Ultra-high-temperature nitriding continuous tunnel furnace

A tunnel furnace, ultra-high temperature technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems such as the air in the furnace is not easy to expel, insufficient nitriding of products, uneven atmosphere in the furnace, etc., to achieve automation Continuous operation, stable and reliable material operation, and the effect of reducing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

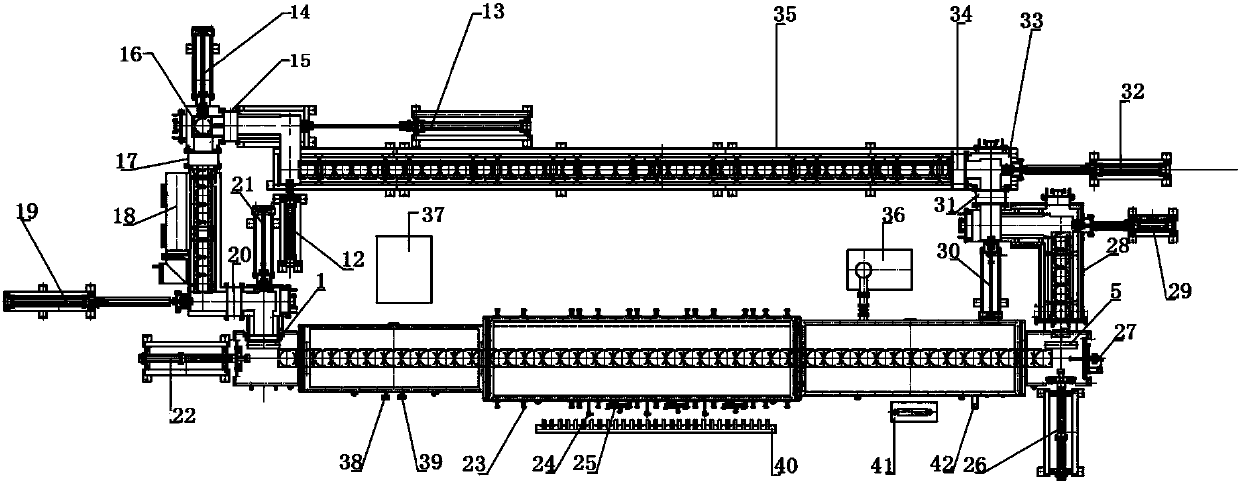

[0036]The present invention will be further described below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

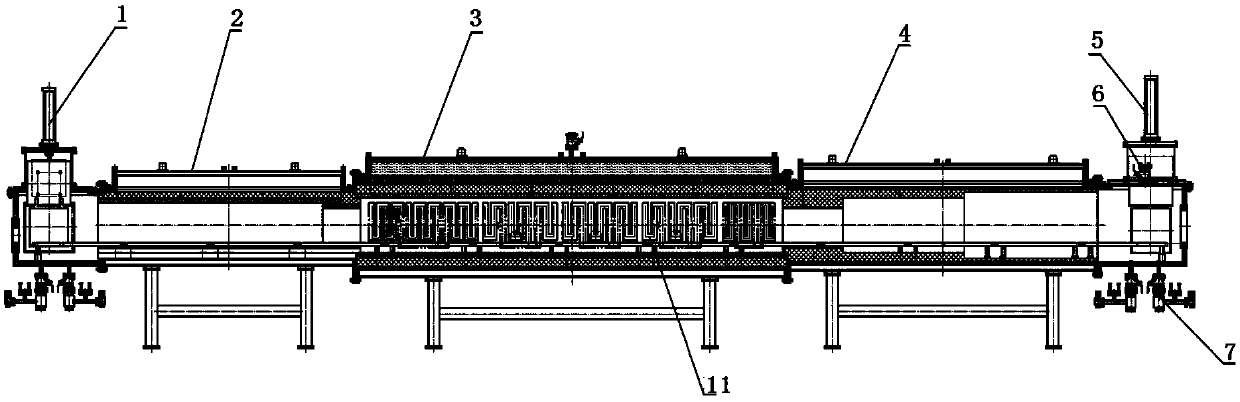

[0037] The overall plane layout of the nitriding tunnel furnace of the present invention is a closed ring structure, and the extension track platform 35 is a non-sealed structure, and the vacuum-tight gate valve 15 from the entrance of the transition cabin in the feeding area to the vacuum-tight gate valve at the exit of the transition cabin in the discharge area 34. The entire furnace body is a sealed cavity structure.

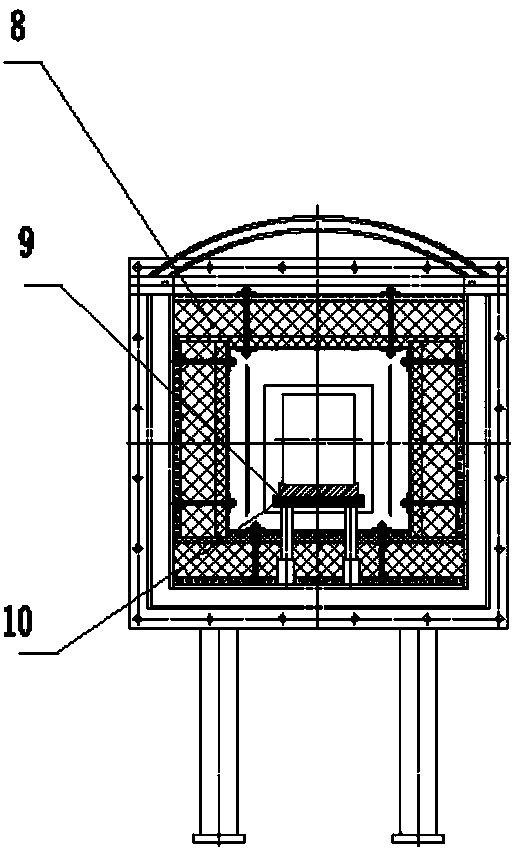

[0038] There are three zones in the furnace shell, including the preheating zone 2 in the front of the furnace body, the main heating zone 3 in the middle and the cooling zone 4 in the rear. Sliding push plate 9 loads the material into the preheating zone 2 in turn, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com