Patents

Literature

120results about How to "Quick in and out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

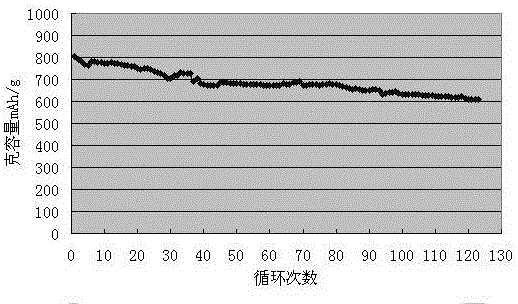

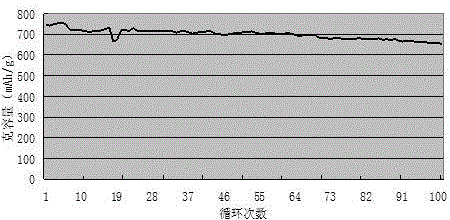

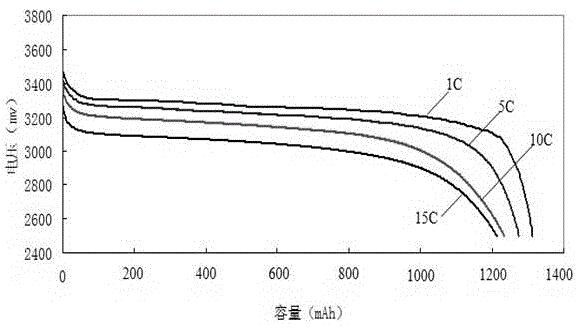

Preparation method of anode material for power lithium ion battery

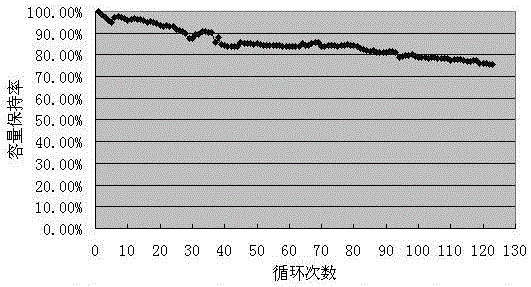

InactiveCN104659366AImprove electrochemical performanceIncrease capacityCell electrodesSecondary cellsCarbonizationDischarge rate

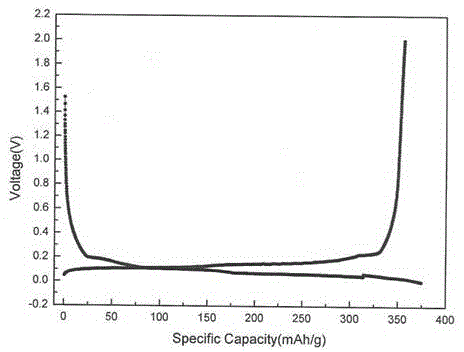

The invention discloses a preparation method of an anode material for a power lithium ion battery. The preparation method comprises the following steps: by adopting petroleum coke ground until the grain size is 1-6mu m, calcined petroleum coke or needle coke as a raw material, adding additives, adding a mixture to a reaction kettle to carry out first high-temperature carbonization coating under the protection of the inert atmosphere, then grinding the mixture with a grinder until the grain size is 5-13mu m, then carrying out superhigh-temperature graphitization at a temperature above 3200 DEG C, adding one or a mixture of petroleum asphalt, coal asphalt and resin to a material obtained after graphitization, and then enabling the mixture to enter a carburization furnace to undergo second coating under the protection of the inert atmosphere to obtain the anode material for the power lithium ion battery, namely a spheroidal artificial graphite material which is formed through bonding after being coated with granules and undergoes two-time coating and three-time high-temperature treatment. The preparation method has the advantages that the discharge rate property of the anode material is improved, the low temperature properties of the anode material are improved, and the latest requirements of the market for the product are further met.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Preparation method of high-capacity silicon-based negative electrode material of lithium-ion battery

InactiveCN106025211AImprove the reunion effectAvoid performance degradationCell electrodesSecondary cellsDispersitySlurry

The invention discloses a preparation method of a high-capacity silicon-based negative electrode material of a lithium-ion battery. The method comprises the preparation processes of: mixing nano silicon, graphite and a pyrolytic carbon organic matter precursor to obtain composite material precursor slurry; and carrying out spray drying to obtain precursor powder; and finally carrying out roasting treatment in an inert atmosphere and then carrying out grinding to obtain an organic matter pyrolytic carbon-coated nano silicon / graphite composite material. According to the preparation method, the dispersity of the nano silicon in the silicon-carbon negative electrode material can be improved; the structure stability of the material in a lithium intercalation and deintercalation process is improved; the condition that the material has relatively high conductivity is ensured; a pyrolytic carbon coating layer effectively coats the surfaces of material particles; the interface characteristic of the material can be effectively improved; and the electrochemical properties of the silicon-carbon negative electrode material are improved.

Owner:田东

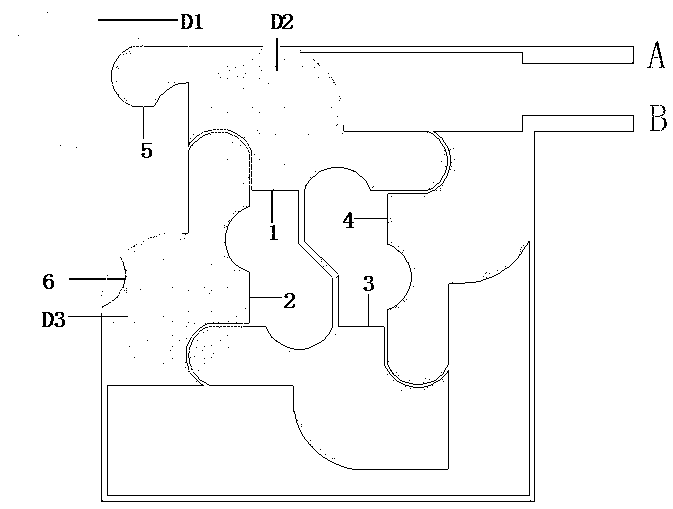

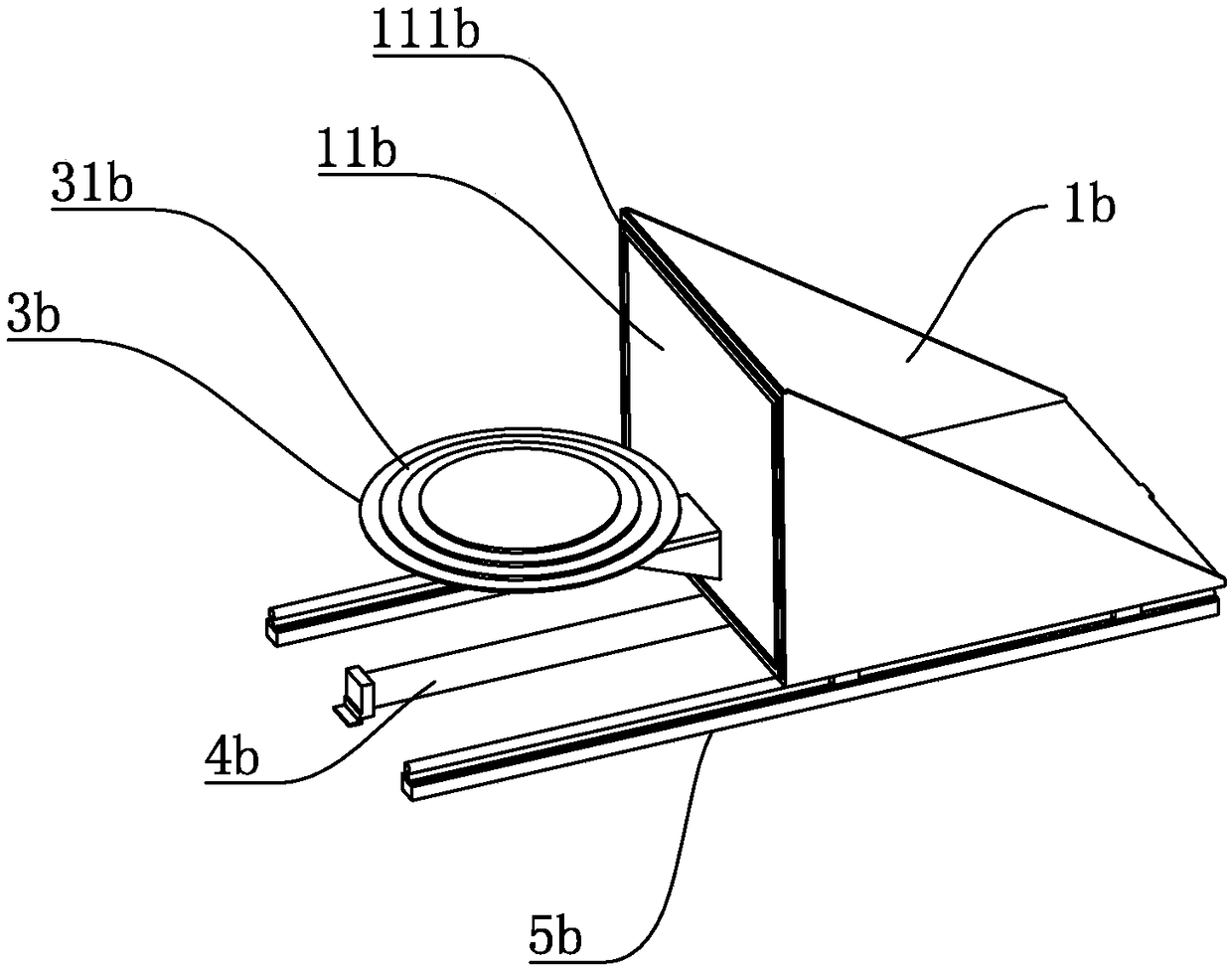

Liquid drop mixing unit based on electro-wetting digital micro-fluid chip

InactiveCN102836653AHigh-speed automatic transport mixingEasy to integrateFlow mixersMixing methodsElectricityFluidics

The invention belongs to the technical field of digital micro-fluidics, and in particular relates to a liquid drop mixing unit based on an electro-wetting digital micro-fluid chip. The mixing unit comprises three parts consisting of an inlet zone, a mixing zone and an outlet zone; the fast, high-efficiency, automatic and reliable mixing of the liquid drops can be realized via the special bidirectional driving electrode and closed-loop electrode arrangement and simplified electrode connection mode. The liquid drop mixing unit has the advantages of novel design, easiness in control, high reliability, excellent practicability, high automation degree, and the like, so that the liquid drop mixing unit can be widely used in various digital micro-fluid chips.

Owner:FUDAN UNIV

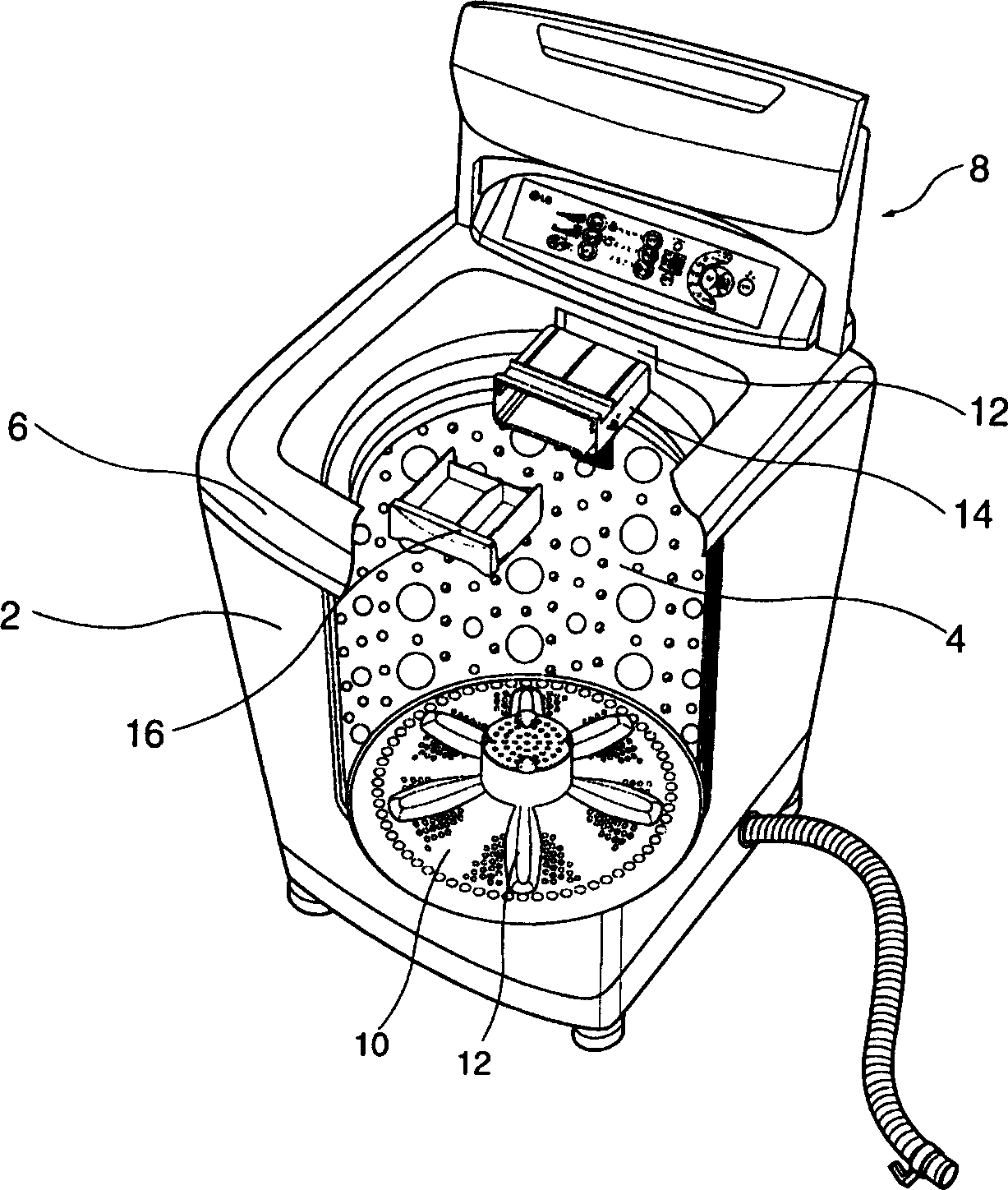

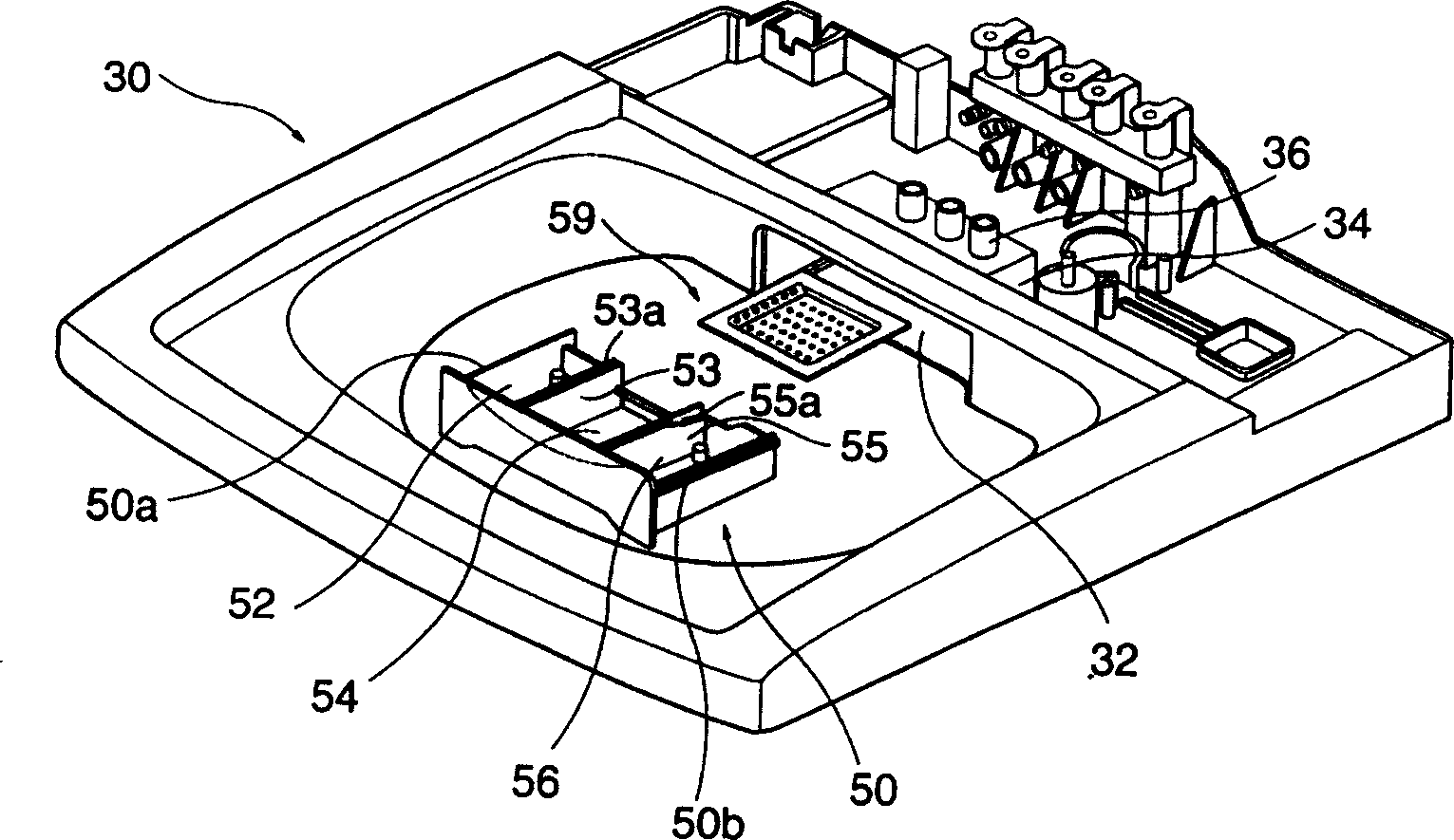

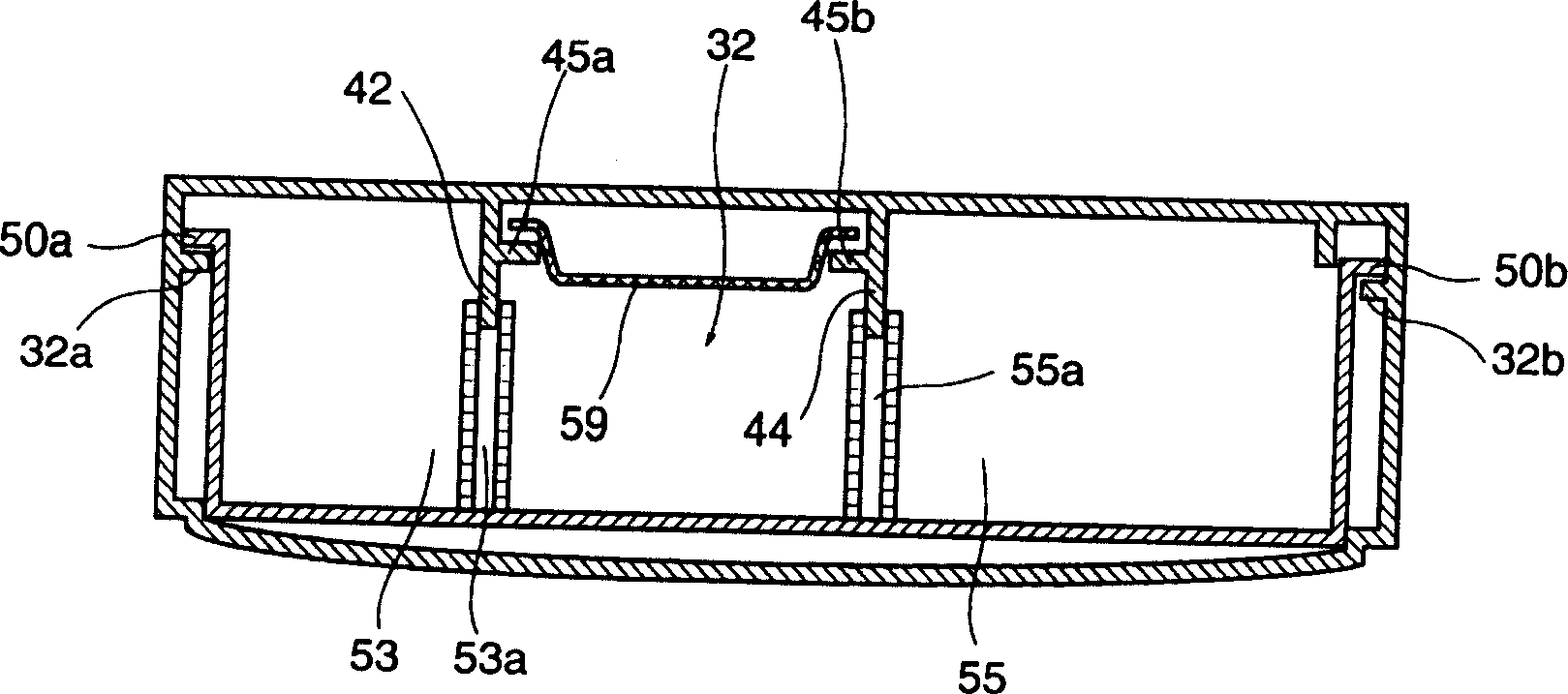

Upper cover with detergent box of washing machine

InactiveCN1536133AQuick in and outSimple structureOther washing machinesTextiles and paperMechanical engineeringEngineering

The present invention relates to an upper lid with detergent box for washing machine. It includes a detergent box mounting space which is positioned in the rear portion of central opened portion and is forward opened; detergent box which can be inserted into the mounting space from its front portion and has several storage spaces including storage space for powder detergent; supporting cross bars which are formed on two sid walls of the mounting space and are projected toward inner side; and supporting projection portion which is outward projected from upper end of two side walls of detergent box and formed and can be hung on the cross bars. Said invention has detergent box with more simple structure and its supporting structure, and said detergent box can be smoothly drawn out and inserted into its mounting space.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Preparation method of high-volume silicon-carbon negative electrode material

The invention relates to a method for preparing a modified graphite negative electrode material of a lithium ion power battery. The method particularly comprises the following steps: adding asphalt and resin into a kneading kettle with heating and stirring devices, heating until the asphalt and the resin are melted into liquid, continuously stirring, stopping heating after mixing uniformly and cooling to obtain a composite coating material block; performing coarse crushing on the composite coating material block and performing ultrafine crushing by using an airflow crushing machine or a cryogenic crushing machine to obtain composite coating material ultrafine powder; completely mixing the composite coating material ultrafine powder and graphite to obtain uniform powder; and performing heating, heat preservation and natural cooling on the uniform powder under the protection of inert gas, and sieving after cooling to obtain the modified graphite negative electrode material of the lithium ion power battery. The most outstanding innovation points are that the coating material precursor is subjected to compound treatment and coated by the graphite; the mixing uniformity of various coating material precursors is guaranteed, any solvents are not required, and environmental friendliness is realized; in addition, the process is simple, low in cost and easy in industrialized production.

Owner:SHENZHEN SINUO INDAL DEV

Traditional Chinese medicine warehouse management method

The invention discloses a traditional Chinese medicine warehouse management method, and belongs to the technical field of traditional Chinese medicine management. The method comprises the steps of warehousing management, delivery management and inventory management. The traditional Chinese medicine warehouse management method normalizes and scientizes the management method, inventory operation, in-stock management, delivery operation, stacking operation, and traditional Chinese medicine in-stock maintenance, has the characteristics of high storage, quick warehousing and delivery rate, good storage, low cost and loss, and high anti-falsification, and has the quality traceability function such as warehousing detection information management and in-stock maintenance and detection information management.

Owner:GANSU HUISEN PHARMA DEV

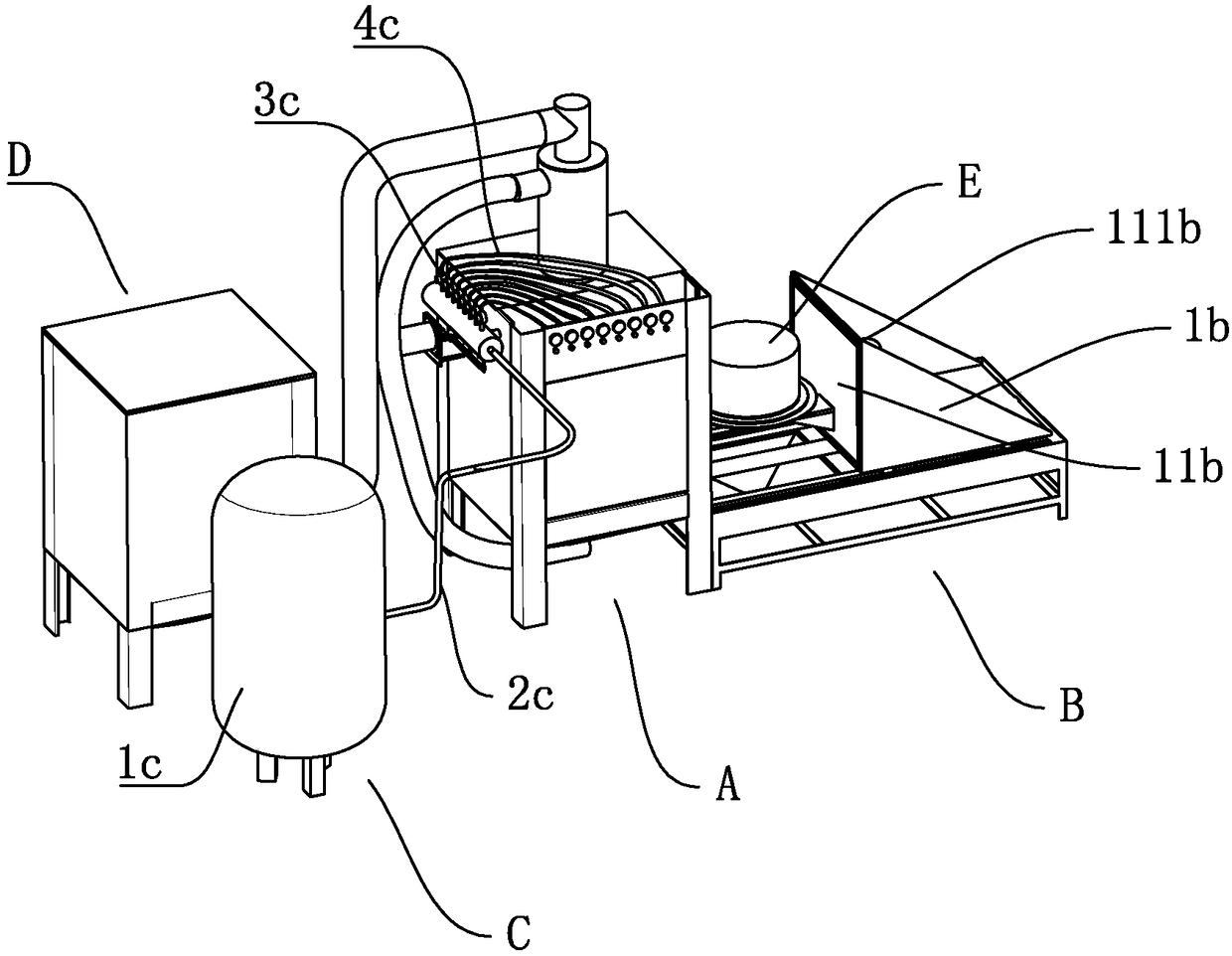

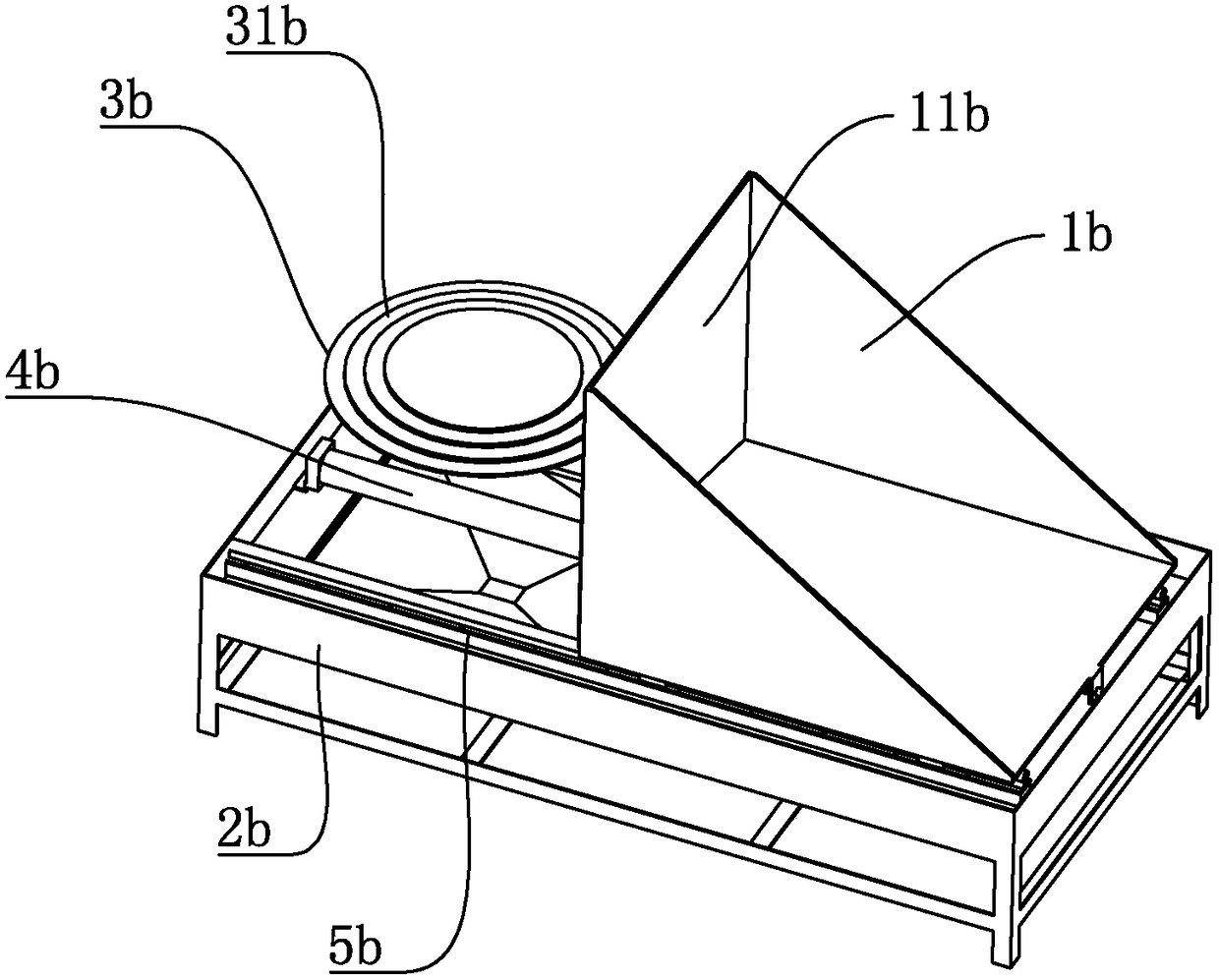

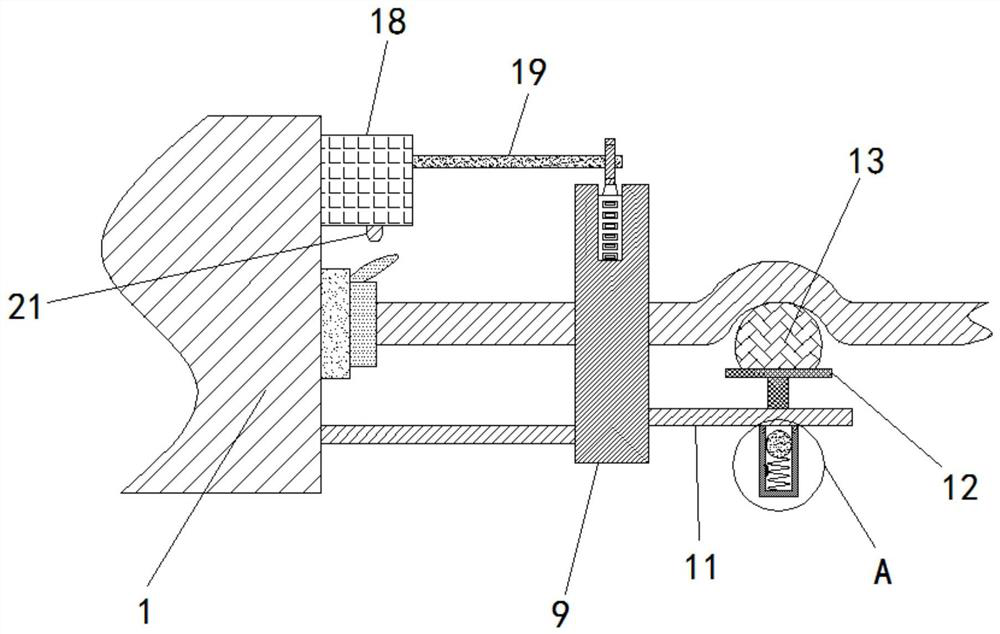

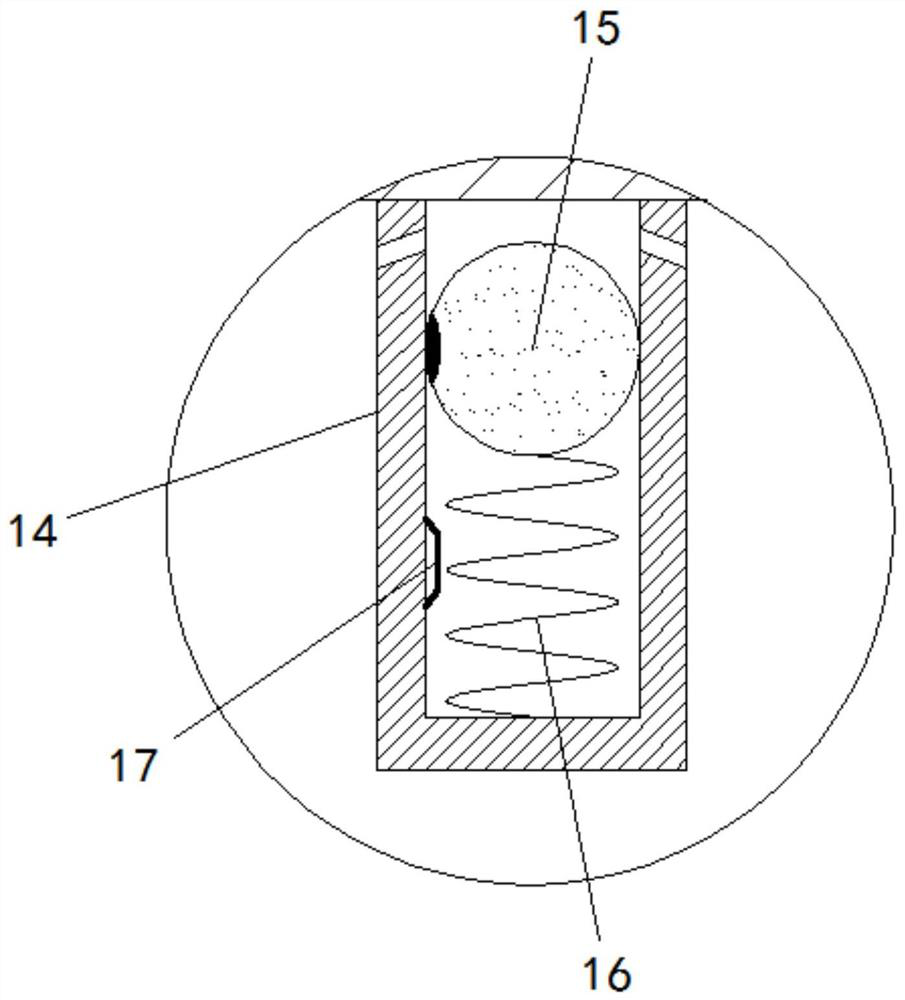

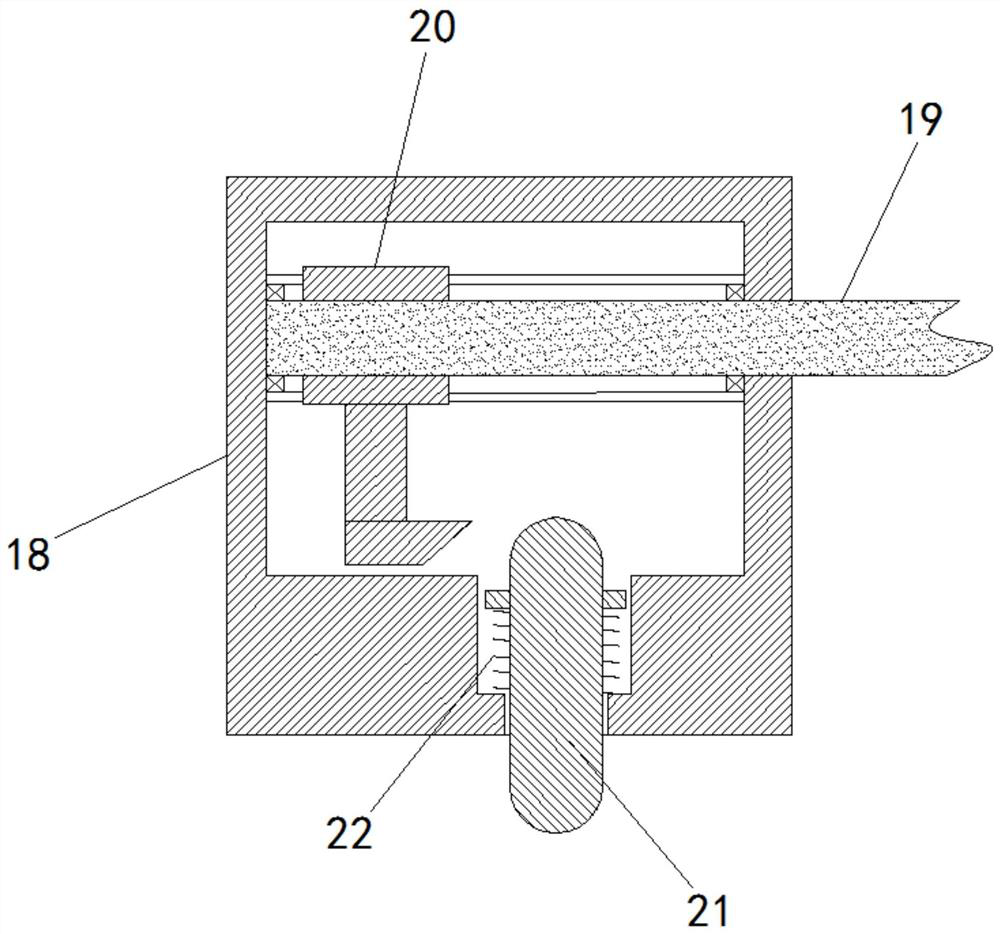

Sand blasting machine

ActiveCN106078533AAdjustable angleAccurate in and outBlast gunsAbrasive feedersSand blastingSpray nozzle

The invention discloses a sand blasting machine, which comprises a sand blasting chamber. The sand blasting chamber comprises a feeding hole for feeding and discharging workpieces, and spray nozzles arranged in the sand blasting chamber; the spray nozzles are fixed on a spray nozzle drive mechanism; a feeding mechanism capable of driving the workpieces to feed and discharge is matched on the feeding hole; the spray nozzle drive mechanism comprises at least one swinging mechanism arranged in the sand blasting chamber; each swinging mechanism is provided with one spray nozzle and is driven by a first drive part to swing to the left and right; the feeding mechanism comprises a placement platform used for placing workpieces and a second drive part; and the placement platform comprises at least one positioning table used for placing the workpieces, and a sealing plate arranged behind the positioning table and matched with the feeding hole of the sand blasting chamber. A plurality of swinging mechanisms are arranged in the sand blasting chamber, and a plurality of spray nozzles can swing to blast sand on the workpieces when being used for blasting sand, so that a uniform and efficient sand blasting effect is realized; and in addition, the workpieces can be quickly fed and discharged in the sand blasting chamber through the feeding mechanism, so that the sand blasting efficiency of the workpieces is further improved.

Owner:宁波精益微型轴有限公司

External preparation for promoting active circulation of skin

ActiveCN102362845ATo promote metabolismHigh speedCosmetic preparationsToilet preparationsSelf-healingCutaneous microcirculation

The invention relates to a skin external preparation, in particular to an external preparation capable of promoting the active circulation of cells. The external preparation comprises the following components in percentage by mass: 20 to 50 percent of glycosaminoglycan, 20 to 50 percent of amino acid, 10 to 30 percent of natural extract, 5 to 10 percent of diguanosine tetraphosphate (Gp4g) and 1 to 5 percent of inorganic salt; and micro elements are added in an amount which is 0.001 to 0.05 percent based on the total mass of the previous components are added. The external preparation is prepared by using distilled water. The external preparation capable of promoting the active circulation of cells, which is provided by the invention, can be externally sprayed or applied on skin to quicklysupply inorganic salt to skin, activate cells and accelerate the metabolism of skin cells; and the external preparation also can supply energy and required water to cells, improve the micro circulation of skin and effectively clean free radicals, activate the self-healing system of human body, quickly penetrate and freely enter and leave cells, repair cells safely, naturally and gently, accelerate cell division, increase metabolic capacity and delay aging.

Owner:GUANGZHOU BAOYAN BIOTECH

Preparation method for tin-carbon composite negative material

InactiveCN105161671AGuaranteed uniformitySimple processElectrode thermal treatmentSecondary cellsCarbon compositesGraphite

The invention provides a preparation method for a tin-carbon composite negative material. An outer layer of the tin-carbon composite negative material is a composite cladding layer jointly formed by asphalt, resin and tin powder, and an inner layer is the tin-carbon composite negative material which is composed of graphite and has a core-shell structure. In the tin-carbon composite material prepared according to the method, high specific capacity characteristic of tin is maintained, meanwhile, a modification effect on the graphite is played, the overall cyclic stability of the material is improved, the energy density of the negative material of a lithium ion battery is improved, thus, the negative material has higher specific capacity than the carbon negative material commonly used in the lithium ion battery in the current market, and the increasing energy density requirement of various portable electric devices on the battery is met.

Owner:田东

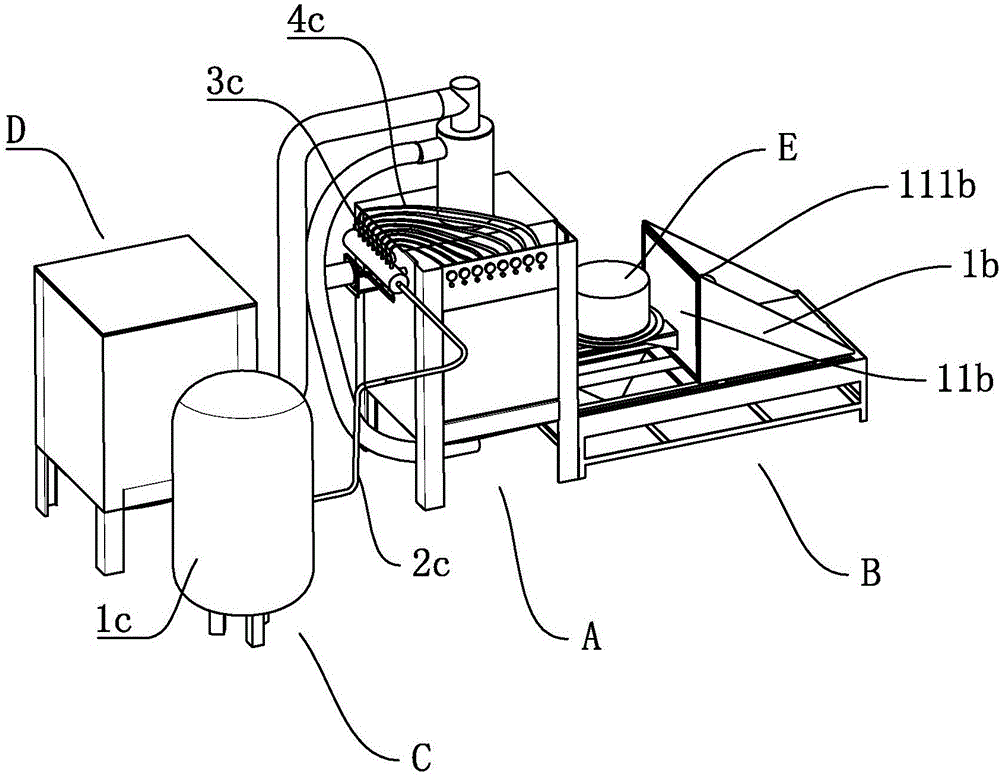

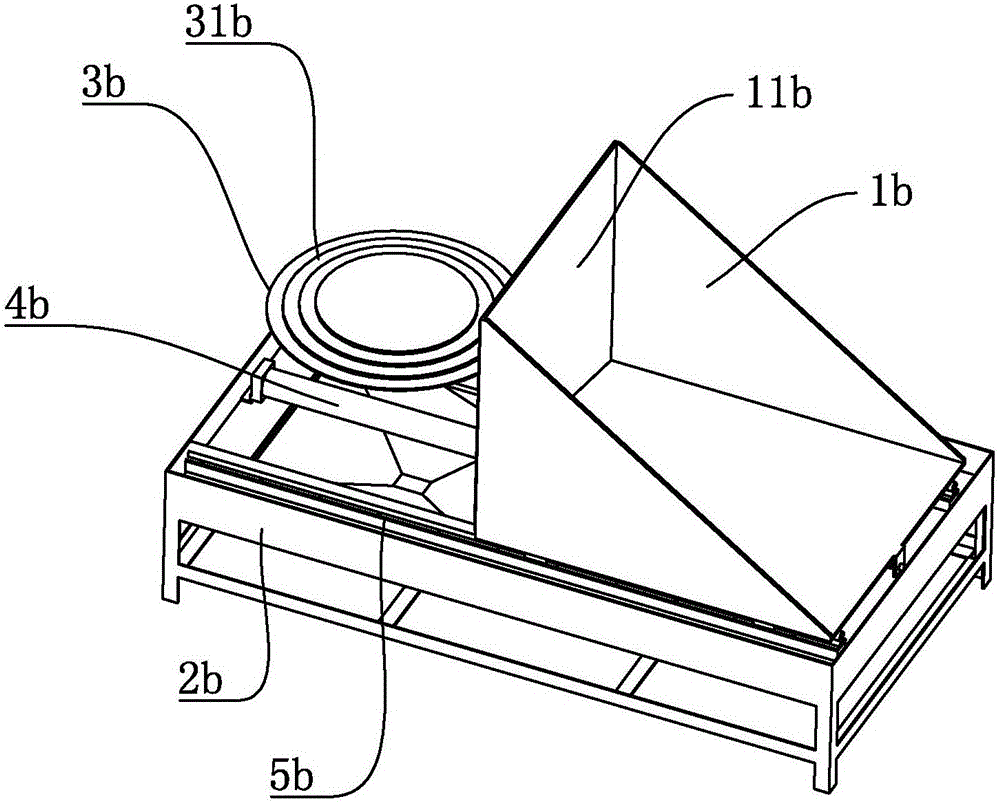

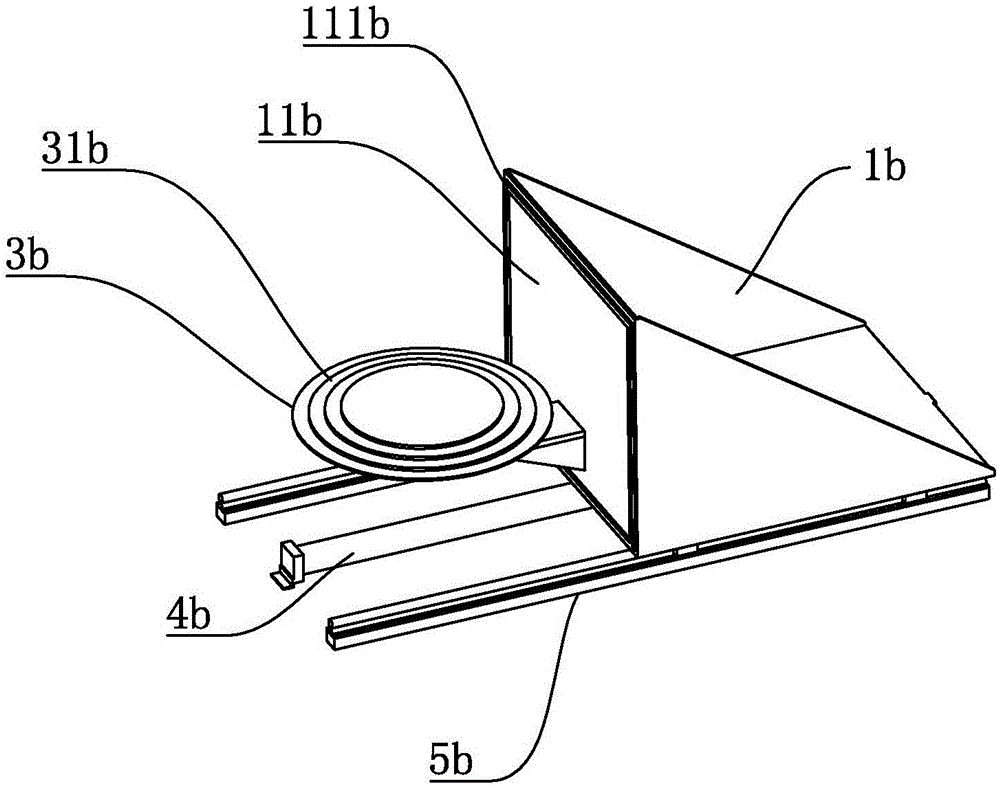

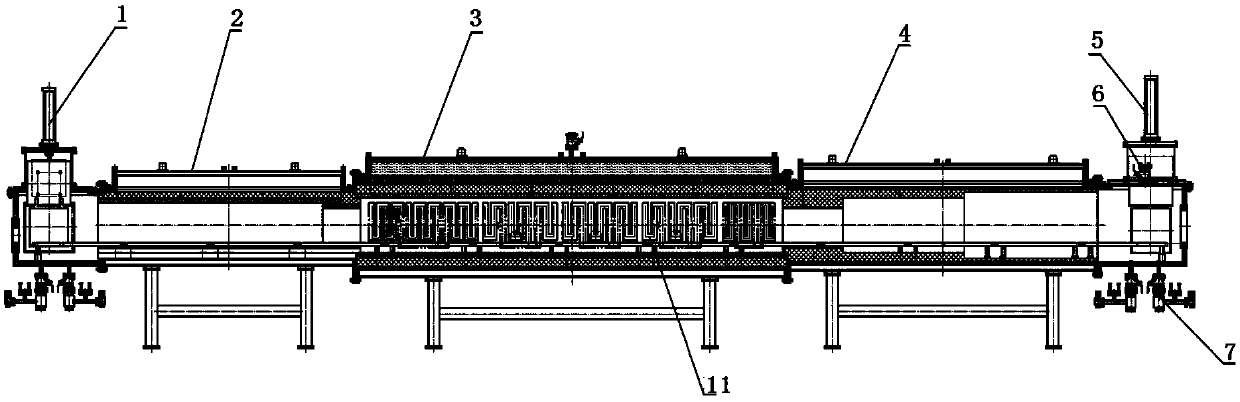

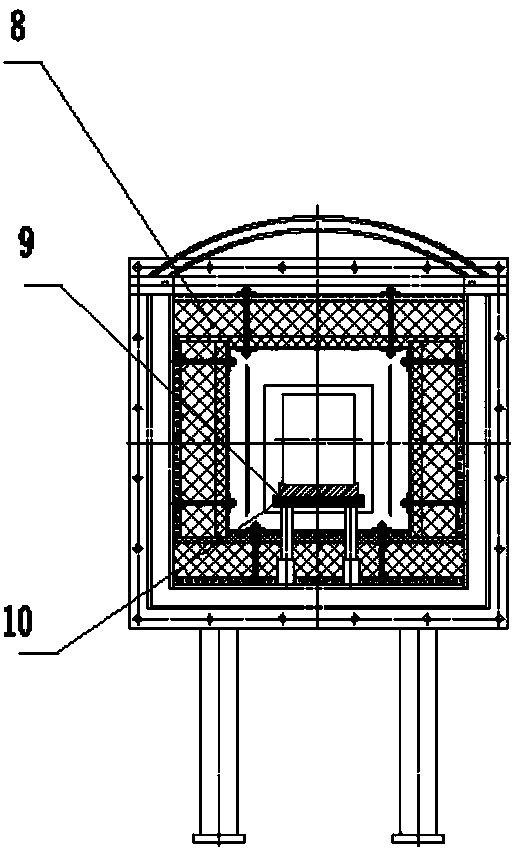

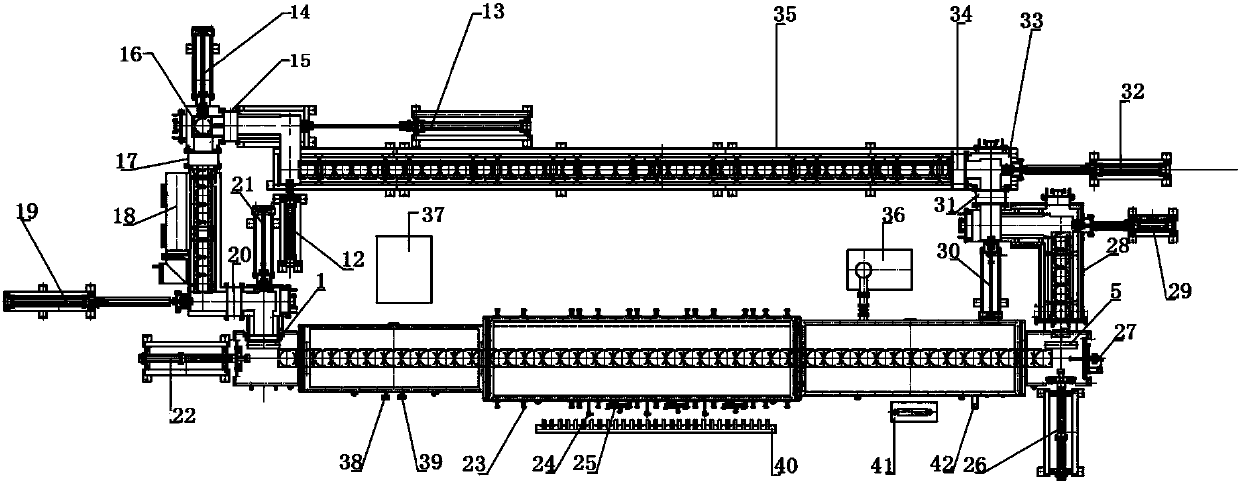

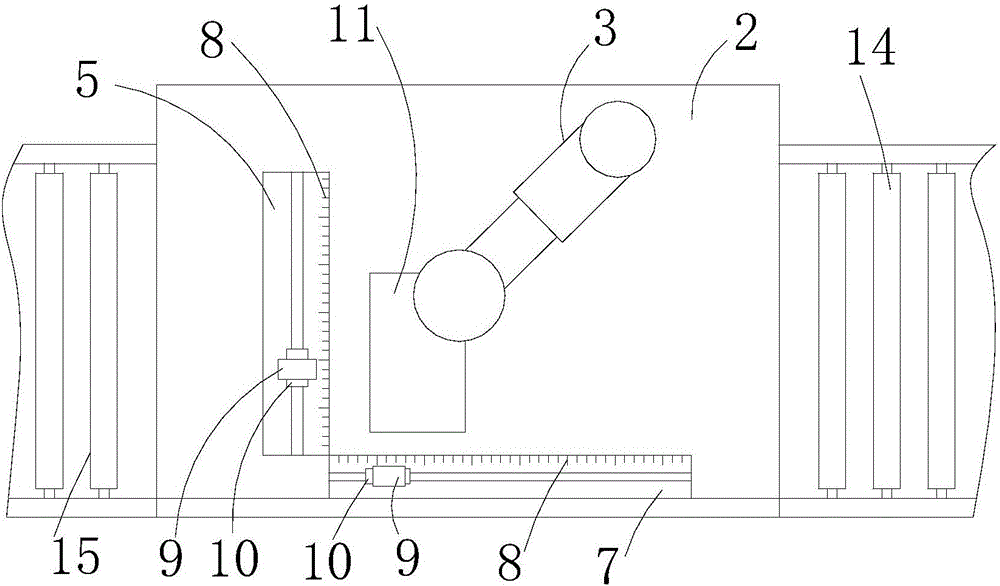

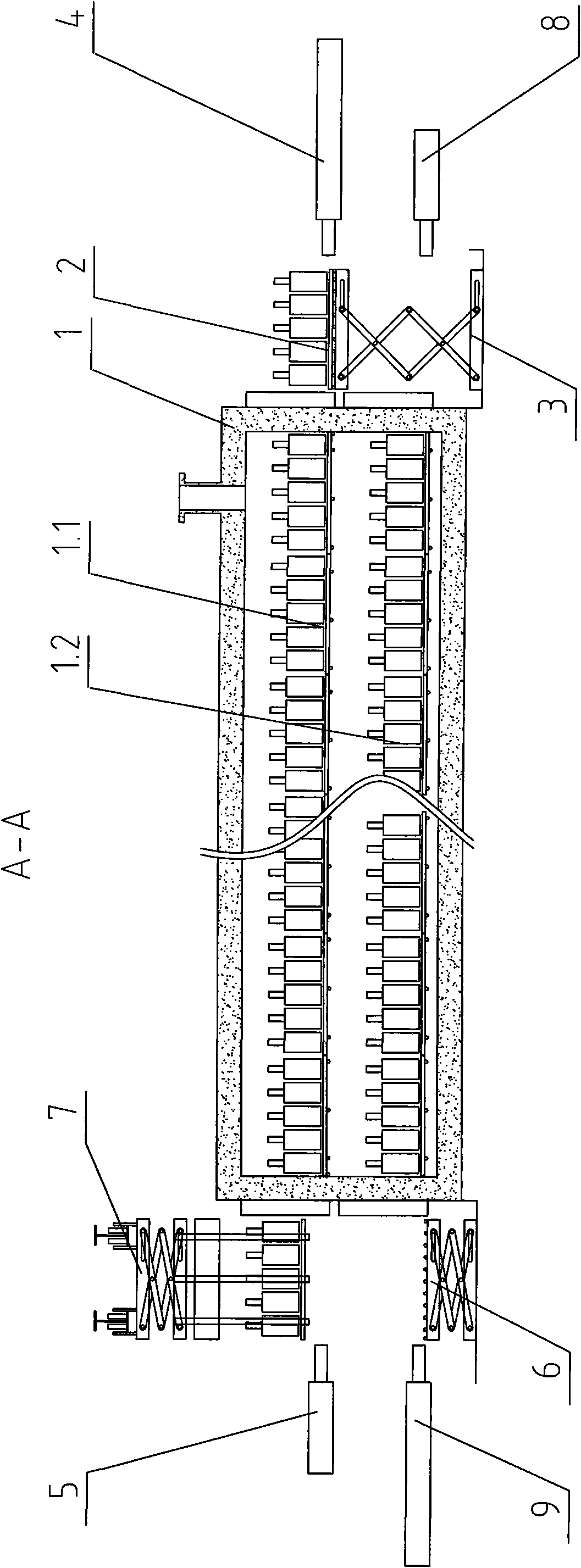

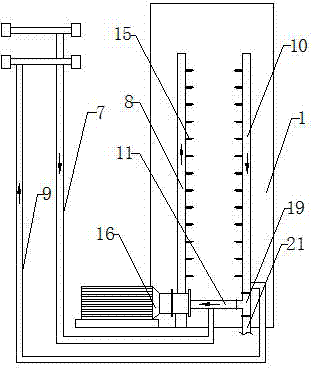

Ultra-high-temperature nitriding continuous tunnel furnace

ActiveCN108020081ASolve the problems of long length, large space occupation and large energy lossRealize fully automatic closed loopFurnace typesEngineeringOxygen

The invention discloses an ultra-high-temperature nitriding continuous tunnel furnace. The furnace comprises an aerobic charging area, a feeding area, a furnace body and a discharging area, wherein the areas are connected in sequence to form a rectangular loop structure, and the areas are independent from one another; the feeding area, the furnace body and the discharging area are of a sealed cavity structure, and the aerobic charging area is of a non-sealing structure; and rails are laid in all the areas, and the materials enter and exit from the areas in a one-way mode. The sintering temperature of the ultra-high-temperature nitriding continuous tunnel furnace can reach 2000 DEG C, and the unique annular structure layout realizes the full-automatic closed circulation of the materials ascompactly as possible, rapid cooling and independent feeding and discharging of the materials in the furnace can be realized, the size is small, and the atmosphere in the furnace is uniform; the circulating production process of discharging the material at one end and feeding the material at the other end can be realized, and the nitriding process of the batch materials is realized; hydraulic propelling is adopted, the whole process is controlled by computers, manual intervention is not needed, and automatic continuous operation is realized; and the furnace is stable and reliable in material running, high in safety performance and low in labor intensity.

Owner:钢研工程设计有限公司

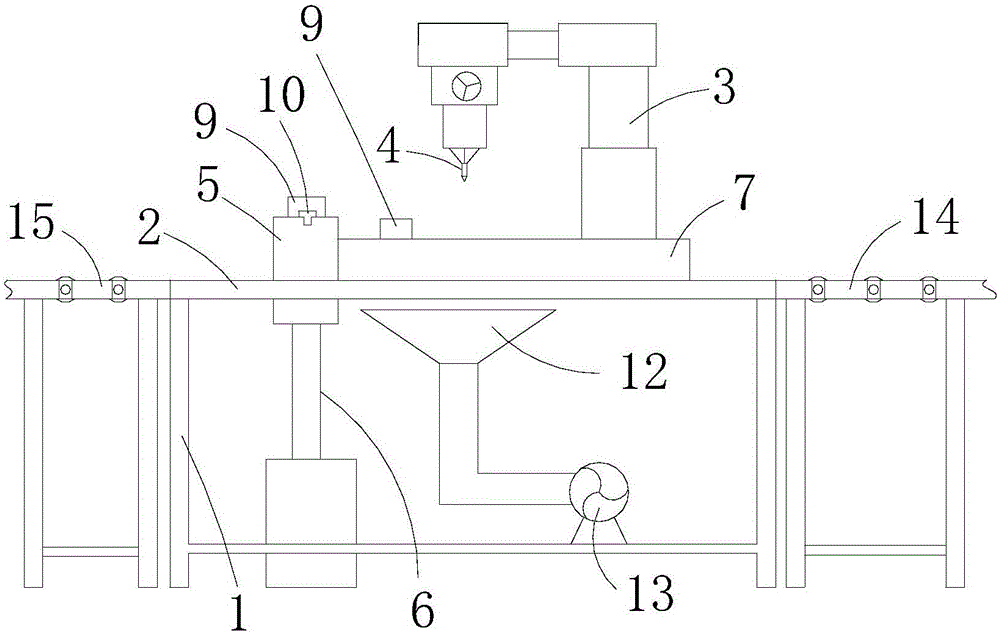

Efficient woodworking drilling machine for costly furniture

InactiveCN106217497ARapid positioningPrecise positioningStationary drilling machinesMeasurement/indication equipmentsCarbonizationHealth hazard

The invention discloses an efficient woodworking drilling machine for costly furniture. The efficient woodworking drilling machine comprises a support, a drilling platform installed on the support, a rotary arm installed on the drilling platform, and a drill bit installed on the rotary arm. A feed slideway is installed on the rear portion of the drilling platform. A discharge slideway is installed on the front portion of the drilling platform. A lifting stop block penetrating through the drilling platform is arranged at the front end of the drilling platform. A side stop block is fixed to the side edge of the drilling platform. The lifting stop block and the side stop block are both provided with scale marks and laser locators. The drilling platform is provided with a drilling opening. A dust suction hood is installed below the drilling opening. The drill bit is provided with a lubricating oil spray pipe. The efficient woodworking drilling machine is simple in structure, convenient to use and capable of locating a wood board needing drilling fast, and dust pollution can be avoided. Health hazards of workers are reduced, meanwhile, feed and discharge are fast, the drilling efficiency is high, and the labor intensity of the workers is relieved. Lubricating oil is added during drilling, so that wood carbonization is avoided, and the machining quality is ensured.

Owner:武侯区华聚家私经营部

Preparation method of tin-based cathode material of high-capacity lithium-ion battery

InactiveCN105810921AGood dispersionImprove conductivityElectrode thermal treatmentSecondary cellsDispersityElectrical battery

The invention discloses a preparation method of tin-based cathode material of a high-capacity lithium-ion battery.The preparation method includes: mixing nano tin and graphite with a pyrolytic carbon organic matter precursor to obtain composite material precursor slurry, performing spraying drying to obtain precursor powder, calcining under inert atmosphere, and grinding to obtain nano tin / graphite composite material wrapped by organic matter pyrolytic carbon.By the preparation method, the dispersity of nano tin in the tin-carbon cathode material can be increased, the material stability during lithium getting off, high conductivity of the material is guaranteed, the pyrolytic carbon wrapping layer effectively wrap the surfaces of the particles of the material, the interface feature of the material can be improved effectively, and the electrochemical performance of the tin-carbon cathode material is increased.

Owner:田东

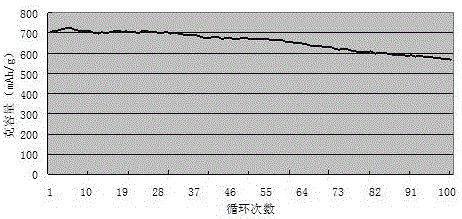

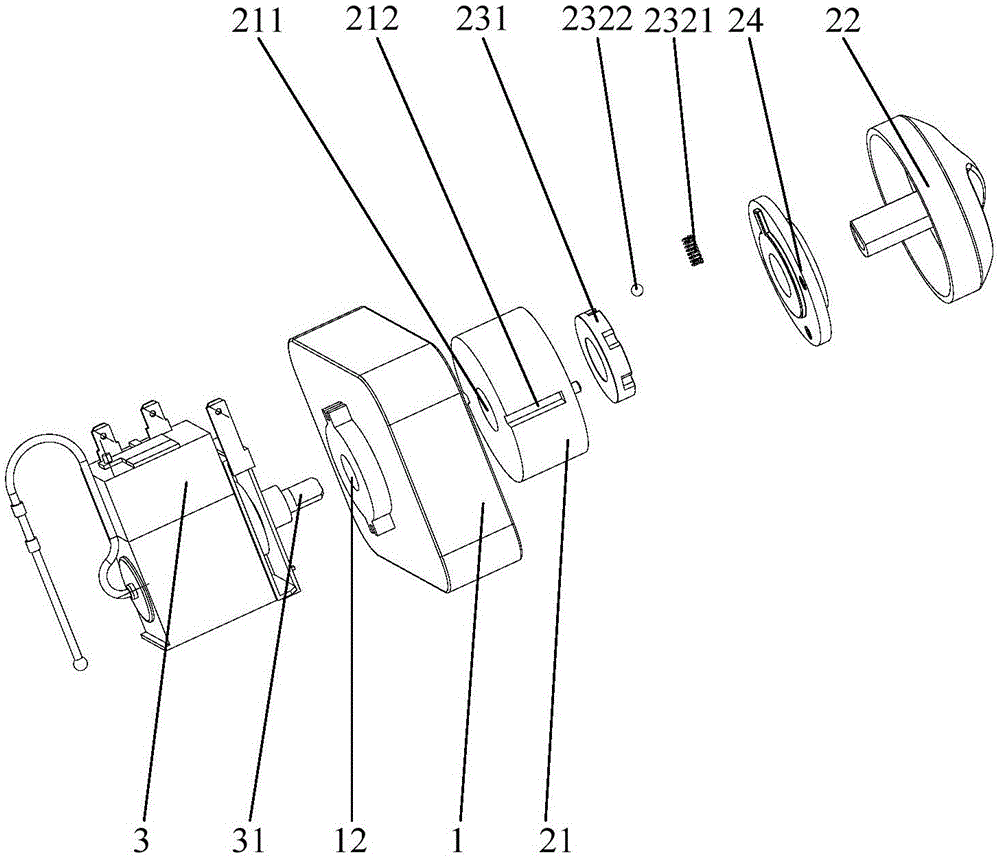

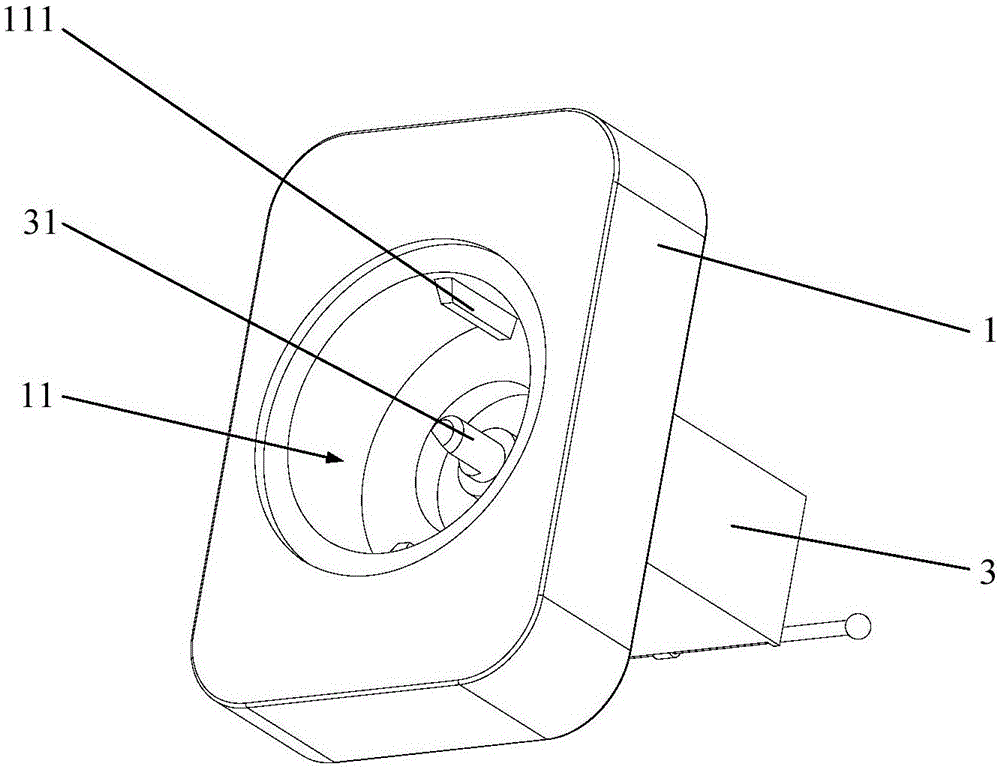

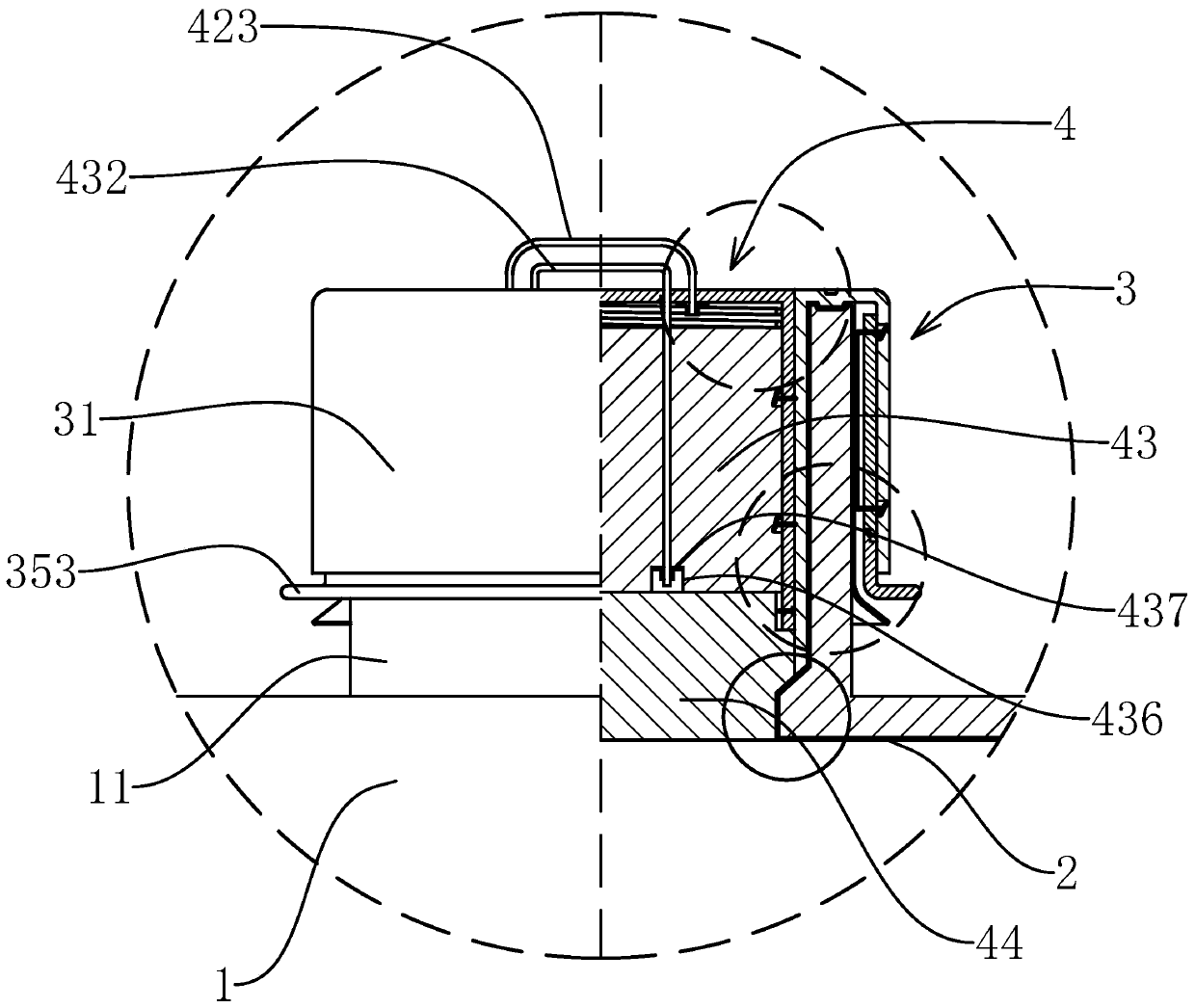

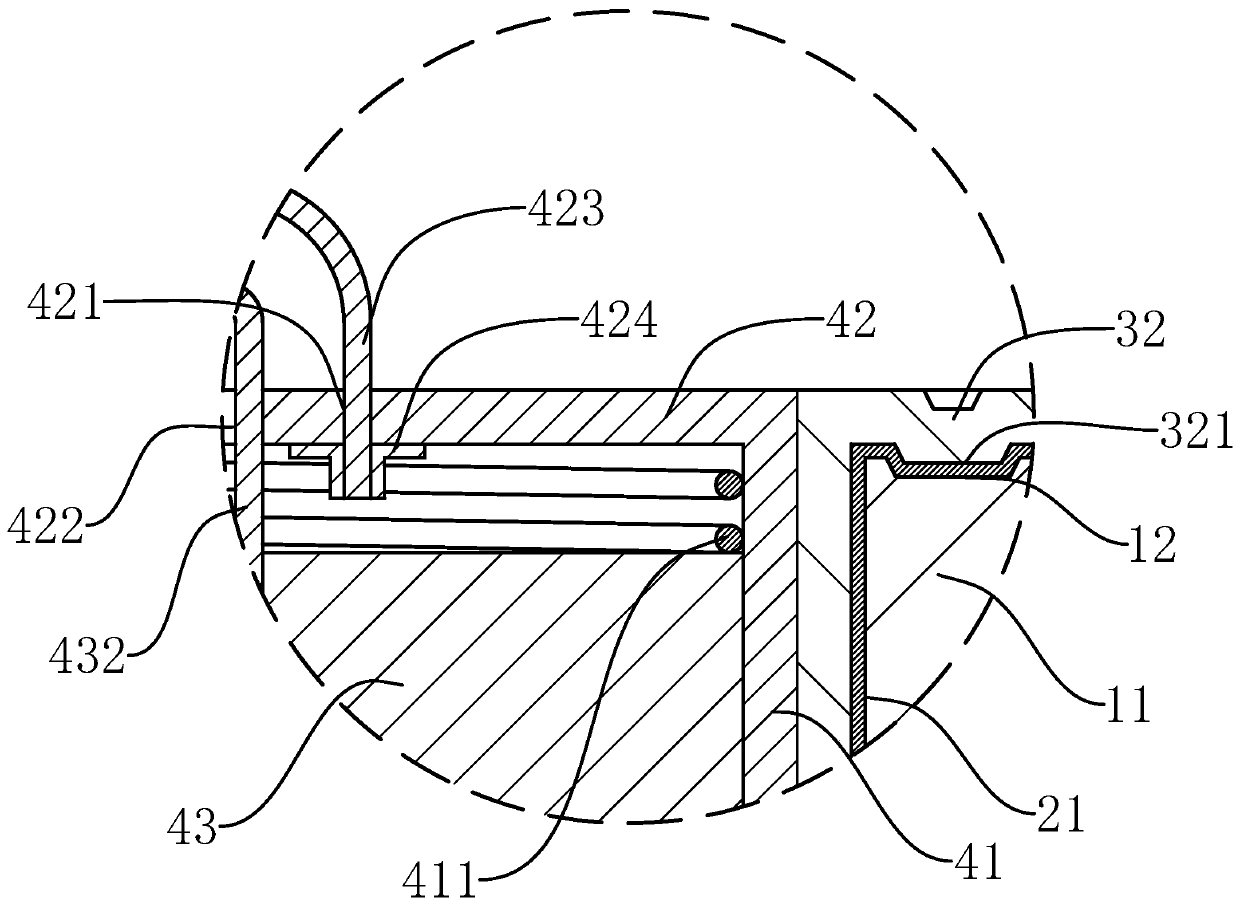

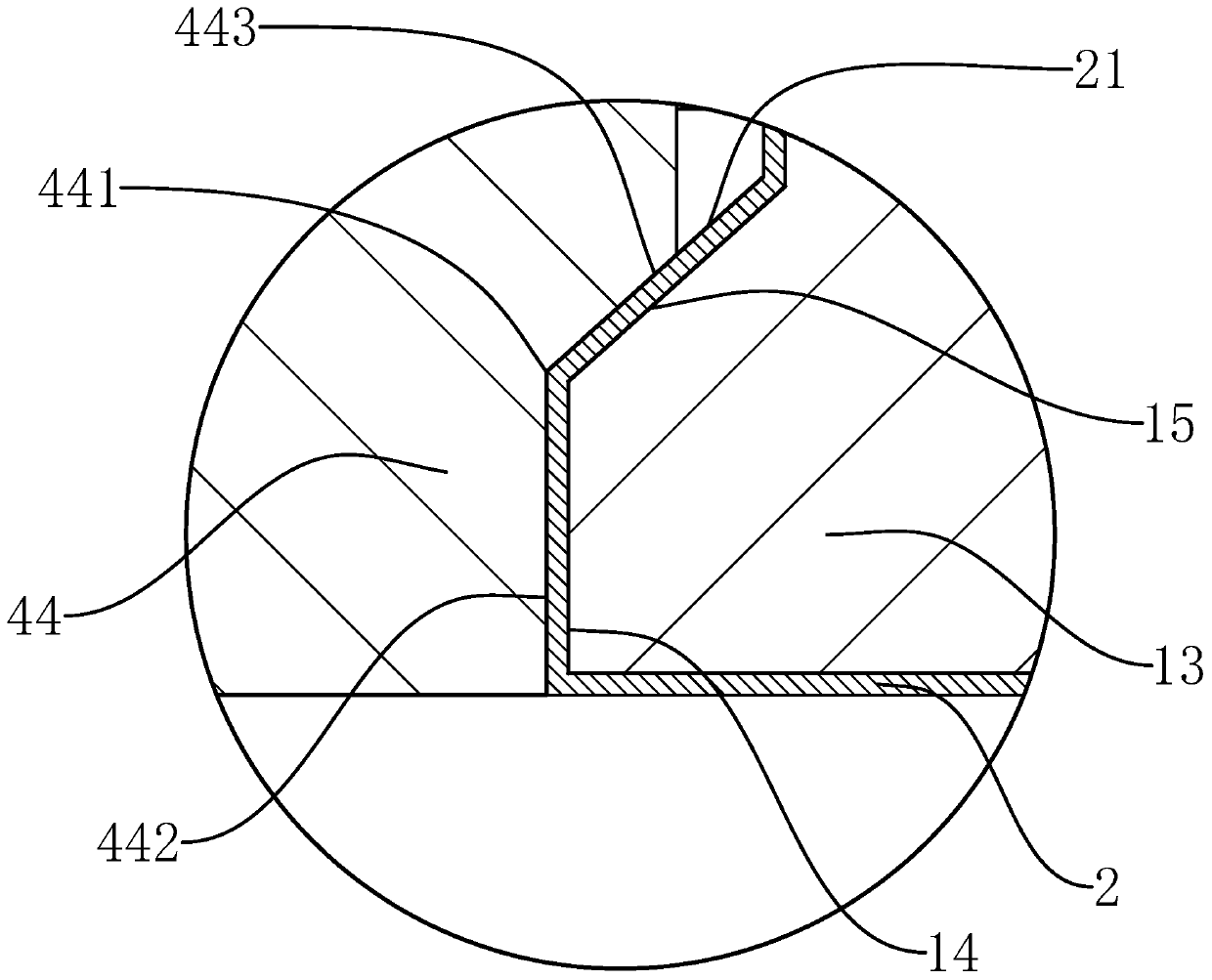

Temperature controller assembly and refrigerator

ActiveCN105043010AImprove flexibilityEasy to rollDomestic cooling apparatusLighting and heating apparatusButt jointEngineering

The invention provides a temperature controller assembly and a refrigerator. The temperature controller assembly comprises a panel, a knob assembly and a temperature controller body. A mounting groove is formed in the panel. The knob assembly comprises a fixed base, a knob body and a rotor assembly, the fixed base is fixed in the mounting groove, and the knob body comprises a torsion cap and a torsion bar. The top end of the fixed base is further provided with a groove, and the rotor assembly is located in the groove, and comprises a rotor body and an elastic clutch portion. Clamping grooves are formed in the outer side wall of the rotor body, the fixed end of the elastic clutch portion is connected with the inner wall of the groove, and the free end of the elastic clutch portion is in butt joint with the clamping grooves. The temperature controller body is connected with the panel, and a rotary shaft of the temperature controller body is connected with the torsion bar. According to the technical scheme, rotating resistance generated when the temperature controller body is adjusted is increased, and the problem that the hand feeling is poor in the rotating adjusting process is effectively solved; and the adjusting experience of a user is improved, the situation that a rotor accidentally rotates under the influence of little external force can be avoided, and the reliability of knob adjustment is effectively guaranteed.

Owner:HEFEI HUALING CO LTD +1

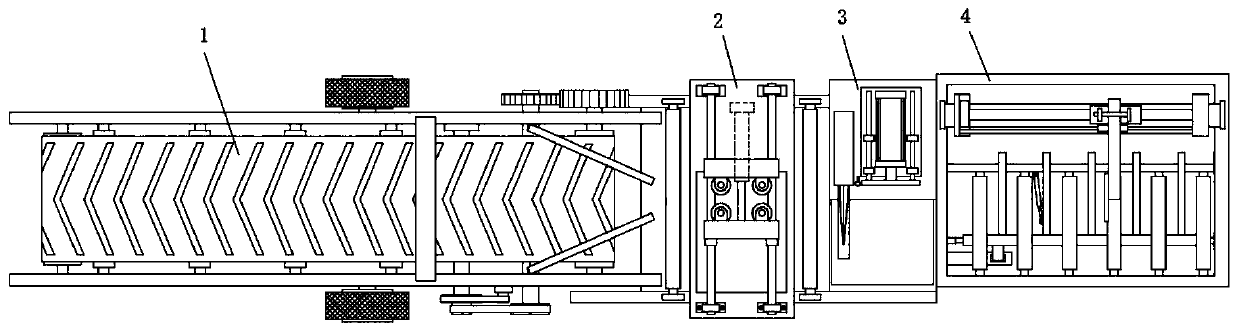

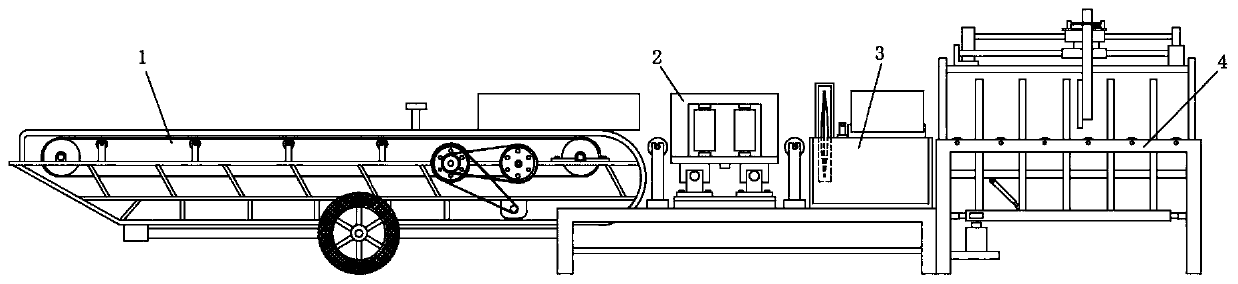

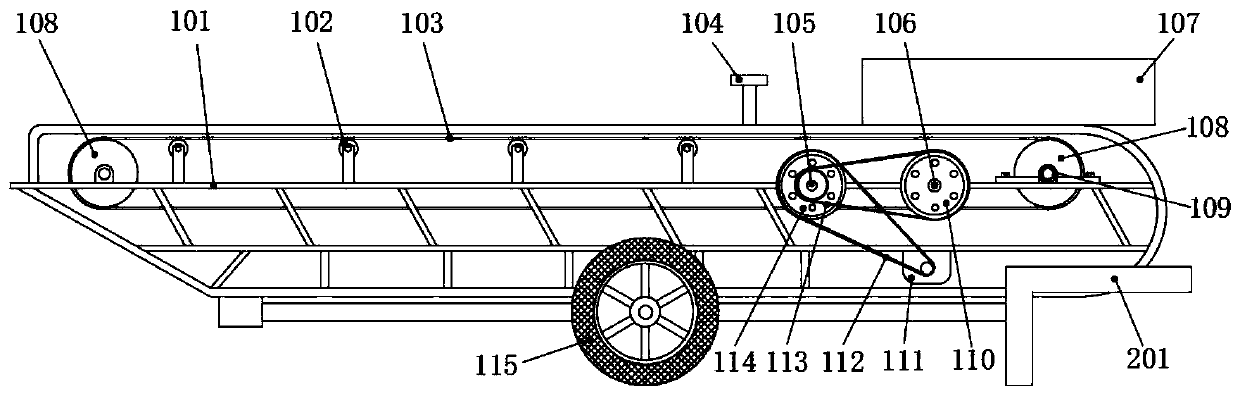

Automatic fixed-section material sawing machine

ActiveCN110053100AImprove labor efficiencyOvercome the shortcomings of slow speed and low efficiencyFeeding devicesCane mechanical workingEngineeringAutomatic processing

The invention discloses an automatic fixed-section material sawing machine which is particularly suitable for automatic processing operations of bamboo wood and can automatically process raw materialslike bamboo. The automatic fixed-section material sawing machine is provided with a feeding mechanism, a clamping mechanism, a sawing-off mechanism and a fixed-section discharging mechanism. The feeding mechanism comprises a conveying belt, and the conveying belt feeds the raw materials into the clamping mechanism. The clamping mechanism comprises a movable clamping base body and a fixed clampingbase body. The movable clamping base body and the fixed clamping base body are matched to clamp the materials and further feed the materials into the sawing-off mechanism. The sawing-off mechanism comprises a saw blade containing cavity. A saw blade is arranged in the saw blade containing cavity and can saw off the raw materials. The fixed-section discharging mechanism comprises a discharging support and a discharging rod. The discharging rod can discharge the sawed bamboo wood. By means of the automatic fixed-section material sawing machine, automatic feeding and discharging can be achievedquickly, labor intensity is low, labor efficiency is high, the lengths of the sawed materials can be adjusted, the desired material lengths can be sawed out, operation is easy, using is made convenient, and the defects that the manual material sawing speed is low and efficiency is also low at present are overcome.

Owner:桃江县湘农机械研制有限公司

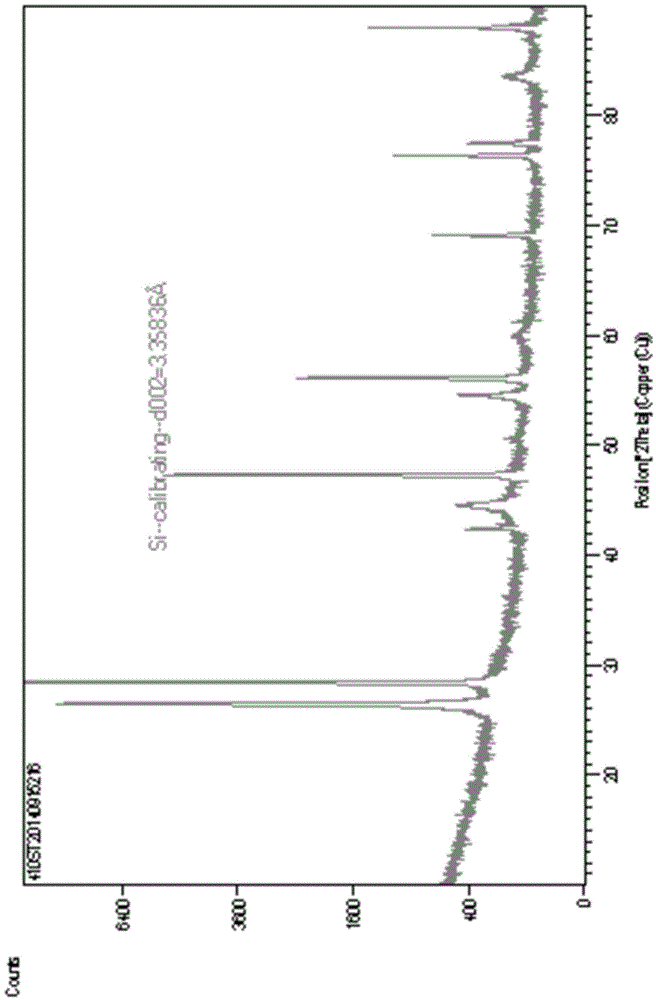

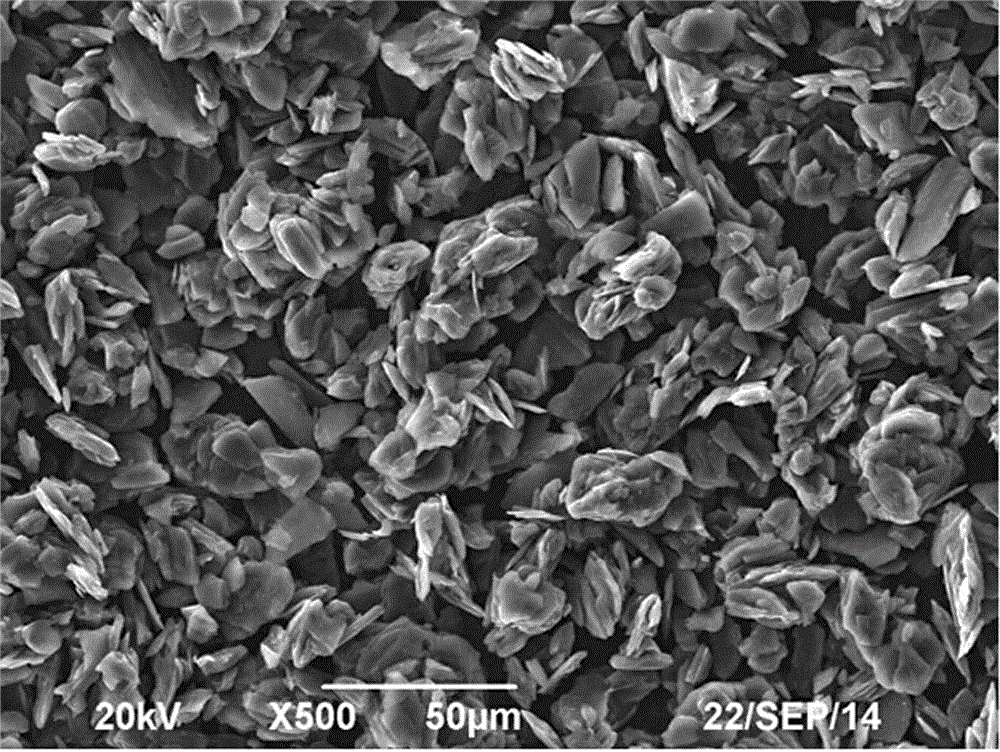

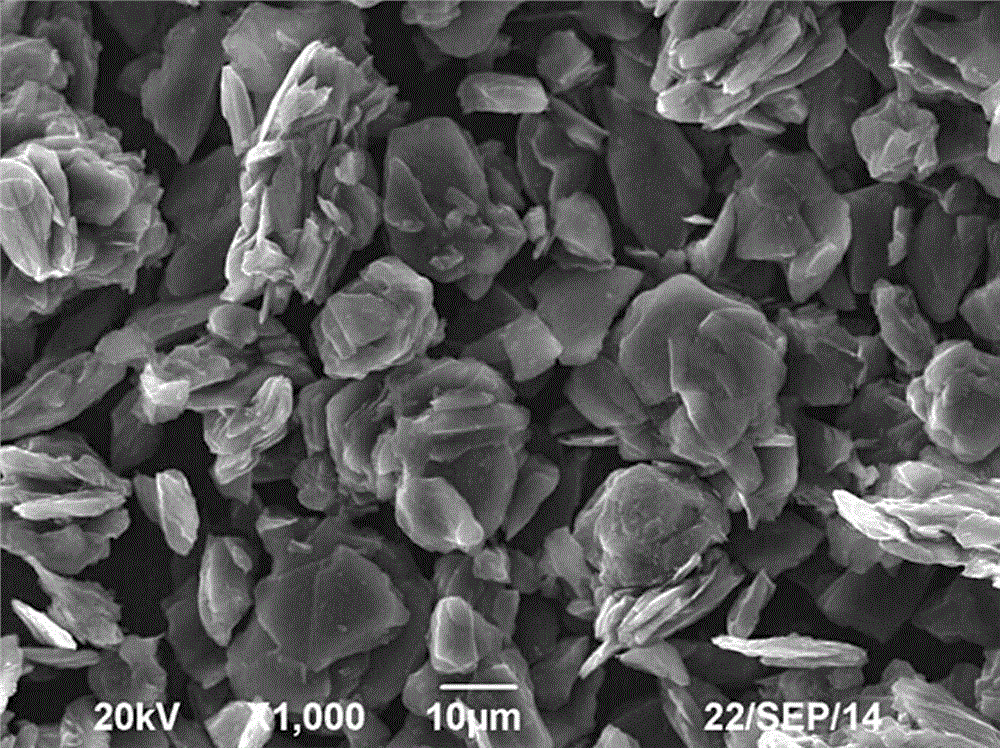

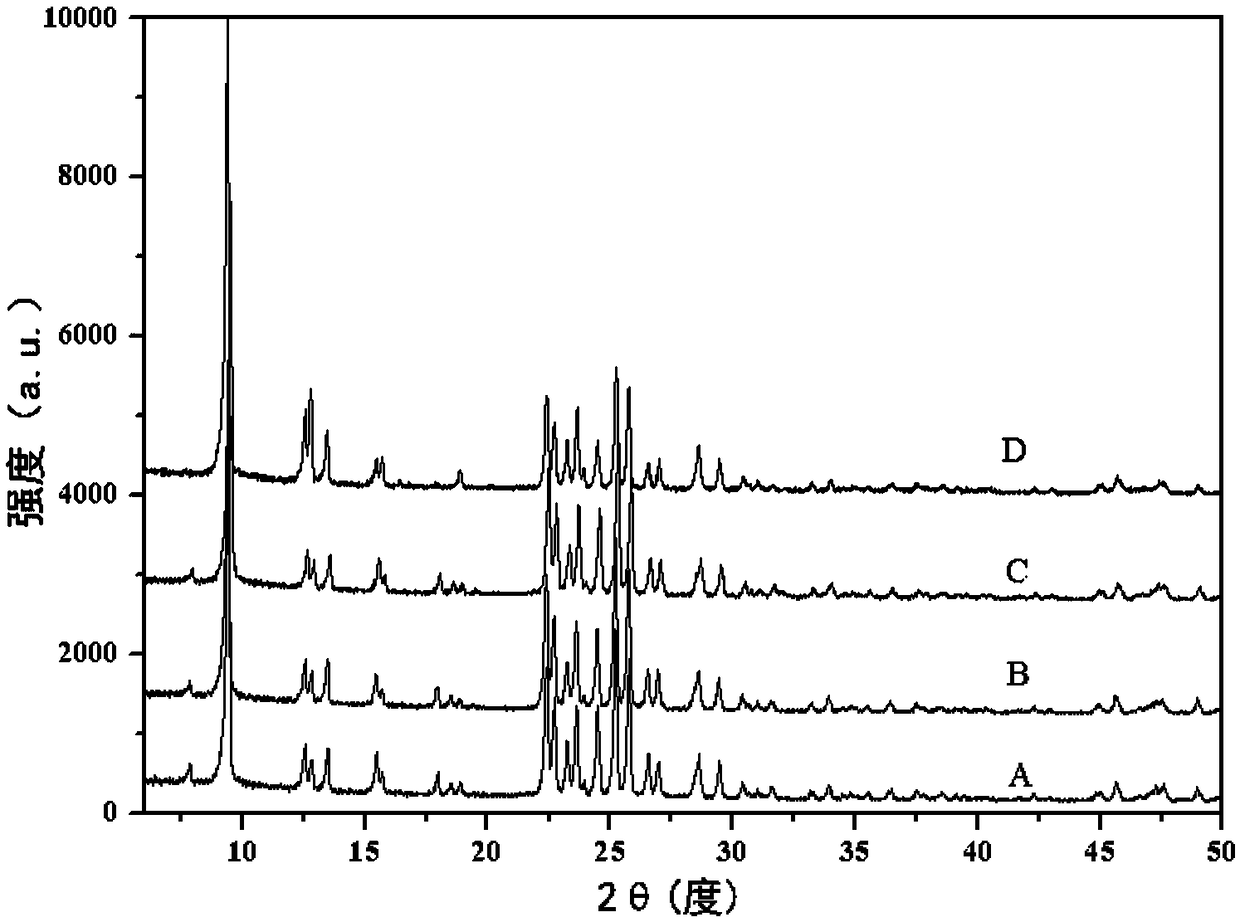

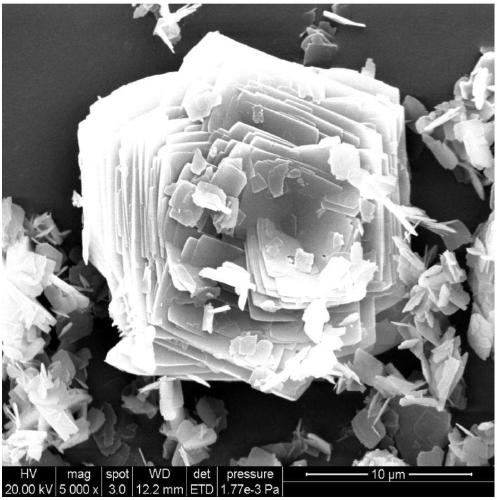

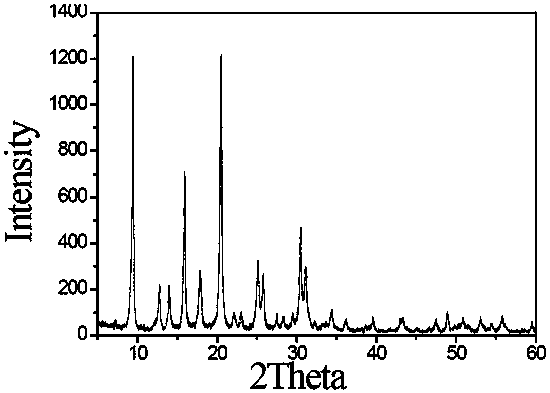

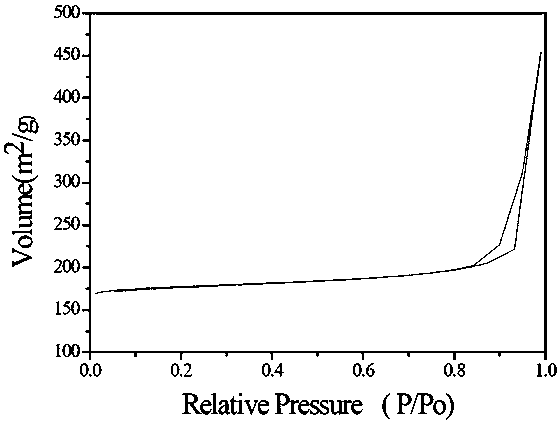

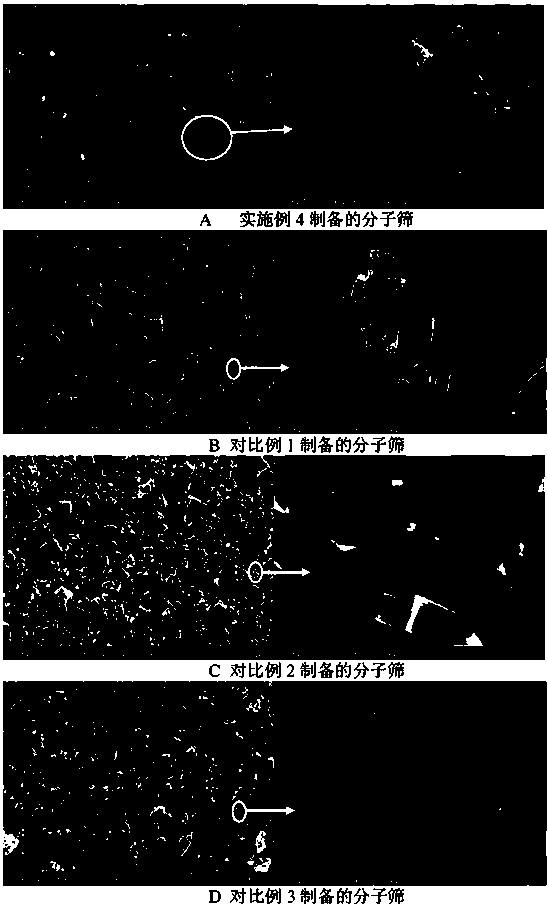

ZSM-35 molecular sieve preparation method

ActiveCN109110779AImprove diffusivityEasy to spreadFerrierite aluminosilicate zeoliteMaterial nanotechnologyMolecular sieveSilicon

The invention relates to a ZSM-35 molecular sieve and a preparation method thereof. The method comprises: carrying out mixing gelling on a silicon source, an aluminum source, an alkali, water, an organic template agent I and an organic template agent II, carrying out hydrothermal crystallization, filtering, washing, drying, and roasting to obtain a ZSM-35 molecular sieve, wherein the ZSM-35 molecular sieve has a sheet-like structure along the c-axis direction. According to the present invention, through the synergistic action of the organic template agent I and the organic template agent II, the prepared nano-sheet-like ZSM-35 molecular sieve has characteristics of small particle size and high specific surface area, wherein the diffusion rate is obviously improved through the small particle size, such that the reactant molecules and the product molecules can rapidly enter and exit the molecular sieve pore channels so as to reduce the occurrence probability of carbon deposition, the gapbetween the molecular sieves is large, and the thickness and the particle size are small so as to prolong the regeneration cycle of the catalyst and improve the selectivity of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

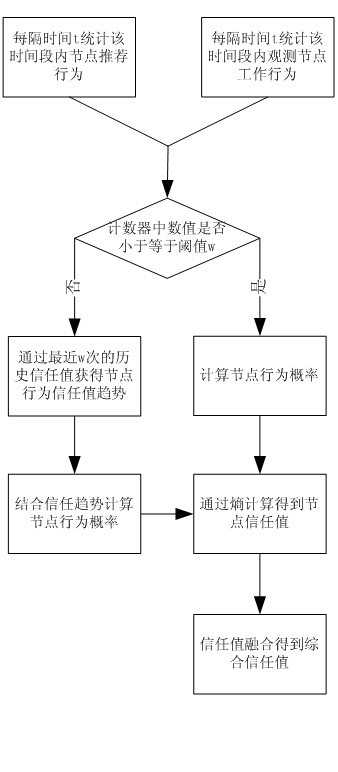

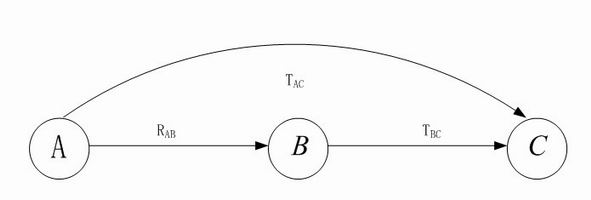

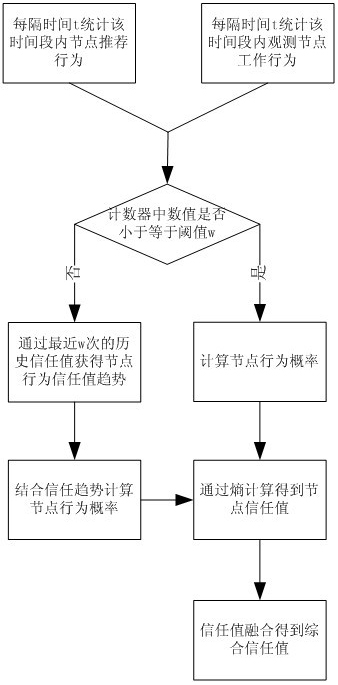

Trust construction method for accelerating trust convergence

InactiveCN102045707AImprove throughputImprove efficiencyNetwork topologiesSecurity arrangementCurrent timeNetwork routing

The invention discloses a trust construction method for accelerating trust convergence. In the trust construction method, in view of the fact that the trust relation among various nodes of an MANET (mobile ad hoc network) has dynamics, the trust relation can dynamically change at all times along with various factors such as network topological transformation, member variation, energy attenuation and the like, thus the history trust values of the nodes in the network are counted, the variation tendency of the trust values in the latest time period is obtained through analyzing the history trust values, and the tendency of the trust values is generated by the method provided by the invention, so that the trust values of the nodes at the current time are calculated by using the tendency of the trust values, and the trust values comprises direct trust values and recommend trust values, thereby effectively and fast estimating the newest comprehensive trust value of each dynamically-changednode. By using the trust construction method, bad nodes can be fast detected, the packet loss rate is inhibited, the transmitting rate is promoted, and the throughput of the whole network and the efficiency of searching routes can be finally improved. Thus, the trust construction method has important practical value in an actual network route.

Owner:HUAZHONG UNIV OF SCI & TECH

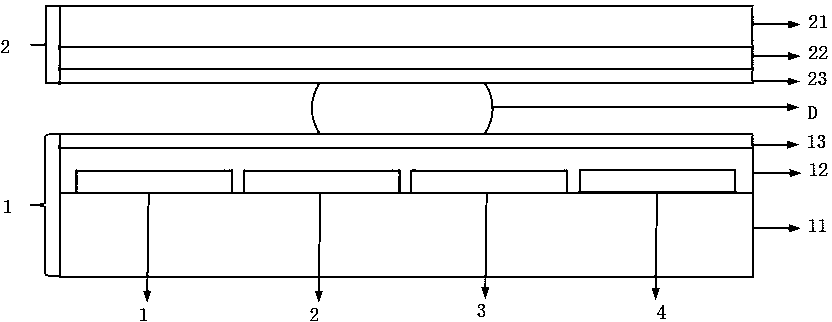

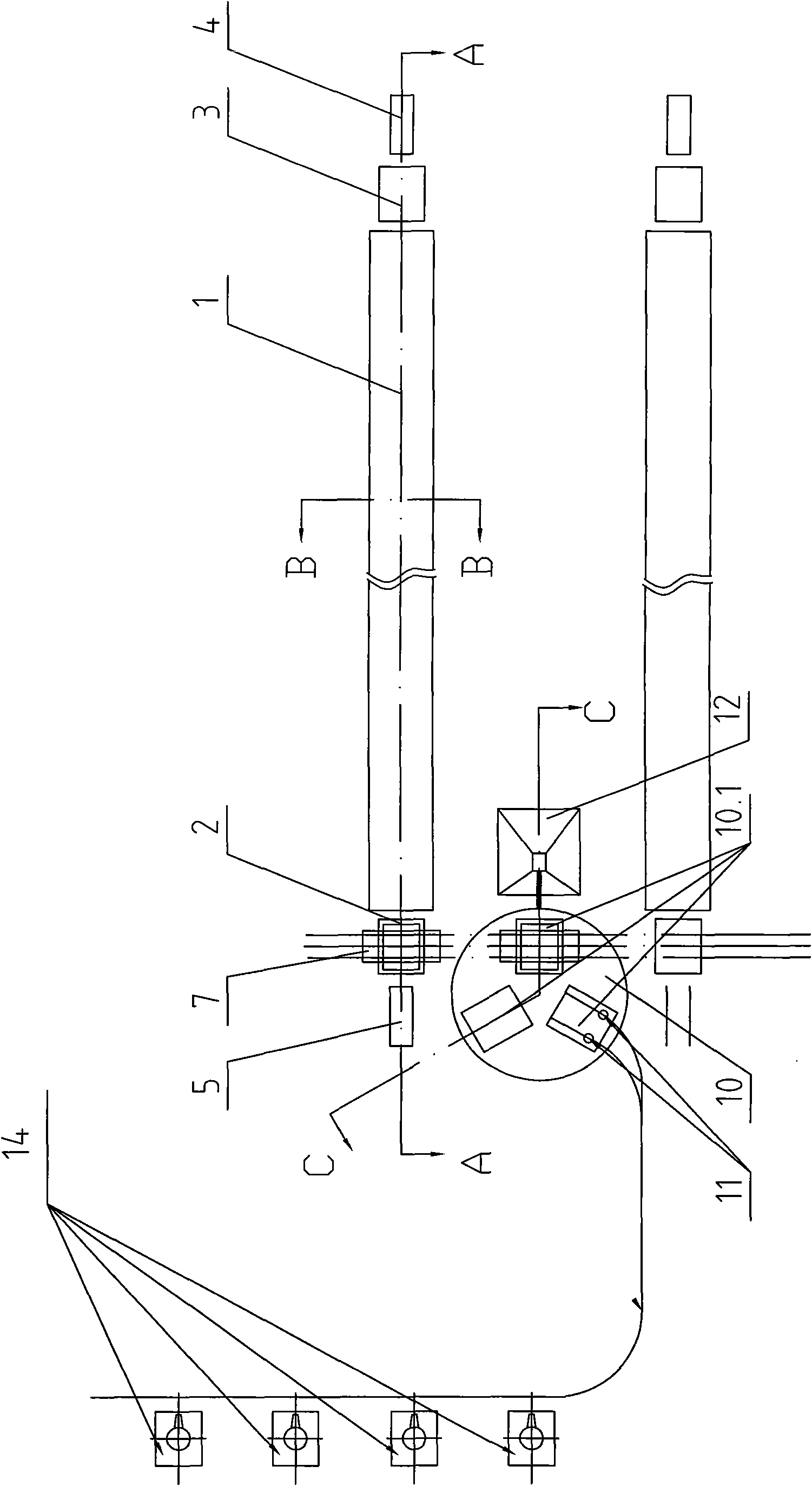

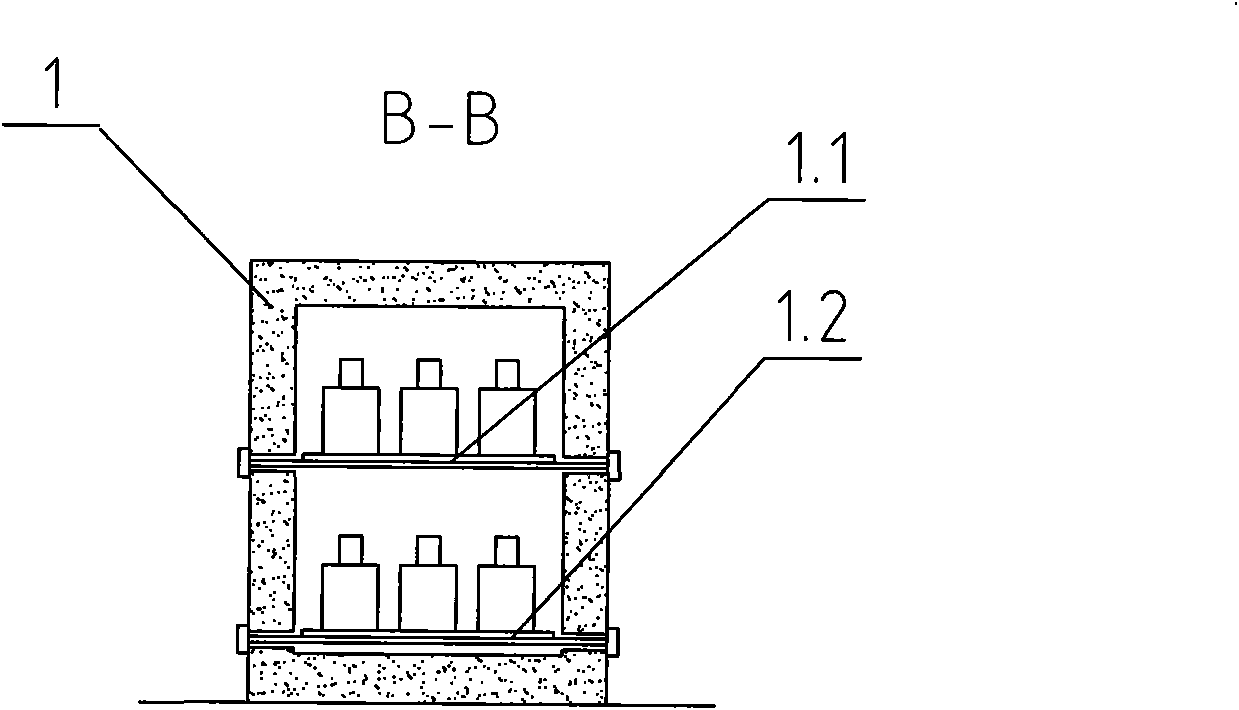

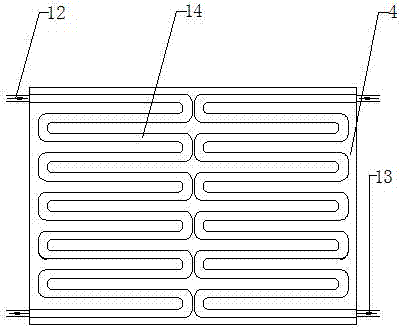

Energy-saving roasting method for investment casting shuttering

InactiveCN101618431AQuick in and outHigh degree of mechanizationFoundry mouldsFoundry coresMetallurgyInvestment casting

The invention discloses an energy-saving roasting method for an investment casting shuttering, which comprises the following steps: fully placing trays (2) provided with shuttering to be roasted on an upper-layer roller way (1.1) in a heat exchange furnace (1); fully placing trays (2) provided with the cast shuttering on a lower-layer roller way (1.2) of the heat exchange furnace (1); roasting the shuttering to be cast by using accumulated heat of the cast shuttering; pushing the trays (2) provided with the shuttering to be roasted onto the lower-layer roller way (1.1), and performing sand filling, casting and sand falling on the roasted shuttering on an interlocking machine (10); and pushing the trays (2) provided with the cast shuttering onto the lower-layer roller way (1.2). The method has high heat efficiency, low energy consumption and low cost.

Owner:应寒冰

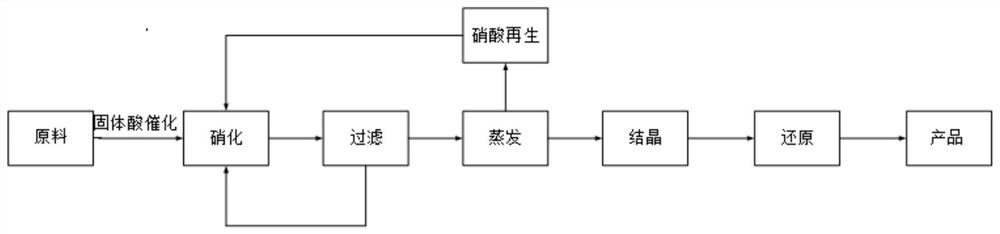

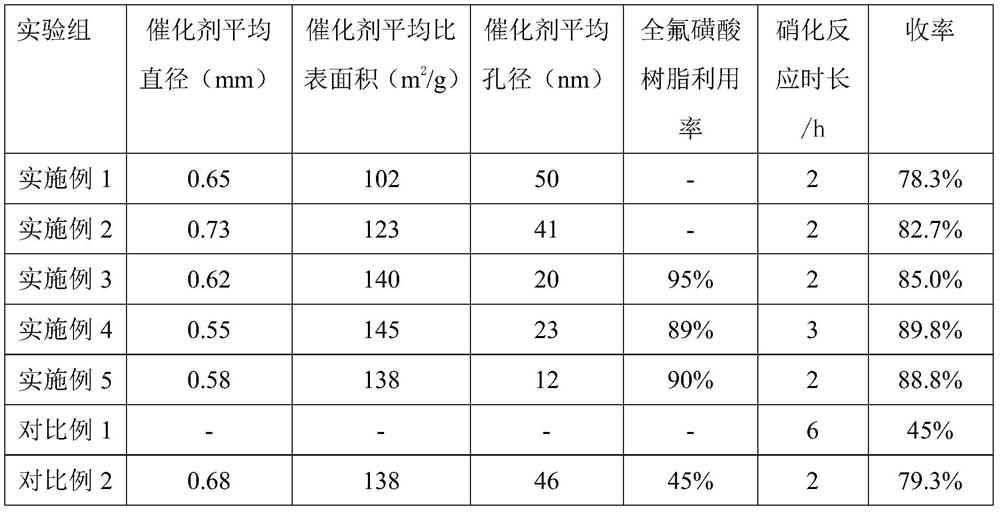

Preparation method of diamino diphenyl ether

ActiveCN112876367AImprove convenienceThe preparation process is environmentally friendlyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDiphenyl etherEther

The invention provides a preparation method of diaminodiphenyl ether. The method comprises the following steps: under the catalysis of solid acid, mixing aromatic ether and nitric acid for nitration reaction; carrying out hot filtration on the nitration reaction product, recovering the filtrate, and carrying out post-treatment on the filtrate; and reducing the filtrate subjected to post-treatment to obtain the diamino diphenyl ether. According to the invention, the requirement of nitration reaction on the concentration of nitric acid is greatly reduced, the yield of the diamino diphenyl ether is increased, and the preparation process is environmentally friendly, efficient and low in cost.

Owner:泰兴中科艾德膜材料科技有限公司 +1

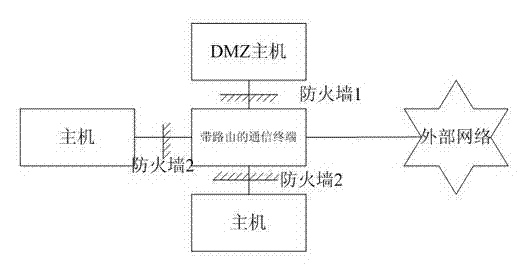

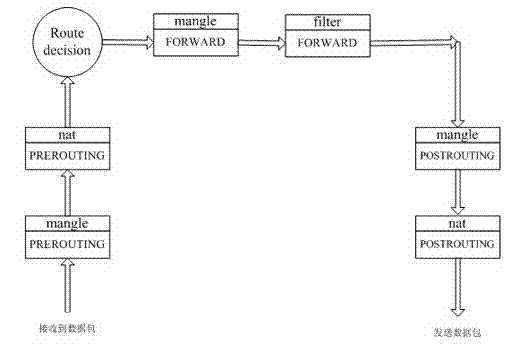

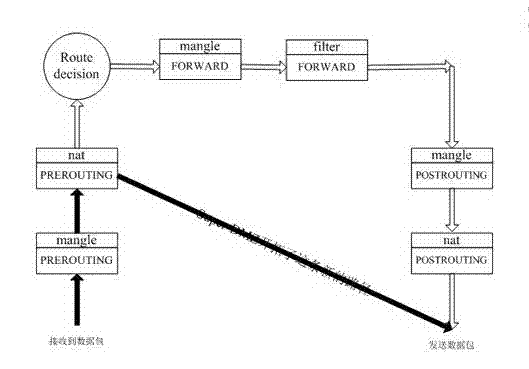

Method for realizing strengthening of demilitarized zone (DMZ) of network

The invention relates to a method for realizing the strengthening of a DMZ of a network. A host computer in the DMZ is connected with a wide area network (WAN) through a communication terminal having a routing function, and an internet protocol (IP) address of a DMZ host computer is set to be identical to that of a WAN interface of the communication terminal. Since the IP address of the DMZ host computer is set to be identical to that of the WAN interface of the communication terminal, a data packet passing in and out of the DMZ host computer can be rapidly completed.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

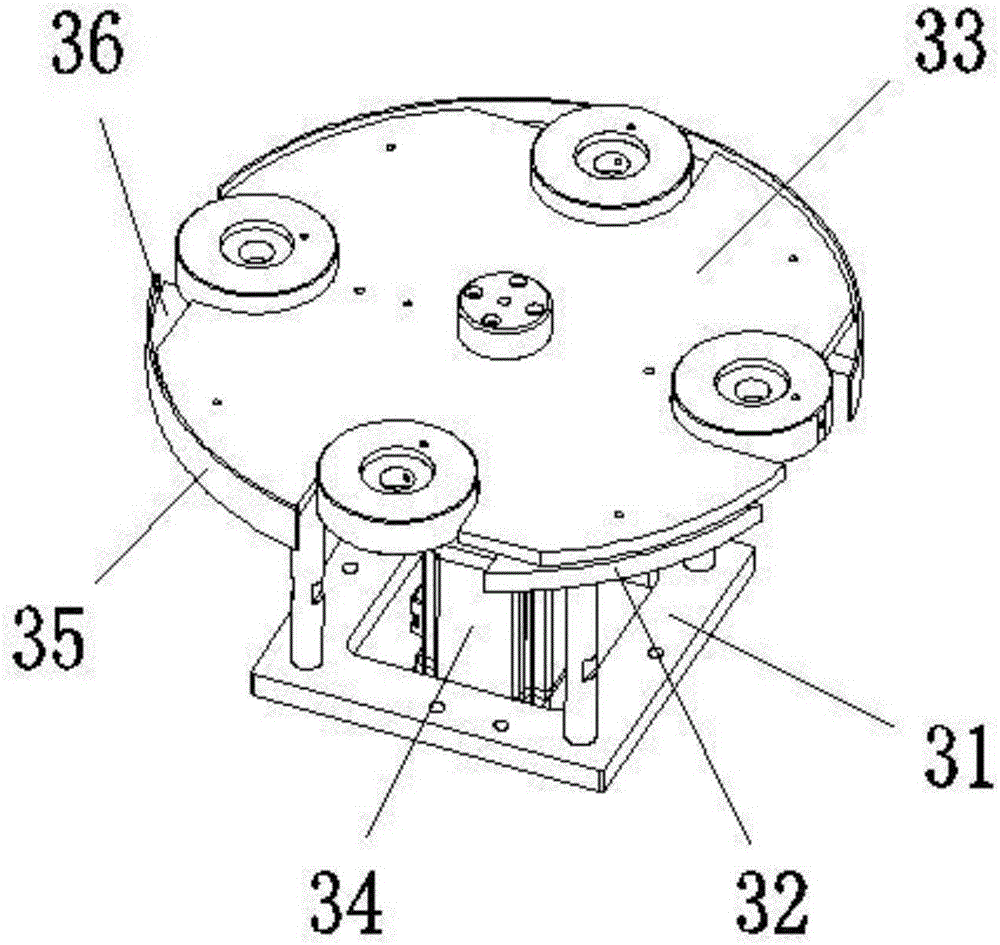

Station switching assembly of fully-automatic polishing machine for rolling wheels

InactiveCN106737067APrevent slippageQuick in and outGrinding machinesGrinding feedersEngineeringFully automatic

The invention discloses a station switching assembly of a full-automatic polishing machine for rolling wheels. The station switching assembly comprises a rotary disc support, and the rotary disc support is fixed; a supporting disc, a switching disc and a rotary disc driving device are arranged on the rotary disc support; and four rolling wheel switching grooves are formed in the switching disc. According to the station switching assembly of the full-automatic polishing machine for the rolling wheels, the rotary disc driving device on the rotary disc support drives the switching disc to rotate so that rapid station switching for rolling wheel workpieces in the rolling wheel switching grooves can be realized, the rolling wheel workpieces are supported by the supporting disk in the switching process, in addition, protection arms can be arranged to prevent the rolling wheels from slipping off, avoiding grooves can be further formed, and therefore the rolling wheel workpieces can be conveniently and quickly moved in and out of the rolling wheel switching grooves, and the machining efficiency can be improved.

Owner:苏州市爱司特塑胶五金有限公司

Terminal crimping quality assessment apparatus, terminal crimping quality assessment method and terminal crimping system

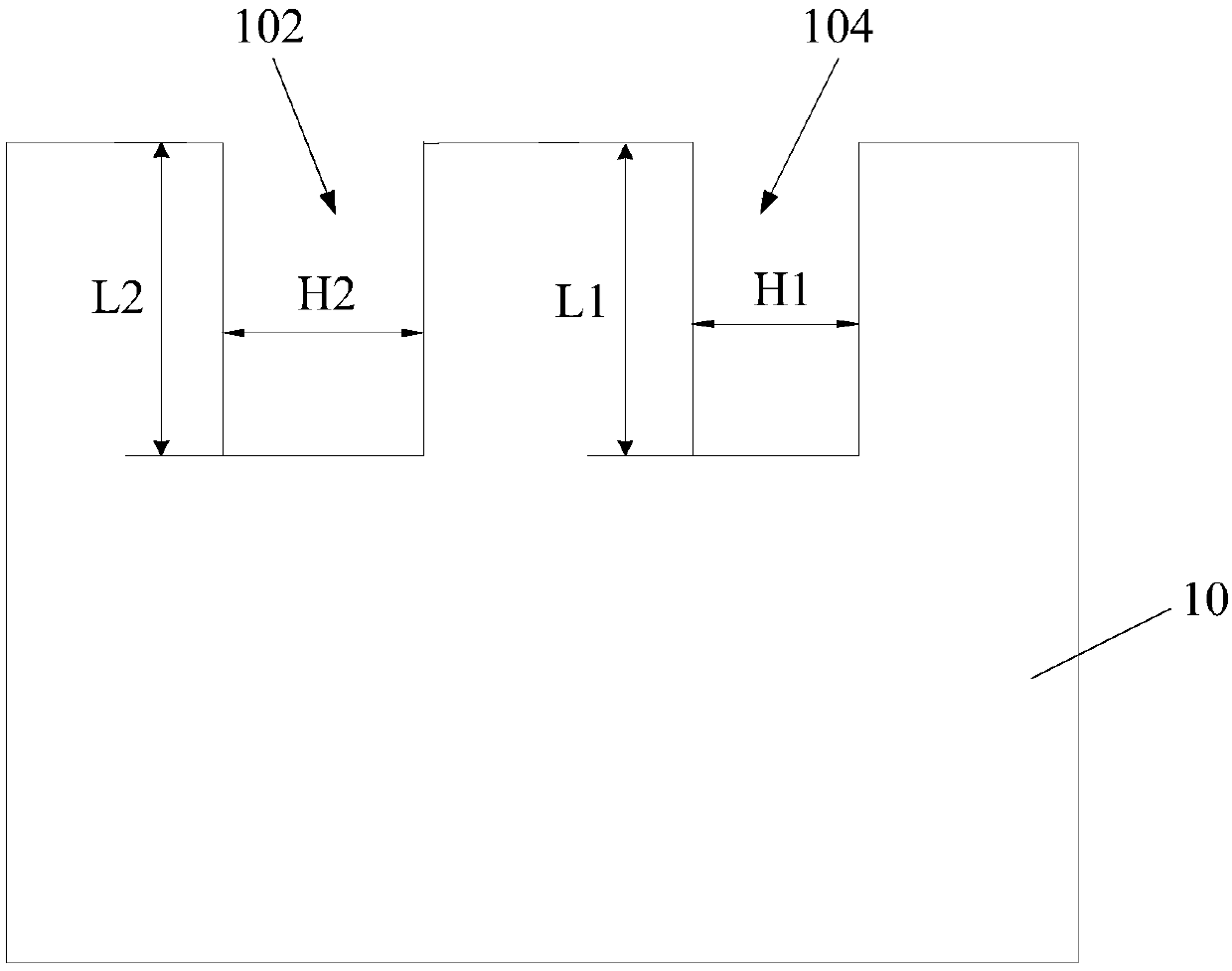

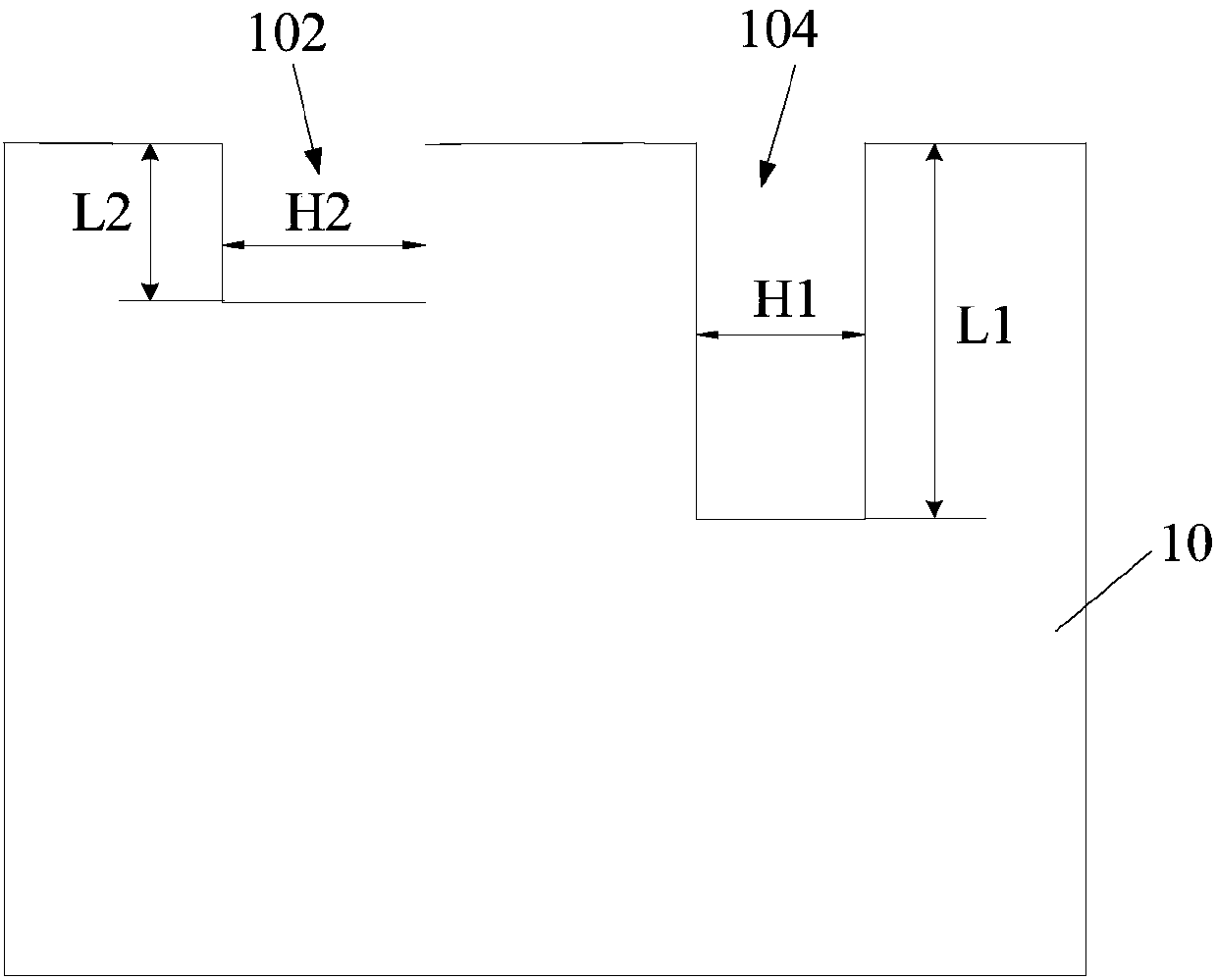

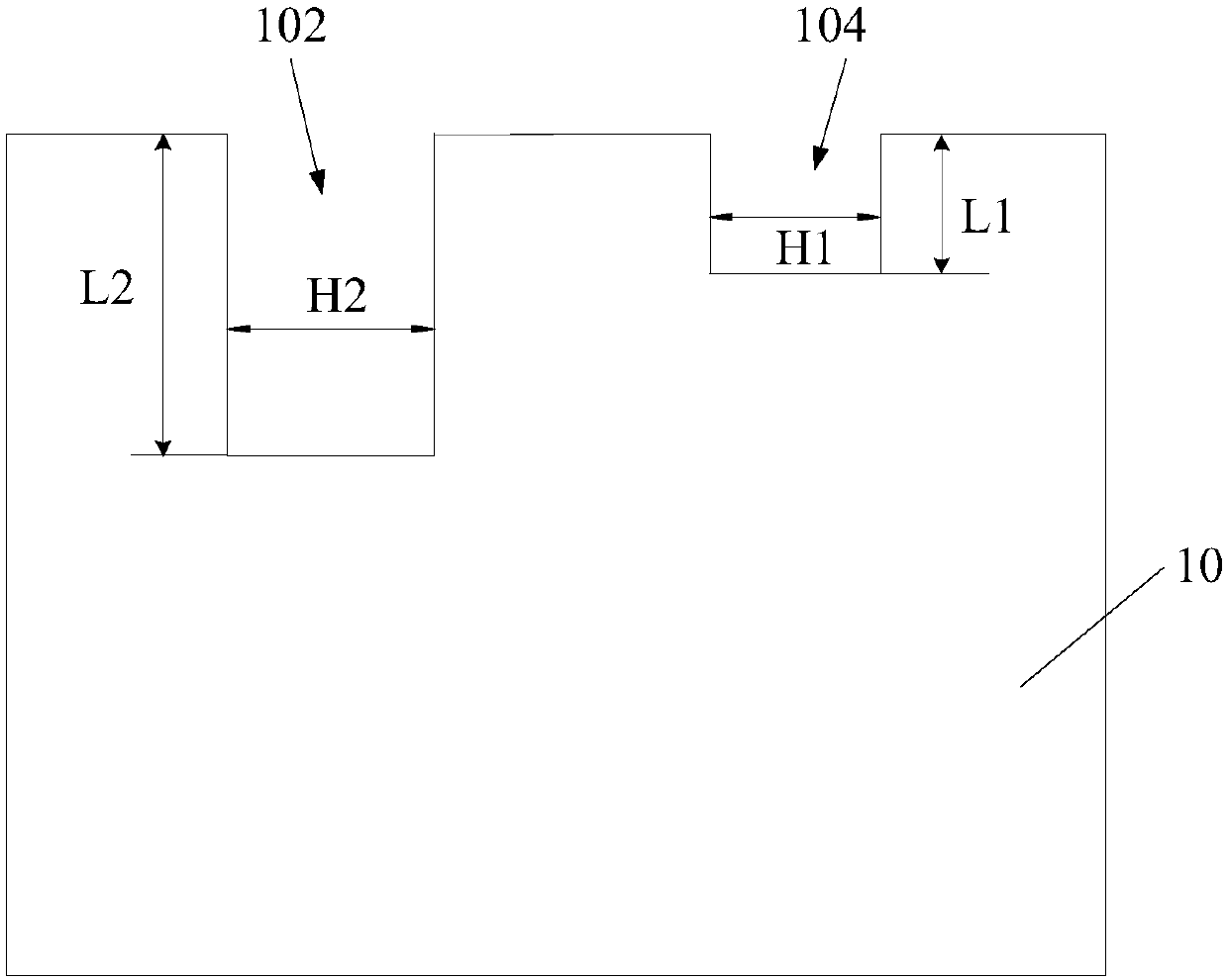

ActiveCN108534637AIntuitive judgment of crimping qualitySolve the bad influence of crimpingMechanical thickness measurementsLower limitQuality control

The invention provides a terminal crimping quality assessment apparatus, a terminal crimping quality assessment method and a terminal crimping system. The terminal crimping quality assessment apparatus includes a testboard, wherein a measurement groove is formed in the testboard; the width direction of the measurement groove is corresponding to the height direction of a core wire crimping portionof a terminal; the measurement groove includes a first segment and a second segment; the width of the inlet of the first segment is equal to the upper limit of the qualified crimping height of the core wire crimping portion; the width of the other portions is greater than or equal to the upper limit, and the depth of the first segment is greater than or equal to half of the crimping width of the core wire crimping portion; and the width of the inlet of the second segment is equal to the lower limit of the qualified crimping height, and the width of each of the other portions is greater than orequal to the lower limit, and the depth of the second segment is greater than or equal to half of the crimping width of the core wire crimping portion. The terminal crimping quality assessment methodhas the advantages of having no demand for destroying the sample so as to reduce the production cost, being high in detection efficiency and short in the test period, being able to realize full inspection coverage of the terminal quality, and being suitable for being included in the QC Quality Control) process of mass production.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Method for video monitoring of community strangers

InactiveCN107545624ADesign scienceEasy to operateClosed circuit television systemsIndividual entry/exit registersPoint of entryDisplay device

The invention provides a method for video monitoring of community strangers. An access control system is arranged at an entrance of the community, photograph cameras are respectively arranged in two sides of the access control system, and a central monitoring chamber is arranged and comprises a microprocessor module and a display and a memory connected to the microprocessor module. Floors in the community are numbered, cameras are arranged at entrances of all the floors to cover the entrance ranges, and the access control system, the cameras and the photograph cameras are respectively communicated with the microprocessor module. The memory stores information of permanent residents in the community. The method comprises carrying out monitoring on people passing in and out of the entrance ofthe community in real time through the microprocessor module and controlling opening and closing of the access control system. The method for video monitoring of community strangers has the advantages of scientific design, simple operation, comprehensive monitoring, strong safety and good protection effect.

Owner:ZHENGZHOU BLUEEYE TECH CO LTD

Liquid storage bag material inlet and outlet mouth structure and assembling and using methods thereof

ActiveCN110239848AEasy to fixImprove general performanceAssembly machinesLarge containersEngineeringMouth opening

The invention provides a liquid storage bag material inlet and outlet mouth structure and assembling and using methods thereof and belongs to the field of modern transportation. The problem that the universality and the sealing property of a liquid storage bag which is mounted on an existing liquid transportation vehicle are poor is solved. The liquid storage bag material inlet and outlet mouth structure comprises a carriage of which the upper side is fixedly provided with a round-sleeve-shaped bag opening mouth, and the bottom end of the bag opening mouth is fixed to the carriage and communicates with the interior of the carriage. The liquid storage bag material inlet and outlet mouth structure further comprises a flexible liquid storage bag body located in the carriage; a flexible round-sleeve-shaped liquid bag mouth is fixed to the liquid storage bag body; and the bottom end of the liquid bag mouth is connected with the liquid storage bag body and communicates with the interior of the liquid storage bag body. The liquid storage bag material inlet and outlet mouth structure is characterized by further comprising a mouth opening mechanism which is used for fixing the liquid bag mouth to the bag opening mouth, and a mouth closing mechanism which is used for sealing the liquid bag mouth to the bag opening mouth. The universality and the sealing property of the material inlet and outlet mouth structure are higher, and material inlet and outlet operation is fast.

Owner:WENZHOU SILIN IND DESIGN CO LTD

a sandblasting machine

ActiveCN106078533BAchieve recyclingIncrease profitBlast gunsAbrasive feedersSand blastingSpray nozzle

The invention discloses a sand blasting machine, which comprises a sand blasting chamber. The sand blasting chamber comprises a feeding hole for feeding and discharging workpieces, and spray nozzles arranged in the sand blasting chamber; the spray nozzles are fixed on a spray nozzle drive mechanism; a feeding mechanism capable of driving the workpieces to feed and discharge is matched on the feeding hole; the spray nozzle drive mechanism comprises at least one swinging mechanism arranged in the sand blasting chamber; each swinging mechanism is provided with one spray nozzle and is driven by a first drive part to swing to the left and right; the feeding mechanism comprises a placement platform used for placing workpieces and a second drive part; and the placement platform comprises at least one positioning table used for placing the workpieces, and a sealing plate arranged behind the positioning table and matched with the feeding hole of the sand blasting chamber. A plurality of swinging mechanisms are arranged in the sand blasting chamber, and a plurality of spray nozzles can swing to blast sand on the workpieces when being used for blasting sand, so that a uniform and efficient sand blasting effect is realized; and in addition, the workpieces can be quickly fed and discharged in the sand blasting chamber through the feeding mechanism, so that the sand blasting efficiency of the workpieces is further improved.

Owner:宁波精益微型轴有限公司

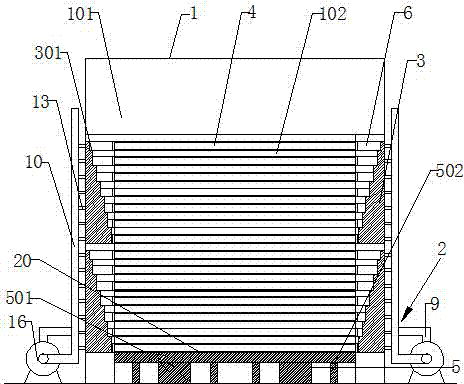

Board hot pressing device

InactiveCN104723419AUniform heatingQuick in and outPlywood pressesVeneer pressesSteel platesHydraulic ram

The invention discloses a board hot pressing device. The board hot pressing device comprises a hot press body. The hot press body is composed of a press frame and a hot pressing cavity. The front side faces of two support legs of the press frame are each provided with at least one gradient positioning groove, the bottom of the hot pressing cavity is fixedly provided with a hydraulic oil cylinder drive system, a bottom pressing board is fixed to the upper end of the hydraulic oil cylinder drive system, at least one set of hot pressing steel boards are arranged on the bottom pressing board, the bottom of each hot pressing steel board is provided with bent flat iron stretching to the front side end of the hot pressing steel board, steel angles with the lengths sequentially reduced are fixedly welded to the two side ends of each set of hot pressing steel boards, and each steel angle corresponds to a press lug of the corresponding gradient positioning groove. The two side ends of the hot press body are each provided with a two-time circulation conduction oil system, and two sets of heat conduction coil pipes are arranged in each hot pressing steel board. One-time circulation conduction oil systems are improved into the two-time circulation conduction oil systems through the hot pressing device, the temperature of the hot pressing steel boards can be quickly increased, the hot pressing steel boards are evenly heated, cold oil in the hot pressing steel boards can be quickly pressed outside, and the boards are hot-pressed at high efficiency and high quality.

Owner:JIANGSU KENTIER WOOD

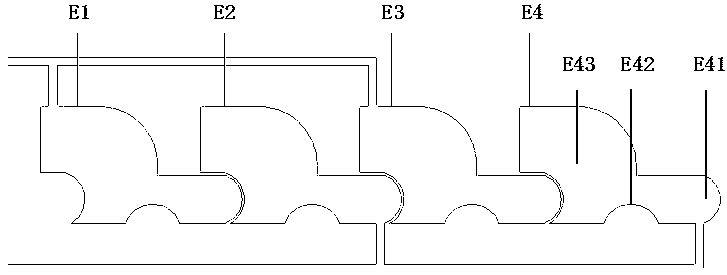

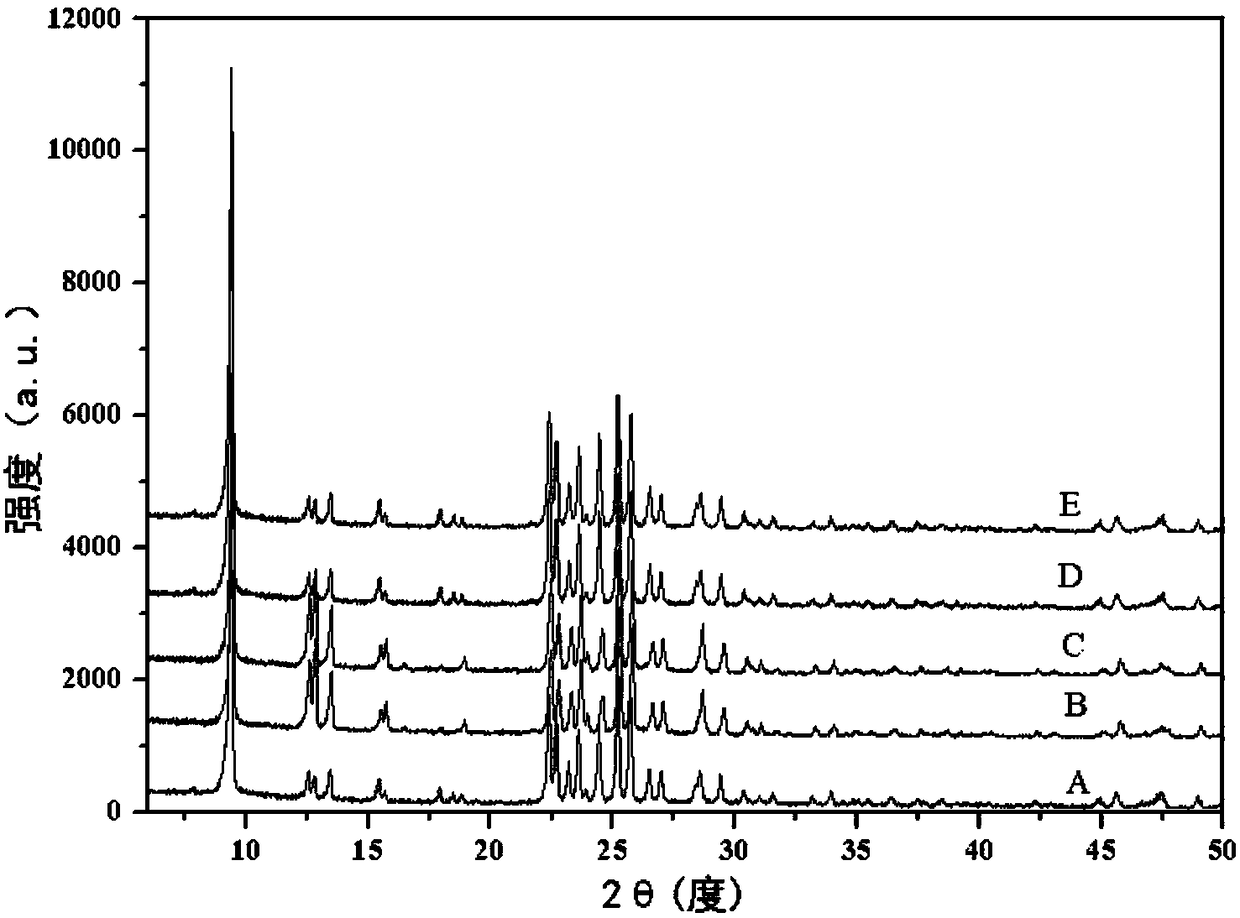

Synthesis method of SAPO-34 molecular sieve with large specific surface area

ActiveCN107827121AQuick in and outHigh crystallinityMaterial nanotechnologyMolecular sieve catalystsFiltrationSynthesis methods

The invention discloses a synthesis method of an SAPO-34 molecular sieve with a large specific surface area. The synthesis method comprises the steps as follows: (1) an aluminum source and water are mixed and pulped, tetraethylammonium hydroxide is added, the mixture is stirred, and a solution A is formed; (2) phosphoric acid, acidic silica sol and water are mixed to form a solution B; (3) the solution A and the solution B are subjected to parallel mixing, a mixed solution formed through parallel mixing is stirred in real time, the pH of the system is adjusted to 5.5-7.5, stirring is performed, and gel is obtained; (4) the gel is dewatered and dried, and a precursor is obtained; (5) the precursor is ground, the ground precursor is placed at the upper part of a reaction kettle, water is putin the lower part of the reaction kettle, and crystallization is performed; and (6) filtration is performed, filter residues are dried and calcined, and the SAPO-34 molecular sieve is synthesized. The prepared SAPO-34 molecular sieve is formed by polymerization of crystal grains of 50-200 nm, has the larger specific surface area and higher mesoporous capacity, contributes to quick access of reaction substances into pores and can improve the catalytic activity.

Owner:SHAANXI YANCHANG PETROLEUM GRP

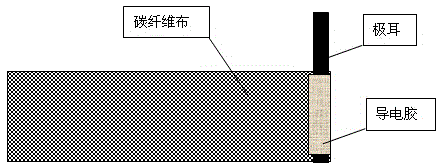

Method for carrying out manufacturing by serving carbon fiber cloth as lithium ion battery cathode slice

InactiveCN104538590AChange the manufacturing processReduce manufacturing costCell electrodesManufacturing technologyCarbon fibers

A method for carrying out manufacturing by serving carbon fiber cloth as a lithium ion battery cathode slice comprises the steps that carbon fiber spinning asphalt is adopted as raw materials, and through protofilament manufacturing, protofilament pre-oxidation, stretch breaking and strip manufacturing, and spinning and weaving, pre-oxidation silk cloth is obtained; finally, carbonization, graphitization, slitting and pole lug welding are carried out, and the lithium ion battery cathode slice completely different from that of an existing manufacturing technology is obtained. The cathode slice manufactured through the method is adopted, so that a traditional manufacturing technology of the lithium ion battery cathode slice is changed, part of auxiliary materials and part of production equipment are omitted, and the production cost is greatly reduced; carbon cellosilk is interwoven in an intricate mode to form a good conductive network, the conductive performance is excellent, internal resistance of a final finished product battery can be greatly reduced, and the large-current charging and discharging requirements of a lithium ion power battery are met.

Owner:江西华昊新能源有限公司

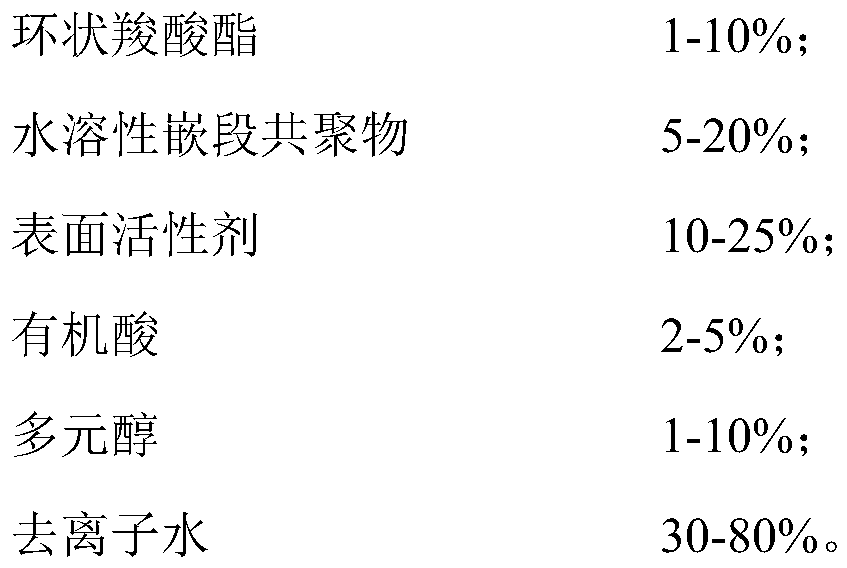

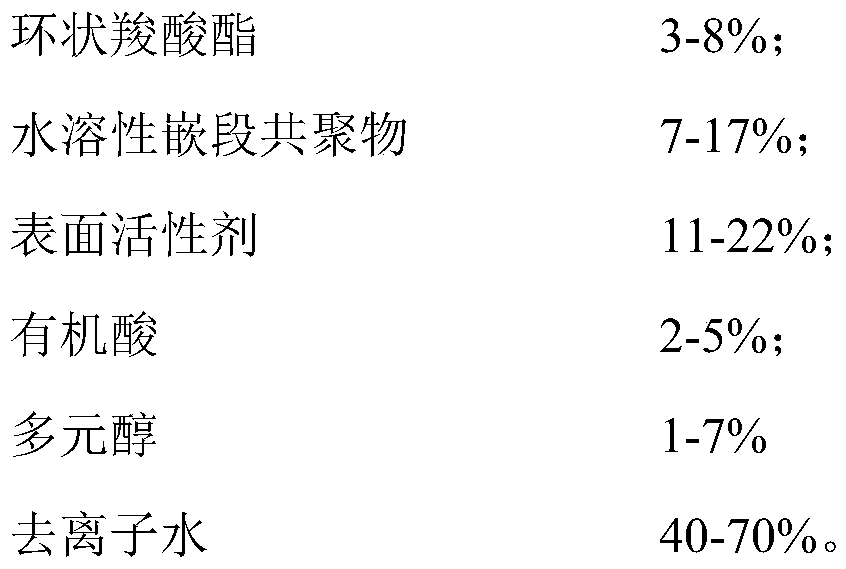

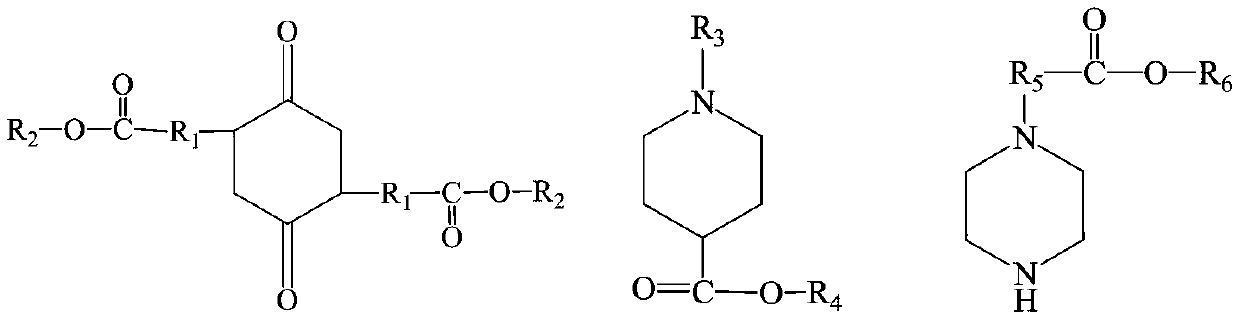

Environment-friendly polyester color-modifying agent and preparation method thereof

The invention discloses an environment-friendly polyester color-modifying agent and a preparation method thereof and belongs to the field of printing and dyeing auxiliaries and preparation methods thereof. The environment-friendly polyester color-modifying agent comprises, by weight, the following components of 1-10% of cyclic carboxylic ester, 5-20% of a water-soluble block copolymer, 10-25% of asurfactant, 2-5% of organic acid, 1-10% of polyol and 30-80% of deionized water. The prepared polyester color-modifying agent has excellent migration properties and dispersity as well as good effectsin oil removal and oligomer removal and can achieve a good color-modifying effect on polyester dyeing defects caused by multiple reasons, and the performance is far better than an existing color-modifying agent; potential irritation or toxicity brought by substances including an aromatic ring swelling agent, an organic solvent and the like can be avoided; and solid content only accounts for 45-50% of the existing color-modifying agent, phosphorus is not contained, the content of auxiliaries in water is remarkably reduced, the COD value of discharged wastewater is lowered, and therefore the polyester color-modifying agent is environmentally friendly and safe in a true sense and is obviously better than the existing color-modifying agent.

Owner:TAICANG BAONI IND CO LTD

Cable protection device for intelligent network control equipment

InactiveCN111725659AAvoid pulling the port by its own weightPrevent self-looseningRelieving strain on wire connectionIntelligent NetworkSmart network

The invention relates to the technical field of intelligent network control equipment. The cable protection device for the intelligent network control equipment comprises a case, wherein the right side of the case is fixedly connected with a limiting ring, sliding columns are evenly arranged in an inner cavity of the limiting ring, a sliding sleeve is slidably connected with the sliding column ina sleeving mode, a limiting block is arranged on the sliding sleeve, a movable ring is rotatably connected with the outer side of the limiting ring, a fixed block is arranged on an upper portion of the right side of the case, a gear rod is rotatably connected with an upper portion of the fixed block, and a movable block is in threaded connection with the position, located in an inner cavity of thefixed block, of the gear rod. The cable protection device for intelligent network control equipment is advantaged in that the limiting ring and the movable ring are arranged, the limiting block is matched to fix the cable, the movable ring is matched to rotate to drive the gear rod to rotate, then the ejector rod extends out to press a plastic elastic piece downwards, and therefore the effects that stability of cable connection is guaranteed within the safety range, and a port and the cable are protected against damage are achieved.

Owner:嘉兴致伟新能源科技有限公司

Method for preparing novel lithium ion battery cathode materials

The invention discloses a method for preparing novel lithium ion battery cathode materials. The lithium ion battery cathode materials are made of carbon fiber filaments and carbon fiber short silk in a combined mode at a certain proportion, wherein the carbon fiber filaments and the carbon fiber short silk are different in length / diameter ratio. Carbon fiber spinnable pitch is used as raw materials, and after being carbonized and graphitized, obtained carbon fibers are close to graphite in material texture and better than the graphite in structure; as the carbon fibers are provided with multiple micro-pore structures, absorption and keeping of electrolytes can be guaranteed, rapid entering and rapid exiting of lithium ions are achieved, and the lithium ion battery cathode materials have the excellent circulation performance and are ideal cathode materials. As the size of the carbon fiber filaments and the size of the carbon fiber short silk are controlled and the proportion between the carbon fiber filaments and the carbon fiber short silk is optimized, the prepared cathode materials are excellent in processing performance, good in pole piece appearance and capable of meeting the requirement of lithium ion battery large-scale production application.

Owner:山东兴丰新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com