Preparation method of tin-based cathode material of high-capacity lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as difficulty in large-scale production, volume expansion of metal tin, and poor long-term cycle performance, and meet the requirements of high-rate charging. Discharge, reduce contact resistance, improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method for a tin-based negative electrode material for a high-capacity lithium-ion battery, comprising the following steps:

[0024] (1) Add 5g nano-tin (50nm particle size) into ethanol solvent, ultrasonically disperse for 60min, then add 100g artificial graphite, mix and stir for 30min, then add 8g phenolic resin, continue mixing and stirring for 60min;

[0025] (2) Spray-dry the uniformly mixed slurry to obtain the precursor powder;

[0026] (3) The powder obtained in step (2) was heated to 800° C. for 8 hours under the protection of argon, cooled down to room temperature, and then ground to obtain a nano-tin / graphite composite material coated with organic pyrolytic carbon.

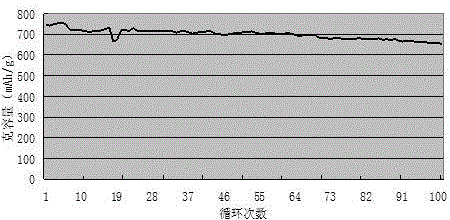

[0027] Coating the prepared composite material, PVDF, and conductive carbon black in a mass ratio of 85:10:5 on a copper foil as a negative electrode, a metal lithium sheet as a counter electrode, and 1mol / L lithium hexafluorophosphorus as an electrolyte , assembled into a button ...

Embodiment 2

[0029] A preparation method for a tin-based negative electrode material for a high-capacity lithium-ion battery, comprising the following steps:

[0030] (1) Add 10g of nano-tin (particle size: 50nm) into ethanol solvent, ultrasonically disperse for 60min, then add 100g of natural graphite, mix and stir for 45min, then add 10g of phenolic resin, continue to mix and stir for 60min;

[0031] (2) Spray-dry the uniformly mixed slurry to obtain the precursor powder;

[0032] (3) The powder obtained in step (2) was heated to 900°C for 10 hours under the protection of argon, cooled down to room temperature, and then ground to obtain a nano-tin / graphite composite material coated with organic pyrolytic carbon.

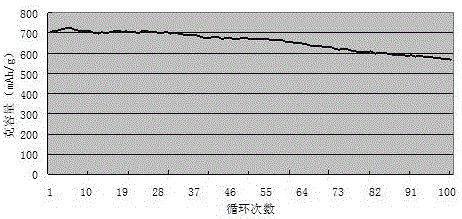

[0033] Coating the prepared composite material, PVDF, and conductive carbon black in a mass ratio of 85:10:5 on a copper foil as a negative electrode, a metal lithium sheet as a counter electrode, and 1mol / L lithium hexafluorophosphorus as an electrolyte , assembled into a but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com