a sandblasting machine

A technology of sandblasting machine and sandblasting chamber, applied in the field of sandblasting machines, can solve the problems of low efficiency of picking and placing workpieces, uneven sandblasting, low sandblasting efficiency, etc., and achieve the effect of improving sandblasting efficiency and sandblasting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

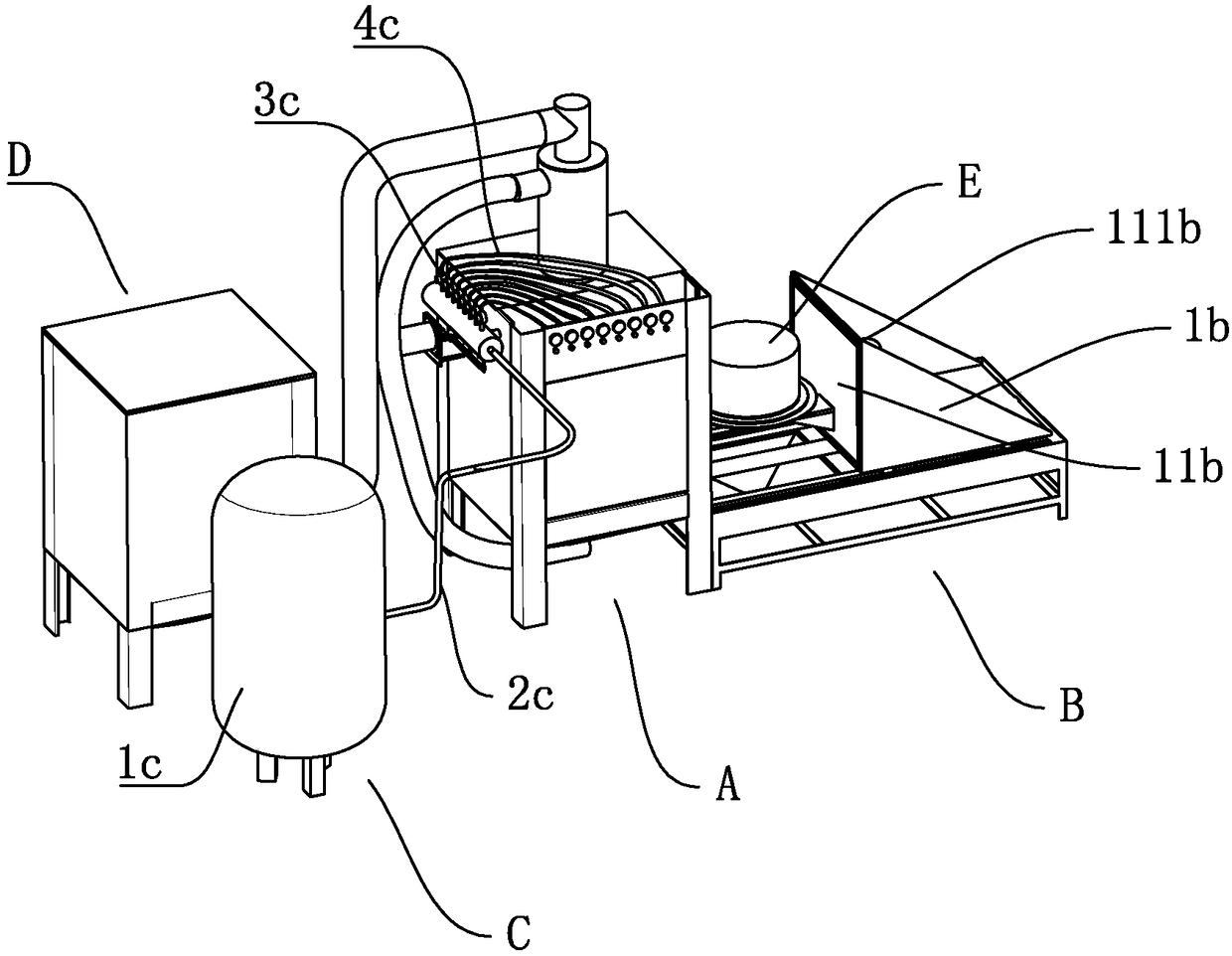

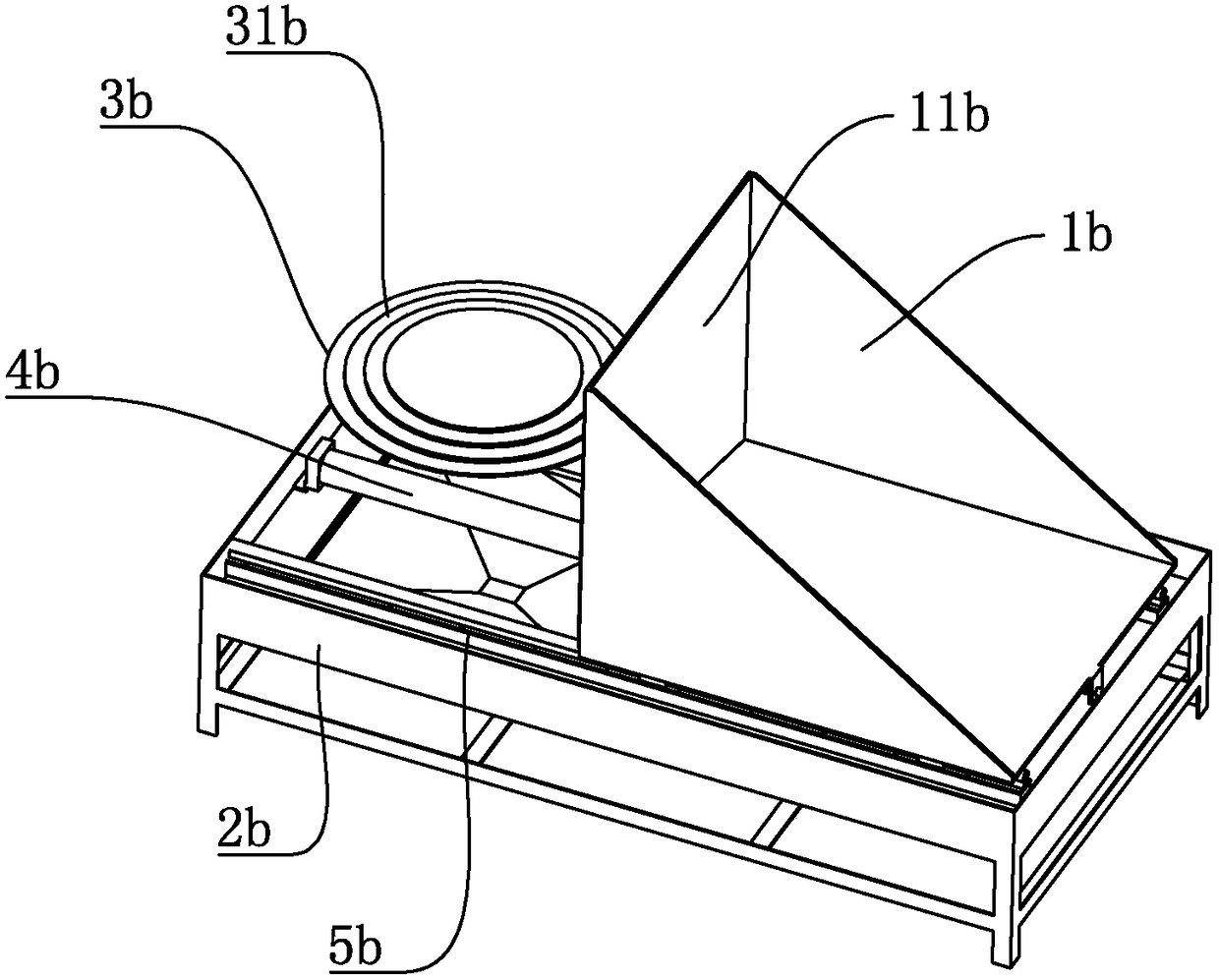

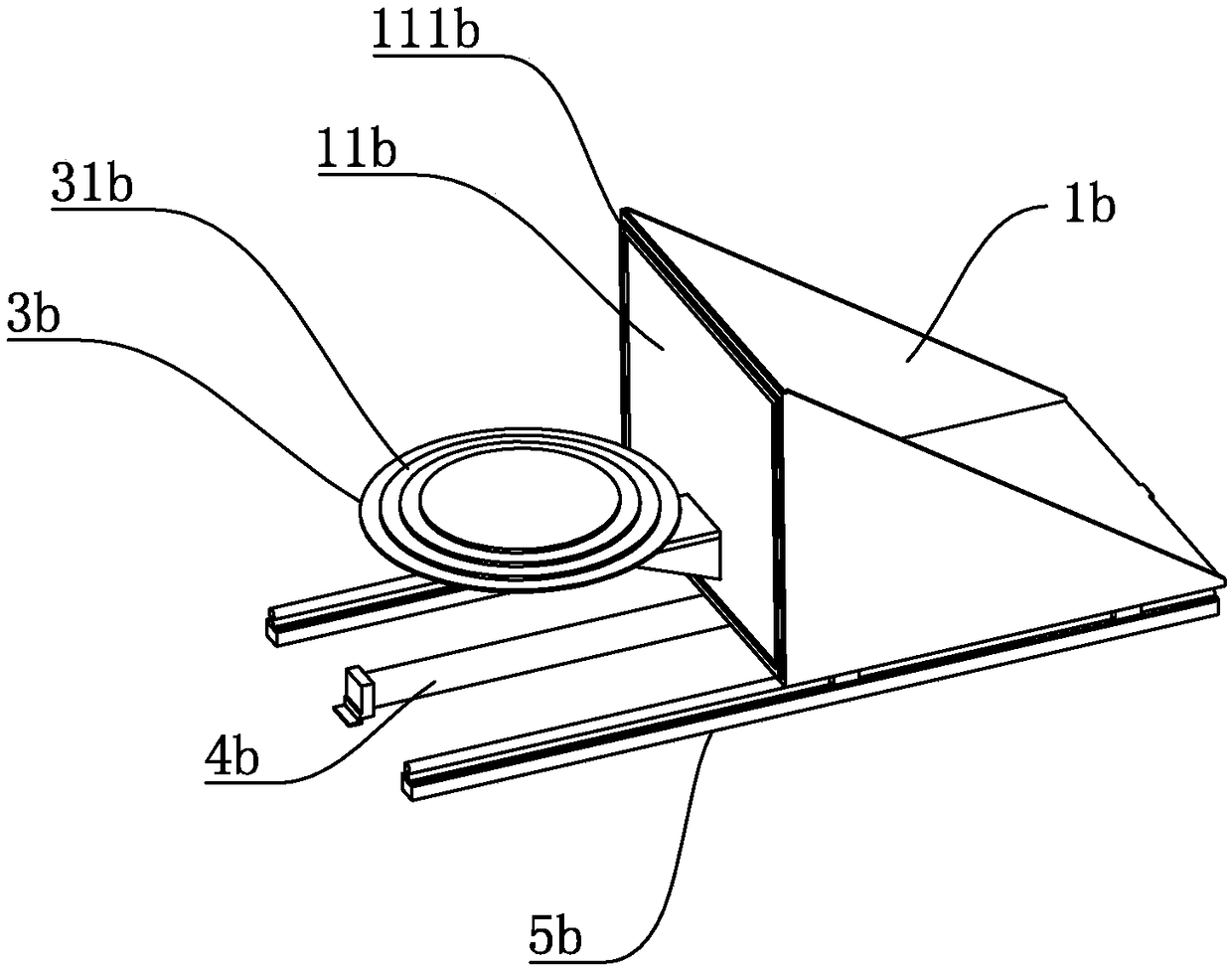

[0041] Embodiment one, a kind of sand blasting machine, take wheel hub E as the workpiece of processing, see attached figure 1 , the sandblasting machine includes a sandblasting part A, a feeding mechanism B, an air intake mechanism C and a dust removal mechanism D, and a sand storage part 2a is arranged on the top of the sandblasting part A, and the upper part of the sand storage part 2a is connected with a cyclone separator Afterwards, the dust removal mechanism D is connected through a pipeline; the air intake mechanism C is mainly the gas source pump 1c, and the gas source pump 1c inputs high-pressure gas into the gas transfer tank through the gas main pipe 2c, and eight pressure regulating valves 3c are arranged on the gas transfer tank , and then through the pressure regulating valve 3c, eight gas branch pipes 4c are connected to cooperate with the nozzle 4a. See attached Figure 4 , the top of the sandblasting chamber 1a is provided with a sand storage part 2a, the bot...

Embodiment 2

[0047] Embodiment two, a kind of sandblasting machine, see the appendix for the difference with embodiment one Figure 9 with 10 , a second motor 6b is provided at the placement platform 1b, the positioning table 3b is rotationally connected with the placement platform 1b, a rotating base 32b is provided at the bottom of the positioning table 3b, and a belt pulley 7 is set between the second motor 6b and the rotating base 32b, thereby The positioning table 3b is driven to rotate.

[0048] Thereby when working, will produce following difference and effect: in the process of sandblasting, second motor 6b drives positioning table 3b to rotate through belt pulley 7, and wheel hub E will also rotate in sandblasting chamber 1a simultaneously, and spray nozzle 4a sprays on When it is on the hub E, it is more uniform, and the sandblasting uniformity and sandblasting quality are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com