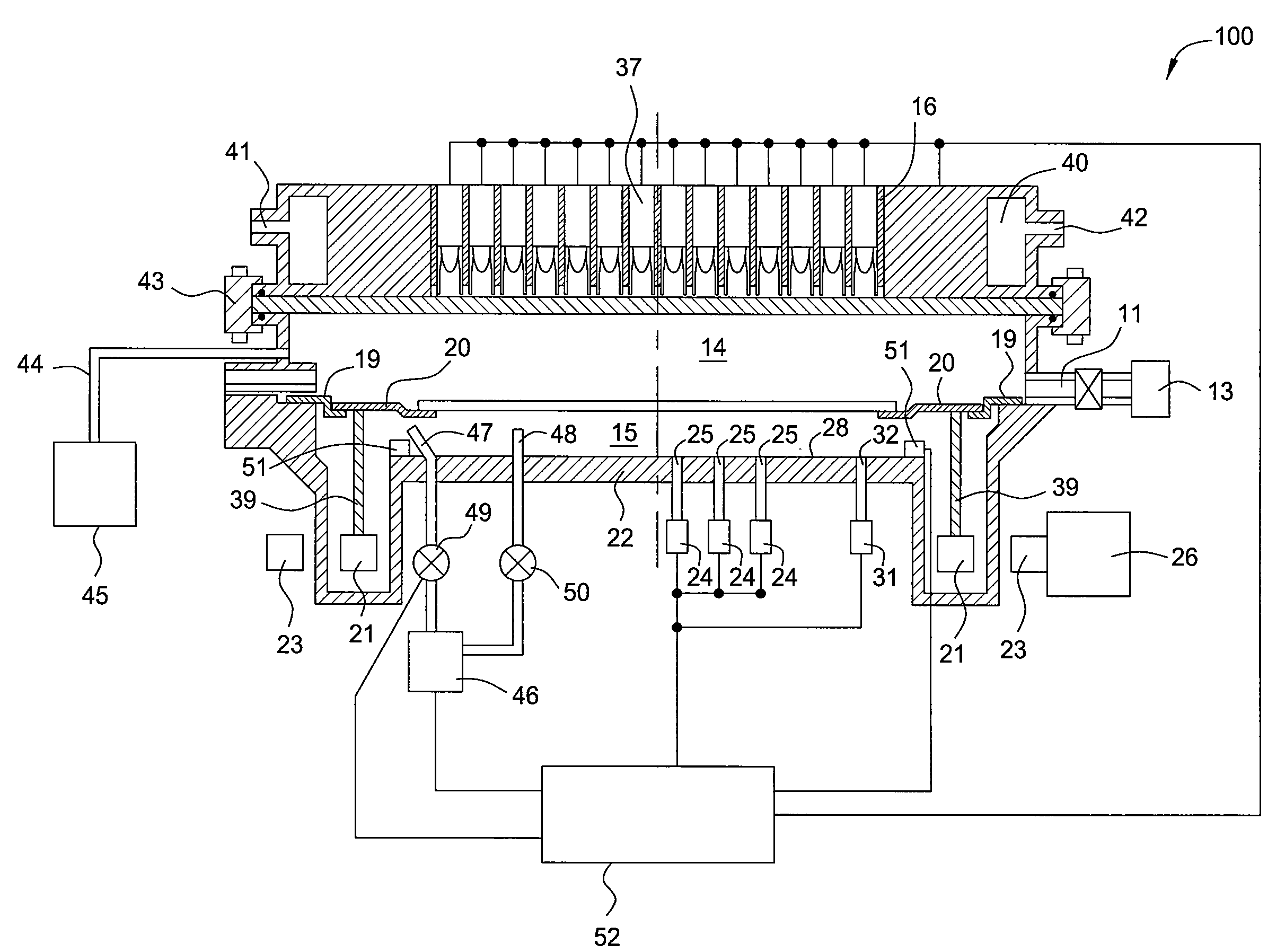

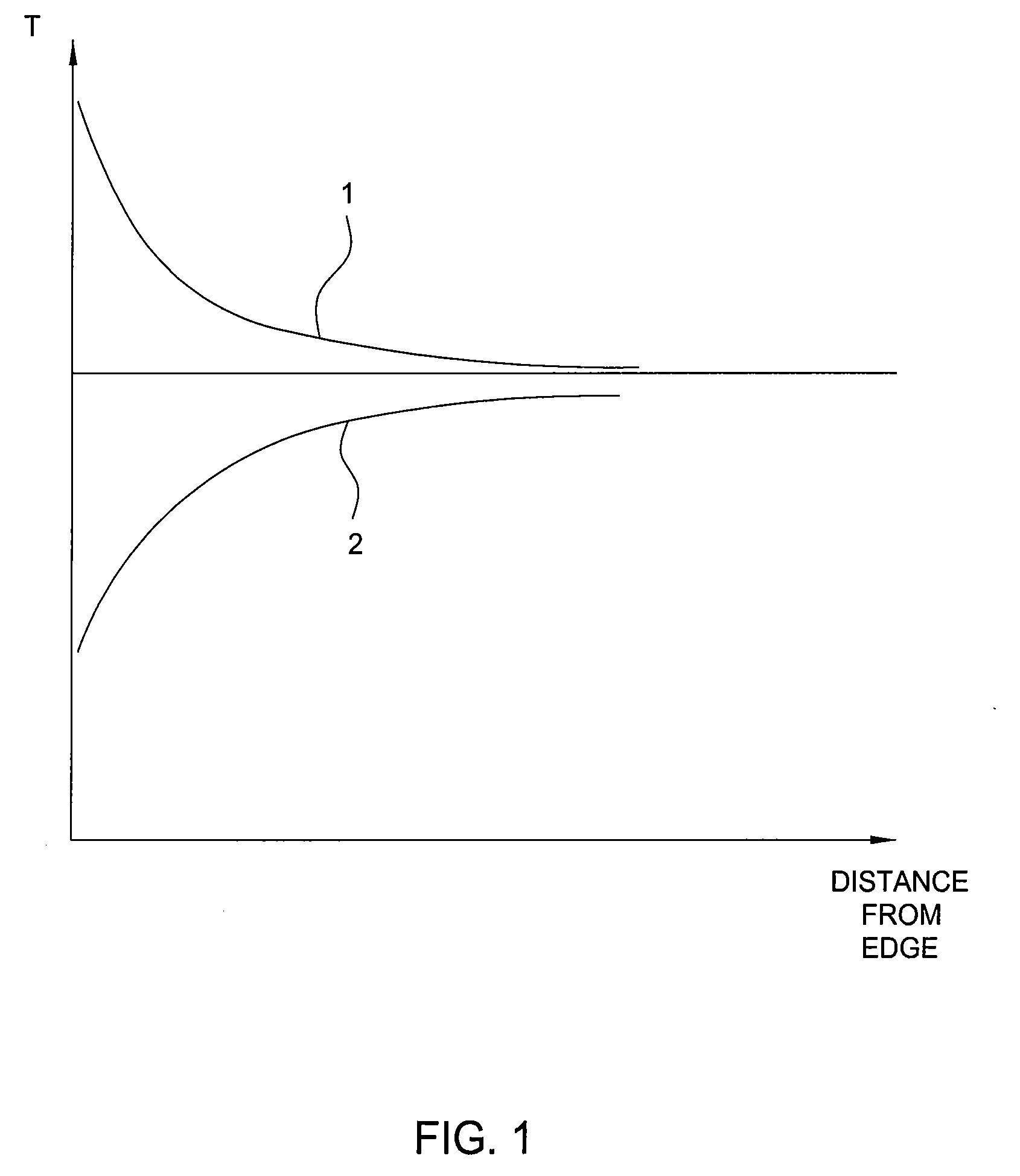

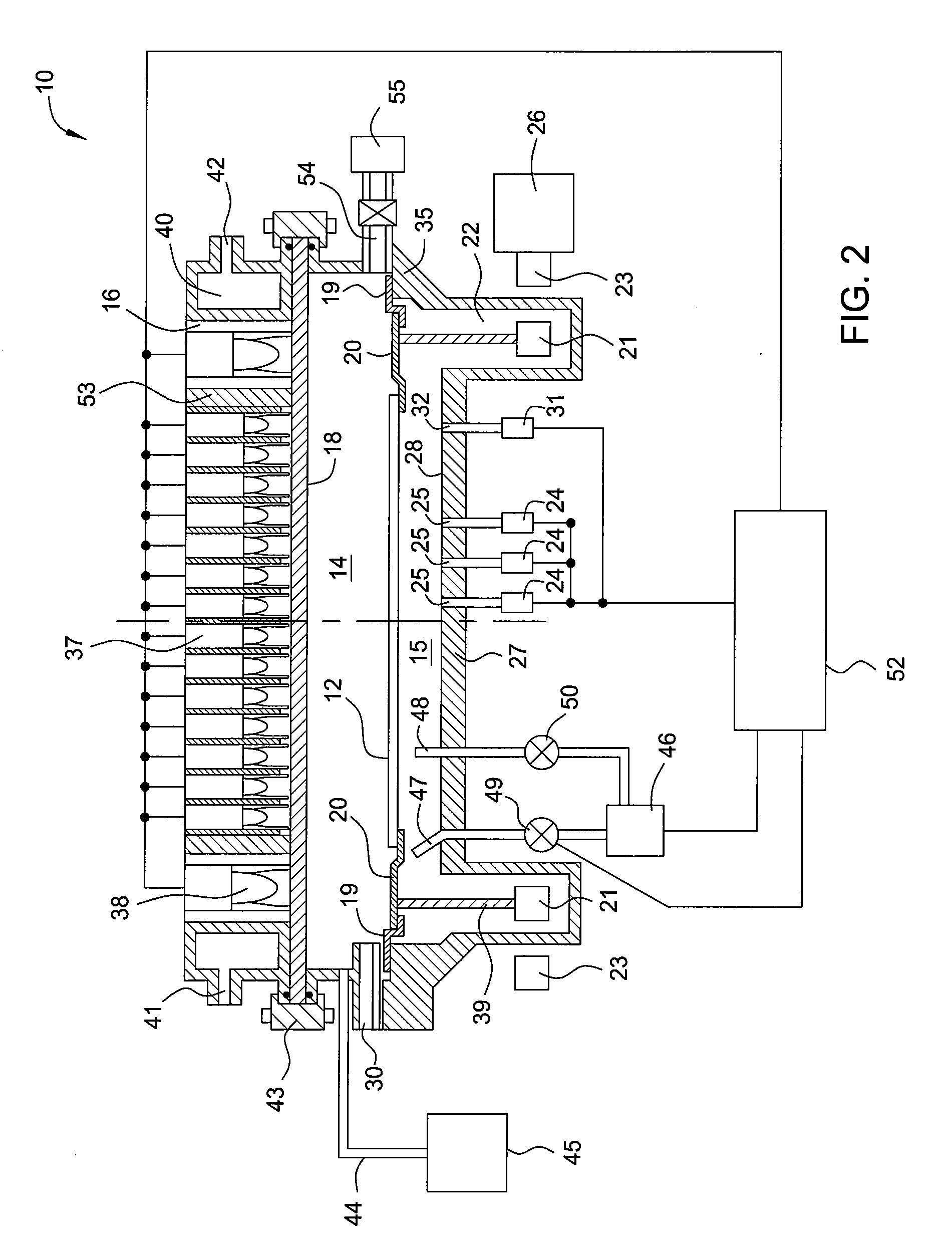

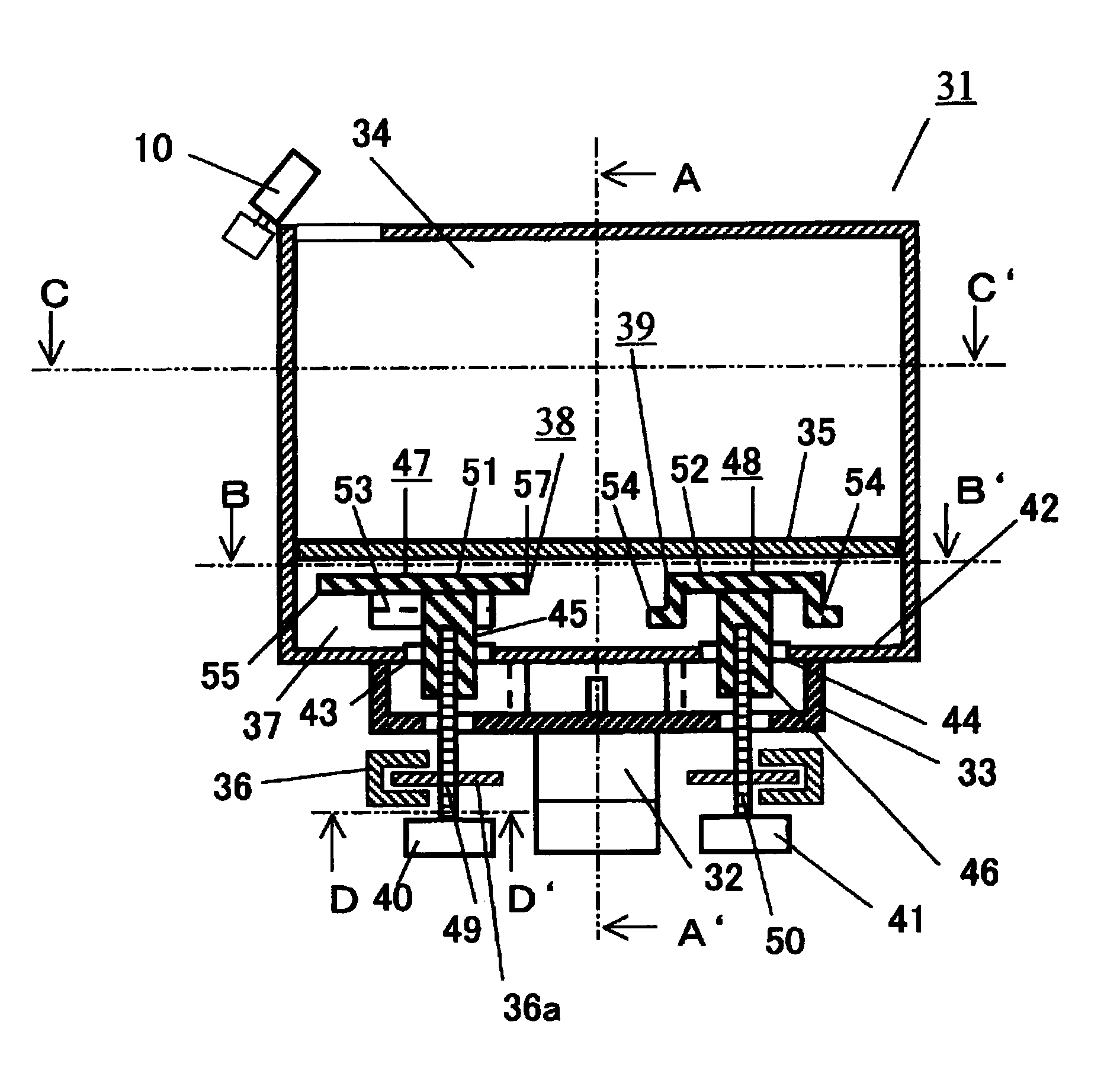

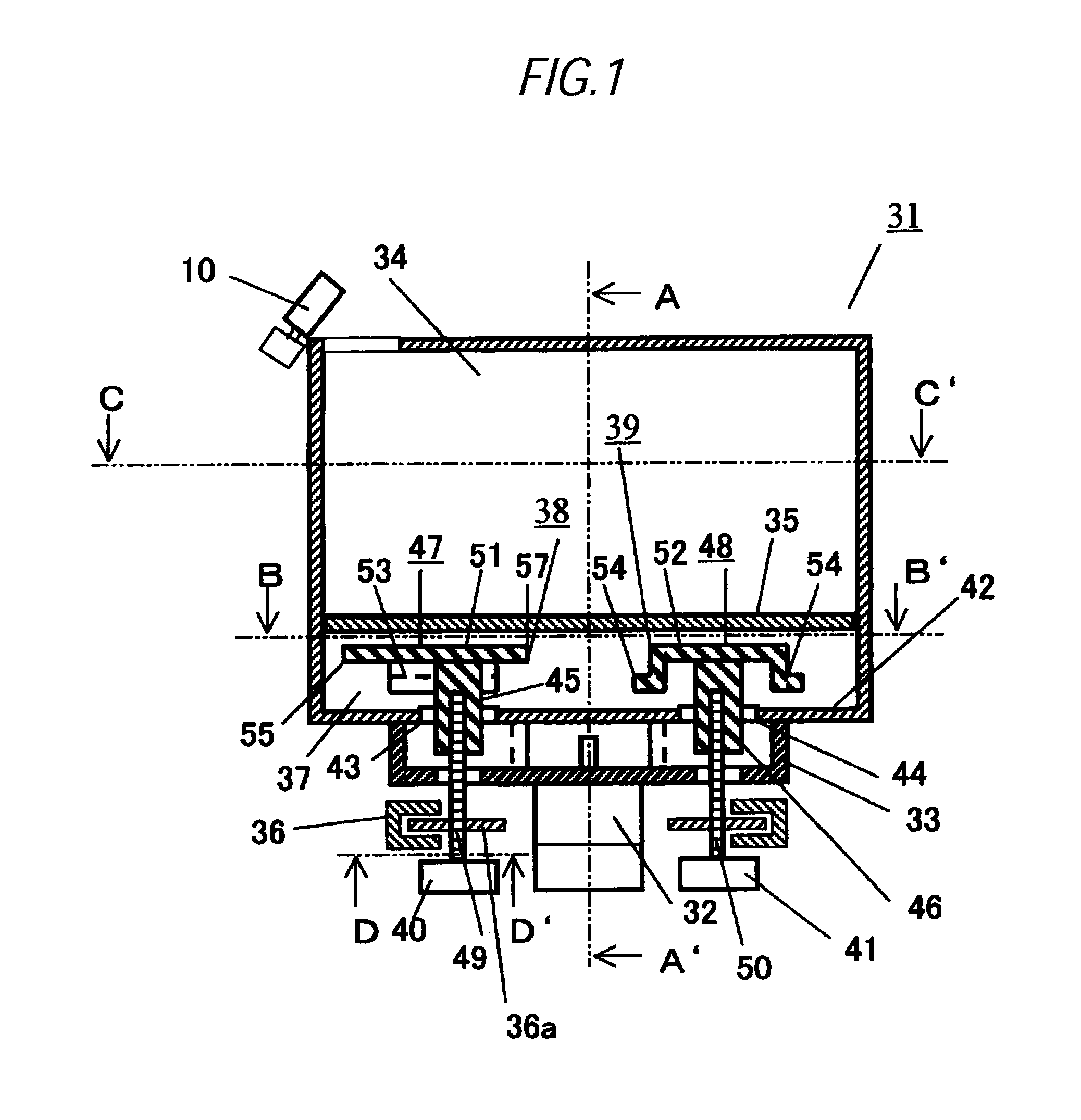

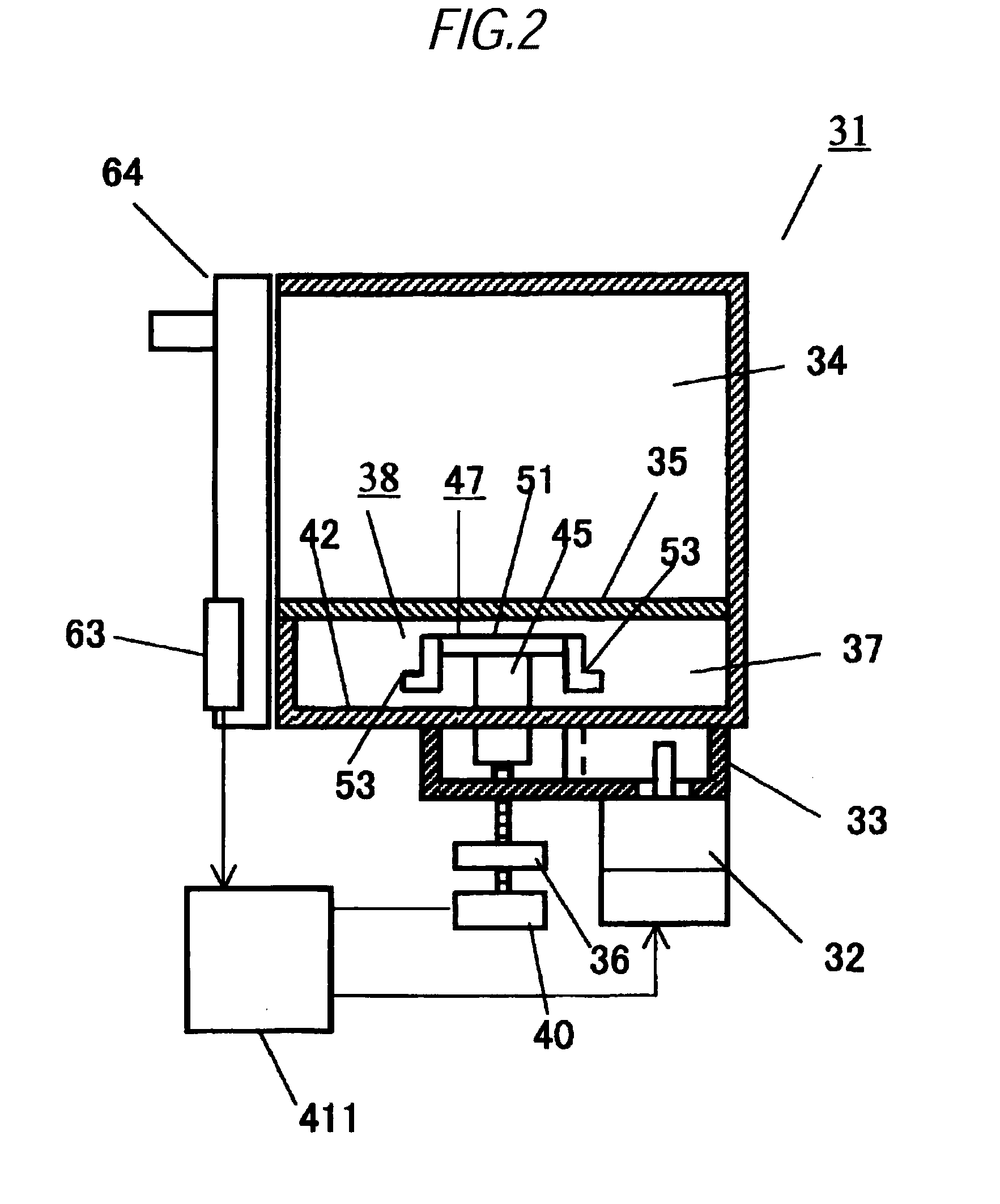

Temperature measurement and control of wafer support in thermal processing chamber

ActiveUS20080170842A1Uniform heatingSemiconductor/solid-state device testing/measurementBaking ovenTemperature measurementEngineering

Owner:APPLIED MATERIALS INC

Microwave heating appliance

An object of the present invention is to provide a microwave heating appliance capable of achieving a locally concentrated heating in answer to the purpose while achieving a uniform heating in the overall heating chamber in a normal mode. A microwave heating appliance of the present invention includes a microwave generating unit, a waveguide for transmitting a microwave from the microwave generating unit, a heating chamber for housing a heated subject that is heated by the microwave, a rotating antenna for radiating the microwave from the waveguide to the heating chamber, a driving unit for rotating and driving the rotating antenna, a temperature distribution detecting unit for detecting a temperature distribution in the heating chamber, and a controlling unit for controlling a direction of the rotating antenna by controlling the driving unit based on a detected result of the temperature distribution detecting unit, wherein the controlling unit controls a sharp part of radiation directivity of the rotating antenna in a direction decided based on the detected result of the temperature distribution detecting unit to execute a concentrated heating, and the driving unit has a position detecting unit for detecting a position of the rotating antenna.

Owner:PANASONIC CORP

Nickel-chromium high-resistance electrothermal alloy

ActiveCN101899593AImproves antioxidant propertiesUniform heatingOperating temperatureOxidation resistant

The invention discloses a nickel-chromium high-resistance electrothermal alloy. The alloy is characterized by comprising the following components in percentage by mass: 0.02 to 0.06 percent of C, 0.010 to 0.020 percent of P, 0.010 to 0.015 percent of S, 0.02 to 0.60 percent of Mn, 1.00 to 1.50 percent of Si, 20.0 to 23.0 percent of Cr, 0.1 to 0.20 percent of Al, 0.4 to 0.8 percent of Fe, 0.1 to 0.20 percent of Ti, 0.20 to 0.50 percent of Zr, 0.01 to 0.05 percent of RE and the balance of Ni. Metal zirconium and a rare-earth material are added into a metal alloy, the zirconium is contacted with the air to form a zirconia protective layer, so that the surface oxidation resistance of the alloy is greatly improved; and moreover, far infrared rays can be generated, and heating is uniform, so that the highest operating temperature of the alloy steel can be up to 1,300 DEG C, and the surface load of the alloy steel can be up to 5 W / cm<2>.

Owner:JIANGSU LIXIN ALLOY IND GENERAL

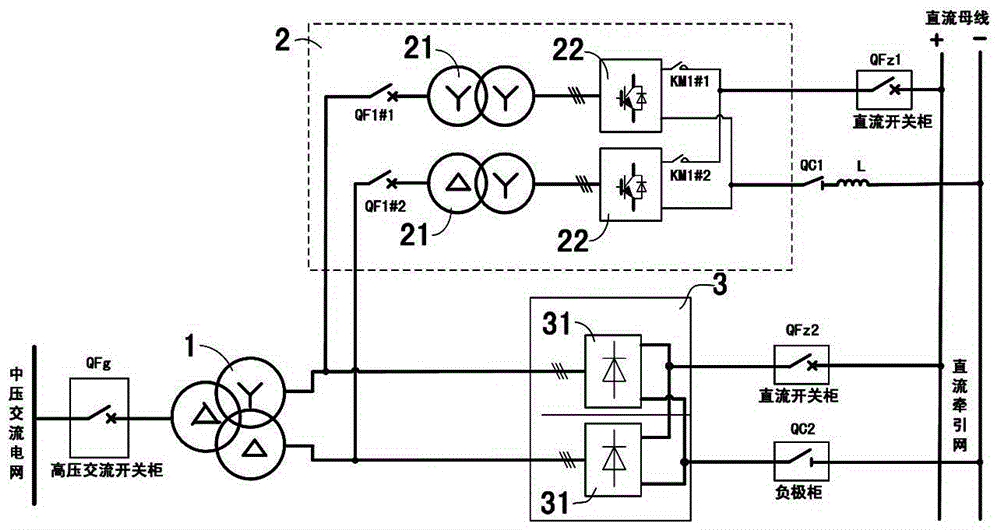

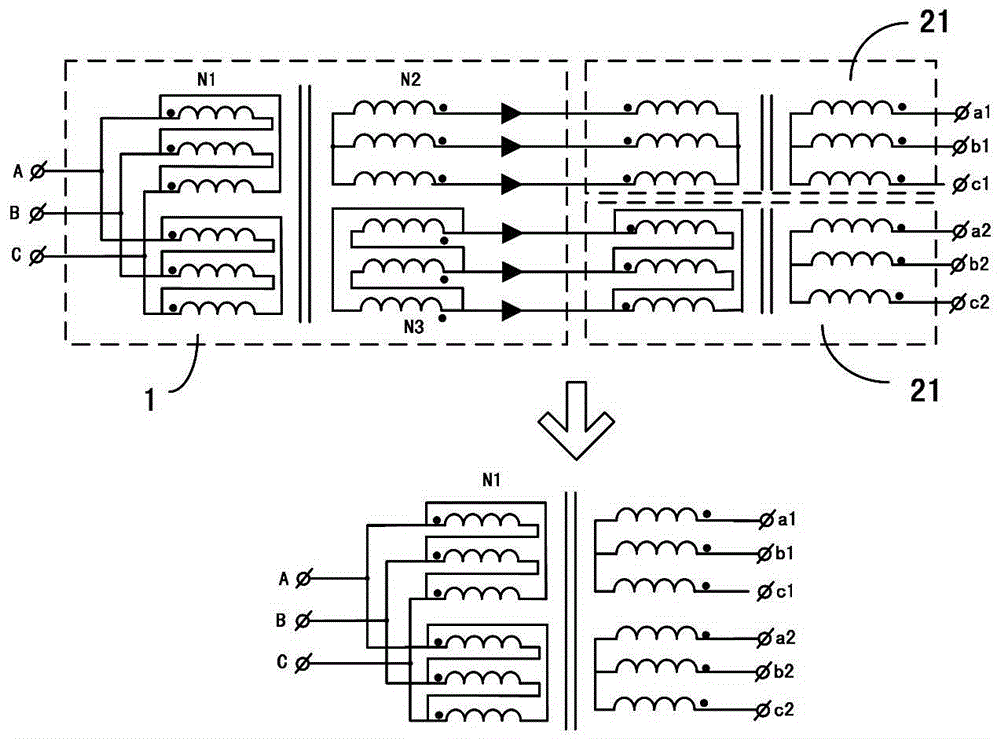

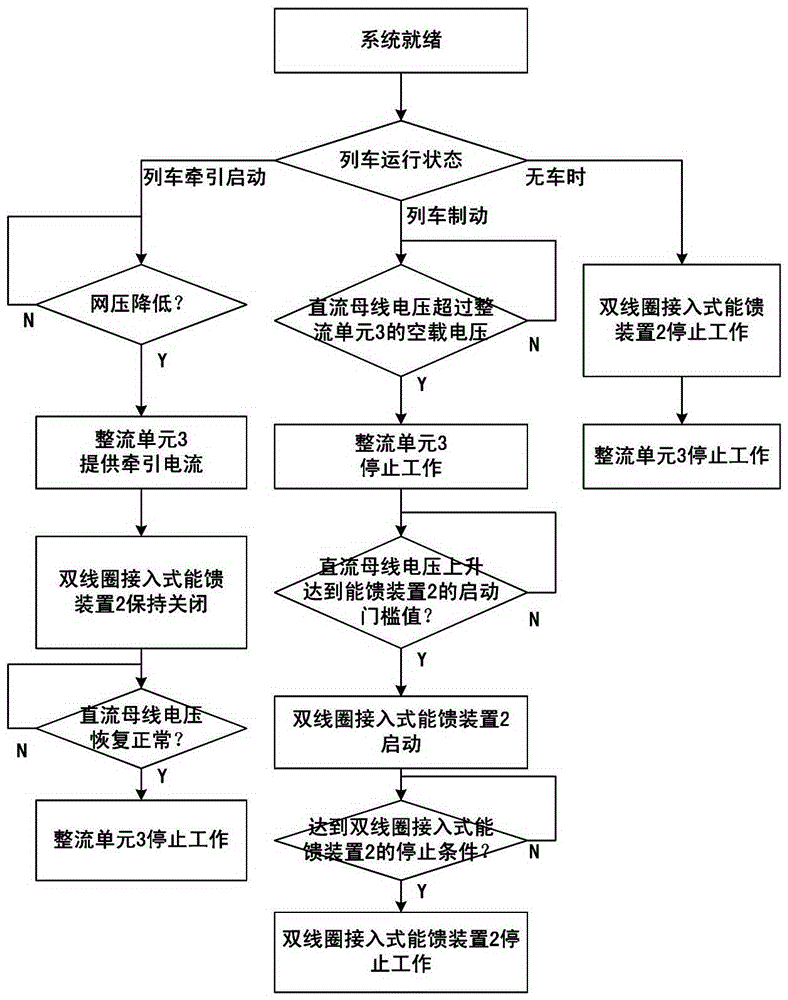

Rail transit power supply system twin coil access medium-voltage energy feed system and method

ActiveCN105226969AHigh energy saving rateUniform heatingClimate change adaptationAc-dc conversionContactorAC power

The invention discloses a rail transit power supply system twin coil access medium-voltage energy feed system and method. The system comprises a rectification transformer, a twin coil access energy feed device, and a rectification unit. The twin coil access energy feed device comprises two energy feed branches arranged in parallel. Each energy feed branch comprises an AC-side low-voltage breaker, an isolation transformer, an inverter, and a DC-side contactor which are successively arranged in series. The method comprises steps that current is acquired from a medium-voltage AC power grid and is supplied to a DC traction network by means of the rectification transformer and the rectification unit when a train is started; and the twin coil access energy feed device is started and train braking energy is fed back to the medium-voltage AC power grid via the twin coil access energy feed device and the rectification transformer when the train is braked. The system may achieve energy conservation and stable DC bus voltage, is good in flexibility, small in size, high in combination with a conventional system, high in power factor, low in harmonic injected into an AC side, and good in universality.

Owner:NINGBO METRO GRP +1

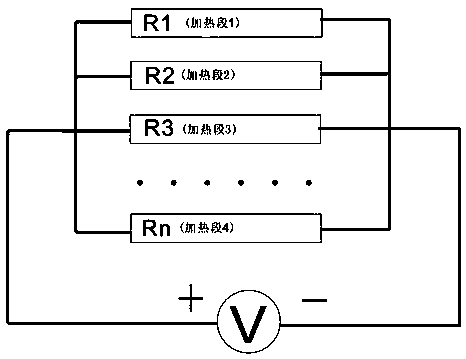

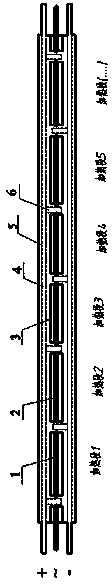

Novel composite sensing optical cable

InactiveCN104183334ALarge resistanceUniform heatingCommunication cablesCross connectionTemperature measurement

The invention discloses a novel composite sensing optical cable comprising a carbon fiber filament, temperature-sensitive fibers, power supply wires, a sheath, and an insulating wrapping layer. The carbon fiber filament, the temperature-sensitive fibers, the power supply wires, and the sheath are wrapped in the insulating wrapping layer. The carbon fiber filament is wrapped in the sheath. More than one temperature-sensitive fiber and a pair of the power supply wires are provided. The carbon fiber filament and the surrounding power supply wires are in crossed connection so as to form a parallel circuit. Power is supplied simultaneously such that the optical cable is uniformly heated at long distance by means of a fact that the carbon fiber filament generates heat after being supplied with power. The temperature-sensitive fibers are wrapped in the carbon fiber filament or arranged in parallel with the carbon fiber filament. The carbon fiber filament is heated after being supplied with power so as to uniformly heat the optical cable. Temperature measurement at various points along the cable is achieved by means of distributed fiber temperature measurement technology. The optical cable can be uniformly heated for long distance (more than 2km) and long-distance leakage can be detected.

Owner:SUZHOU NANZEE SENSING TECH

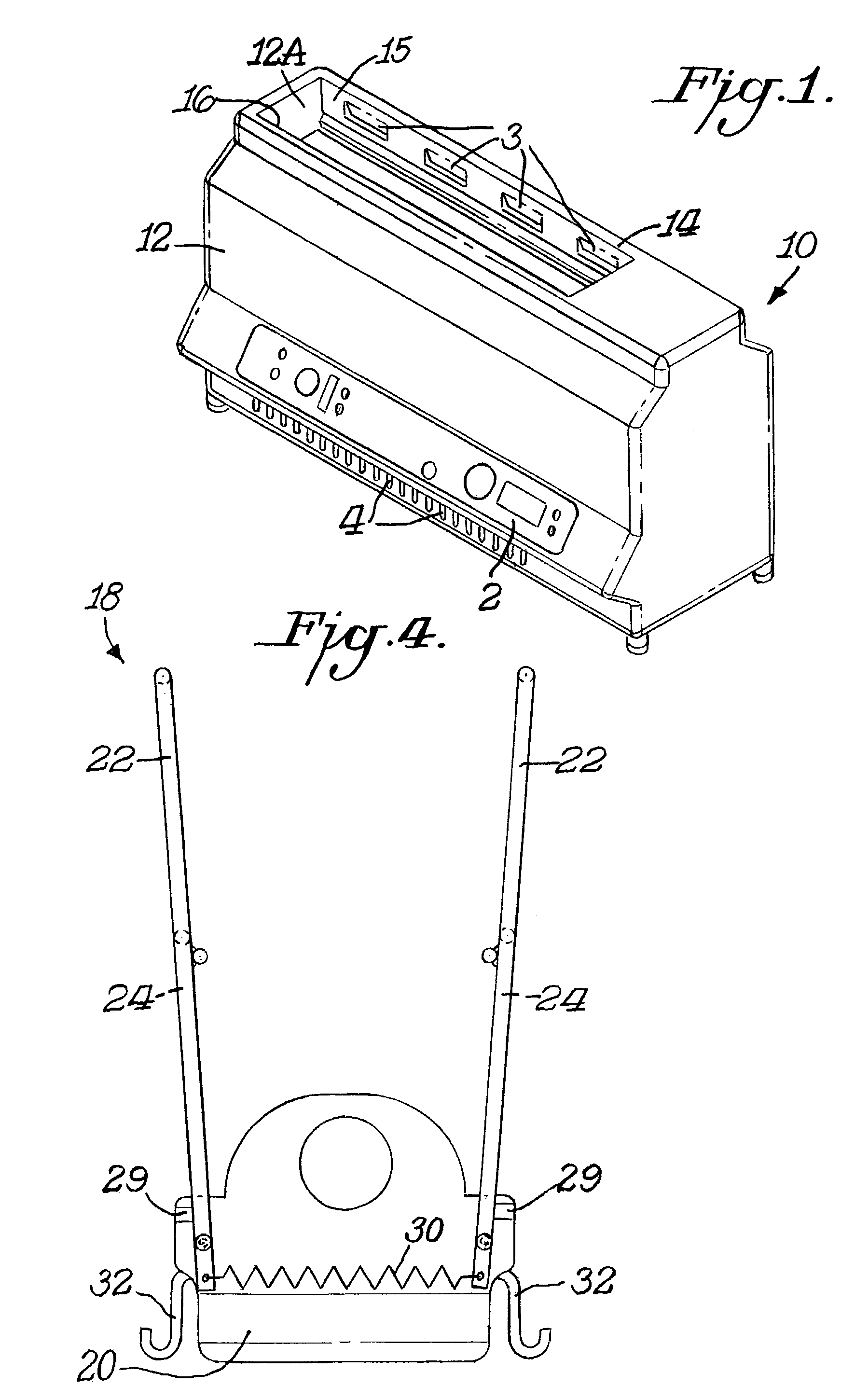

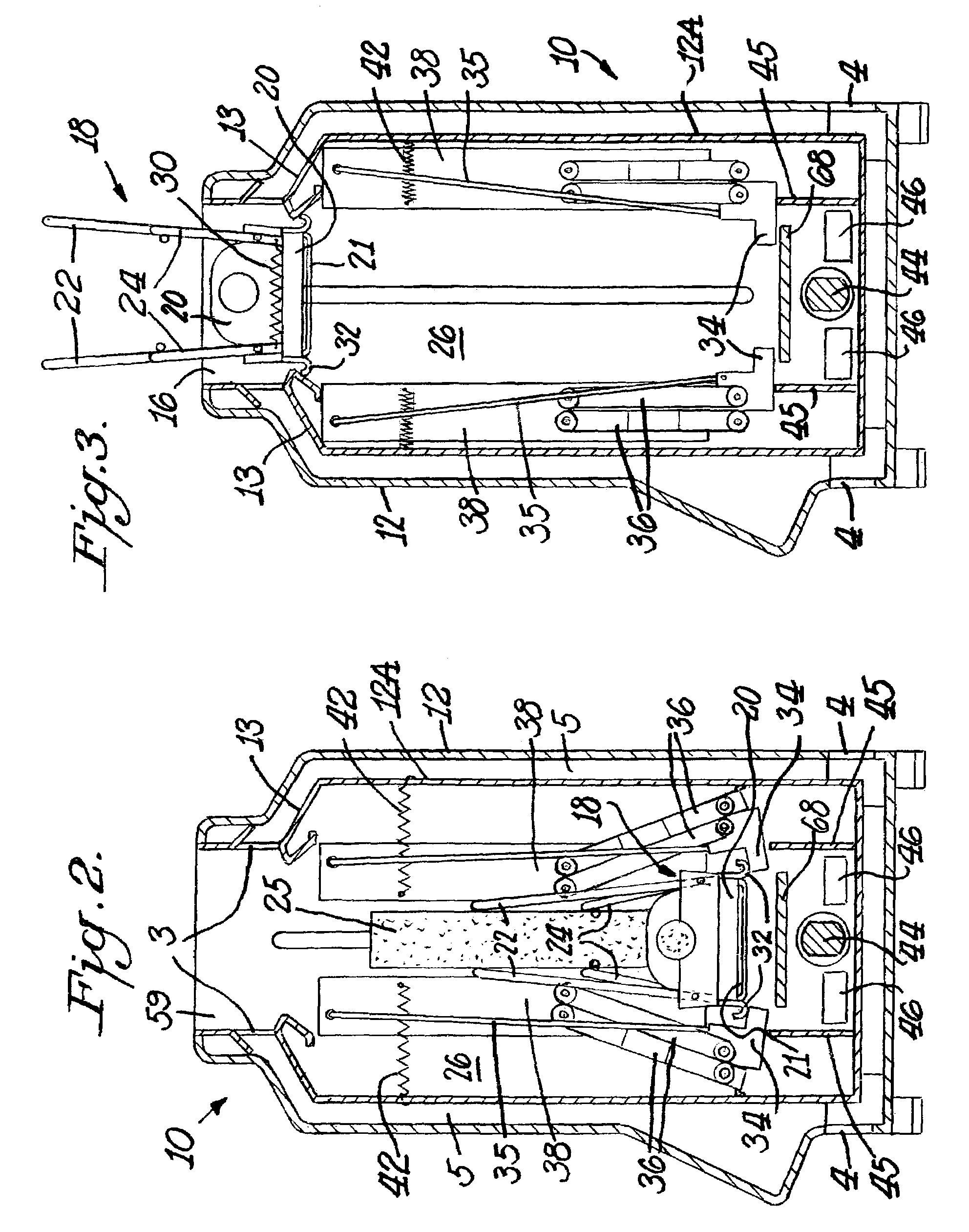

High speed baking in novel toasting apparatus

InactiveUS7036424B2Uniform heatingReduce densityBoiling over preventionBaking ovenEngineeringHeating element

An electric baking oven includes an open mesh vertically oriented baking basket to hold food while the food is baked in air by a programmed combination of radiant and convective and conductive energy transfer. An electrical programming control controls the energy from vertically oriented toaster heating elements located juxtaposed to the large vertical faces of the basket and from at least one elongated heating member located below the vertical baking basket with the axis of the elongated heating member oriented nominally horizontal and parallel to the longer horizontal axis of the vertically oriented baking basket.

Owner:EDGECRAFT

Process method for baking angilica keiskei koidzumi

ActiveCN103719305AGuaranteed nutrition and health careReduce lossesPre-extraction tea treatmentVitamin CTwo step

The invention relates to the field of tea preparation and particularly relates to a process method for baking angilica keiskei koidzumi. According to the process method, an angilica keiskei koidzumi baking technical method, comprising the steps of baking at low temperature, adding jasmine flowers and producing fragrance at high temperature, is established, the steps of a preparation process are simple, the loss of chalcone and vitamin C in angilica keiskei koidzumi during preparation is reduced, and the content of chalcone and vitamin C is obviously higher than that of tea products which are prepared by only frying leaves under conventional process conditions, so that the nutritional healthcare effects of angilica keiskei koidzumi are guaranteed; according to the prepared angilica keiskei koidzumi product, baking and frying processes are replaced with low-temperature baking, so that the tea is uniform in heated degree and good in sensory character, and the problem of charring due to excessive baking and frying is effectively solved; due to the two steps of adding jasmine flowers and producing fragrance at high temperature, the fragrance of angilica keiskei koidzumi is guaranteed.

Owner:青岛海隆达生物科技有限公司

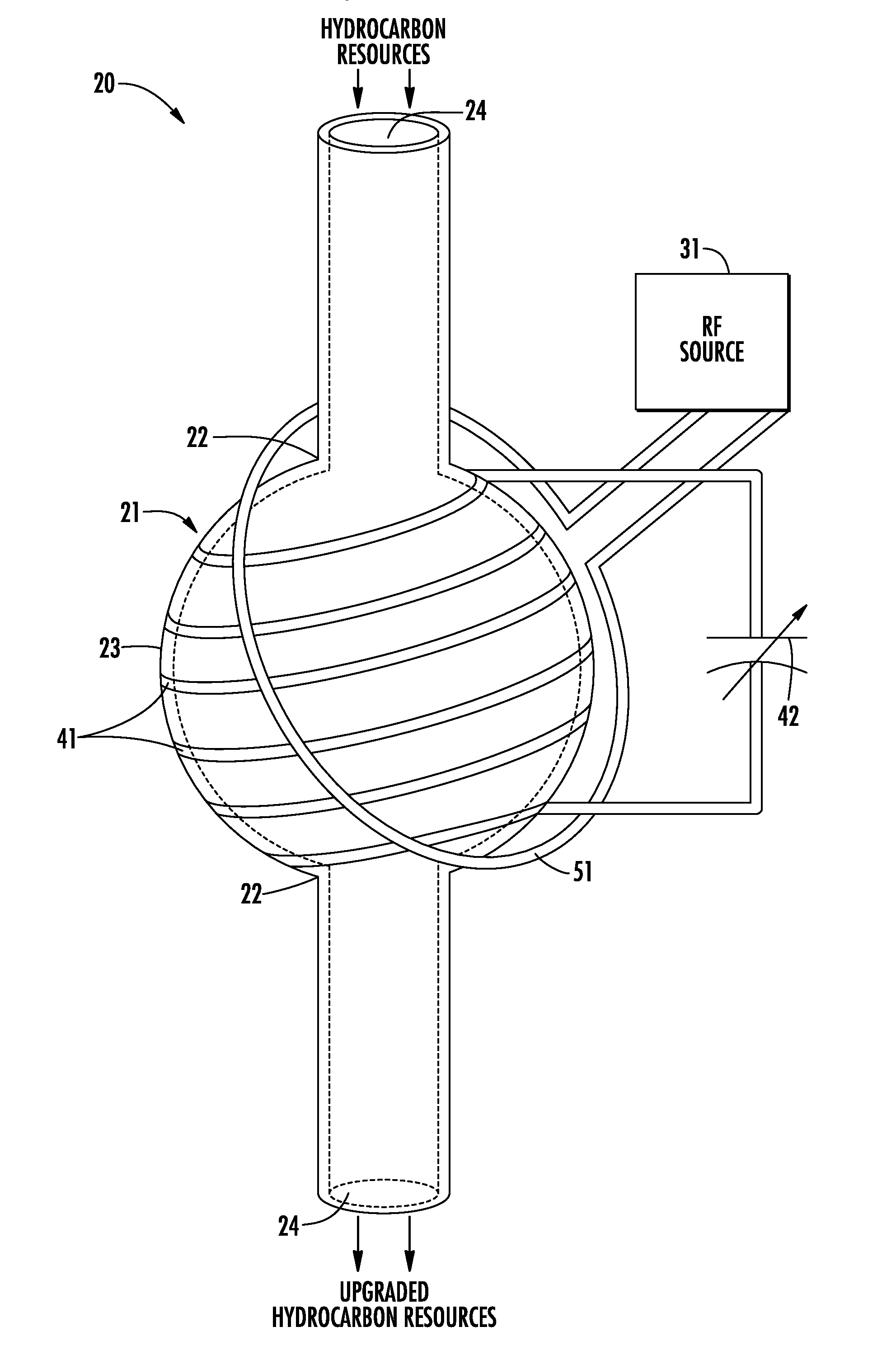

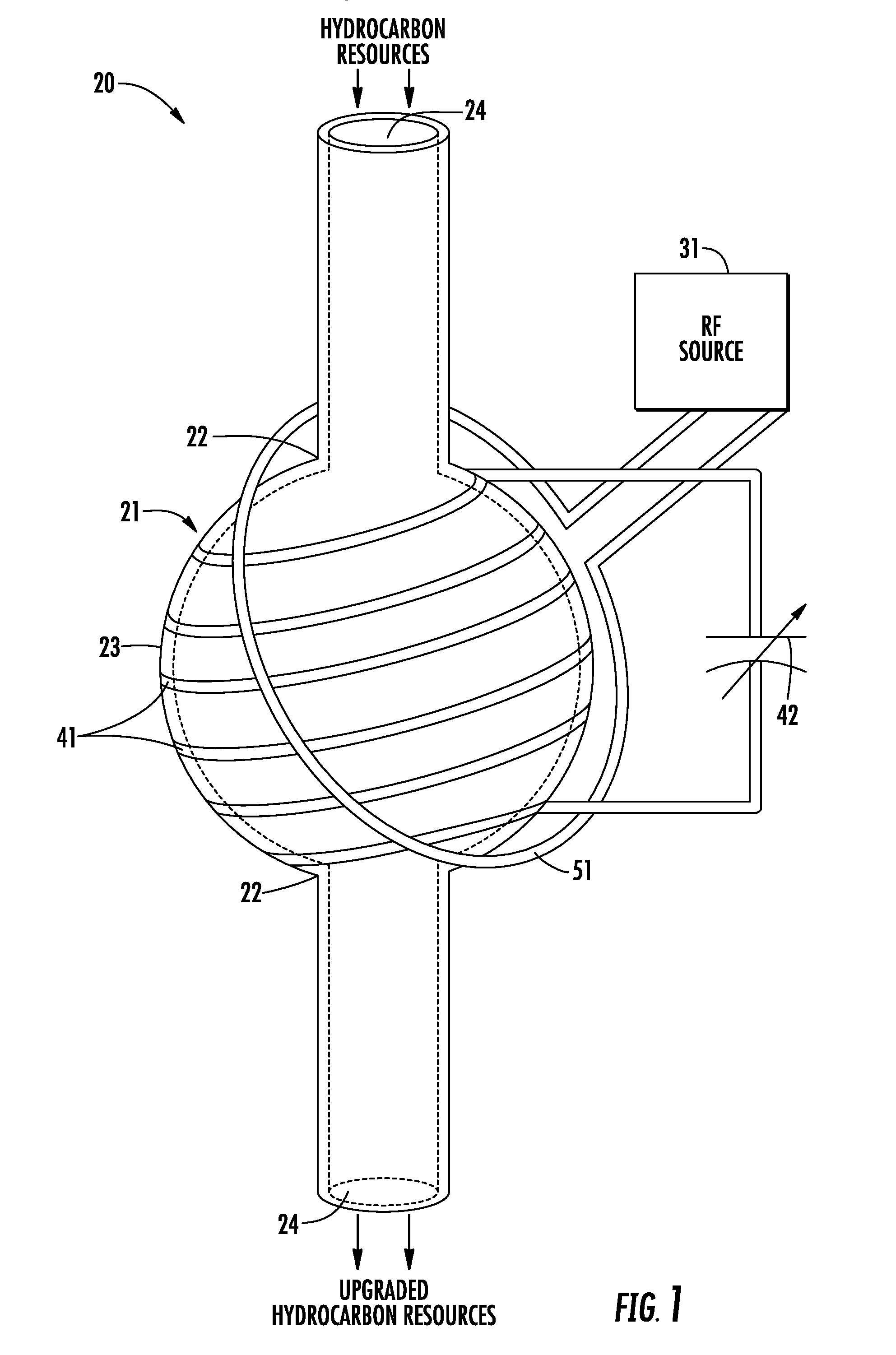

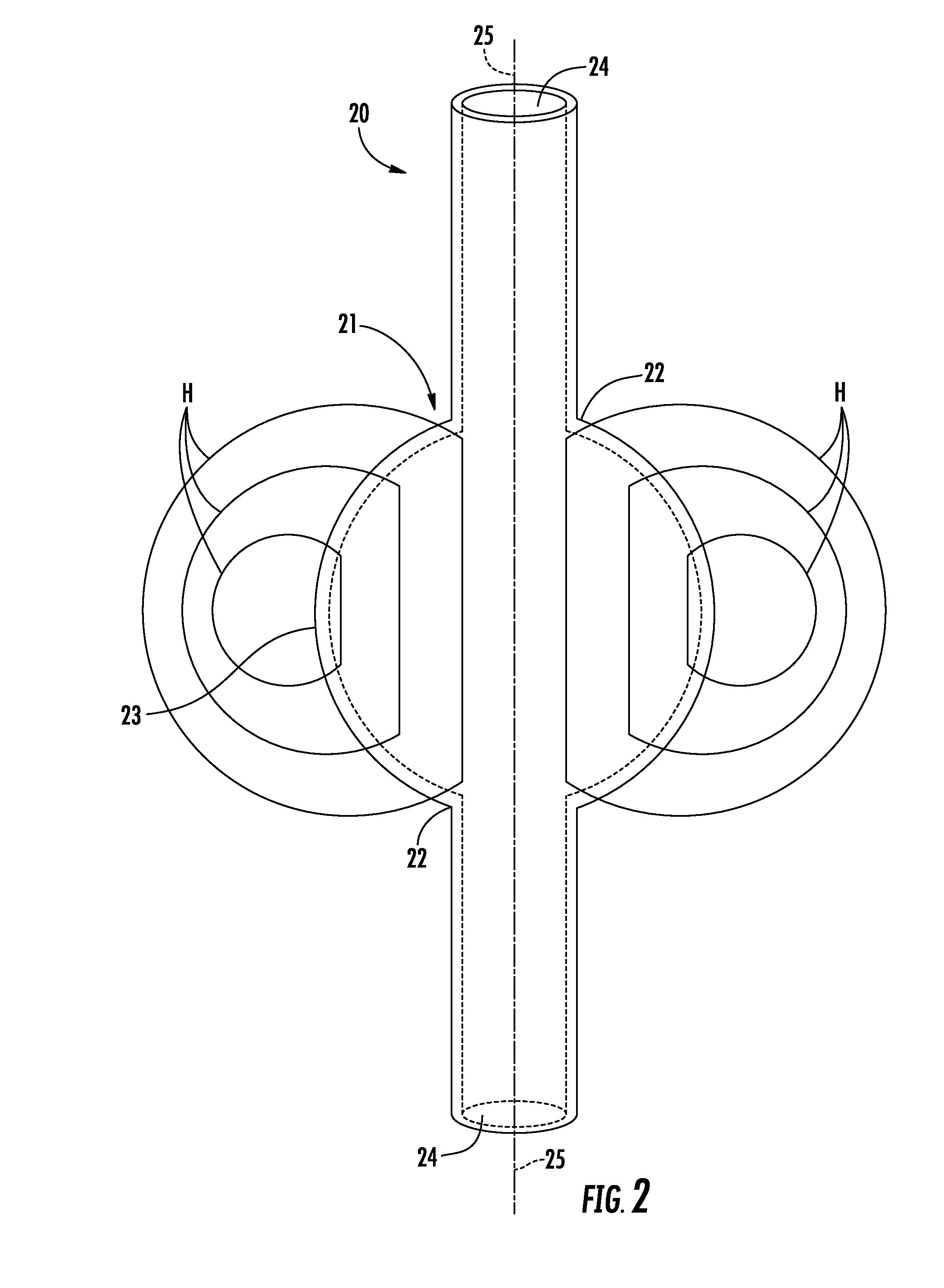

Electromagnetic oven including spirally wound electrical conductor and related methods

InactiveUS20130180980A1Reduction of hot and cold spotUniform heatingCoil arrangementsRadio frequencyElectrical conductor

An electromagnetic oven may include a housing and a food heating chamber carried by the housing. The food heating chamber may have a pair of opposing ends with an enlarged width medial portion therebetween. The electromagnetic oven may include a radio frequency (RF) source carried by the housing, and a spirally wound electrical conductor surrounding the food heating chamber and coupled to the RF source. The spirally wound electrical conductor may be configured to generate magnetic fields within the food heating chamber that are parallel with an axis thereof.

Owner:HARRIS CORP

Bottom-blowing and side-blowing molten pool reducing furnace for liquid state high lead slag

The invention discloses a bottom-blowing and side-blowing molten pool reducing furnace for liquid state high lead slag. The bottom-blowing and side-blowing molten pool reducing furnace for the liquid state high lead slag comprises a furnace body and support bases arranged on the two ends of the furnace body. The outer wall of the furnace body is fixedly provided with rolling rings. The furnace body can be rotatably installed on the support bases through the rolling rings and is driven to rotate by a driving device. The top of the furnace body is provided with a smoke outlet opening, a first material-adding opening and a second material-adding opening from left to right in sequence. The lower part of a side plate of the right end of the furnace body is provided with a slag-discharging opening. A reducing spraying gun device is arranged at the bottom, under the first material-adding opening, of the furnace body. A heating spraying gun device is arranged below the second material-adding opening. The heating spraying gun device is located on the side wall of the furnace body and arranged close to the slag-discharging opening. According to the bottom-blowing and side-blowing molten pool reducing furnace for the liquid state high lead slag, fuel and combustion improver are sprayed from a heating spaying gun into a slag layer of a molten pool, on the one hand, lead oxide of the slag layer is further subjected to reduction reaction, the lead content rate of the slag is decreased, and the direct recovery rate of lead is increased; and on the other hand, the temperature of the slag layer of the molten pool is improved, the slag is conveniently discharged, meanwhile, the distance of the spraying gun and the slag-discharging opening is shorted, the temperature of the molten poll is reduced, and the consumption of energy is reduced.

Owner:HENAN YUGUANG GOLD & LEAD

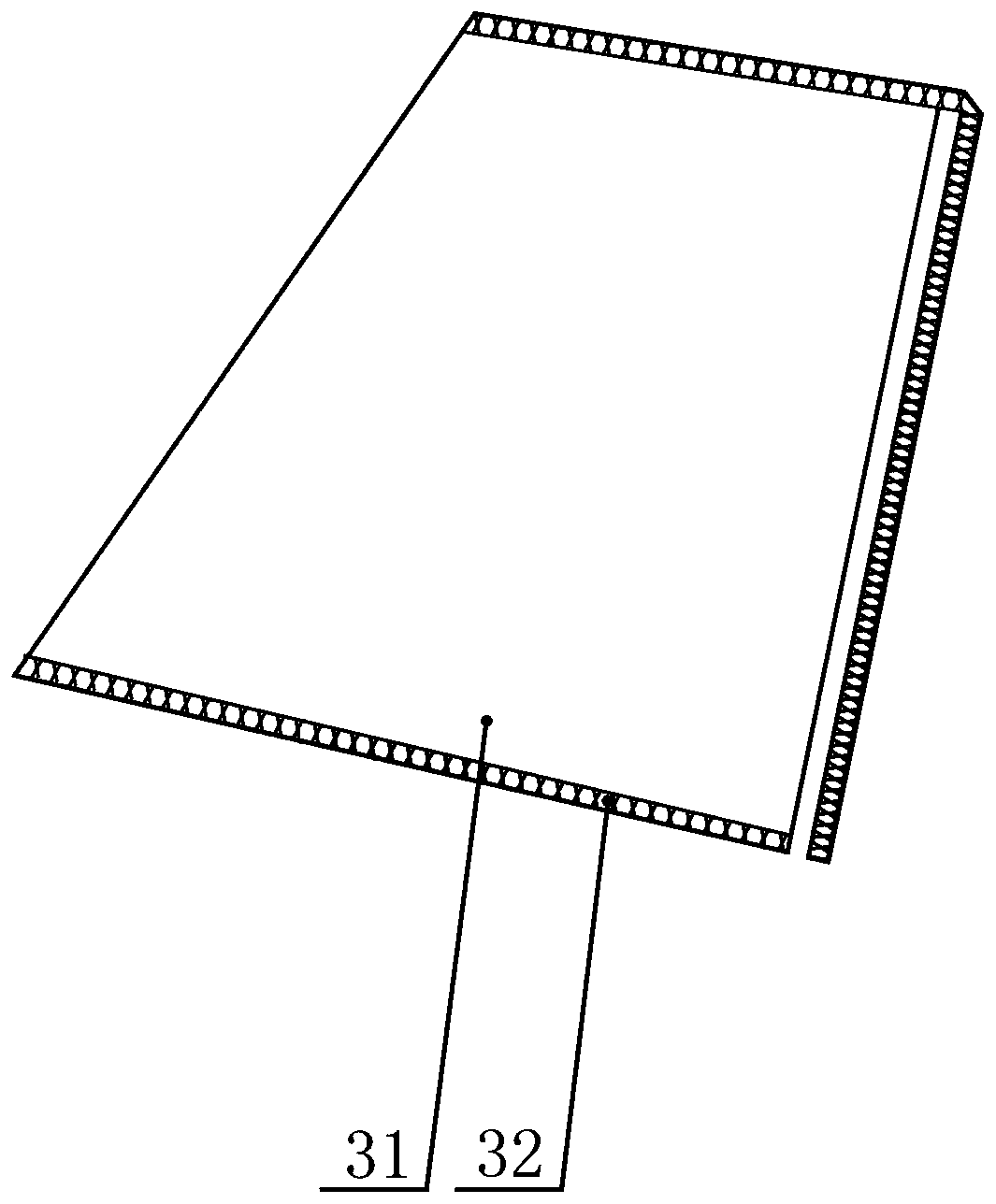

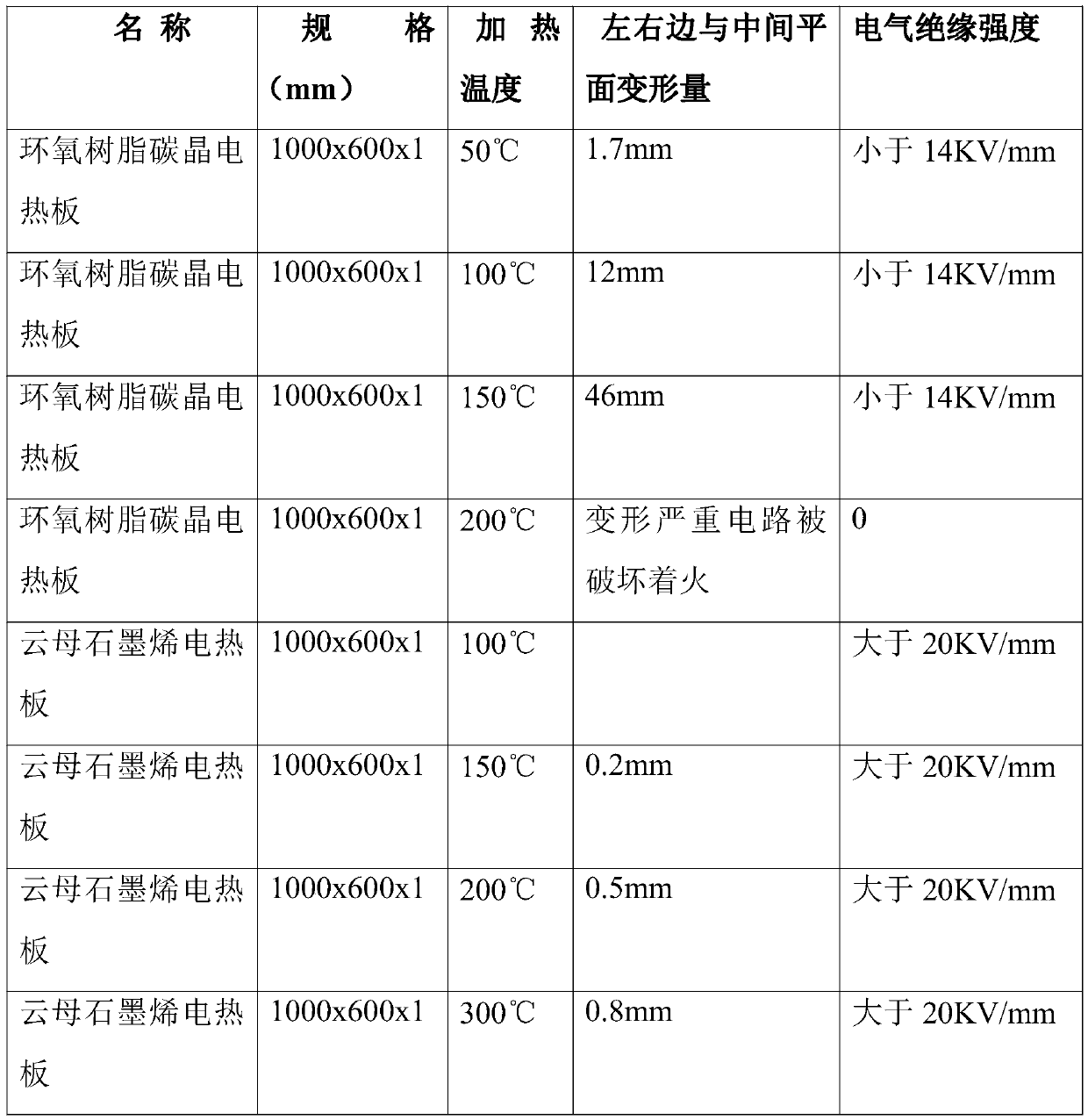

High-temperature resistant graphene mica electrical heating plate and fabrication method thereof

InactiveCN110213845AUniform heatingFast feverChemical industryLaminationHeating filmTemperature resistance

The invention relates to an electrical heating plate and a fabrication method thereof, in particular to a high-temperature resistant graphene mica electrical heating plate and a fabrication method thereof. The high-temperature resistant graphene mica electrical heating plate comprises a surface modification layer, an upper mica insulation layer, a graphene heating layer and a lower mica insulationlayer which are sequentially laminated from top to bottom and are hot-pressed by a hot-press machine. The high-temperature resistant graphene mica electrical heating plate employs graphene conductivepaper as a heating core layer, the mica paper with fireproof class is used as an insulation material, the electrical heating plate is synthesized by hot-pressing of a hot-press machine and by takingorganic silicon as an adhesive has the advantages of fireproof performance, high safety class, high temperature resistance (300 DEG C), high insulativity, high heating efficiency, rapid heating speed,structure stability and long service lifetime and can be used for a long time between 200-300 DEG C, the limitation of an electrical heating film and an epoxy electric coupling plate which are only used within 100 DEG C and a phenomenon that a fire is easily caused are solved, and the electrical heating plate is suitable for promotion and application.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

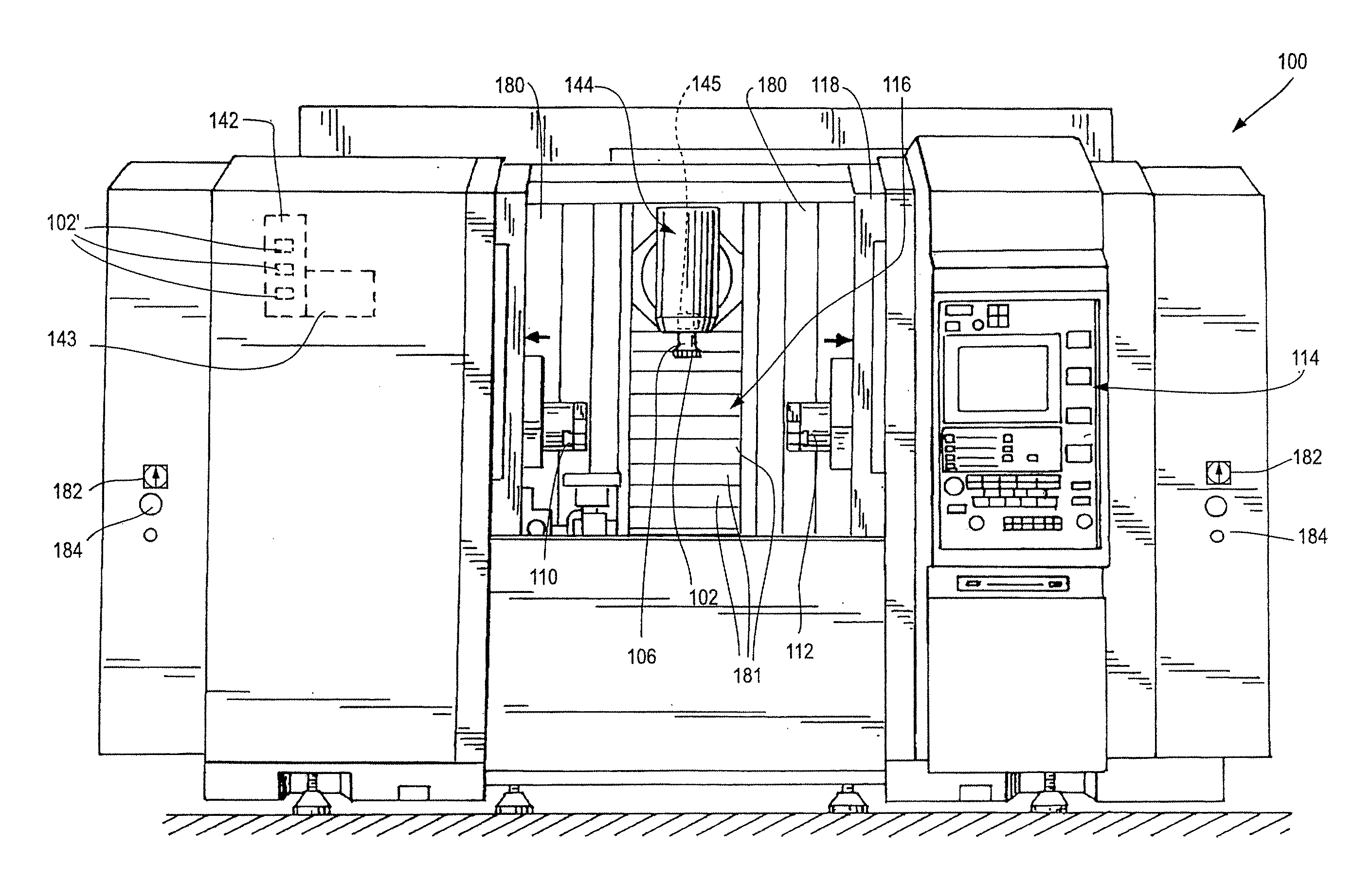

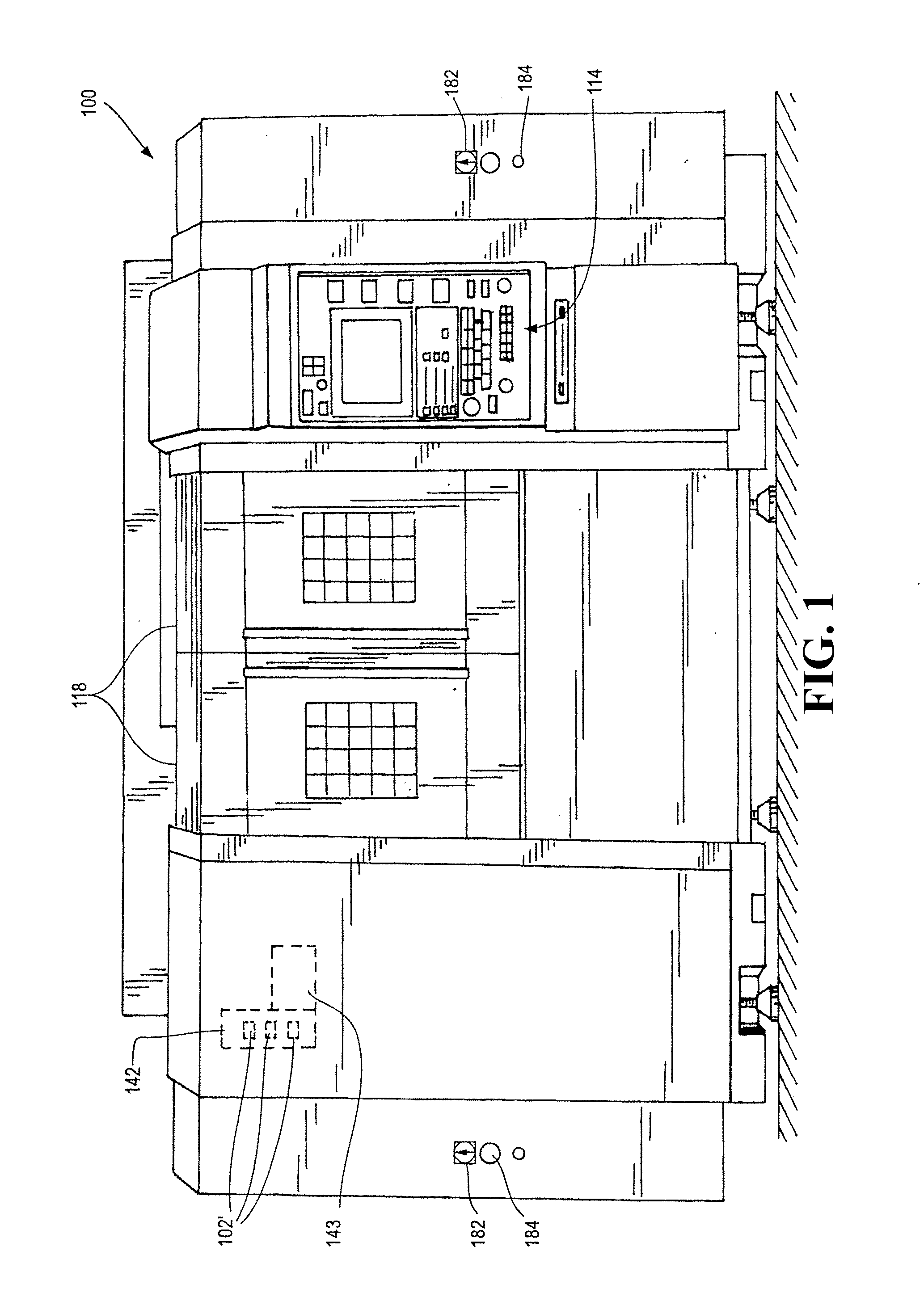

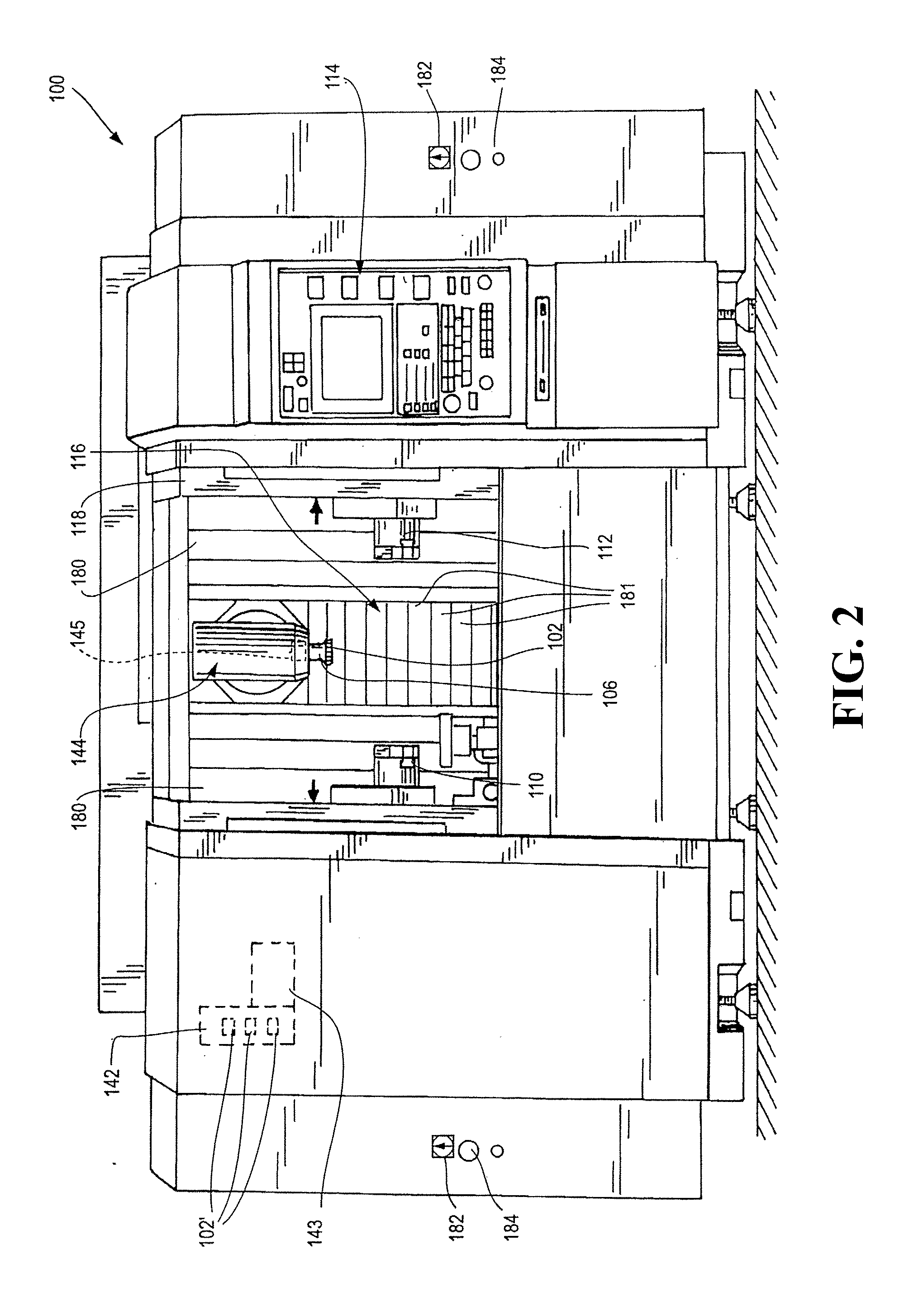

Grind Hardening Method and Apparatus

ActiveUS20130273811A1Uniform heatingSufficient heatRevolution surface grinding machinesGrinding feed controlGrindEngineering

A method of grind hardening a workpiece is provided. The method may include securing the workpiece in a workpiece retainer and a grind tool in a tool retainer, rotating the grind tool in a first angular direction at a first angular speed, controlling the workpiece and tool retainers such that the grind tool engages the workpiece, and controlling the workpiece and tool retainers such that the grind tool is guided along a grinding track of the workpiece. The grind tool may engage and / or disengage the workpiece at portions of sacrificial material disposed thereon. Coolant and cleaning nozzles may be provided and controlled such that at least a portion of the coolant from the coolant nozzle is diverted to the cleaning nozzle in a manner which reduces heat dissipation, improves thermal efficiency of the grind hardening and reduces loading of the grind tool.

Owner:DMG MORI SEIKI CO LTD

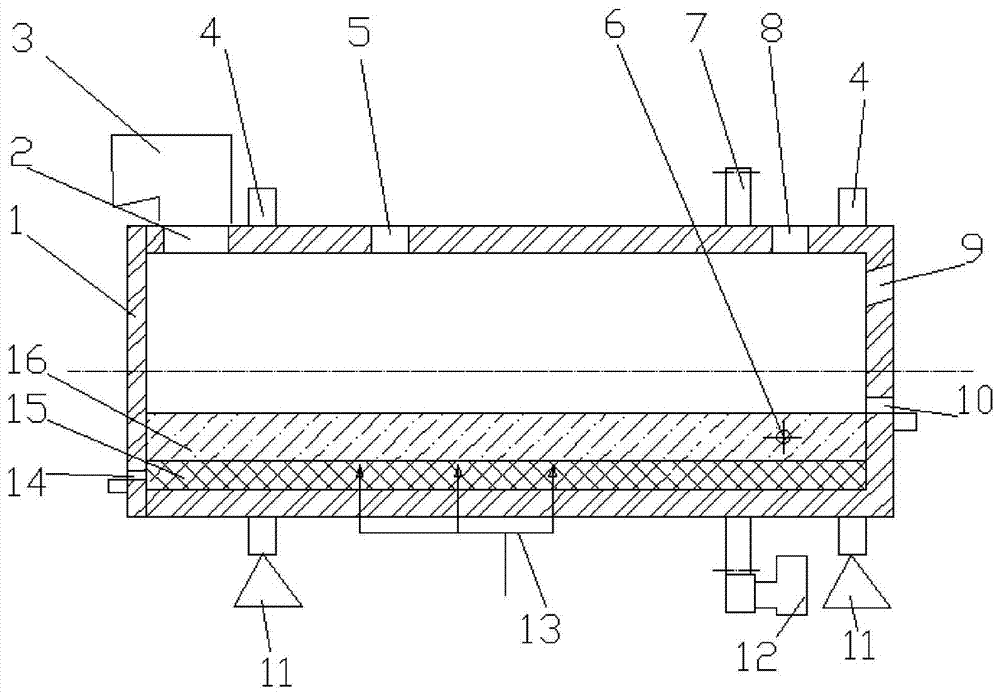

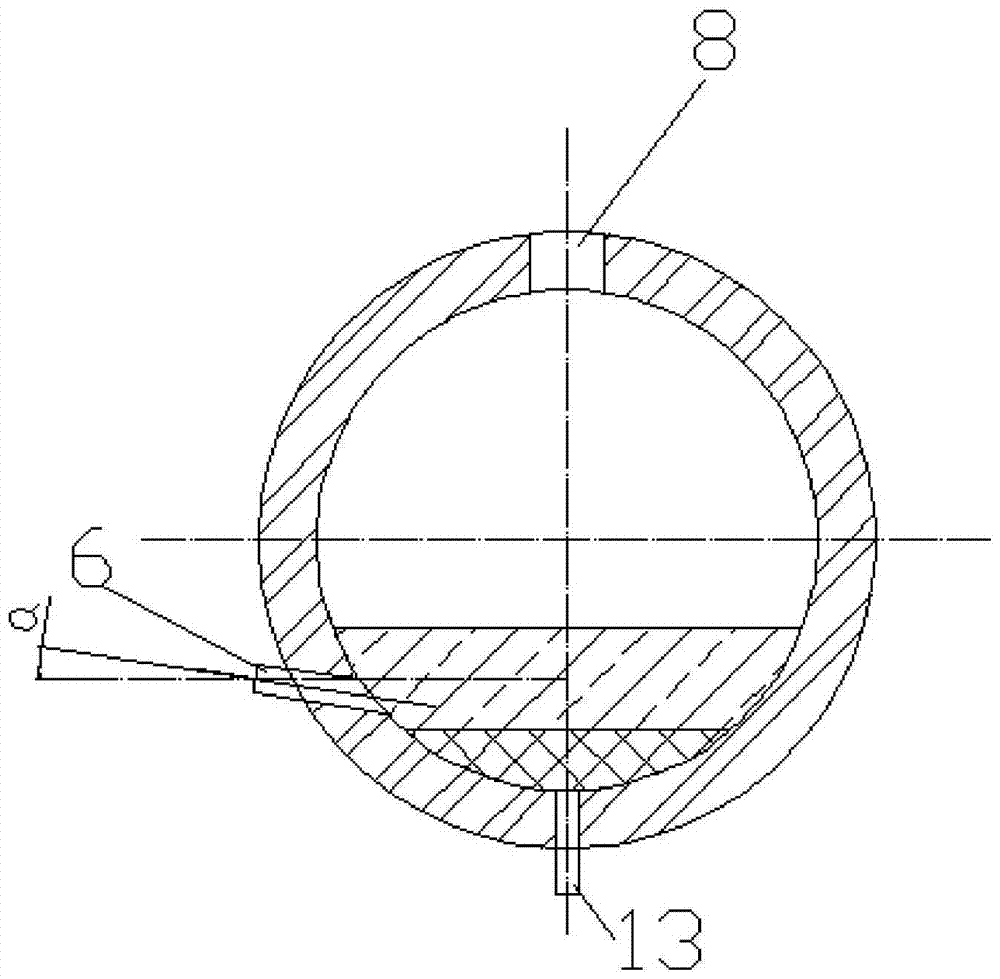

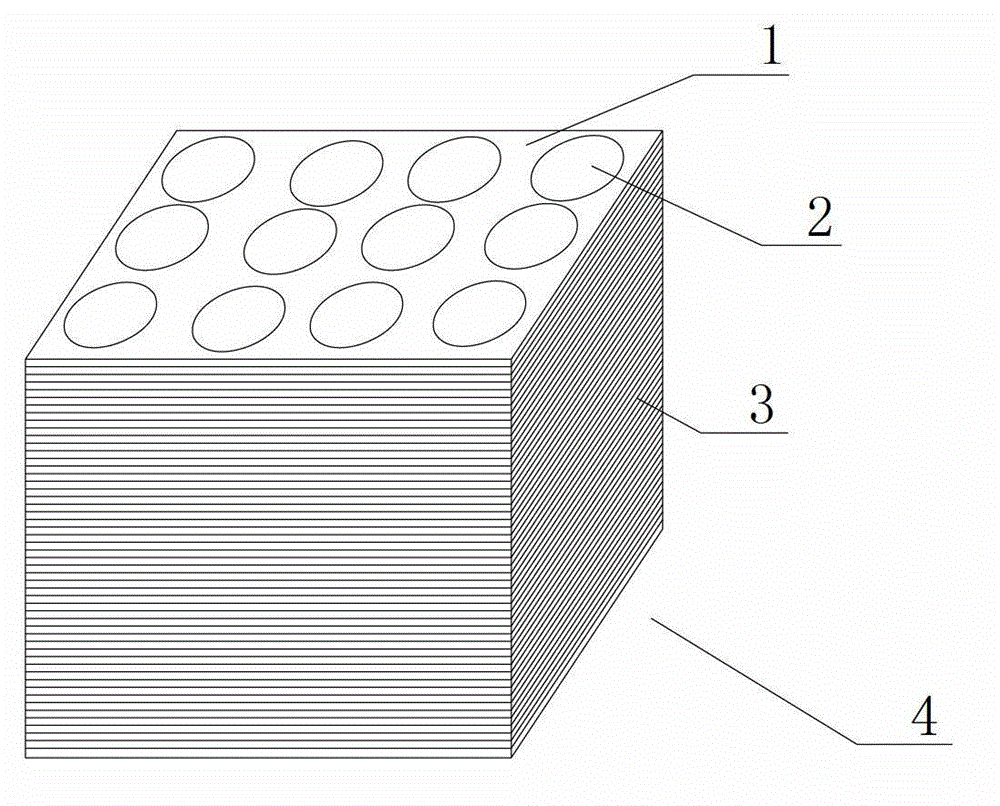

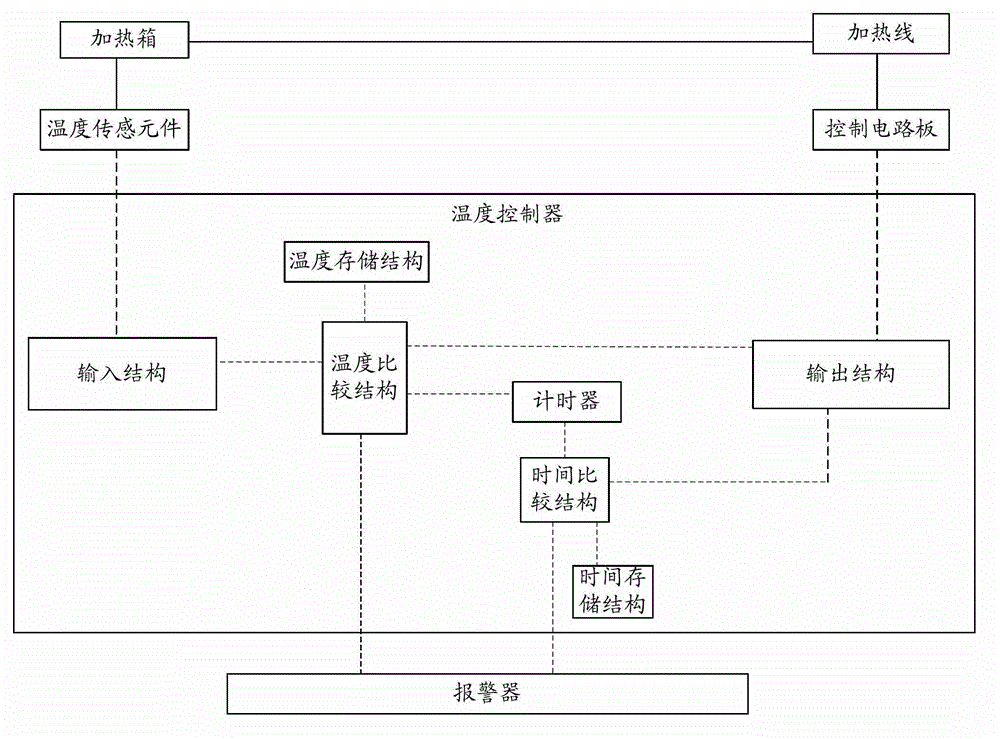

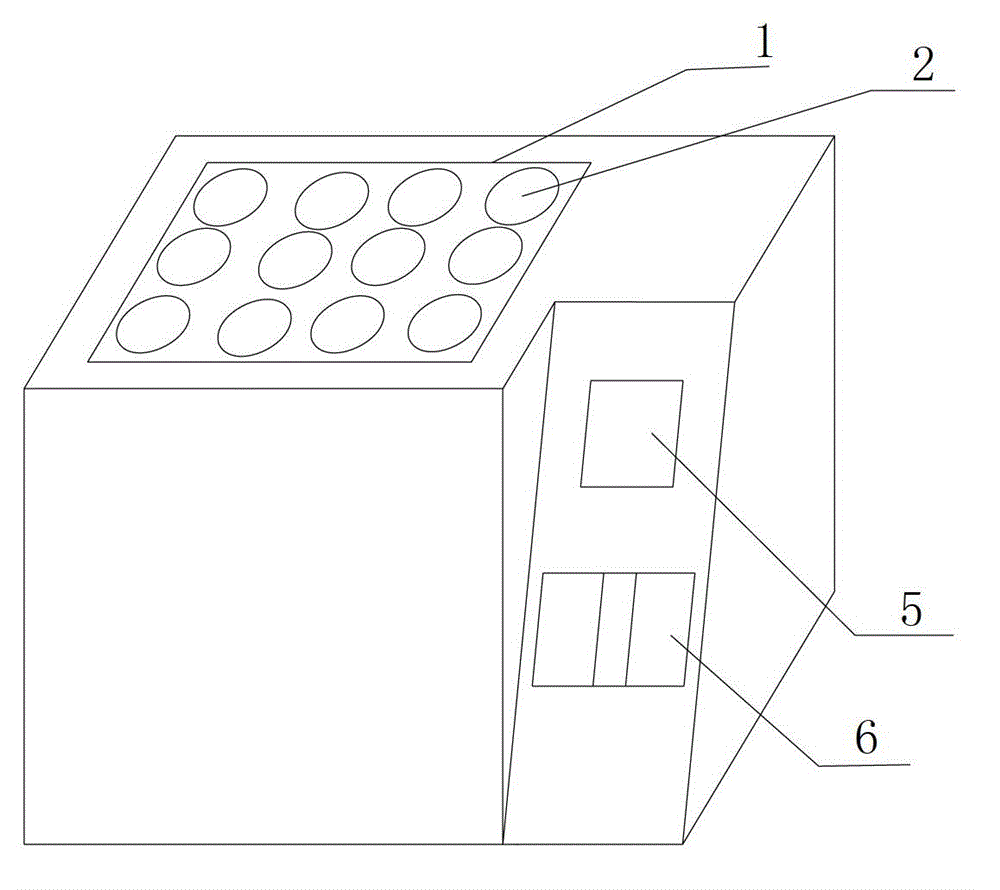

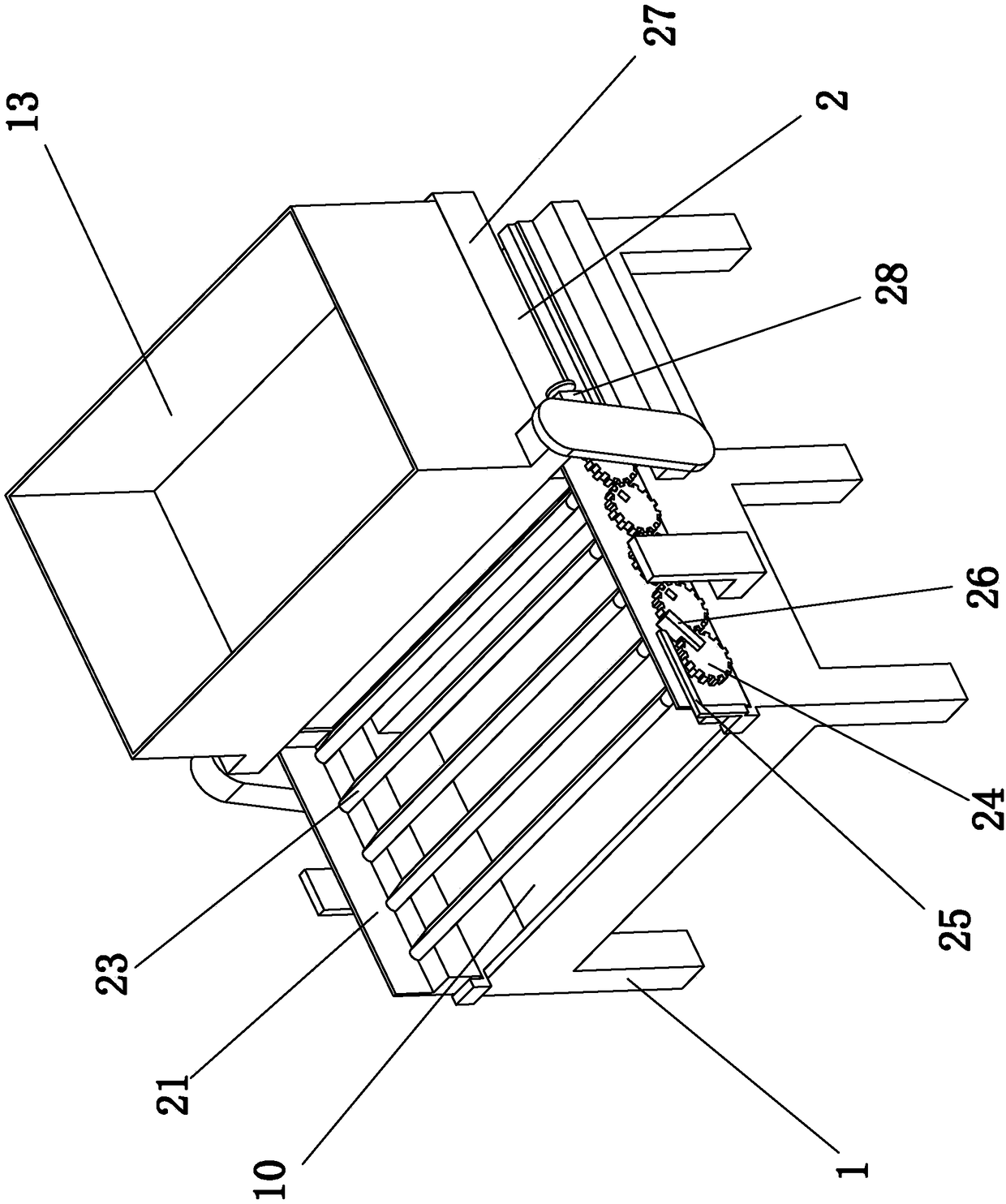

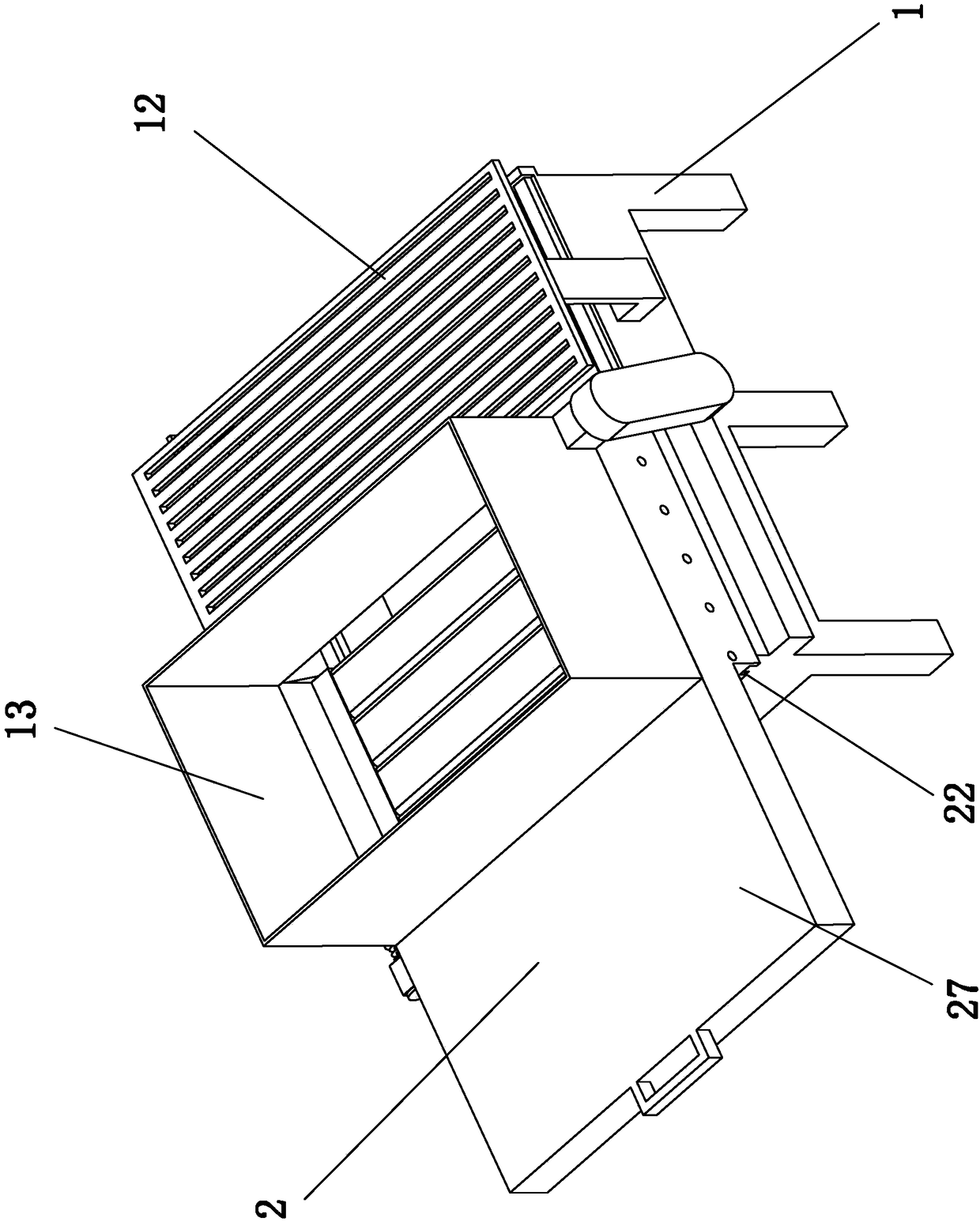

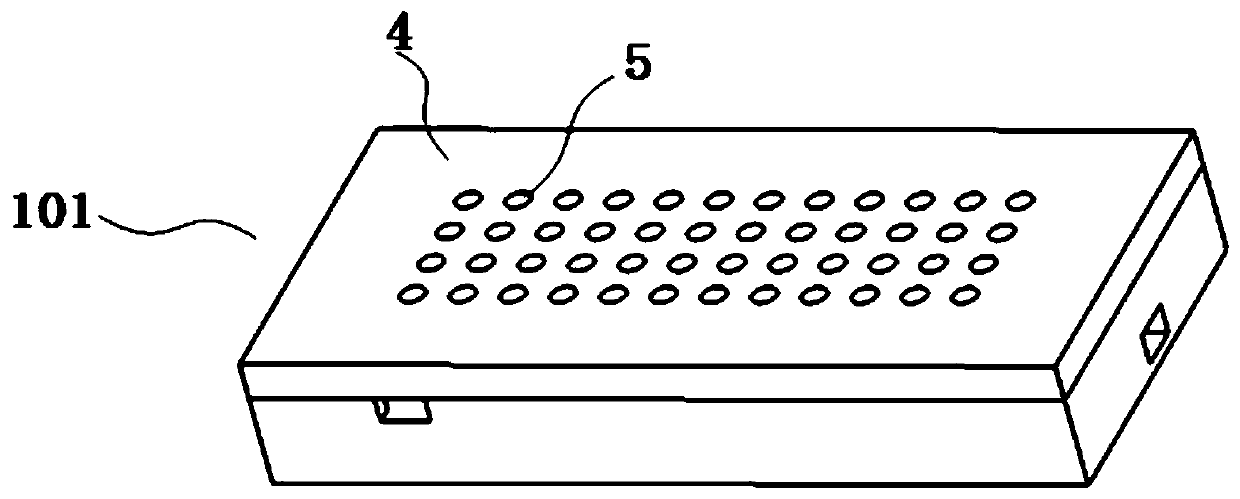

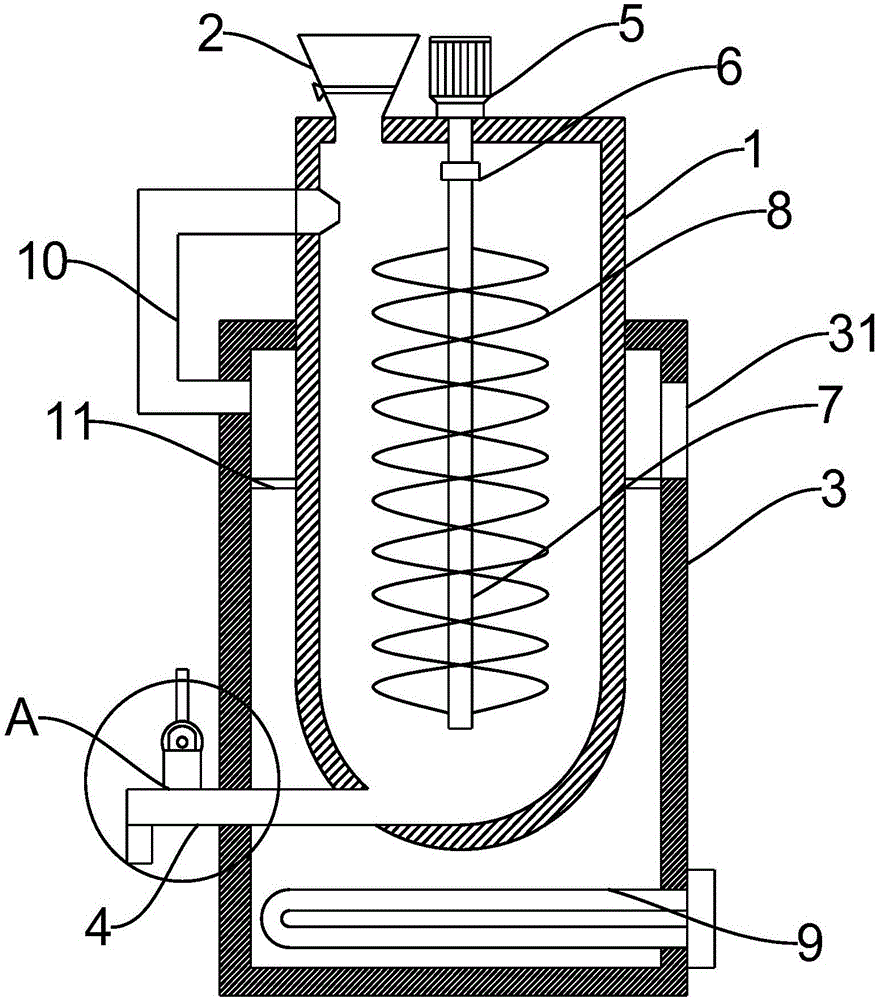

Chemical oxygen demand (COD) digestion instrument and working method thereof

InactiveCN102944463AUniform heating temperatureUniform heatingPreparing sample for investigationControl systemEngineering

The invention relates to the detection field, in particular to a chemical oxygen demand (COD) digestion instrument and a working method thereof. The COD digestion instrument comprises a control circuit board, a heating wire, a heating box, a heating disc and a control system used for controlling temperature of the heating disc. The heating wire is warped on the outer wall of the heating box and is connected with the control circuit board. The heating disc is arranged at the top of the hating box, and a plurality of heating holes are arranged on the heating disc. The control system is connected with the control circuit board and controls temperature of the heating disc by controlling opening and closing of the control circuit. The working method of the COD digestion instrument includes that when a sample is needed to be heated, the sample is placed in the heating box with the outer wall at the bottom and the outer portion of the lateral wall simultaneously heated to be heated. Compared with the prior art, the heating wire is wound on the outer wall of the heating box so that the whole heating box is located in the heated environment and temperatures at all positions of the heating box are even.

Owner:赵爱国

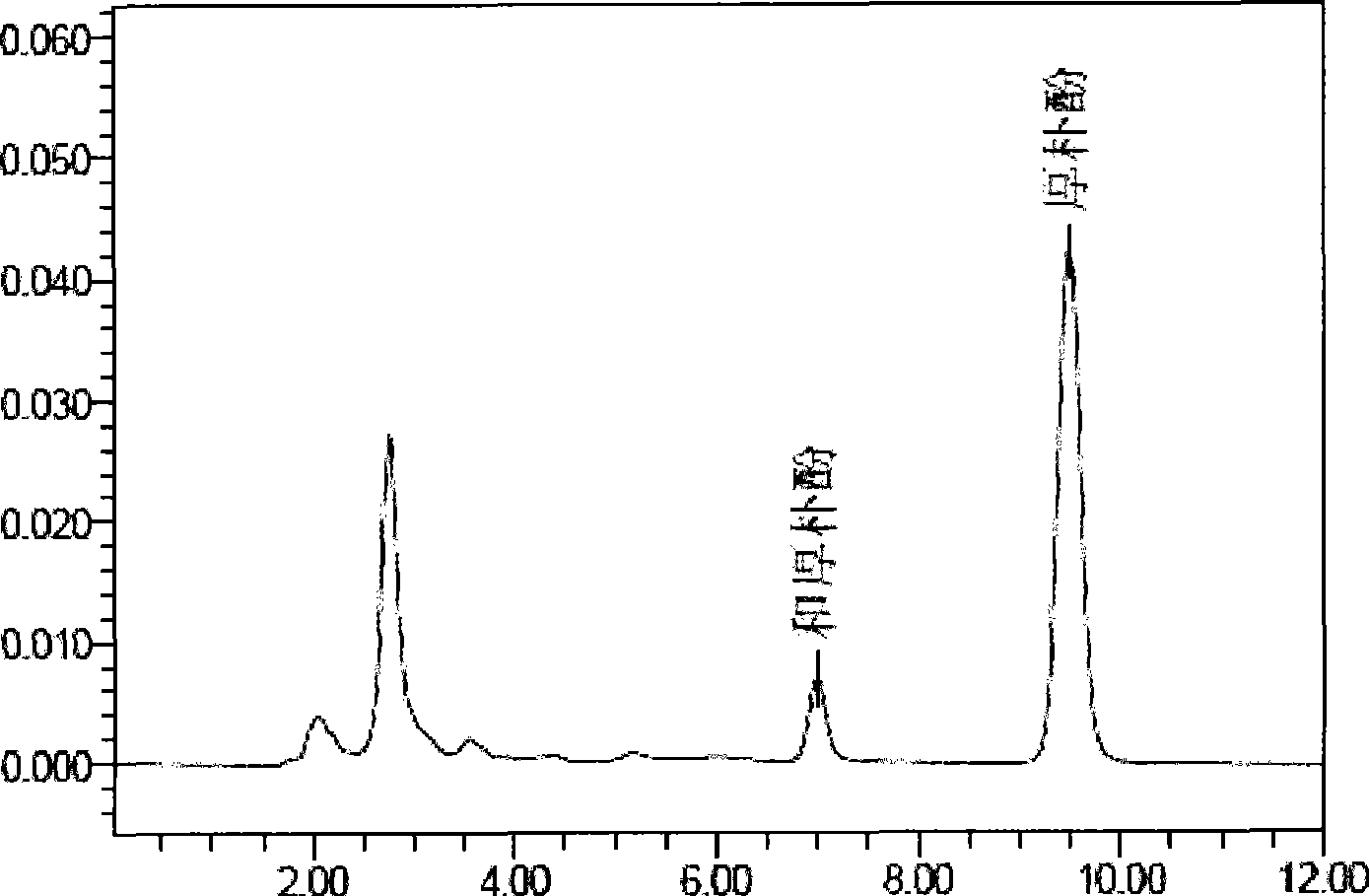

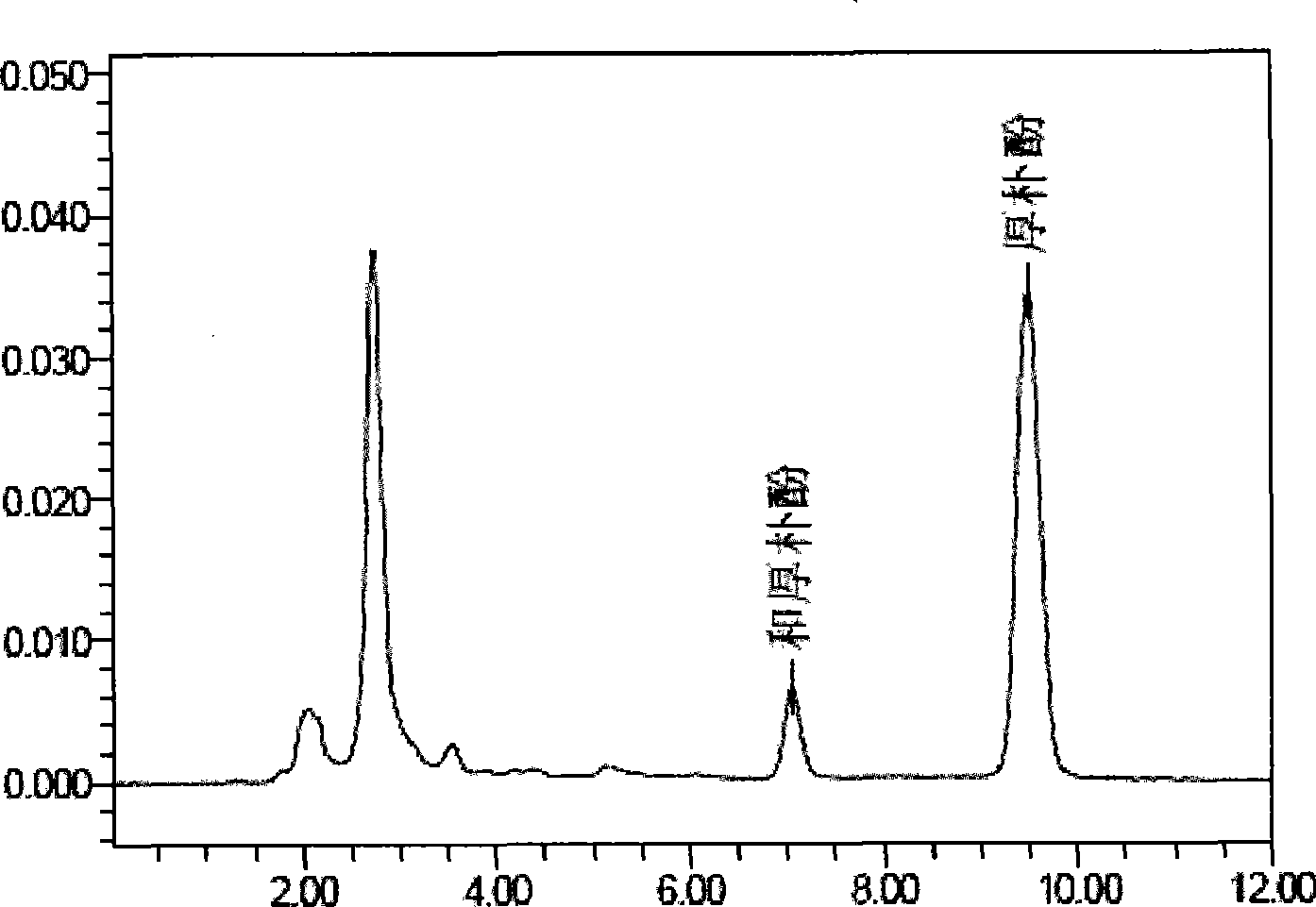

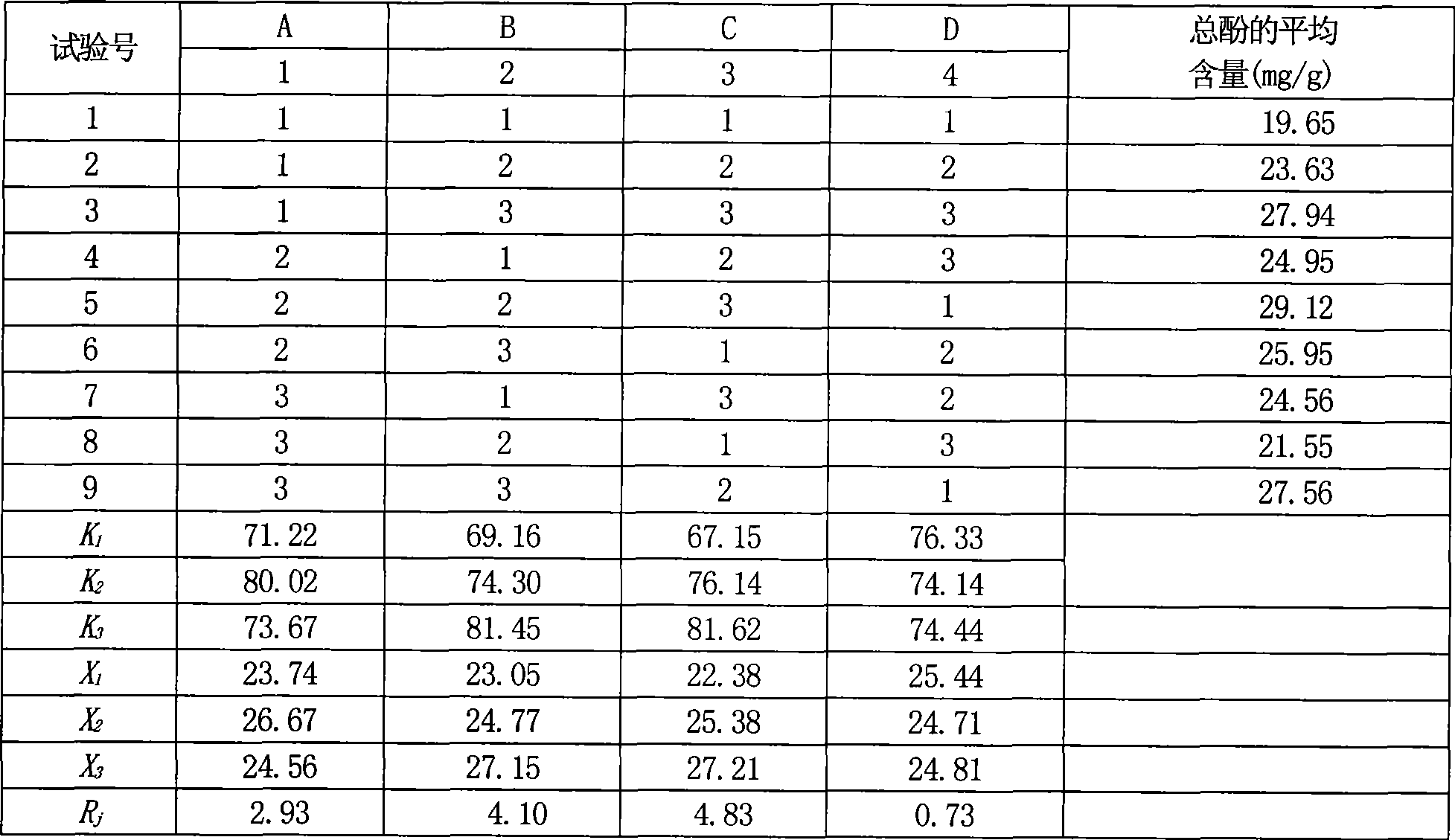

Method for processing Chinese medicine magnolia bark

The invention relates to a method for concocting a traditional Chinese medicine ginger Houpo, belonging to the technical field of methods for concocting traditional Chinese medicines. The method includes the following steps: Houpo medicinal materials are selected and cleaned, and raw barks are removed and cleaned; after being softened at a normal temperature, the Houpo medicinal materials are sliced into 1 cm threads, the threads are put into a baking oven with the temperature ranging from 50 to 60 DEG C to be dried for 1 to 1.5 hours, and prepared Houpo raw products are kept for standby; green rhizomes is extracted into juices, and the use amount of the green rhizomes is 10 to 15 percent of the amount of the Houpo raw products; after being diluted by water, the green rhizomes juices are led into the Houpo raw products to be stewed and impregnated for 60 to 90 minutes, and the quality of the green rhizomes juices is 40 to 60 percent of that of the Houpo raw products after dilution; and the green rhizomes juice Houpo is led into a microwave oven to be concocted for 15 to 30 minutes under the power of 400 to 700W, and after the green rhizomes juice Houpo is taken out to be cooled, the concocted product of the traditional Chinese medicine green rhizomes Houpo can be obtained. The method has the advantages of standard concocting steps, uniform technical parameter and easy control of concocting process; and compared with the traditional green rhizomes Houpo concocted product, the prepared green rhizomes Houpo concocted product has lower loss of content summation of effective components, and can effectively meet the requirement of green rhizomes Houpo decoction pieces for clinical use.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Barbecue oven capable of changing charcoal rapidly

The invention discloses a barbecue oven capable of changing charcoal rapidly. The barbecue oven comprises a supporting frame, a charcoal cavity is formed in the supporting frame, supporting rods are arranged on the two sides of the supporting frame respectively, and a barbecue grill is arranged on the supporting rods and located above the charcoal cavity. The barbecue oven is characterized in thata charcoal storage bin is arranged beside the charcoal cavity, and a charcoal adding mechanism capable of laying a layer of charcoal in the charcoal storage bin into the charcoal cavity is arranged on the supporting rods. By arranging the charcoal adding mechanism, the charcoal in the charcoal storage bin can be rapidly laid into the charcoal cavity, and the effect of changing charcoal rapidly isachieved; besides, the charcoal can be uniformly laid, so that uniform heating is achieved in the barbecuing process, and efficiency is improved; moreover, the barbecue oven is simple in structure and convenient to use.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

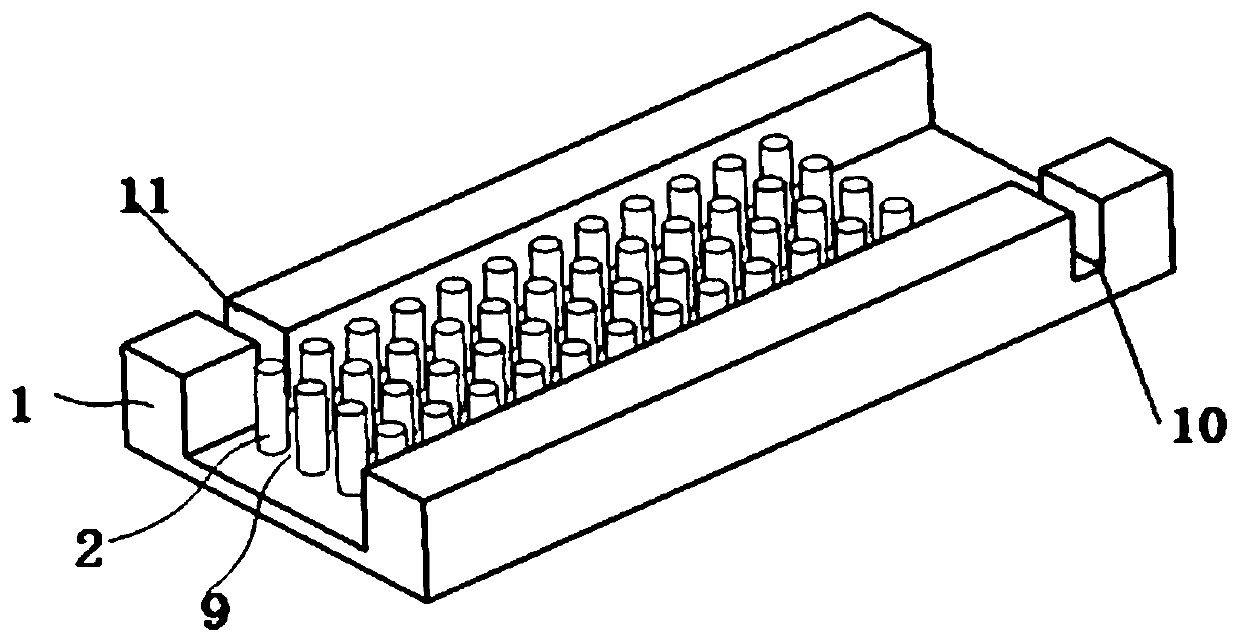

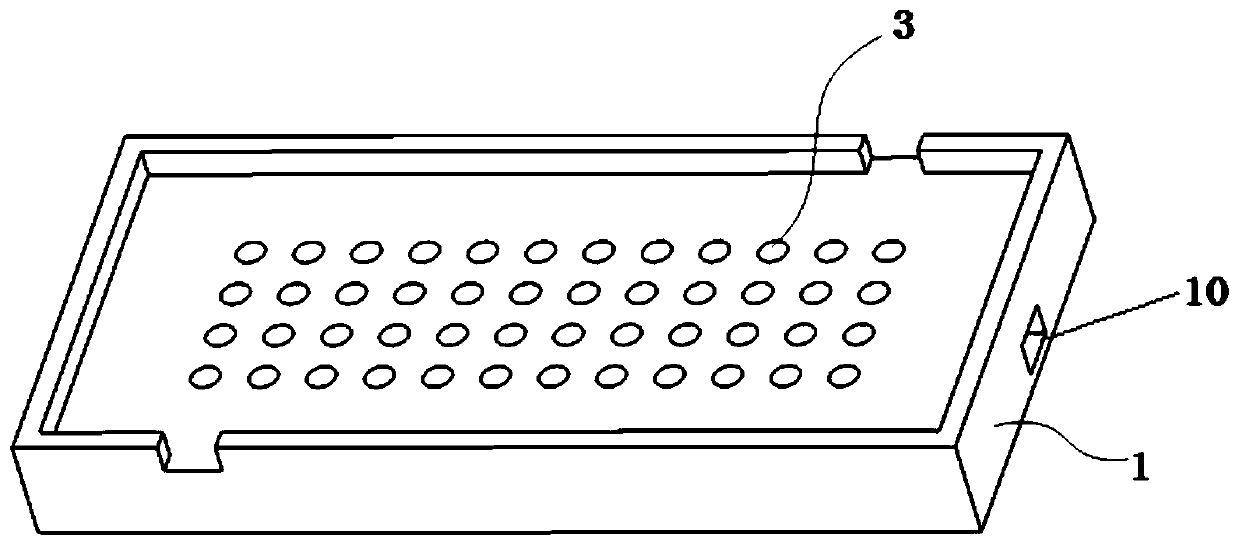

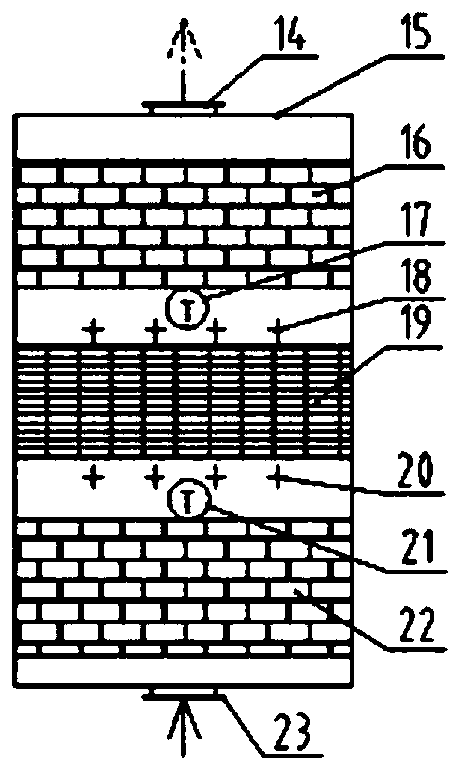

Micro-channel electronic cigarette atomization chip and preparation method thereof

The invention discloses a micro-channel electronic cigarette atomization chip and a preparation method thereof. The micro-channel electronic cigarette atomization chip comprises a silicon substrate (1) and a glass cover (4). A microcolumn (2) array or a micropore (3) array, an inlet end (10) and an outlet end (11) are arranged on the silicon substrate (1), a plurality of micro-channels (9) are defined by the microcolumn (2) array, or a smoke liquid channel penetrating through micropores (3) is arranged on the silicon substrate (1). Air holes (5) penetrating through the glass cover (4) are formed in the glass cover (4). The glass cover (4) and the silicon substrate (1) are fixedly connected through a bonding process. According to the micro-channel electronic cigarette atomization chip and the preparation method thereof, silicon is adopted as a base material of the atomization chip, the cost is low, the manufacturing cost of the electronic cigarette atomization chip is greatly reduced, and the atomization chip of this type can be produced on a large scale.

Owner:CHINA TOBACCO YUNNAN IND

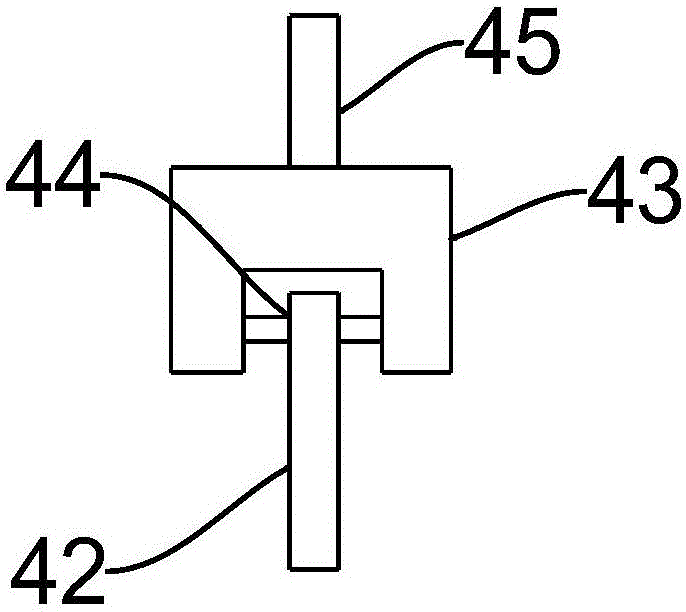

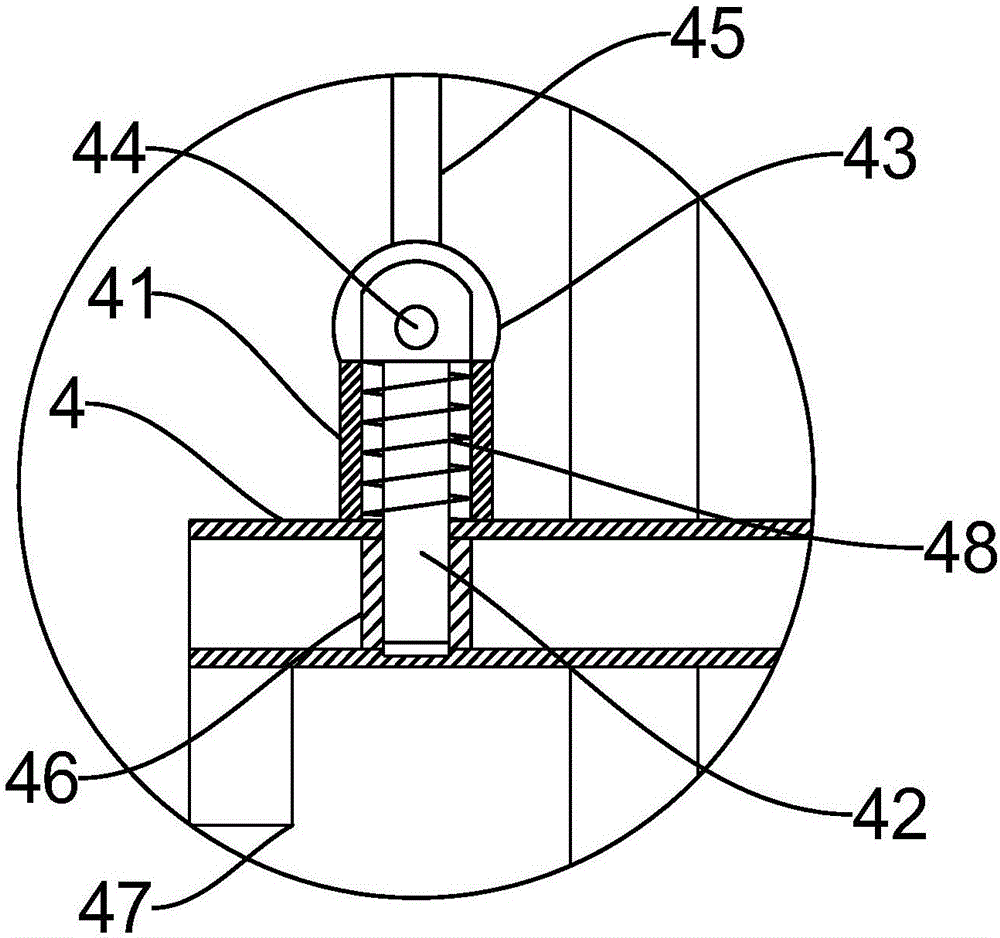

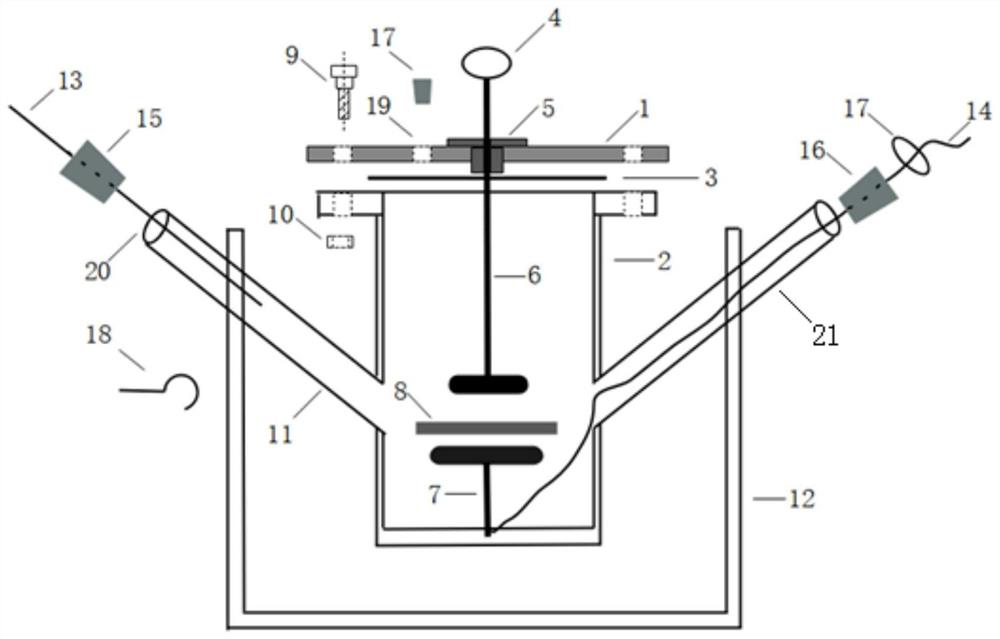

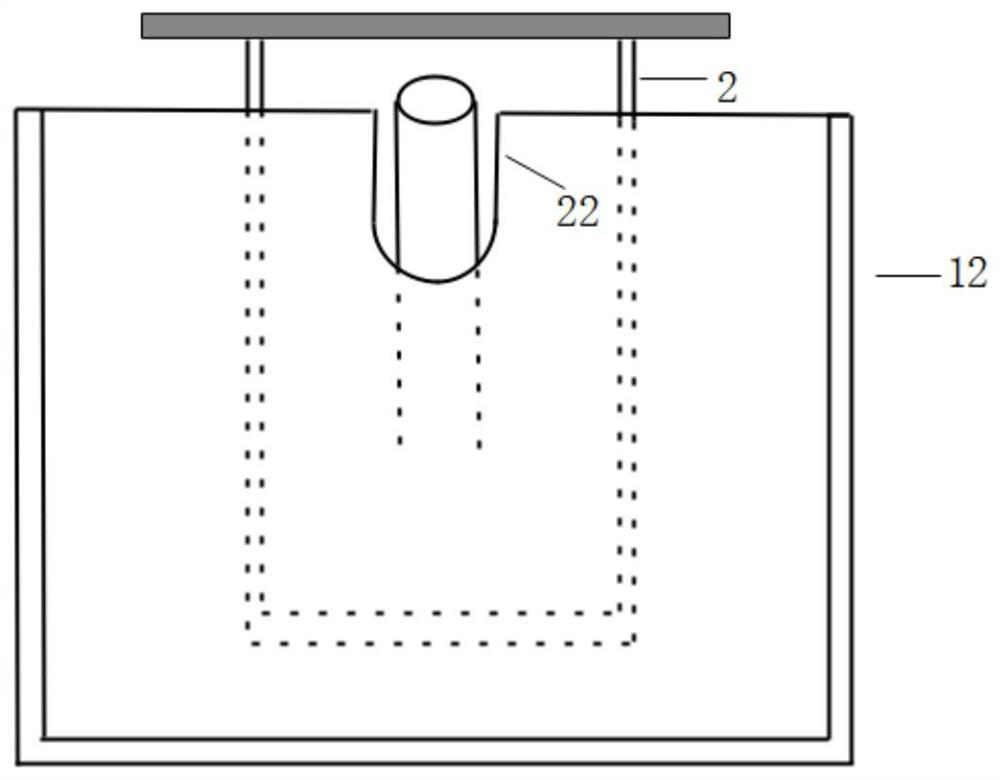

Heating and stirring vessel for pasty traditional Chinese medicine

InactiveCN106823917ANo burnt phenomenonAvoid excessive viscousRotary stirring mixersTransportation and packagingWater bathsCoupling

The invention discloses a heating and stirring vessel for pasty traditional Chinese medicine. The heating and stirring vessel comprises a kettle body, a water bath heating box, a discharge pipe, a stirring motor, a stirring shaft, a stirring blade and an air duct, wherein the kettle body is sequentially provided with a feed hopper, the water bath heating box, the discharge pipe, the stirring motor, a coupling, the stirring shaft and the stirring blade; the water bath heating box is sequentially provided with a water inlet, a heating pipe, the air duct and a reinforcing partition plate; and the discharge pipe is sequentially provided with a support pipe, a valve rod, a rotating block, a rotating shaft, a handle, a sealing block, a discharge hole and a connection spring. The water bath heating box is adopted for heating, so heating is more uniform and local overheating of a material is avoided; water vapor is introduced into the kettle body through the air duct, and the pasty medicine can be better stirred through coordination of the double helical stirring blades, so that the uniformity is higher and long-term stirring and storing can be achieved; and by adopting a flipping discharge mode, the heating and stirring vessel is simpler and more convenient and favorable for use.

Owner:苏州兰灵医药科技有限公司

Transformer oil paper insulation long-time electric heating combined aging experiment device and method

ActiveCN111880054AAvoid corrosionAvoid thermal expansion and contractionTesting dielectric strengthHeating oilLow voltage

The invention discloses a transformer oil paper insulation long-time electric heating combined aging experiment device and method. An electrode plate of a high-voltage electrode is located in a sealing tank, an electrode stem of the high-voltage electrode extends out of an upper cover plate of the sealing tank, the electrode stem of the high-voltage electrode can move relative to the upper cover plate, and a low-voltage electrode is arranged at the bottom of the sealing tank. An insulation sample is arranged between the high-voltage electrode plate and the low-voltage electrode plate, the sidewall of the sealing tank is provided with a temperature measuring conduit and a ground wire wiring conduit which are communicated with the sealing tank, the temperature measuring conduit is blocked by a first rubber plug, the ground wire wiring conduit is blocked by a second rubber plug, and the temperature sensor shell is embedded into the first rubber plug. An inductive probe of the temperaturesensor is arranged at the bottom of the sealing tank, the grounding wire is embedded into and penetrates through the second rubber plug to be connected with the low-voltage electrode, the oil bath groove heats the sealing tank through heating oil in the oil bath groove, and the high-frequency current sensor is installed on the grounding wire. Accurate data reference can be provided for operationand maintenance decisions of the transformer.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +4

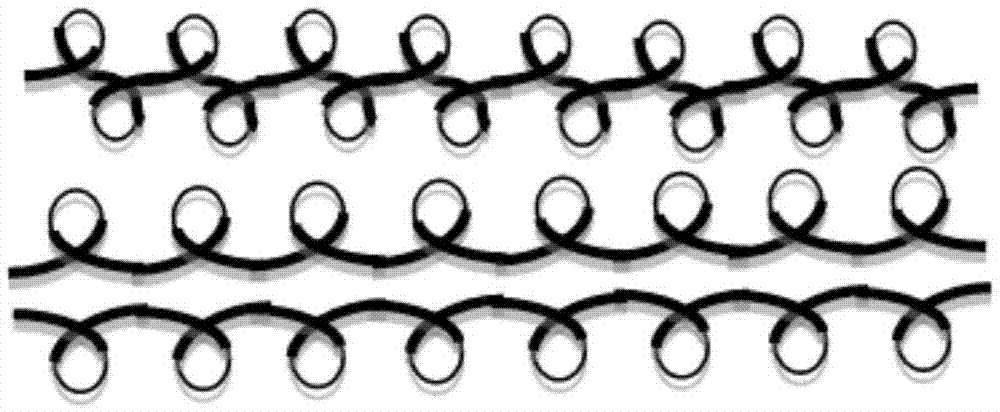

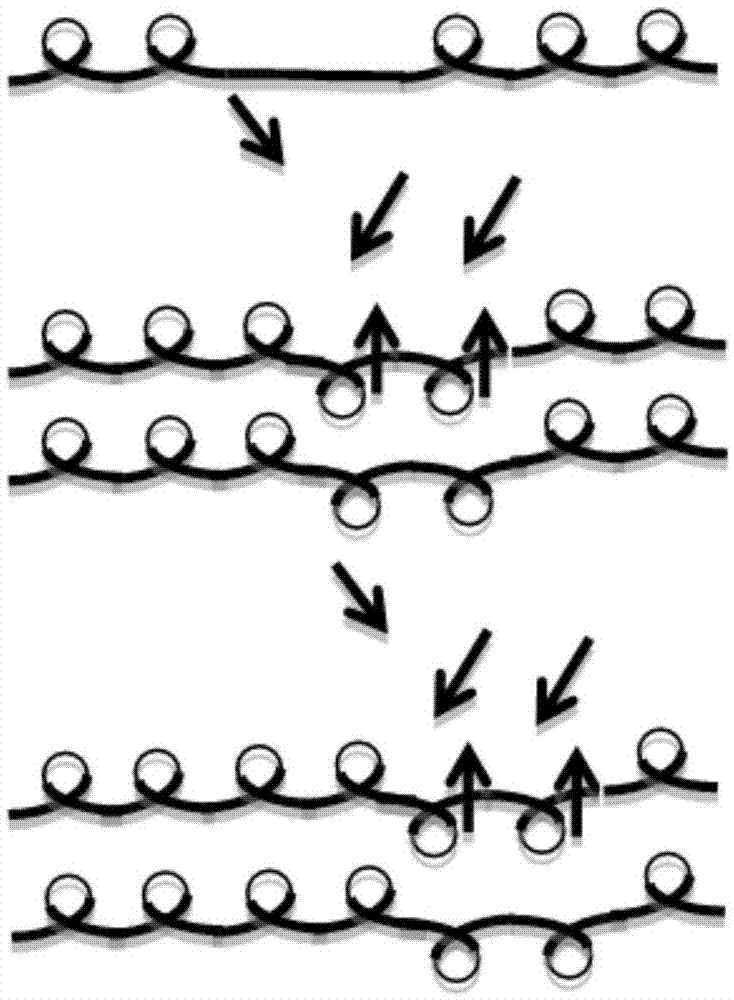

Electric heating element and heating method thereof

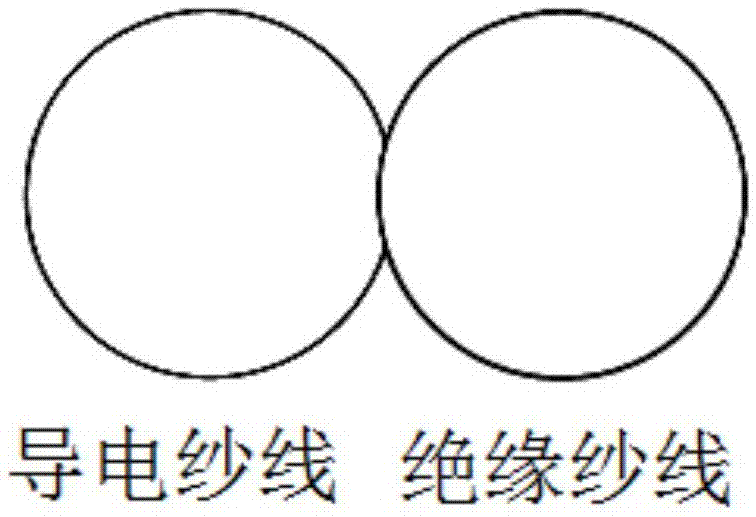

InactiveCN106982479AUniform heatingEvenly heatedWeft knittingOhmic-resistance heating detailsConductive yarnElectric heating

The invention provides an electric heating element and a heating method thereof. The electric heating element includes an electric heating fabric which includes an electric heating yarn unit. The electric heating yarn unit includes a conductive yarn and a resistor yarn. The conductive yarn and the resistor yarn are connected in parallel. The electric heating element also includes a pair of electrodes which respectively penetrate the front side and back side of the electric heating fabric and provide voltage between the front side and the back side of the electric heating fabric. According to the invention, the electric heating element has an electric heating fabric which is composed of the conductive yarn and the resistor yarn which are woven together, and provides a voltage between the front side and back side of the electric heating fabric. According to the invention, the electric heating element heats evenly, and can be applied to the fields of orthotics and the like.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

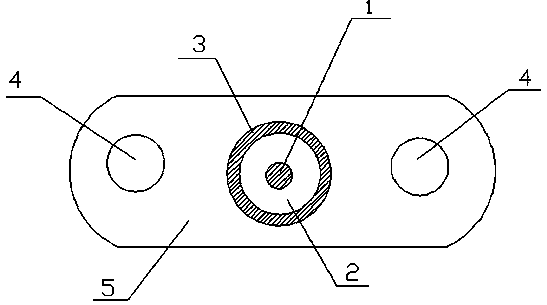

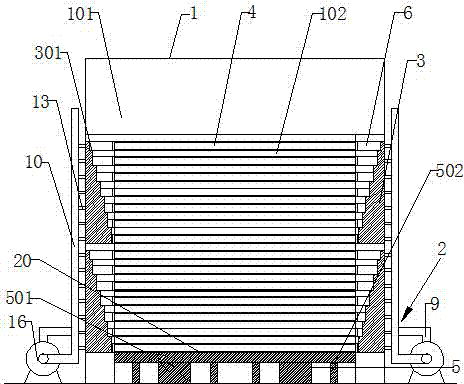

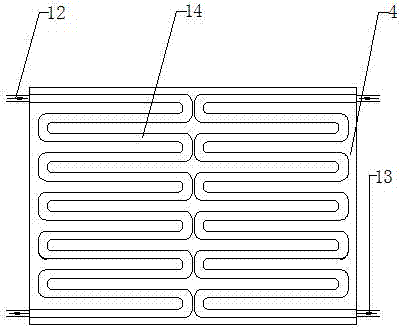

Heating chip

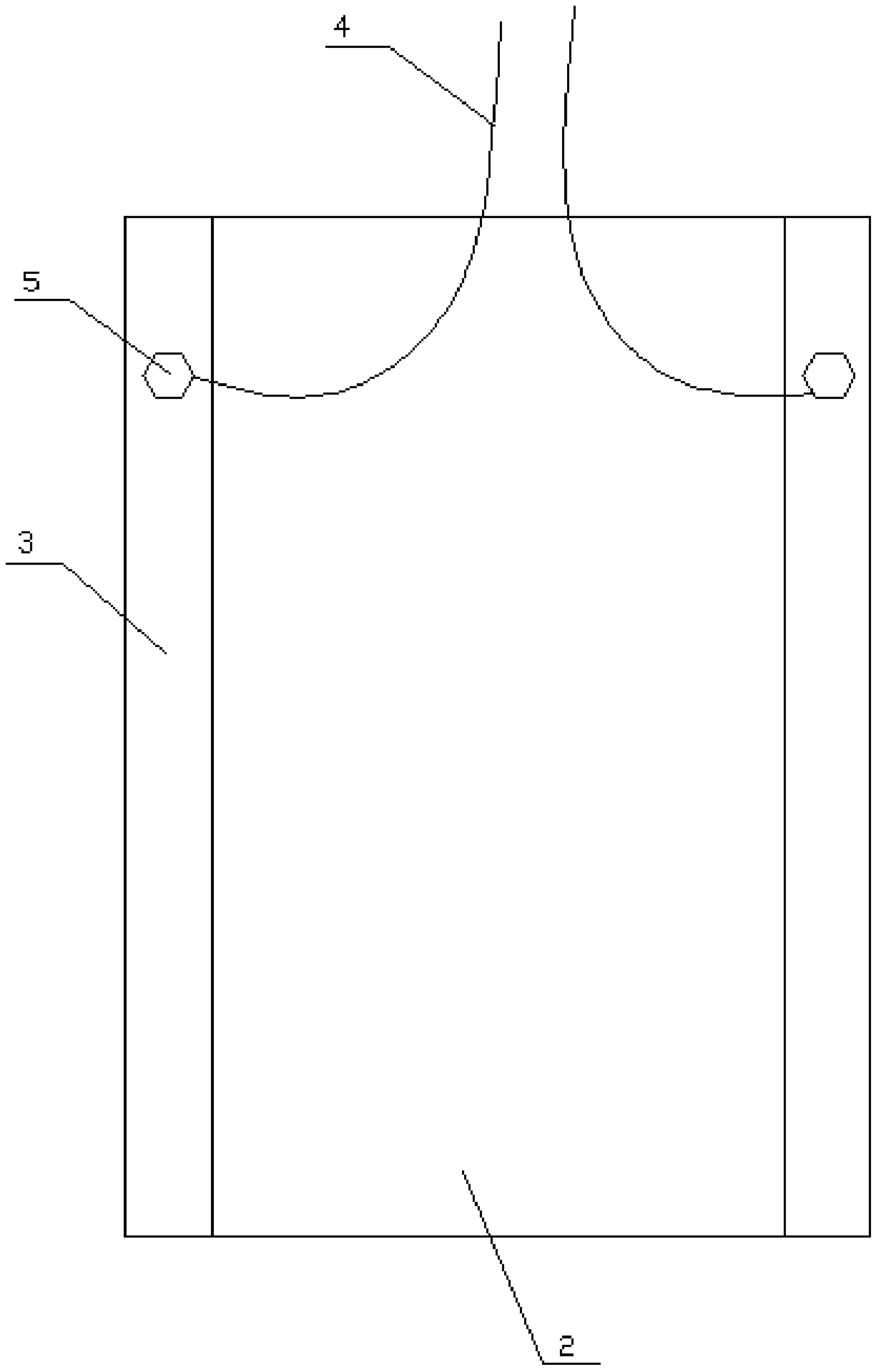

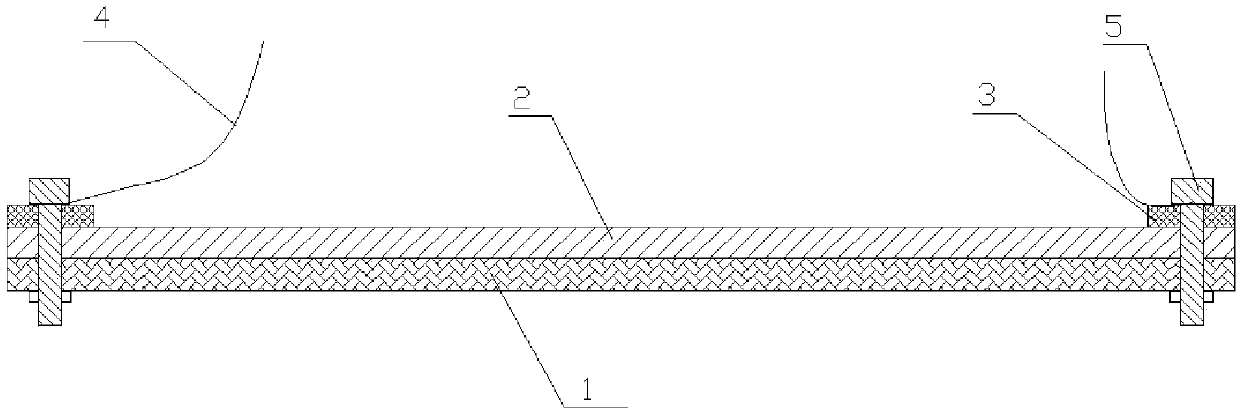

InactiveCN109526075AUniform heatingGood heating effectHeating element materialsEngineeringHeat generation

The present invention relates to a heating chip comprising a substrate layer (1), wherein the substrate layer (1) is provided with a heating layer (2); both sides of the heating layer (2) are providedwith two electrode strips (3) along the length direction of the heating layer; lead-out wires (4) are connected to the electrode strips (3); the lead-out wires (4) are connected to the electrode strips (3) via lead-out bolts (5). The heating chip has uniform heat generation and a good heating effect.

Owner:江苏科强新材料股份有限公司

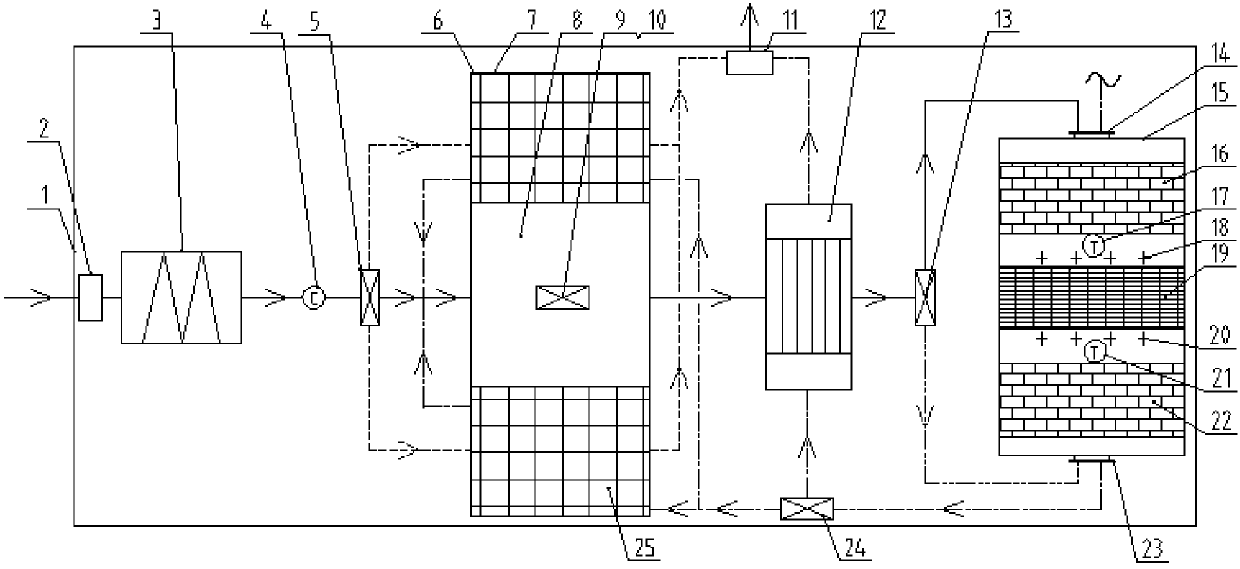

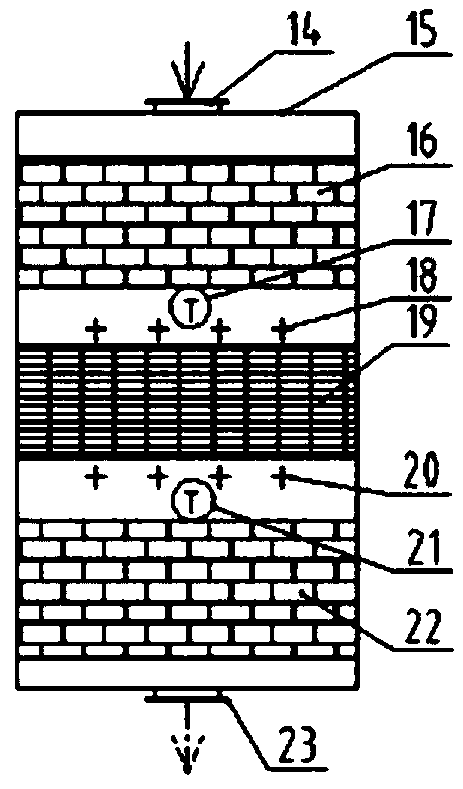

High-efficiency integrated heat storage catalytic oxidation system for concentration fluctuation waste gas

ActiveCN109595574ASafe heating methodHeating evenlyDispersed particle filtrationIncinerator apparatusCatalytic oxidationProcess engineering

The invention discloses a high-efficiency integrated heat storage catalytic oxidation system for concentration fluctuation waste gas. The high-efficiency integrated heat storage catalytic oxidation system comprises a filter section, a concentration detector, a concentration adjusting section, a heat exchanger and a heat storage catalytic oxidation section which are integrated together through an equipment housing, wherein an equipment air inlet and an equipment air outlet are formed in the equipment housing; the equipment air inlet communicates with the filter section; the filter section, theconcentration detector, the concentration adjusting section, the heat exchanger and the heat storage catalytic oxidation section are integrally connected in series; and the equipment air outlet and anair outlet of the concentration adjusting section communicate with an air outlet of the heat exchanger. The heat storage catalytic oxidation system adopting the structure disclosed by the invention adopts integrated structural design, so that the structure is compact, and the occupied area is low; the high-efficiency integrated heat storage catalytic oxidation system has the advantages of being low in potential safety hazards, low in energy consumption, low in cost and sufficient in residual heat utilization; and the purposes of being long-term high-efficiency stable and low-energy consumption operation are achieved.

Owner:长沙工研院环保有限公司

Modified shoe drying cabinet

InactiveCN103251226AGuaranteed comfortUniform heatingWardrobesFootwear cleanersRotating discSupport plane

The invention discloses a modified shoe drying cabinet which comprises a shoe cabinet body, and a power wire is connected to the shoe cabinet body. The modified shoe drying cabinet is characterized in that drying devices are symmetrically arranged on the upper surface and the lower surface of the shoe cabinet body, a supporting frame is arranged between the drying devices on the upper surface and the lower surface of the shoe cabinet body, two ends of supporting frame are fixed through rotating discs, a fixed support is arranged on the supporting frame, a fixed head is arranged on the head of the fixed support, and deodorants are arranged in the fixed head. The modified shoe drying cabinet has the advantages that the drying devices in the shoe cabinet body can dry shoes timely, maintain the inside of each shoe to be dry and comfortable, and guarantee comfort of feet; the supporting frame for placing the shoes is designed to be rotatable, and the shoes can be dried evenly; the drying devices are placed annularly so that heat can be even; illumination devices are arranged at two ends of the supporting frame, and light in the shoe cabinet body is improved.

Owner:蒋海丹

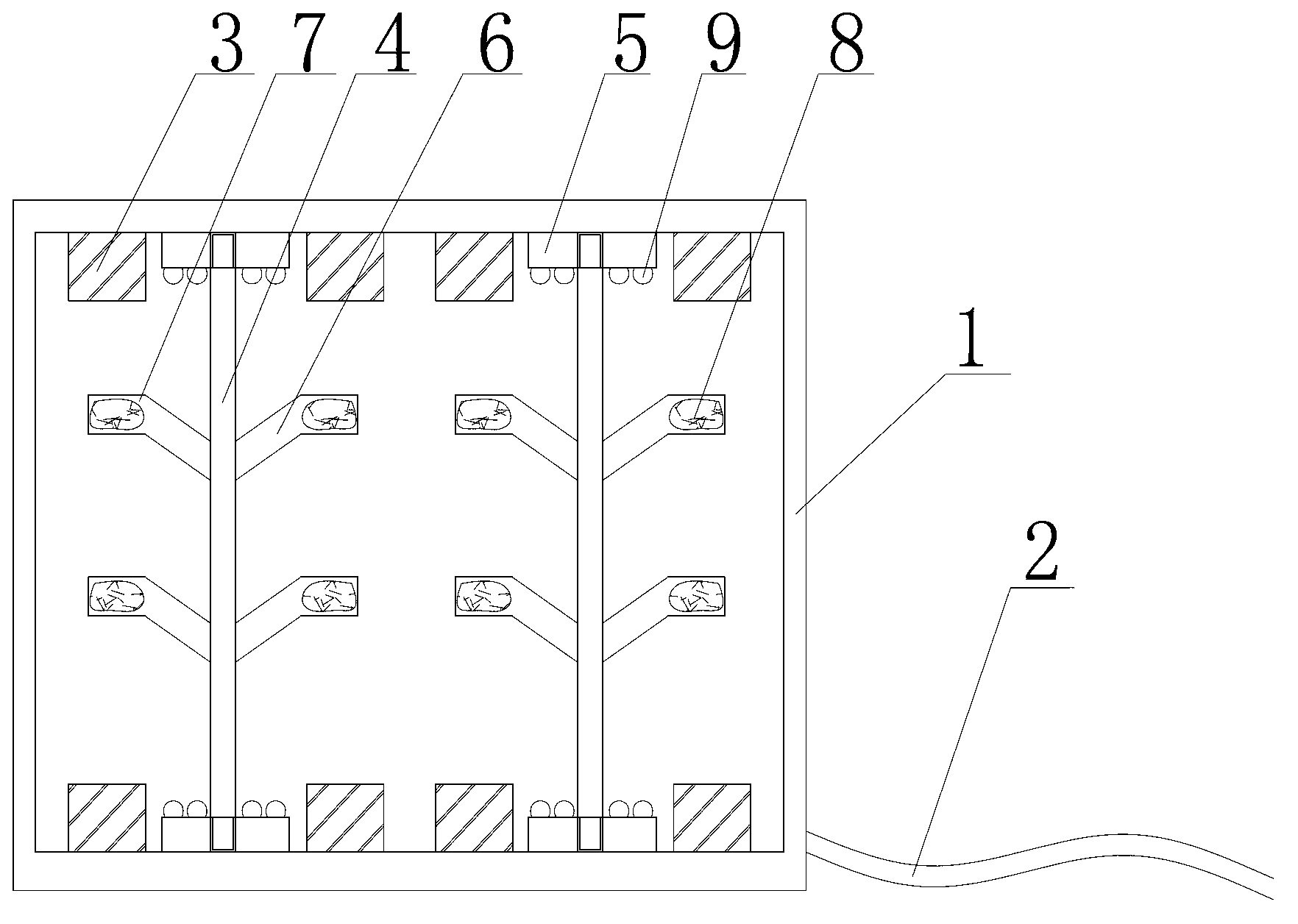

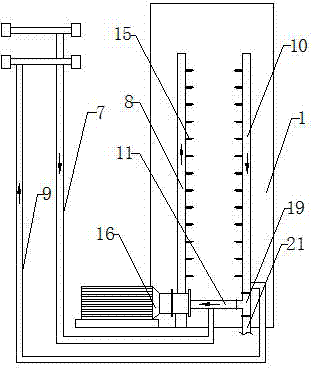

Board hot pressing device

InactiveCN104723419AUniform heatingQuick in and outPlywood pressesVeneer pressesSteel platesHydraulic ram

The invention discloses a board hot pressing device. The board hot pressing device comprises a hot press body. The hot press body is composed of a press frame and a hot pressing cavity. The front side faces of two support legs of the press frame are each provided with at least one gradient positioning groove, the bottom of the hot pressing cavity is fixedly provided with a hydraulic oil cylinder drive system, a bottom pressing board is fixed to the upper end of the hydraulic oil cylinder drive system, at least one set of hot pressing steel boards are arranged on the bottom pressing board, the bottom of each hot pressing steel board is provided with bent flat iron stretching to the front side end of the hot pressing steel board, steel angles with the lengths sequentially reduced are fixedly welded to the two side ends of each set of hot pressing steel boards, and each steel angle corresponds to a press lug of the corresponding gradient positioning groove. The two side ends of the hot press body are each provided with a two-time circulation conduction oil system, and two sets of heat conduction coil pipes are arranged in each hot pressing steel board. One-time circulation conduction oil systems are improved into the two-time circulation conduction oil systems through the hot pressing device, the temperature of the hot pressing steel boards can be quickly increased, the hot pressing steel boards are evenly heated, cold oil in the hot pressing steel boards can be quickly pressed outside, and the boards are hot-pressed at high efficiency and high quality.

Owner:JIANGSU KENTIER WOOD

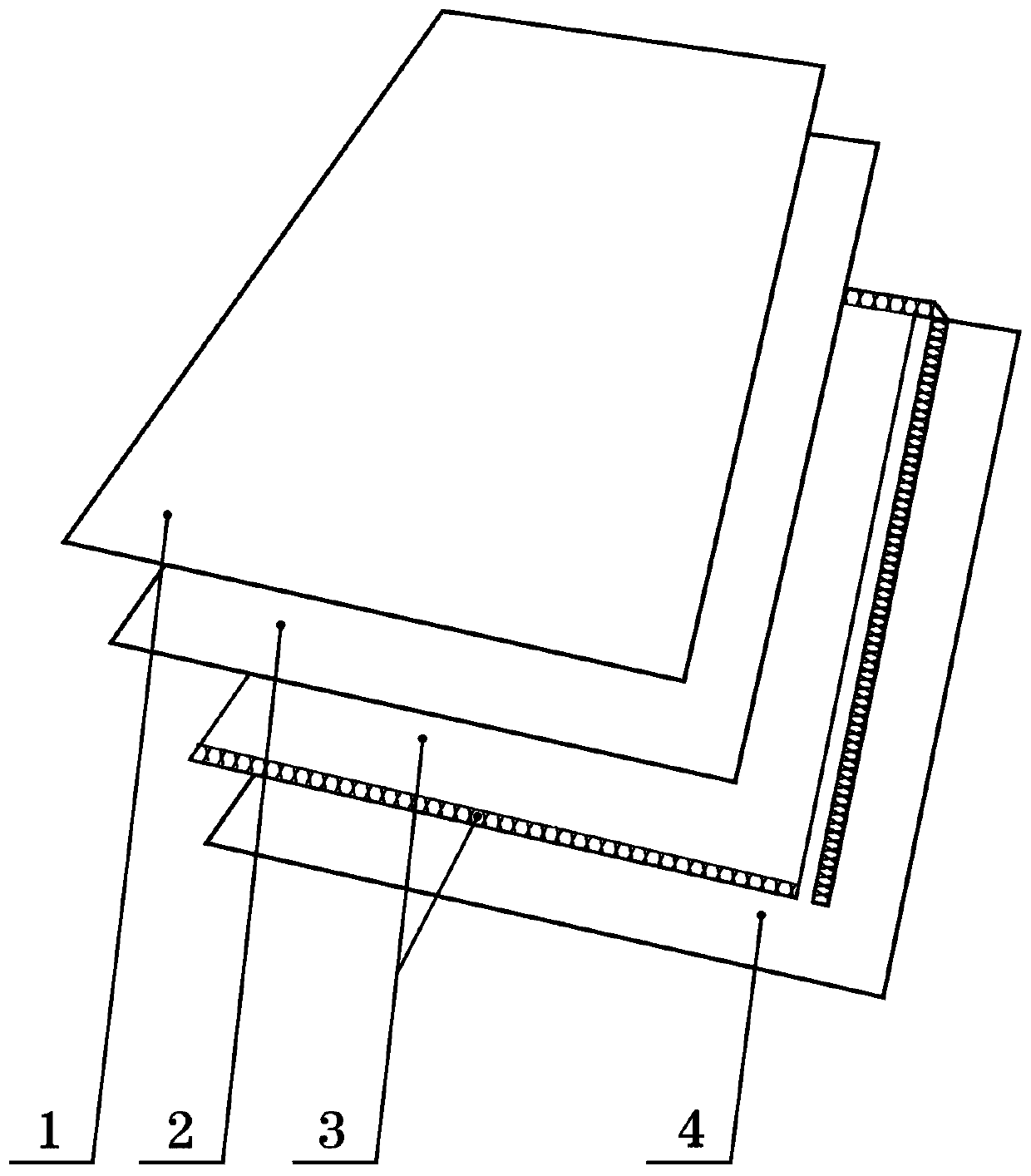

Waterborne CNTs-graphene composite wire dye paste, heating wire and heating cloth

InactiveCN110054949AUniform conductivityUniform heatingHeating element shapesHeating element materialsCarbon nanotubeWetting

The invention relates to waterborne CNTs (carbon nanotubes)-graphene composite wire dye paste, a waterborne CNTs-graphene composite heating wire and waterborne CNTs-graphene composite heating cloth. The waterborne CNTs-graphene composite wire dye paste is prepared from, by mass, 0.01-35 parts of waterborne graphene solution, 50-70 parts of waterborne carbon nanotube solution, 0.01-1 part of an antifoaming agent, 0.01-1.5 parts of a wetting agent, 5-30 parts of resin and 0.01-5 parts of a thickening agent. The waterborne CNTs-graphene composite heating wire is coated with the waterborne CNTs-graphene composite wire dye paste. The waterborne CNTs-graphene composite heating cloth comprises the waterborne CNTs-graphene composite heating wire. The waterborne CNTs-graphene composite wire dye paste is small in particle size range and uniform in conductivity, the average particle size is about 1micron, a resistance range of a graphene wire formed by coating of a wire with the wire dye paste is200 ohm / cm-300 ohm / cm, the waterborne CNTs-graphene composite heating cloth formed by the CNTs-graphene composite heating wire is uniform in heating, and the temperature difference of per square meter of the heating cloth is smaller than 5 DEG C.

Owner:北京爱上地科技集团有限公司

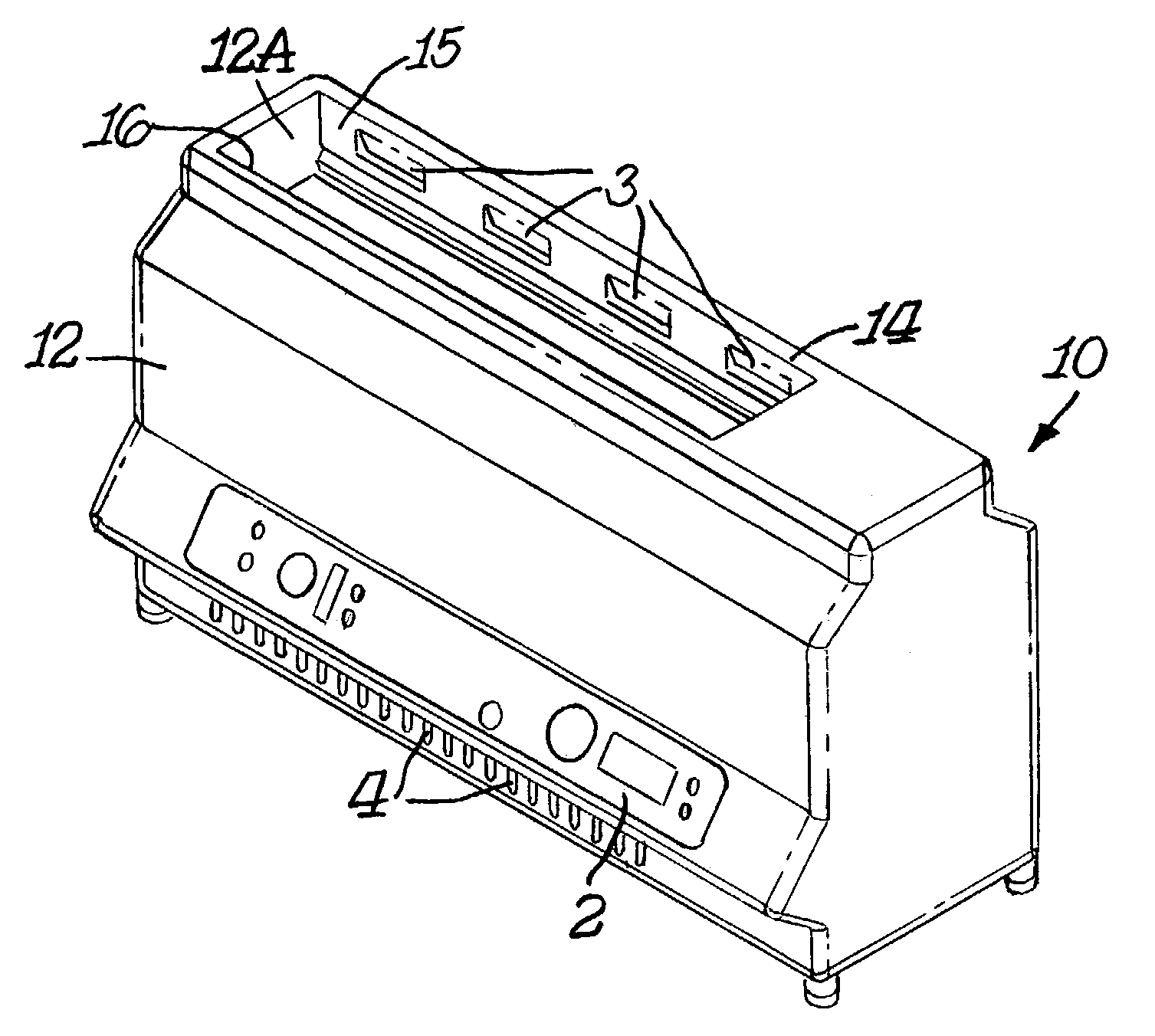

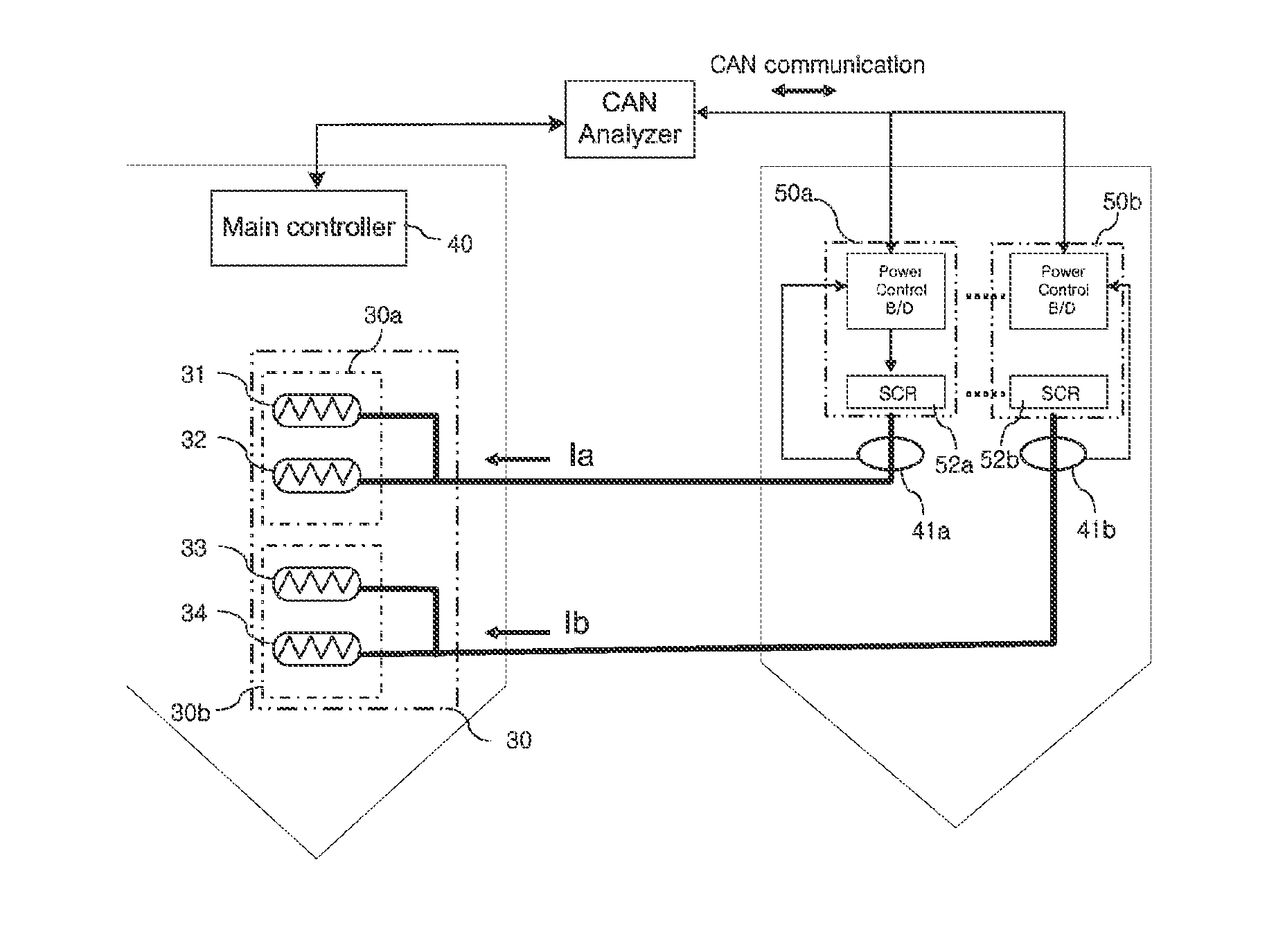

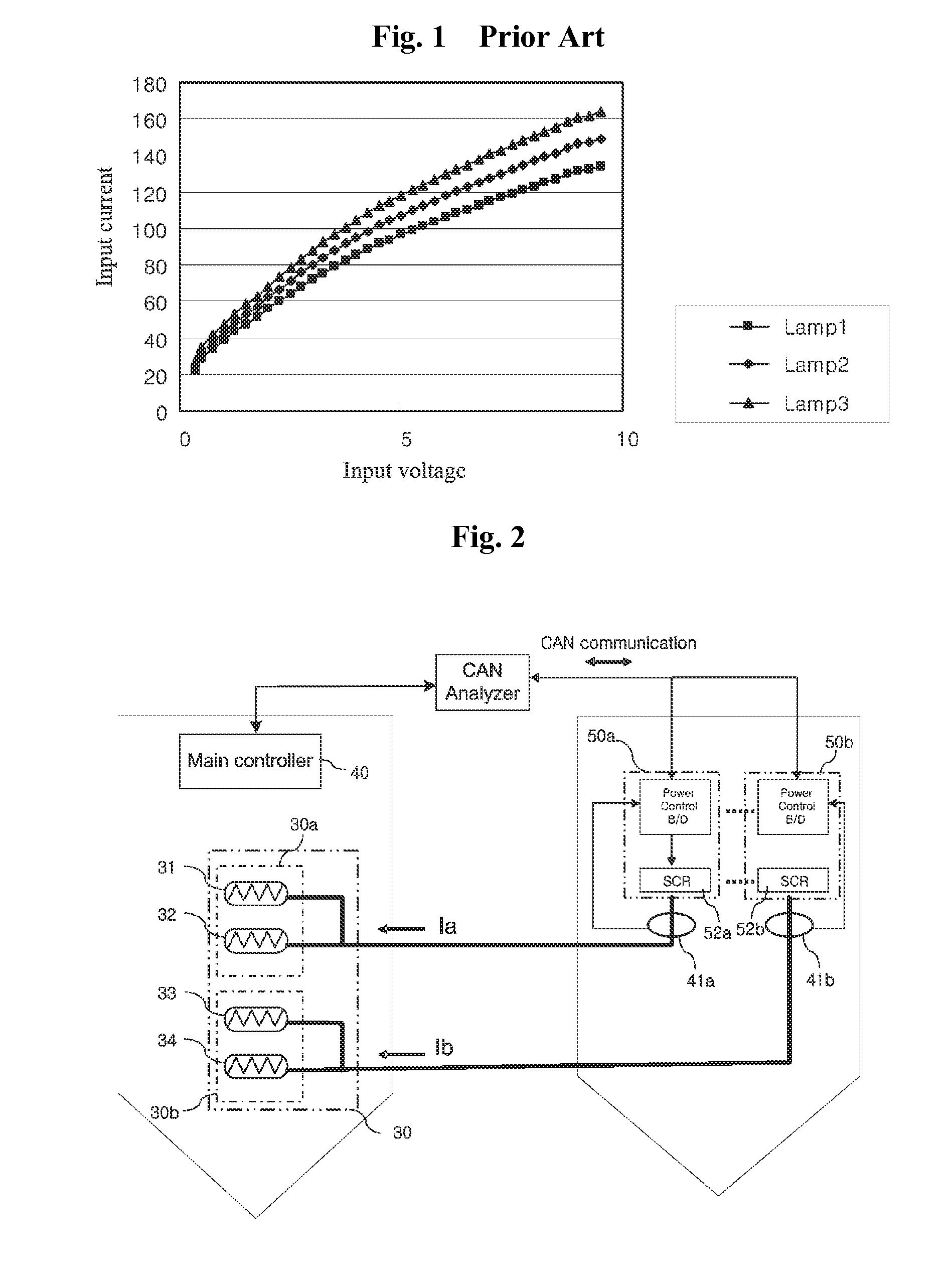

Apparatus and method for controlling heating lamp of rapid heat treatment equipment

InactiveUS20110255848A1Uniform heatingHeating evenlyDrying solid materials with heatElectric heating for furnacesVoltageGraphics

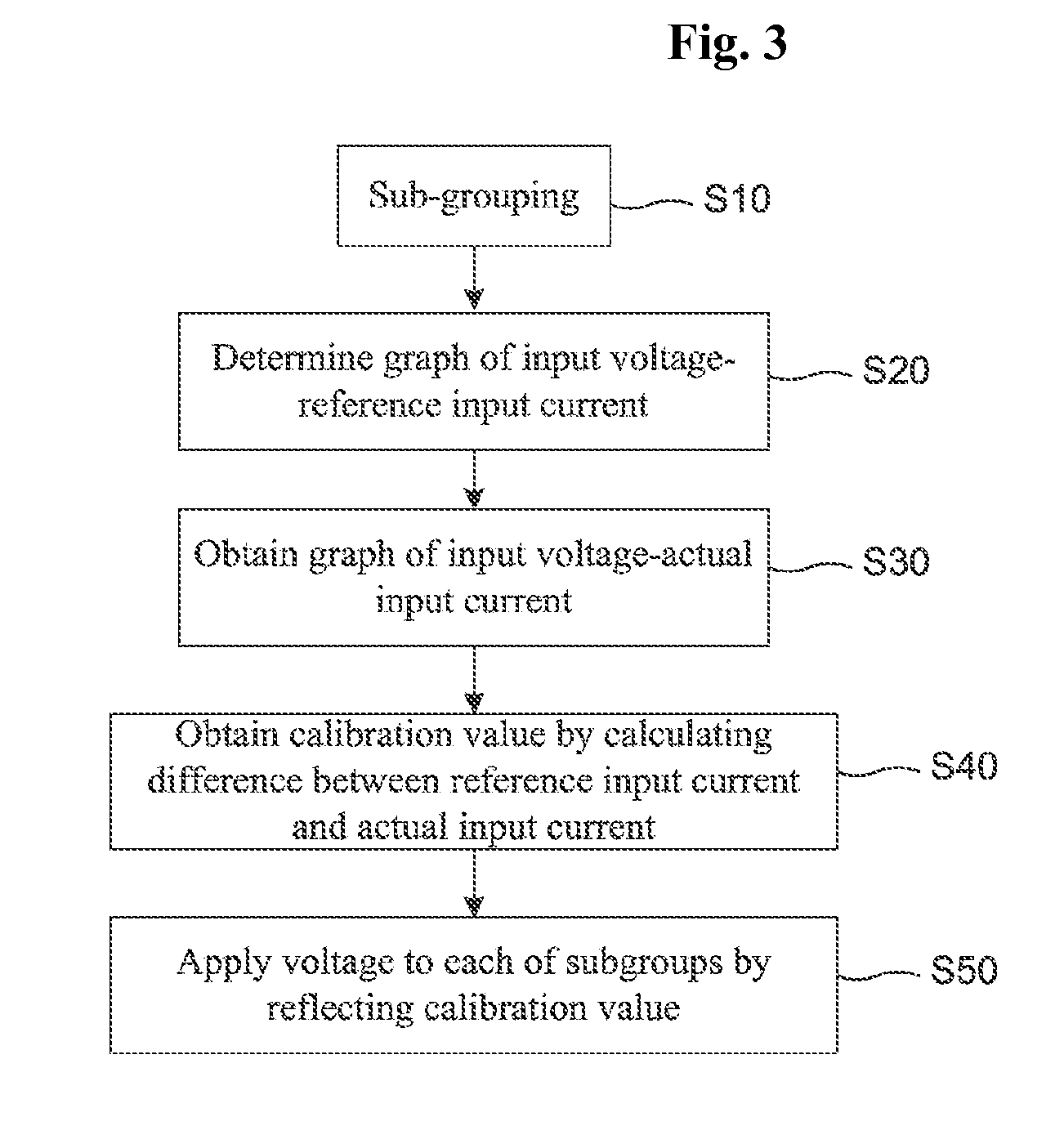

The method of the present invention for controlling a heating lamp of rapid heat treatment equipment comprises: a step wherein a heating lamp group is divided into a plurality of subgroups to determine graphical data regarding input voltage versus the reference input current that is applied to the subgroups uniformly; a step wherein actual input current respectively applied to each group is measured to obtain graphical data regarding input voltage versus actual input current; a step wherein a difference value for calibration of each subgroup is obtained from the difference between the reference input current and the actual input current; and a step wherein the difference value for calibration is reflected to apply a voltage to said subgroup individually. According to the present invention, substrate heating takes place uniformly because differences of calibration are reflected in actual input current to apply a voltage to a subgroup.

Owner:ASIA PACIFIC SYST

Fusing apparatus and image forming apparatus provided with the same, and heating apparatus

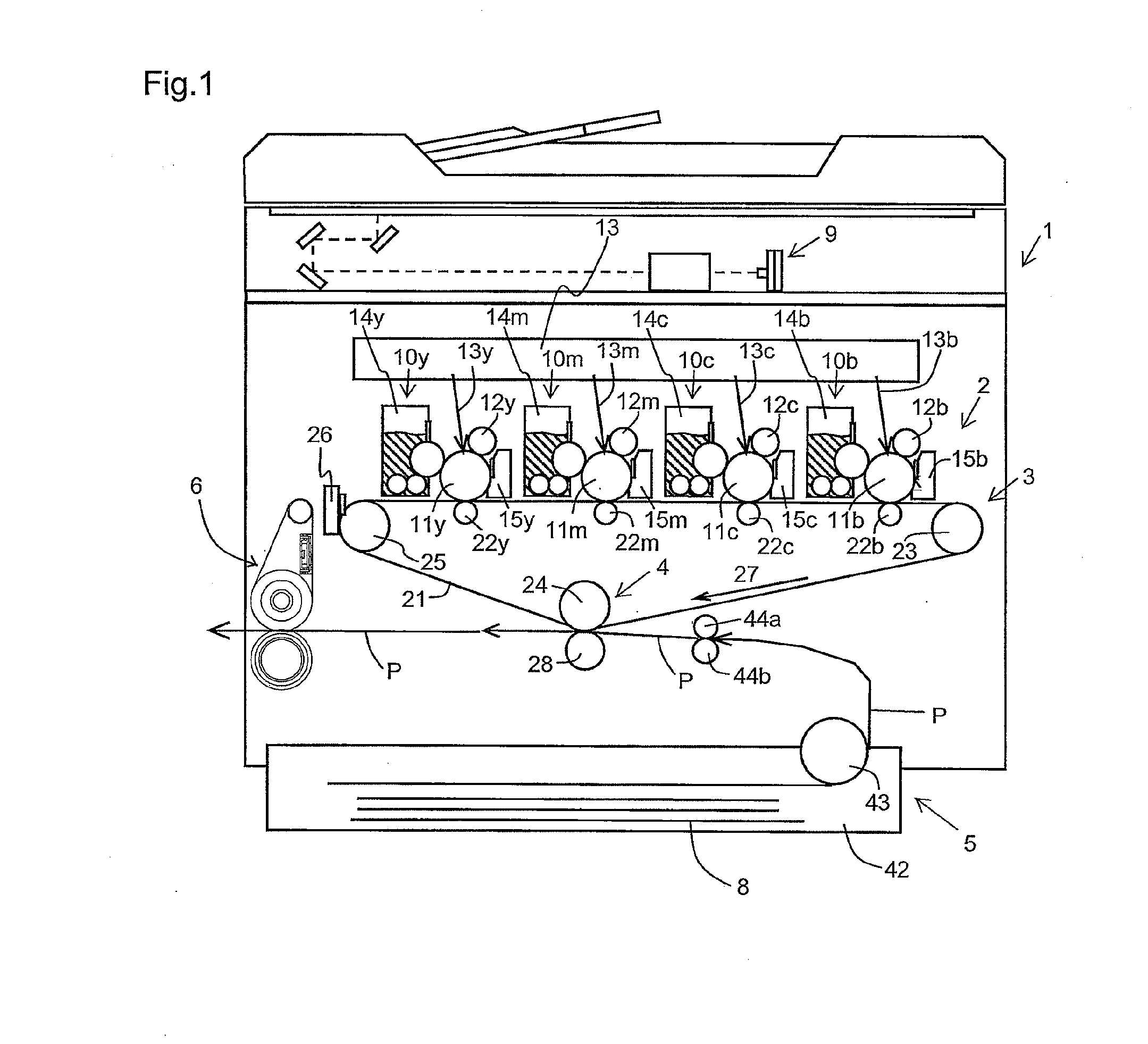

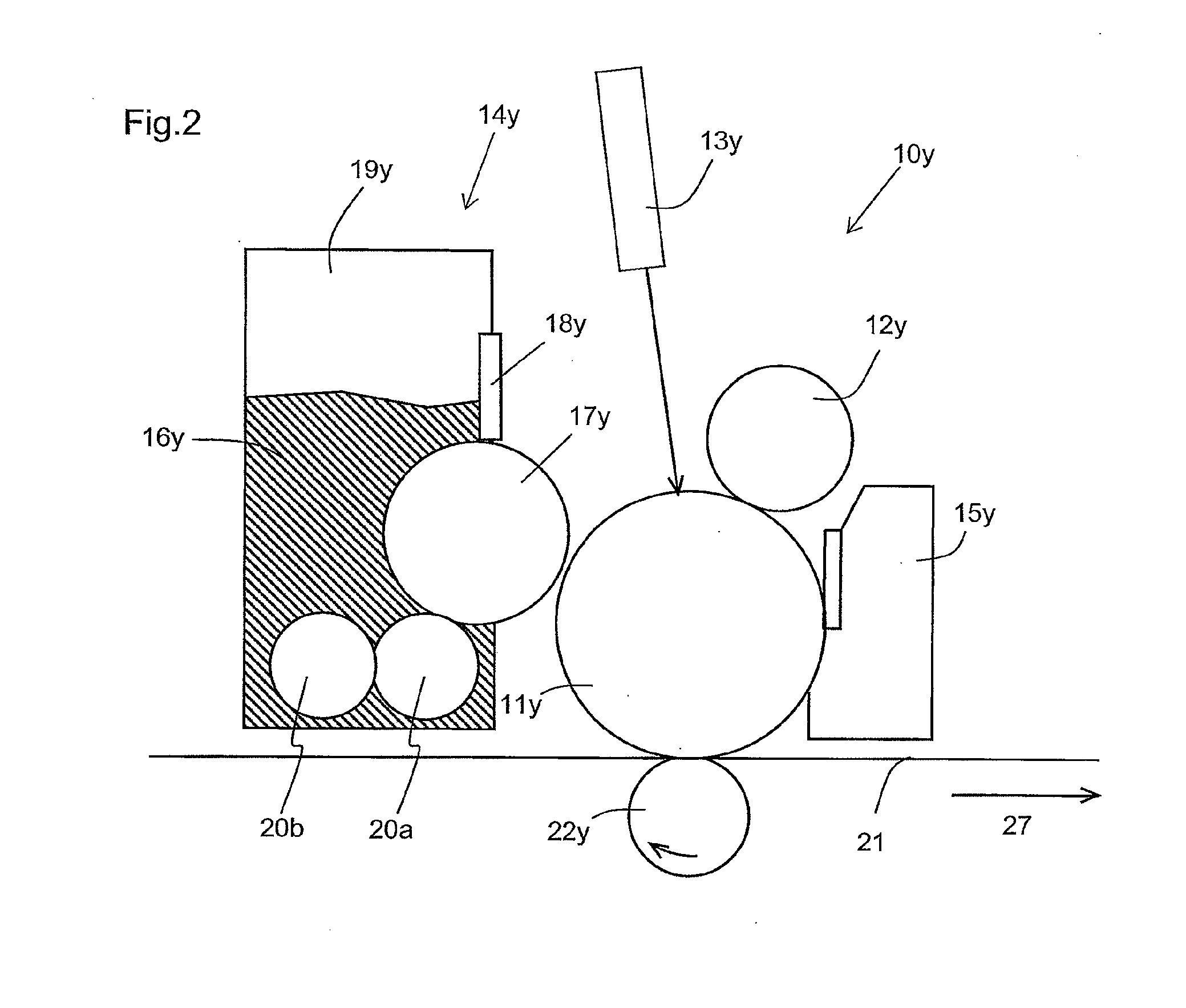

ActiveUS20120045261A1Robust and stableUniform heatingElectrographic process apparatusIntermediate regionEngineering

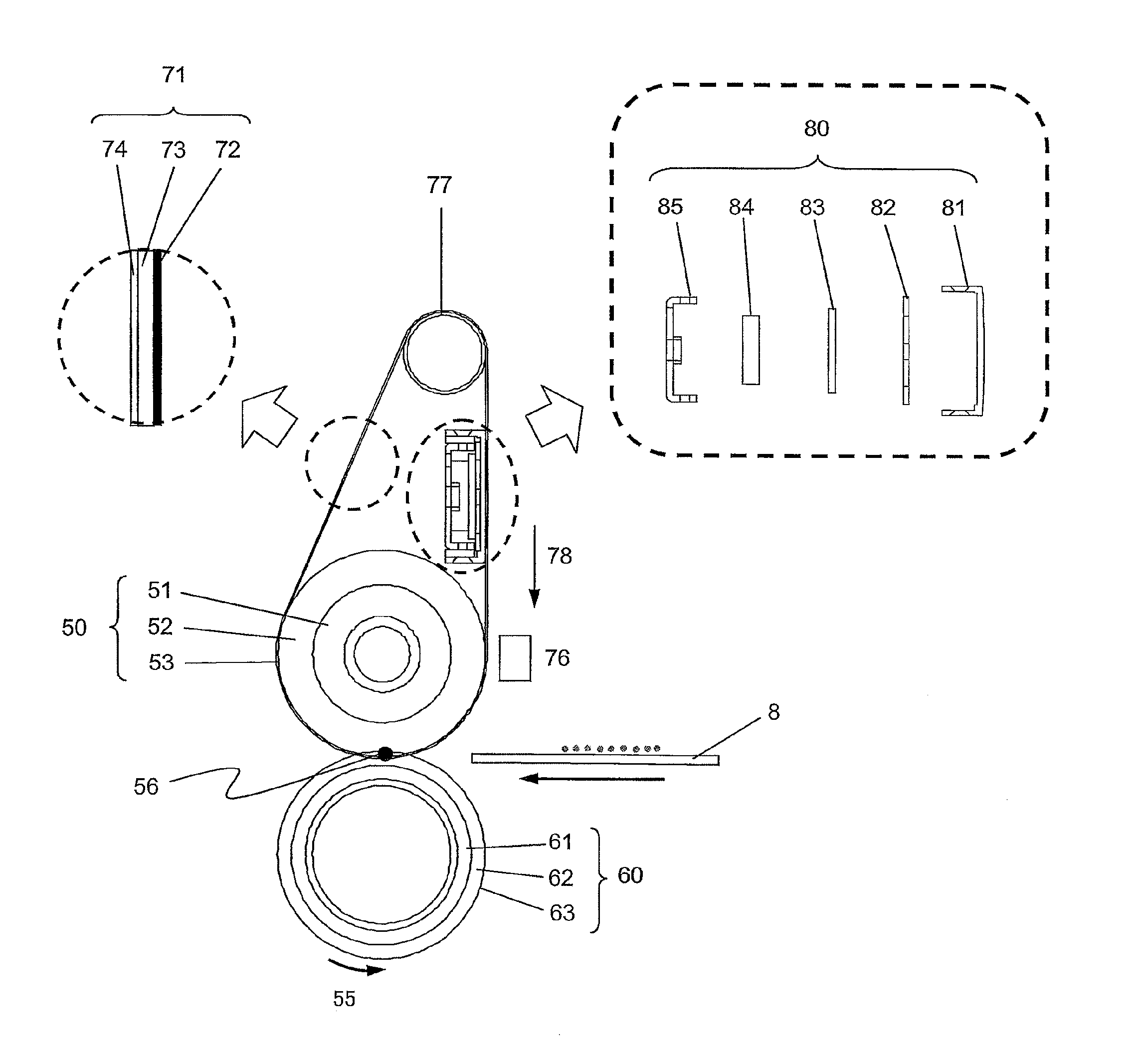

A fusing apparatus that including a sheet heating element for generating heat to fix a toner image being transferred onto a sheet; an endless belt; a rigid member for conducting the heat to the endless belt and being arranged to contact with the sheet heating element and the endless belt respectively; and a pressure member for pressing the sheet heating element against the rigid member, wherein the endless belt is arranged to contact with the sheet, the sheet heating element includes an elongated substrate extending in a widthwise direction of the endless belt, plural resistance heating layers which are formed on a surface of the substrate along a longitudinal direction thereof and arranged parallel to one another, and at least one conduction portion formed in at least one place of an intermediate region between one end and another of each resistance heating layer to connect the different resistance heating layers, and the pressure member presses the sheet heating element against the rigid member at a position other than a position where the conduction portion is formed.

Owner:SHARP KK

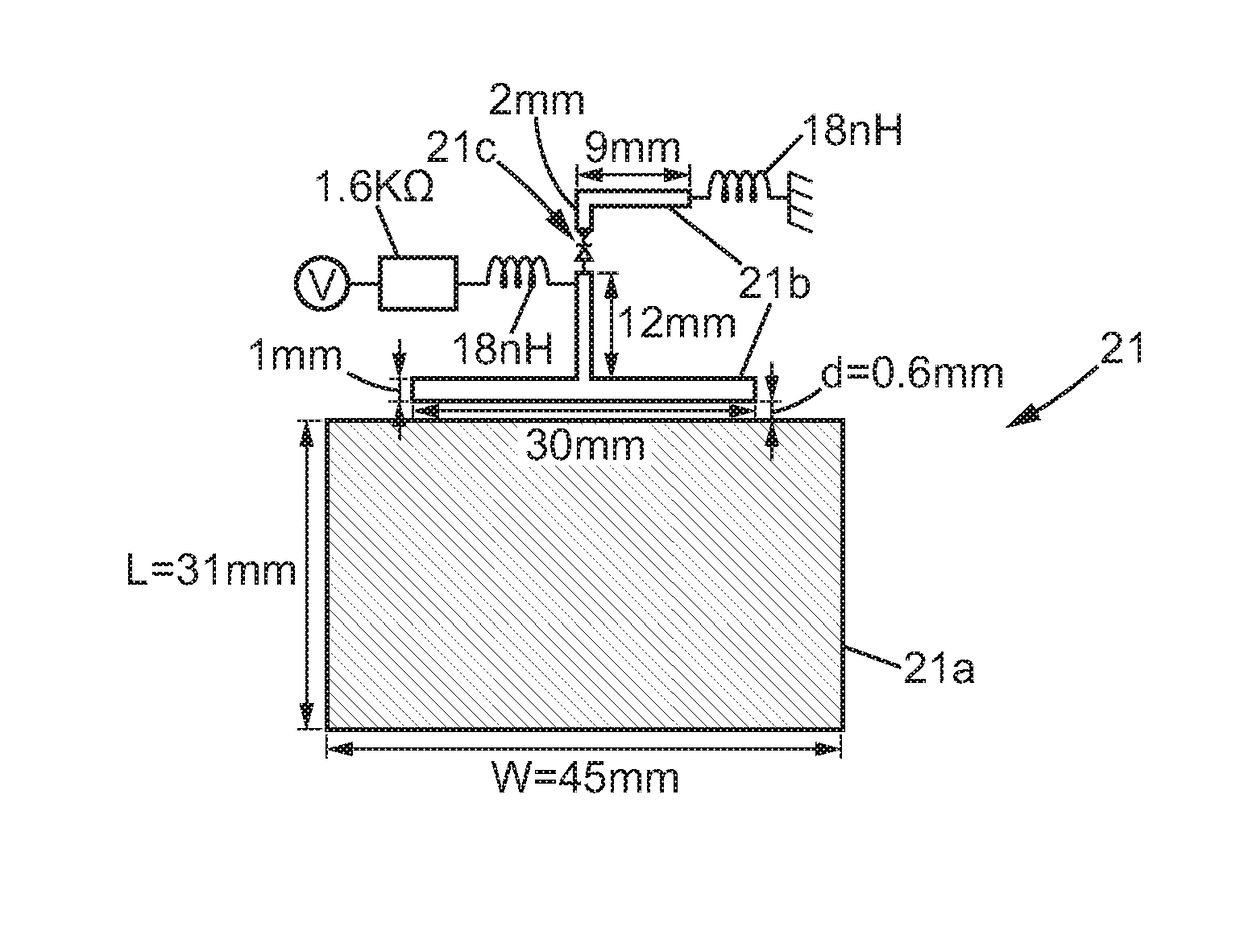

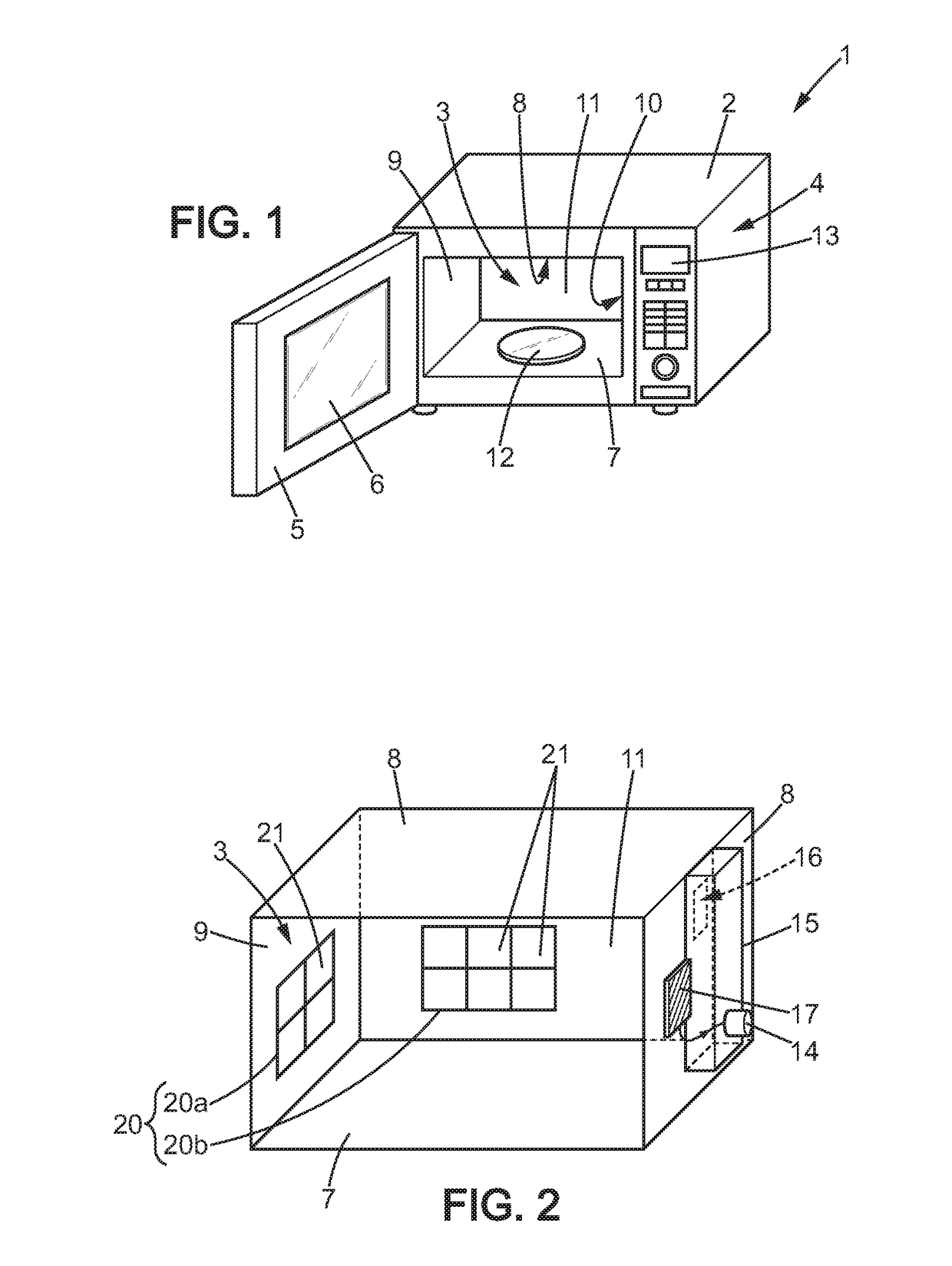

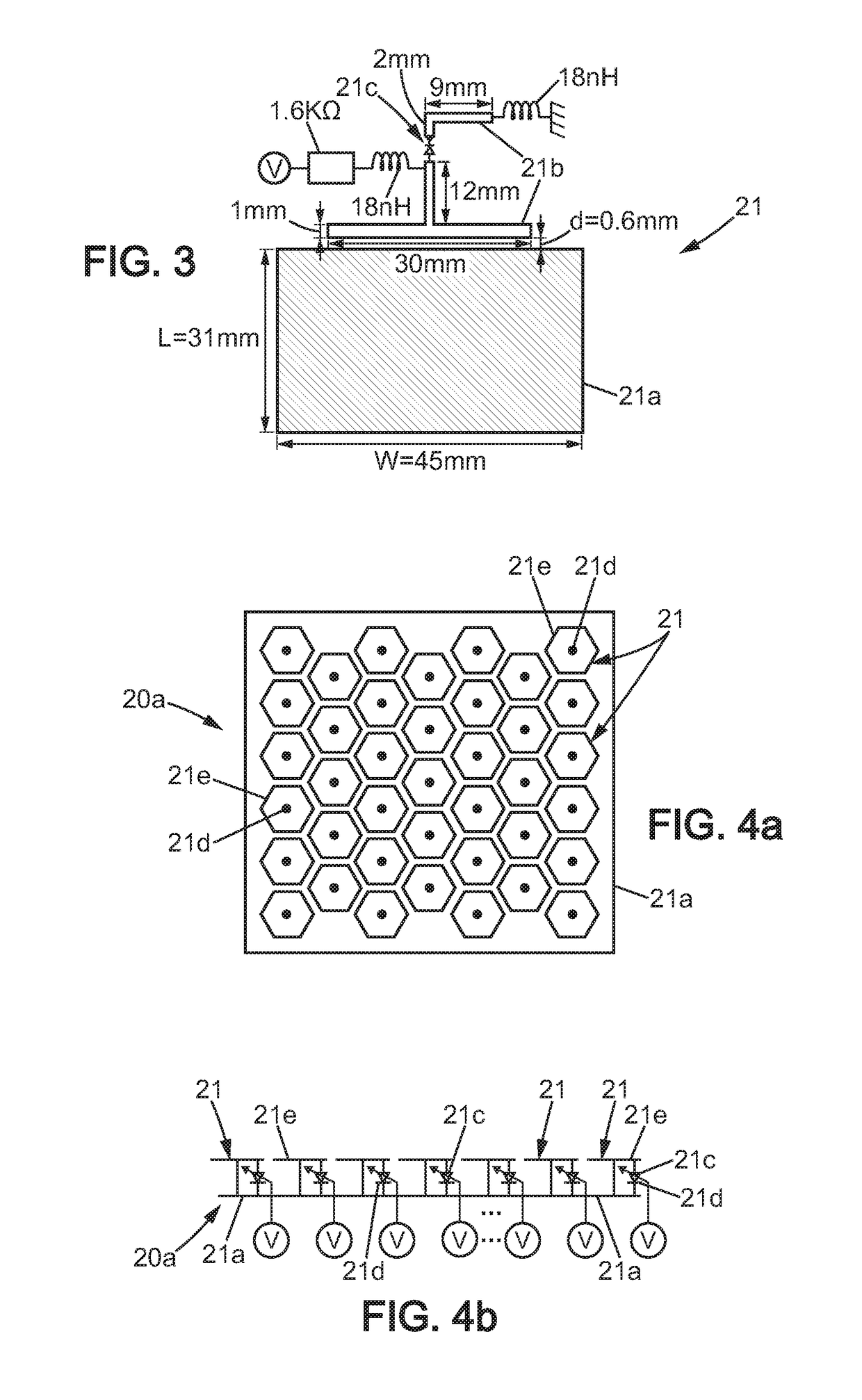

A Microwave Oven

ActiveUS20170164429A1Uniform heatingHeating evenlyMicrowave heatingWaveguide type devicesMicrowave ovenEngineering

A microwave oven comprising a cavity in which a material can be placed for heating and a magnetron for generating a microwave. The microwave oven further comprises an electromagnetic element adapted to interact with microwaves into the cavity and a control unit that provides a control signal to the electromagnetic element for modifying an impedance of the electromagnetic element during time of heating.

Owner:UNIVERSITÉ PARIS CITÉ +1

Energy-saving type water bath traditional Chinese medicine heating device

InactiveCN106821752AUniform heatingImprove heating efficiencyPharmaceutical product form changeDomestic articlesPistonCondensed water

The invention discloses an energy-saving water-bath heating device for traditional Chinese medicine, which comprises a heating tank, a water-bath pot, an upper cover, a heat-exchanging tank and a condensation pipe. Block, positioning plate, positioning spring, air guide tube and drug outlet tube; water inlet, heating tube, reinforcement plate and heat exchange tank are arranged in sequence on the water bath, and condensation pipe, liquid inlet and condensed water collection are arranged in the heat exchange tank Tank; the upper end of the condensation pipe, the right end of the air guide pipe and the water bath are connected with a three-way pipe. The invention adopts water bath heating and cooperates with a steam collecting device to effectively utilize steam heat energy; adopts elastic pressure control and cooperates with segmented exhaust to stabilize pressure control.

Owner:苏州兰灵医药科技有限公司

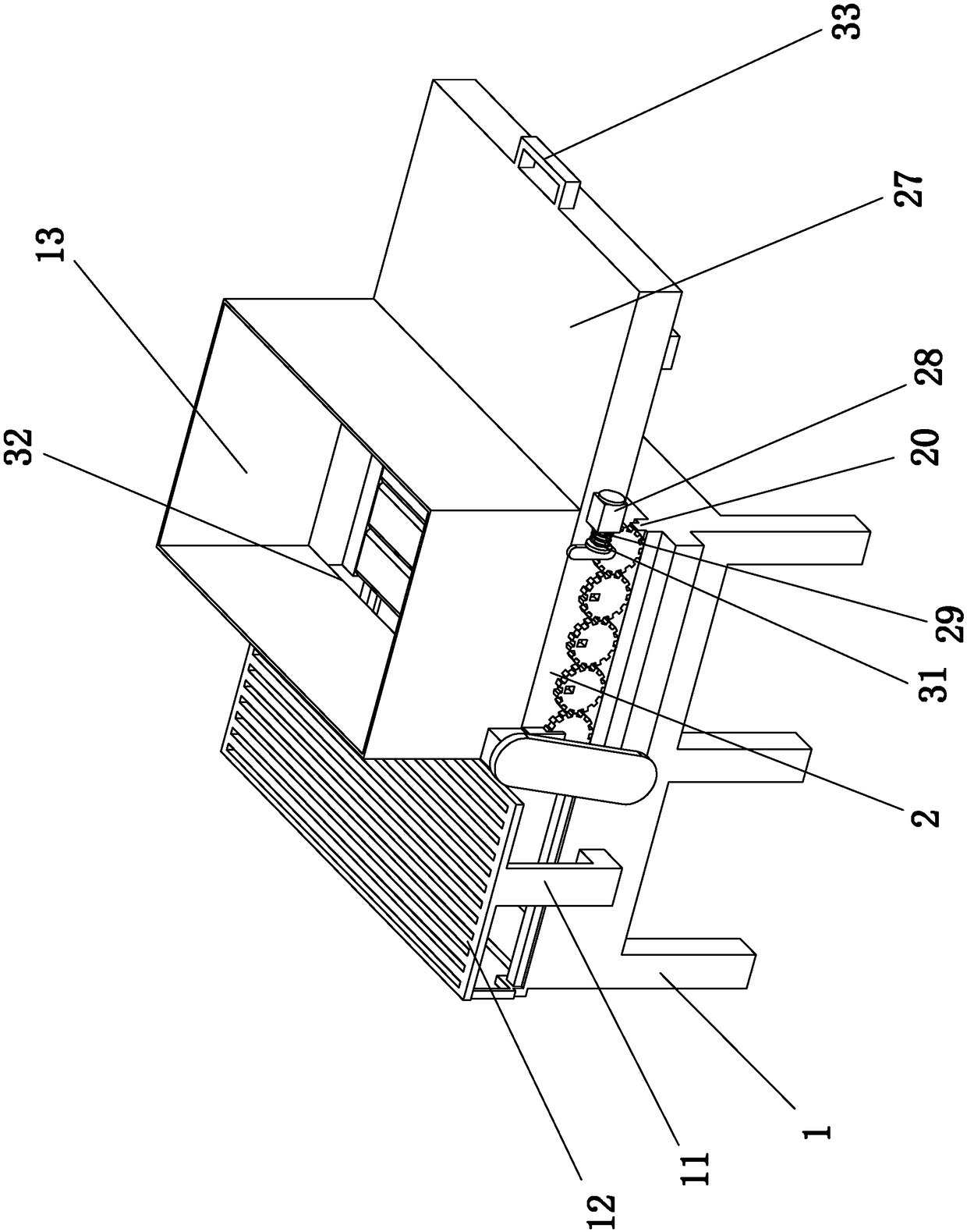

Equipment for flange forging production

The invention discloses equipment for flange forging production. The equipment comprises a base, a furnace body main body and a regenerative furnace, a lower furnace body is arranged above the base, alower furnace sealing door is arranged below the outer surface of the lower furnace body, a first connecting pipeline is arranged on the outer side of the lower furnace body, the left side and the right side of the furnace body main body are provided with heat return pipes, the furnace body main body is located on the outer sides of the lower furnace body and the upper furnace body, an outer heating layer is arranged on the outer side of the regenerative furnace, and the regenerative furnace is located on the side, close to the outside, of a stop valve. According to the equipment for the flange forging production, a steel ingot, square steel or round steel are taken as raw materials, after the corresponding weight and size are cut through a sawing machine, the raw materials enter the furnace to be heated to be made into a rough blank, the rough blank returns to the furnace again to be heated and then is discharged out of the furnace for ring milling, a mold with the shape matched withthe shape of a product is utilized to enable the rough blank to directly form the shape close to the shape of the finished product through ring milling, so that materials are saved, the weight of thematerials is reduced, the finish machining time is saved, and the machining time is greatly saved by carrying out machining according to the shape.

Owner:浙江海盛金环机械有限公司

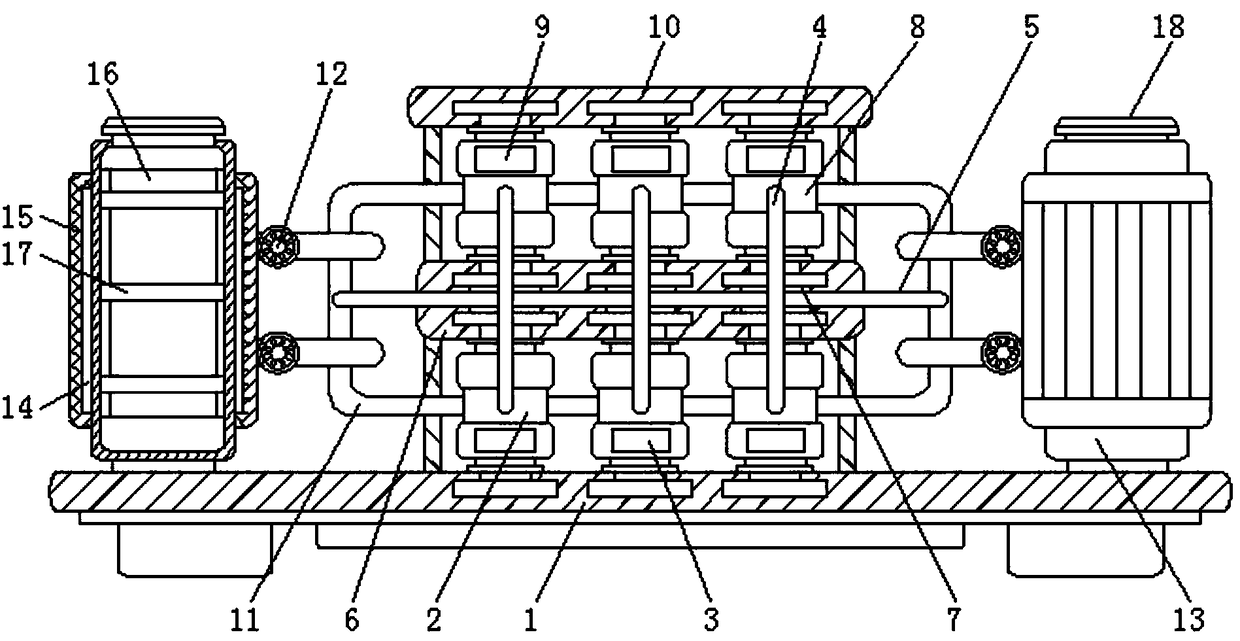

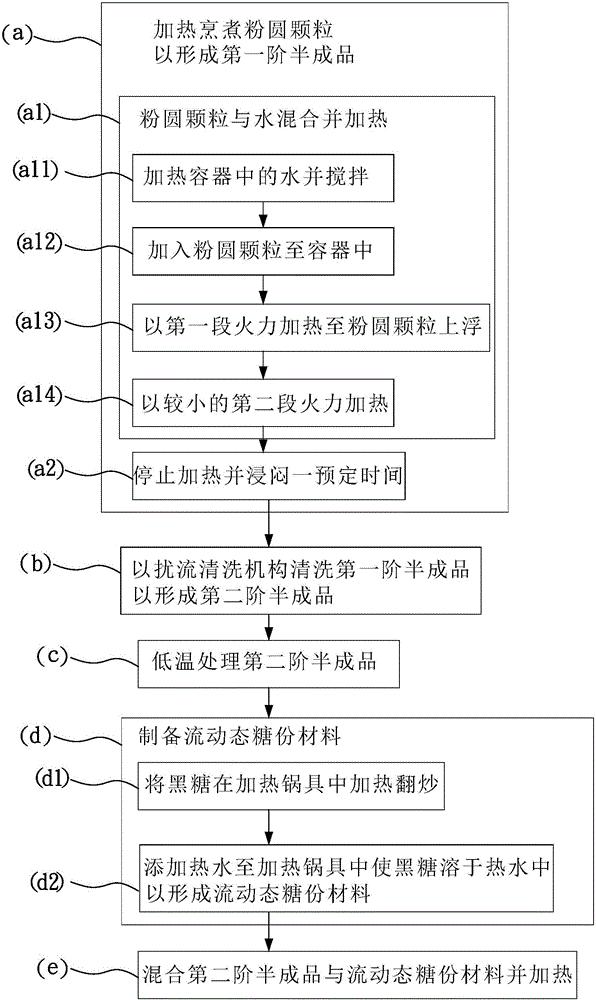

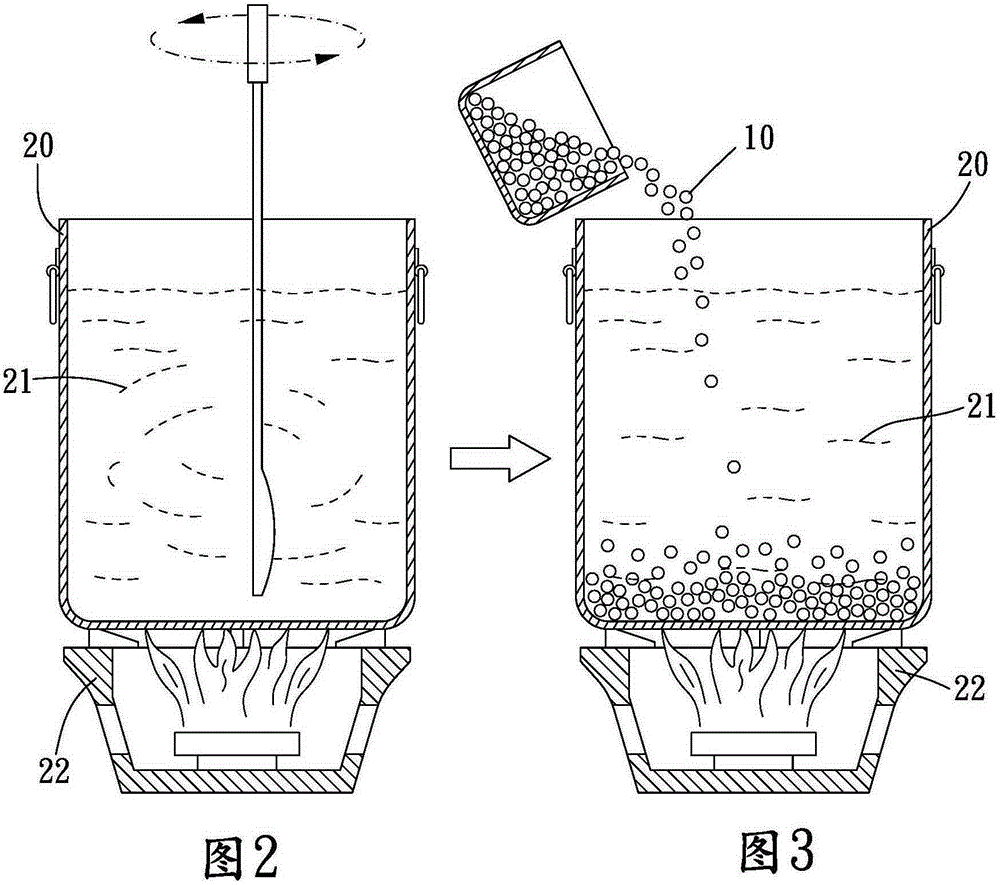

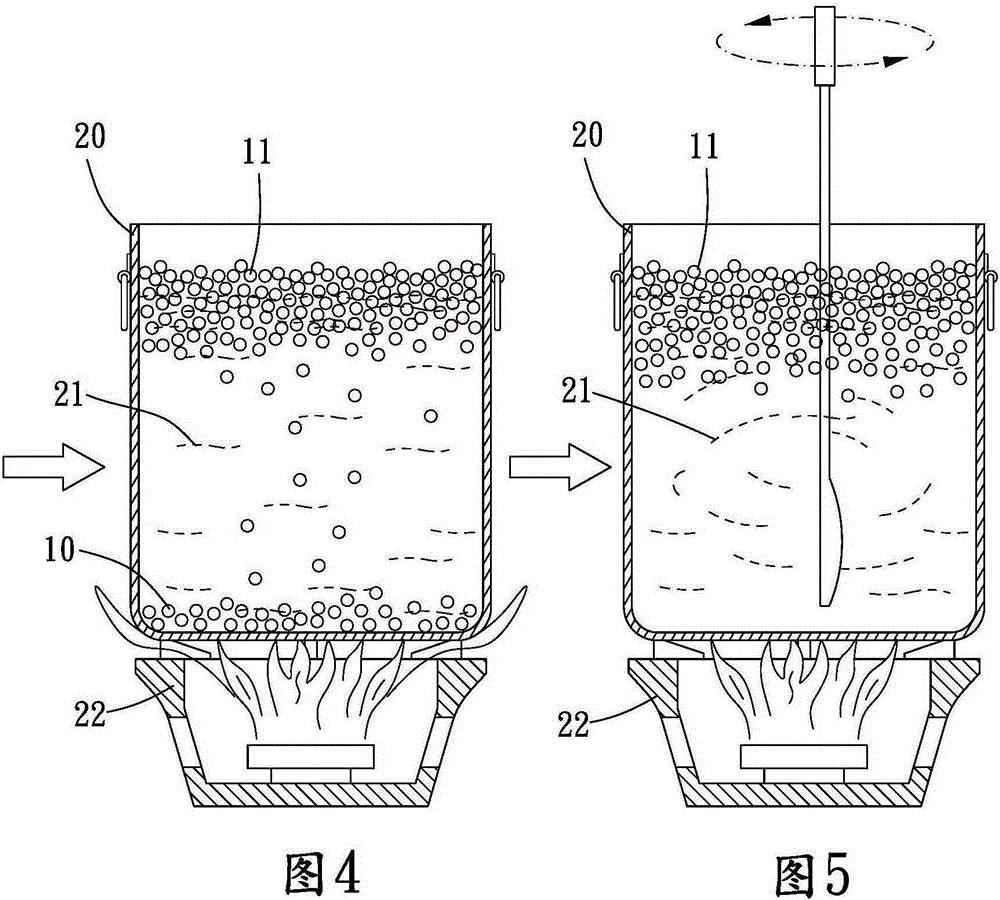

Tapioca pearl product, and preparation method and preparation system thereof

The invention discloses a tapioca pearl product, and a preparation method and a preparation system thereof. According to the preparation method and preparation system, before / after heating tapioca pearls, the water is stirred, so the water temperature becomes uniform and the heating is uniform, a flow disturbing washing mechanism is used, tapioca pearls are washed by disturbing the water flow in an overall covering mode, then tapioca pearls are mixed with a flowing sugar material, which at least contains black sugar, the mixture is heated, a proper amount of candied melon can be selectively added, and thus the tapioca pearl product is prepared. Through the abovementioned technical scheme, the tapioca pearl product, which is more elastic and has a better taste, a black sugar flavor, and a richer baking aroma, can be simply, rapidly, and massively produced.

Owner:郭琳圭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com