Electric heating element and heating method thereof

An electric heating element and electric heating technology, applied in the direction of ohmic resistance heating parts, heating element material, heating element shape, etc., can solve the problem of inability to obtain uniform temperature, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

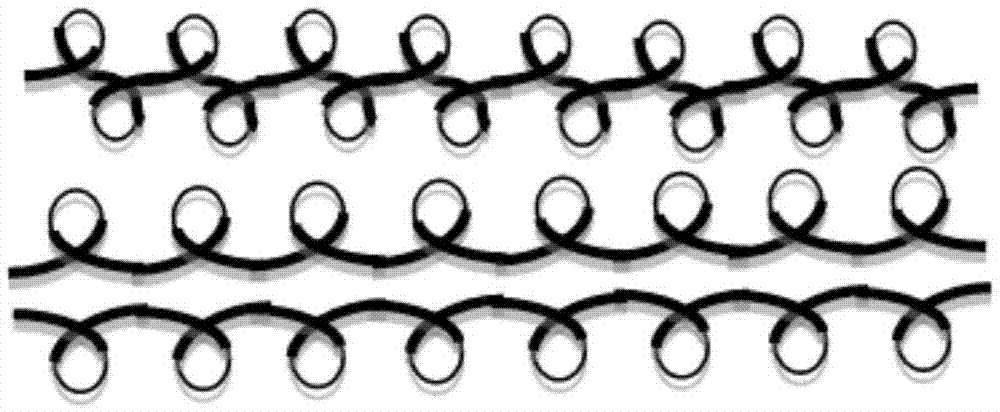

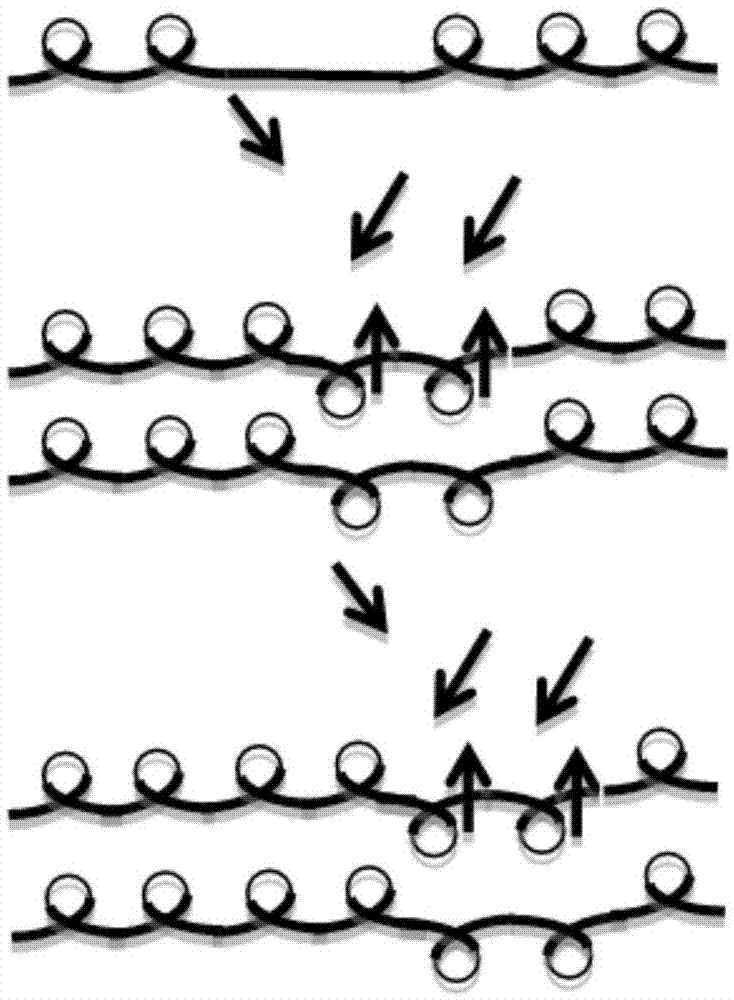

[0026] The present invention aims at the problem that the existing electric heating fabric cannot obtain uniform temperature when it is energized, and proposes an electric heating element, which can realize uniform electric heating performance in the plane or three-dimensional direction; the electric heating element of the present invention is light in weight , soft, uniform heating, avoiding the problem of local overheating that limits the application range of existing fabrics. The electric heating element includes electric heating fabric, and the electric heating fabric includes conductive yarn, which can conduct low-voltage current; in addition, the electric heating fabric also includes resistance yarn, which is used to block the passage of electric current to generate heat energy and has a certain insulation effect. Electric heating fabrics can be textile composites or layered fabrics, and are woven from conductive and resistive yarns. Under a certain DC voltage, evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com