Liquid drop mixing unit based on electro-wetting digital micro-fluid chip

A technology of digital microfluidics and mixing units, applied in fluid mixers, mixers, mixing methods, etc., can solve problems such as long droplet transport paths, long mixing times, chip contamination, etc., to reduce control complexity, The effect of fast mixing speed and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

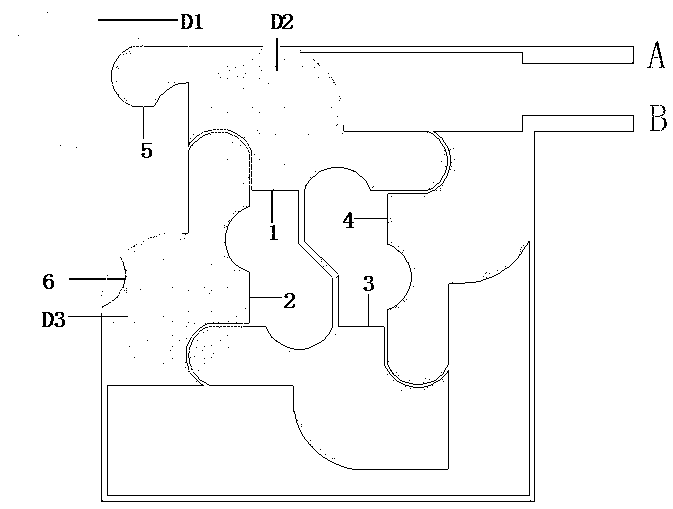

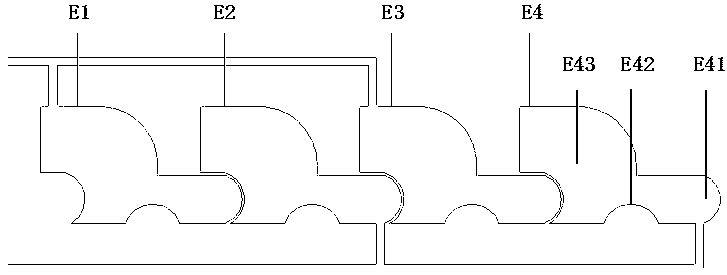

[0031] The droplet mixing unit based on the electrowetting digital microfluidic chip provided by the present invention can have various specific chip implementation methods. This embodiment only lists a common digital chip structure to illustrate its implementation principle. It should be noted that this embodiment is provided for illustrative purposes and is not intended to limit the scope of the present invention in any way.

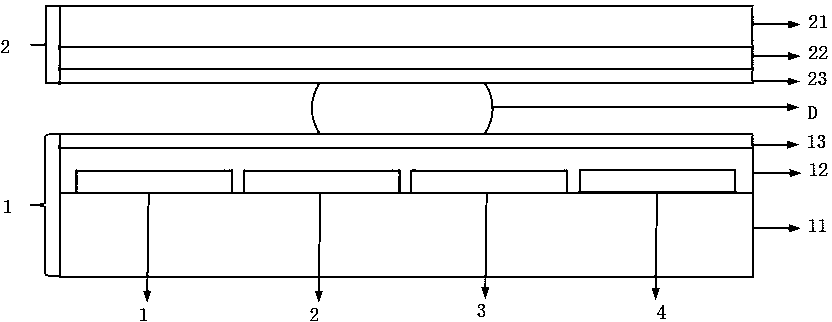

[0032] An electrowetting digital microfluidic chip structure based on the present invention such as figure 1 shown. On the substrate 11 are the hybrid cell drive electrodes 1-4 of the present invention. The material used as the substrate is not fixed, as long as it is insulating, such as quartz, glass, insulating silicon wafer, etc.; and the electrodes (including the ground electrode described below) can be made of any conductive material. It should be noted that the hybrid driving electrodes in the schematic diagram only take 4 as an example, but th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com