Tapioca pearl product, and preparation method and preparation system thereof

A technology of powdered balls and products, applied in the field of powdered balls and its preparation method and preparation system, to achieve the effect of good taste, better taste, rich brown sugar flavor and burnt aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

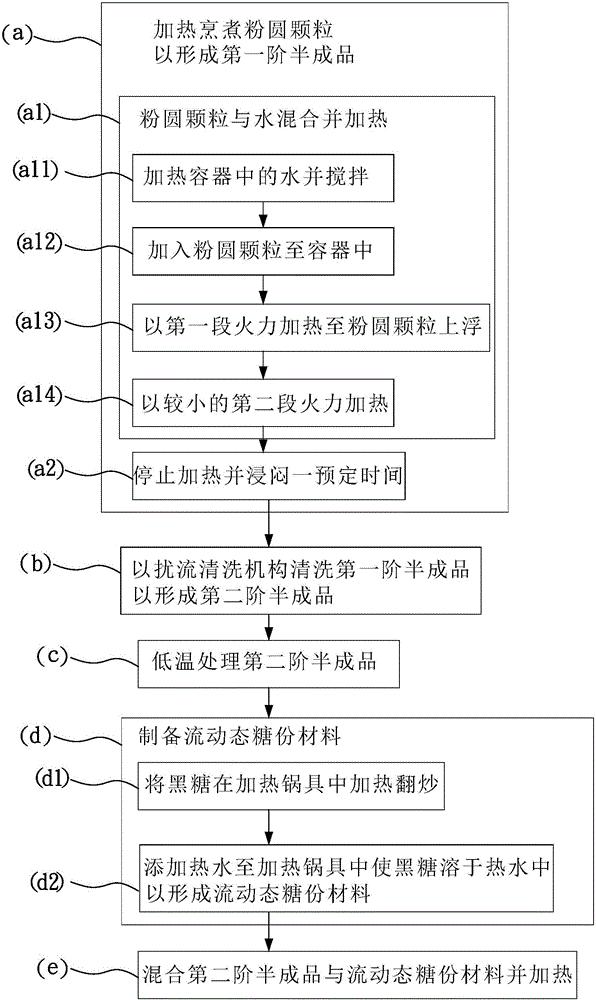

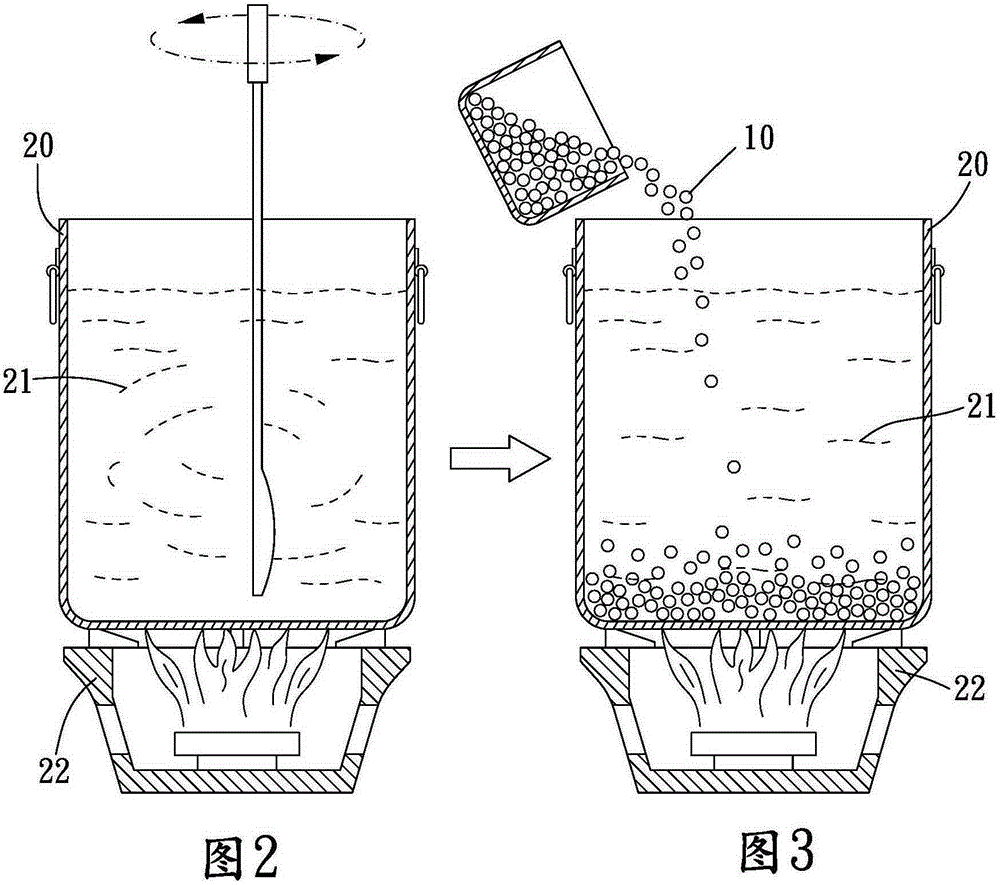

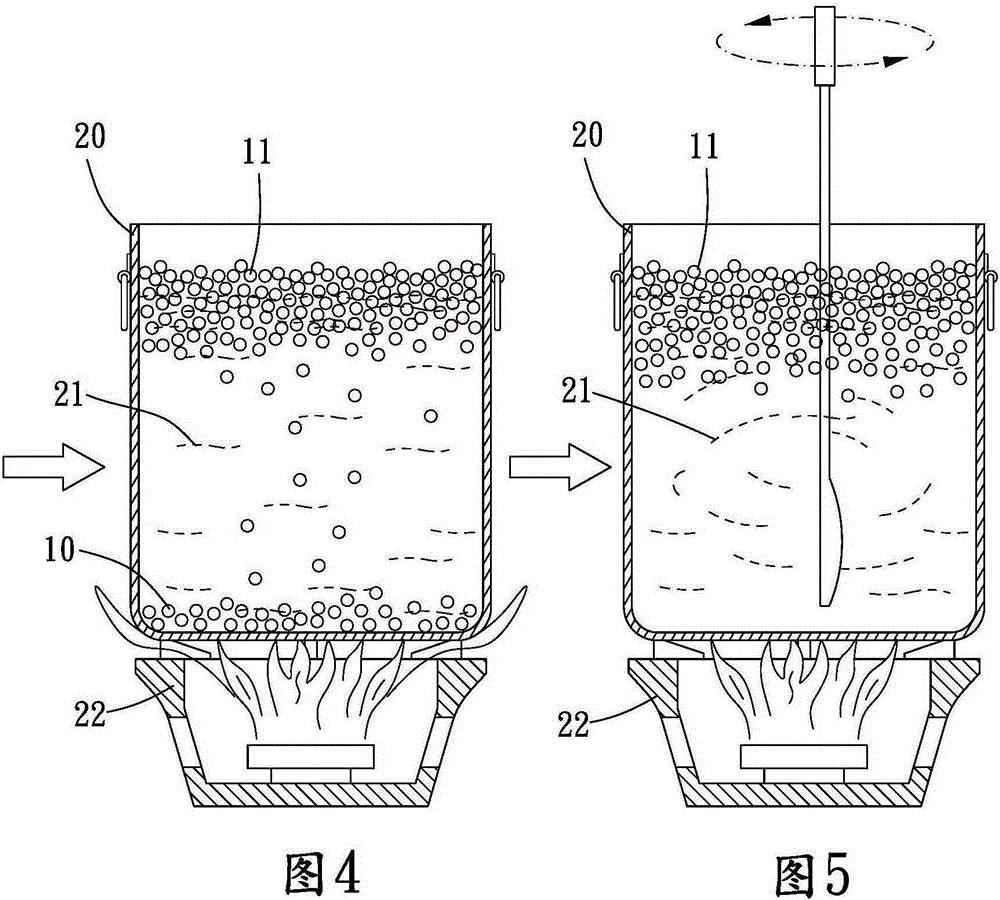

[0028] Please refer to figure 1 And Fig. 2 to 11, it shows a preferred embodiment of the present invention, the preparation method of the powder round product of the present invention comprises the following steps: Step (a), puts the powder round particle 10 into a container 20 and cooks, To form a first-order semi-finished product 11; step (b), in a disturbed flow cleaning mechanism 30, clean the first-stage semi-finished product 11 with a disturbed water flow as a whole to form a second-order semi-finished product 12; step (c ) process the second-stage semi-finished product 12 at low temperature; step (d), prepare a first-class dynamic sugar material 40, the flow dynamic sugar material 40 at least includes brown sugar; step (e), combine the second-stage semi-finished product 12 with the flow The dynamic su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com