Patents

Literature

45results about How to "Uniform atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-dimensional transition metal disulfides monocrystalline, and preparation method and applications thereof

InactiveCN104846434AControl vulcanizationDegree of controlPolycrystalline material growthFrom chemically reactive gasesGas phaseSingle crystal

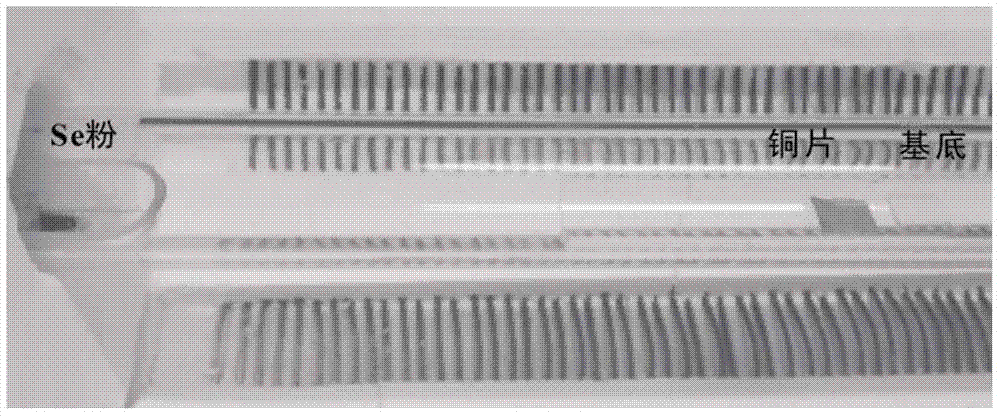

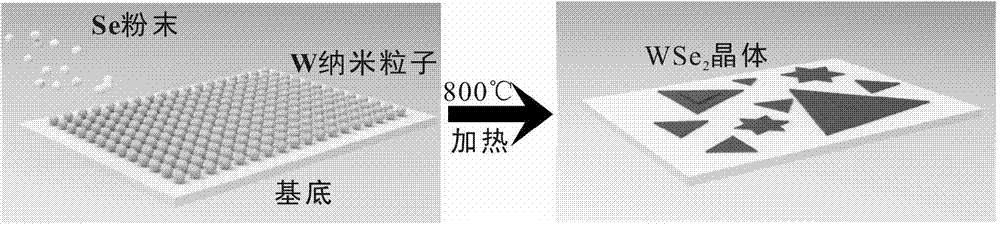

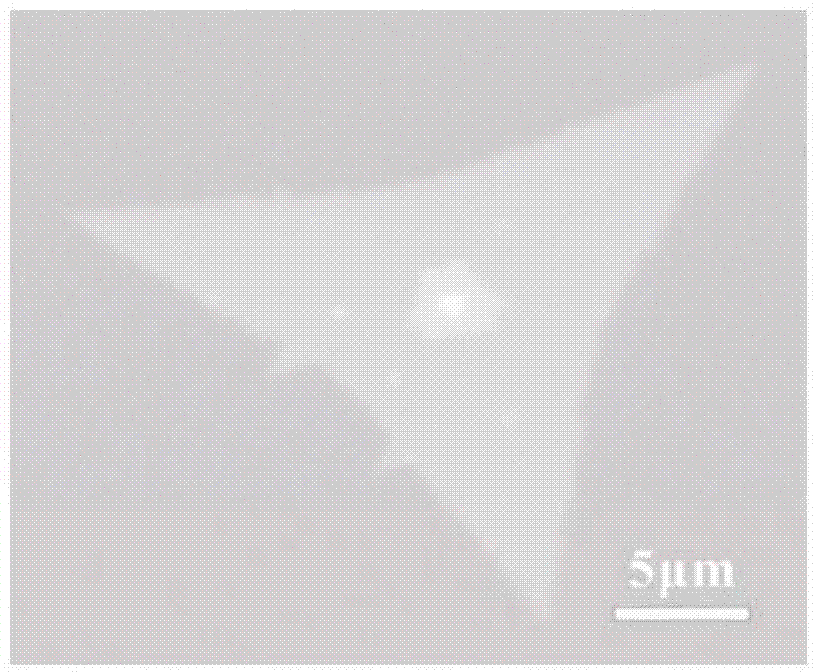

The invention discloses a two-dimensional transition metal disulfides (TMDs) monocrystalline, and a preparation method and applications thereof. According to the preparation method, in an inert atmosphere, assist control of the concentration of S or Se in a system is realized with common metal which is capable of reacting with sulfur family elementary substance (S, Se) and hydrogen so as to control sulfuration degree or selenylation degree of a transition metal layer, and controllable growth of TMDs monocrystalline is realized via chemical vapor deposition; deposition temperature is controlled to be 750 to 850 DEG C, and deposition time is controlled to be 5 to 15min so as to complete TMDs monocrystalline preparation; wherein, strict control on high-quality two-dimensional transition metal disulfides monocrystalline is realized via optimization of preparation parameters such as substrate sputtering treatment method, sulfur family elementary substance powder using amount, absorbed S / Se metal area and kinds, hydrogen concentration, growth temperature, and growth time.

Owner:WUHAN UNIV

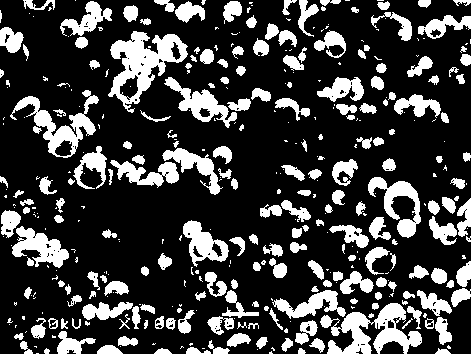

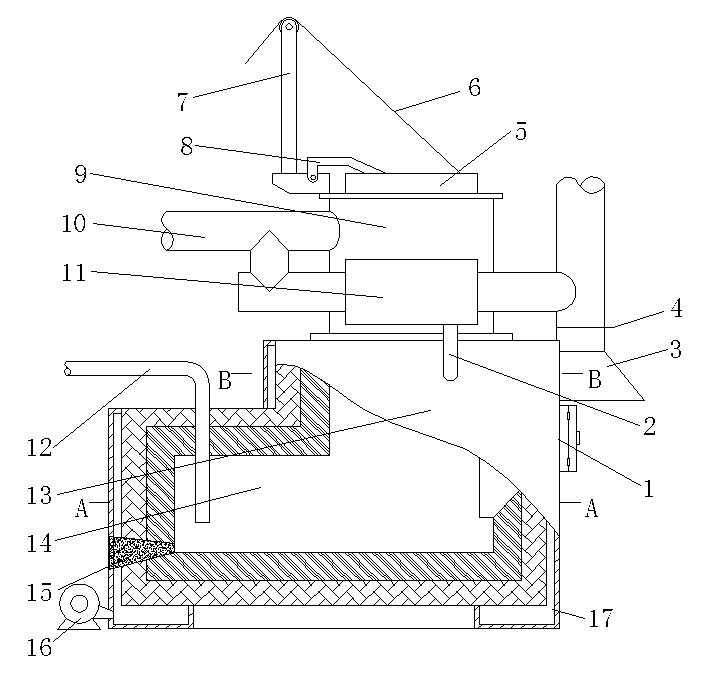

High-activity ultrafine aluminum powder preparing process and device

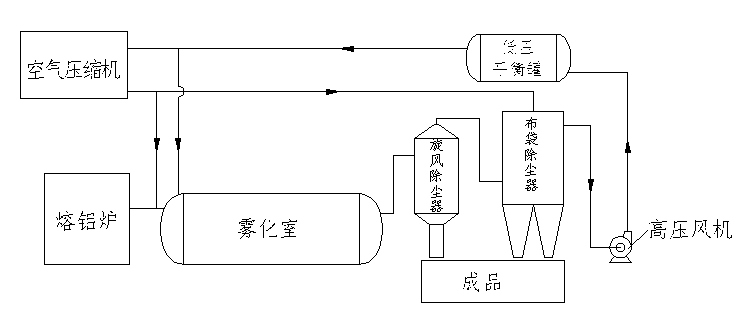

The invention relates to a high-activity ultrafine aluminum powder preparing process and a high-activity ultrafine aluminum powder preparing device. The high-activity ultrafine aluminum powder preparing process comprises melting, atomizing and classifying steps. The high-activity ultrafine aluminum powder preparing device relates to a special aluminum melting furnace and a gas atomizing nozzle, wherein the aluminum melting furnace comprises an aluminum melting furnace body with a circular furnace bottom, a burner nozzle installed in the aluminum melting furnace body, and a furnace door installed on the aluminum melting furnace body; a vertical furnace body is installed at the upper end of the aluminum melting furnace body; a feed port is formed in the upper end surface of the vertical furnace body; the high-activity ultrafine aluminum powder preparing device is characterized in that an aluminum liquid heat-preserving area is arranged on one side inside the aluminum melting furnace body with the circular furnace bottom; one end of an aluminum liquid suction pipe is communicated with the aluminum liquid heat-preserving area; the other end of the aluminum liquid suction pipe is connected with aluminum powder producing equipment; a flue gas recycling hood is installed at the upper end of the furnace door; an air preheater is communicated with the flue gas recycling hood and the vertical furnace body; and an air inlet of the burner nozzle is connected with the air preheater. The high-activity ultrafine aluminum powder preparing process and the high-activity ultrafine aluminum powder preparing device have the characteristics of simple process, low production cost, recyclability of a mixed gas, reasonable structures of the aluminum melting furnace and the gas atomizing nozzle, high production efficiency and the like.

Owner:宁夏新和新材科技有限公司

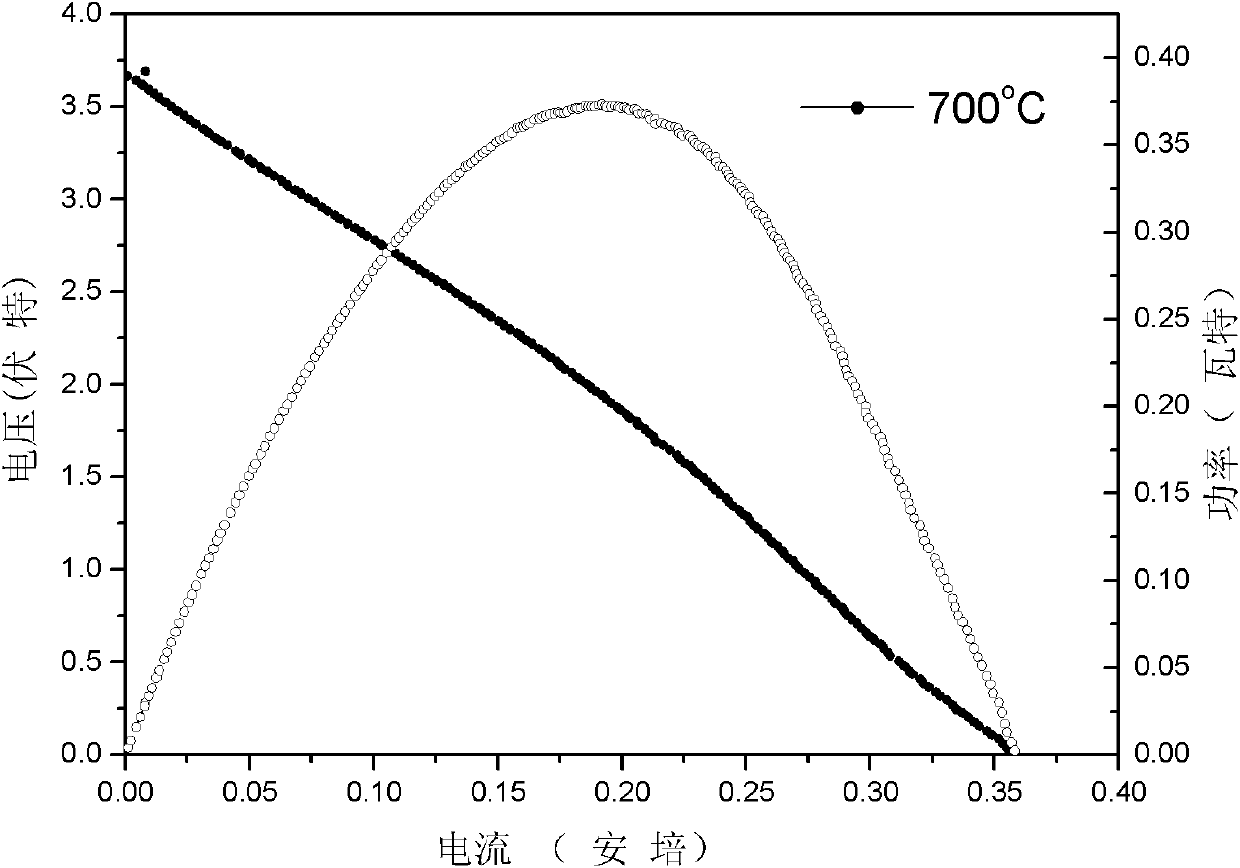

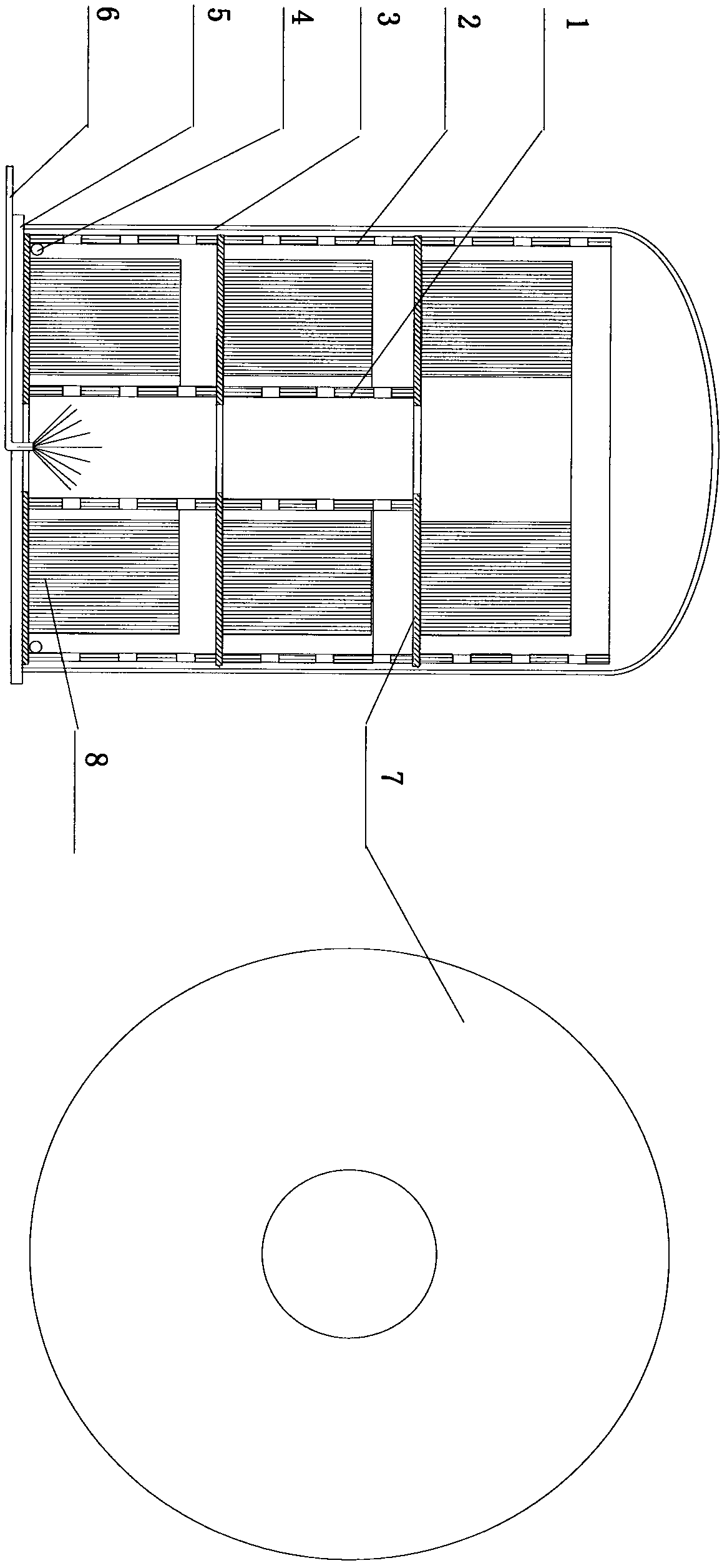

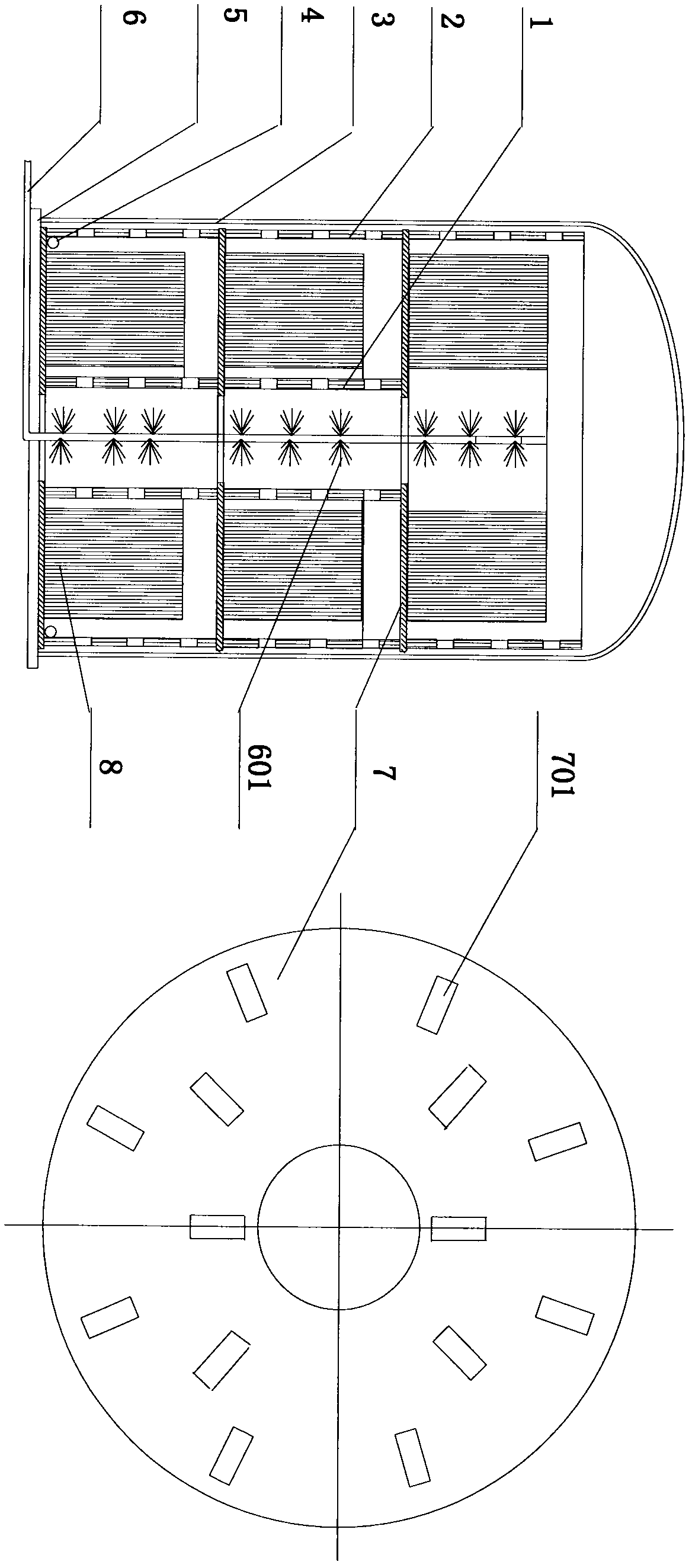

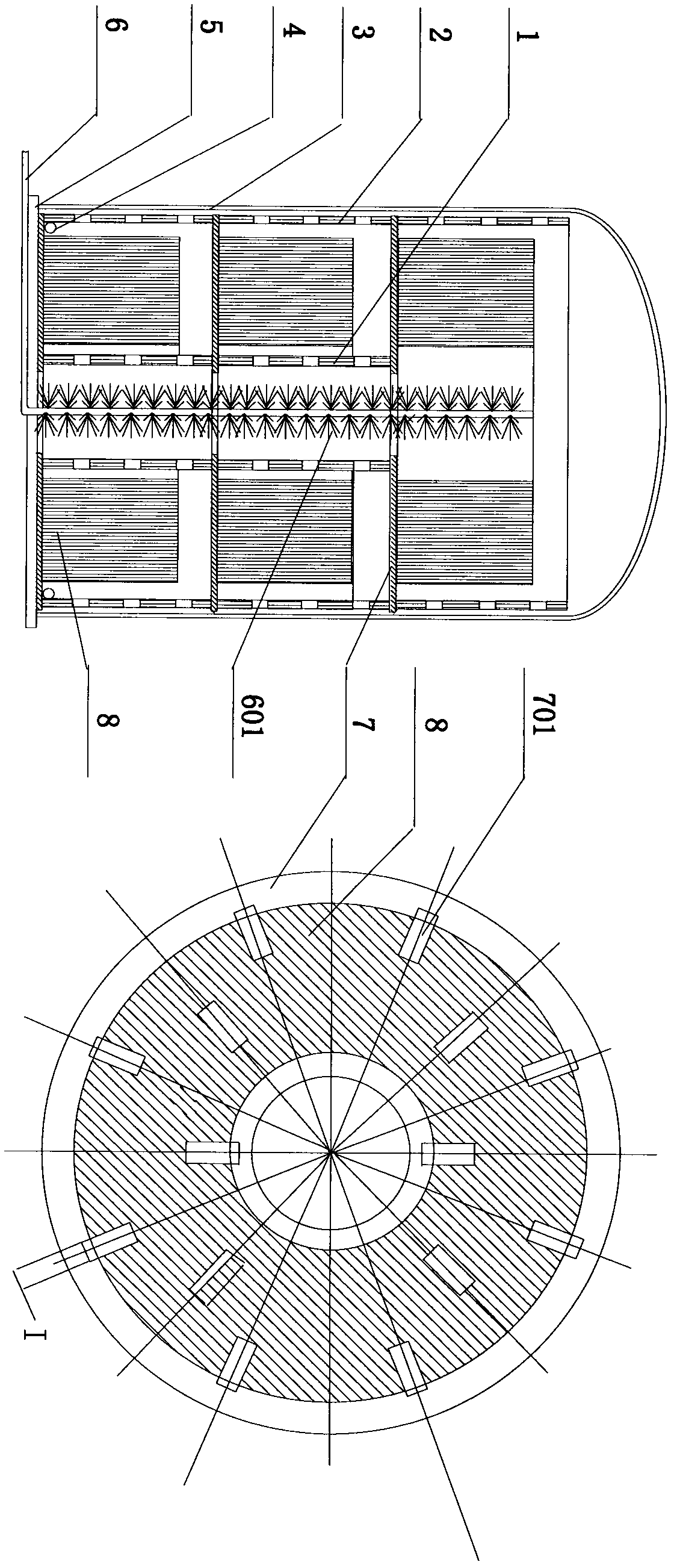

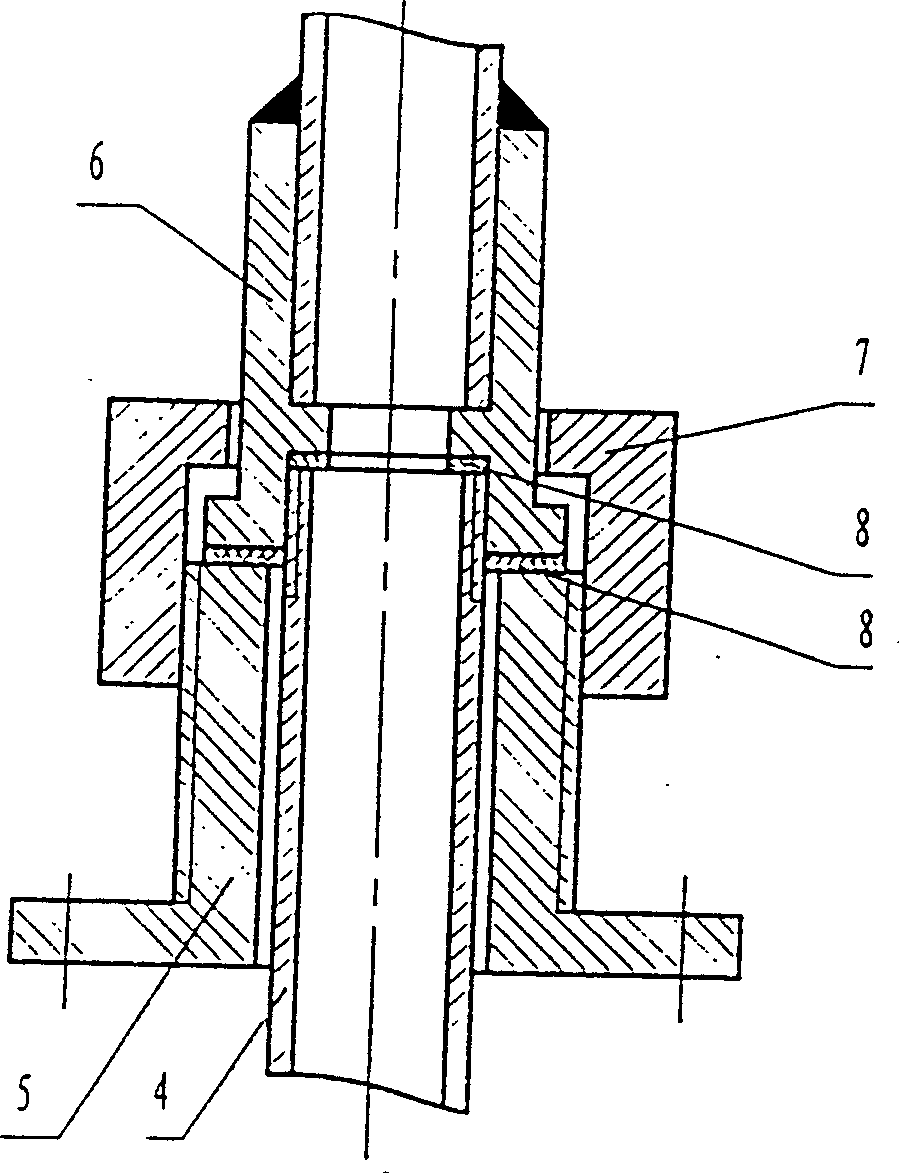

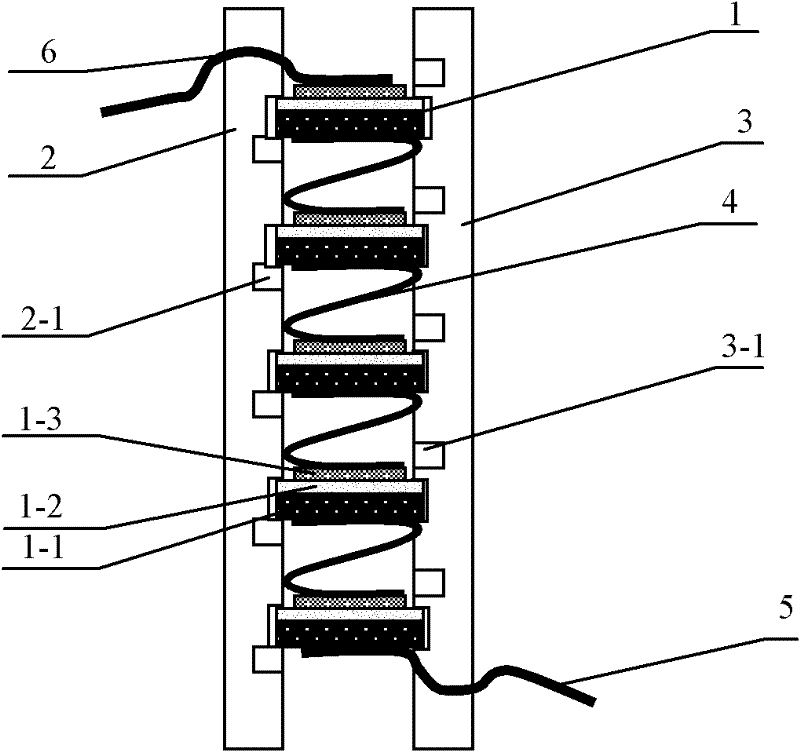

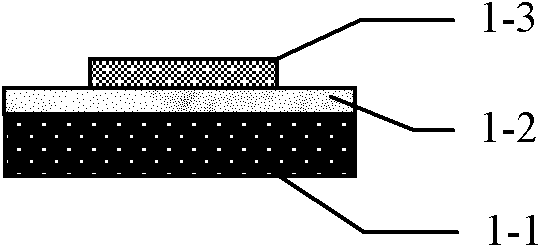

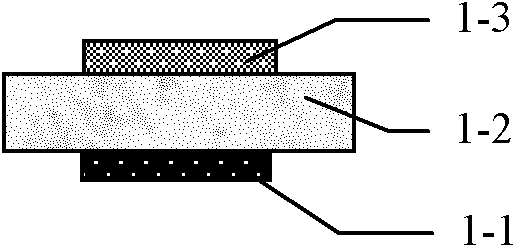

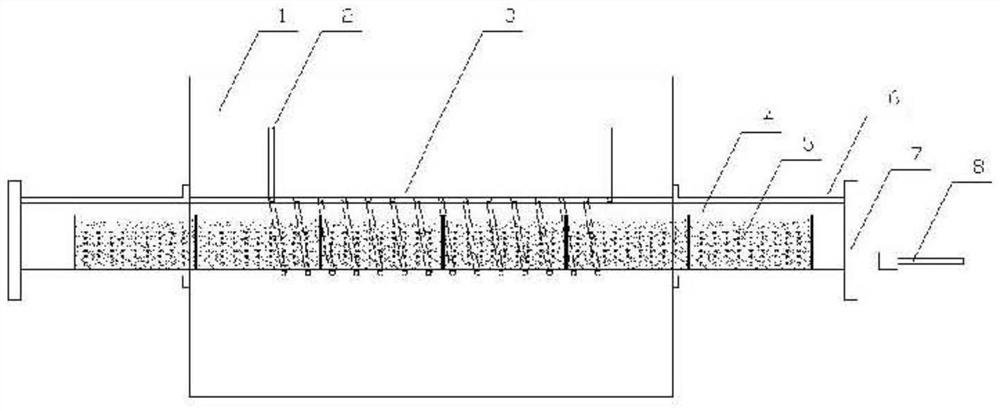

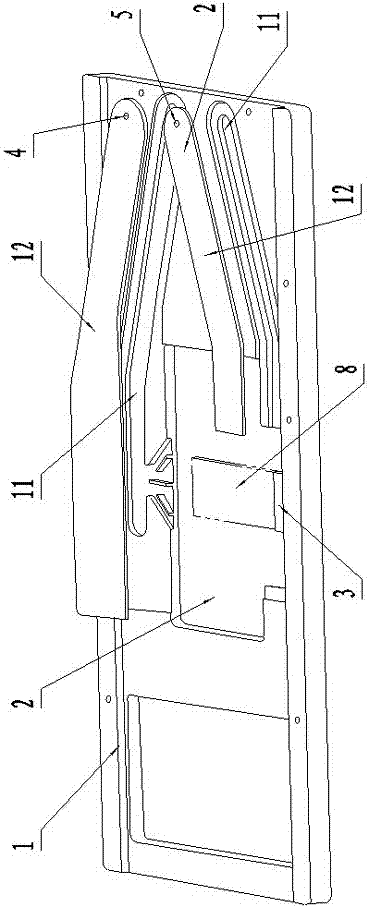

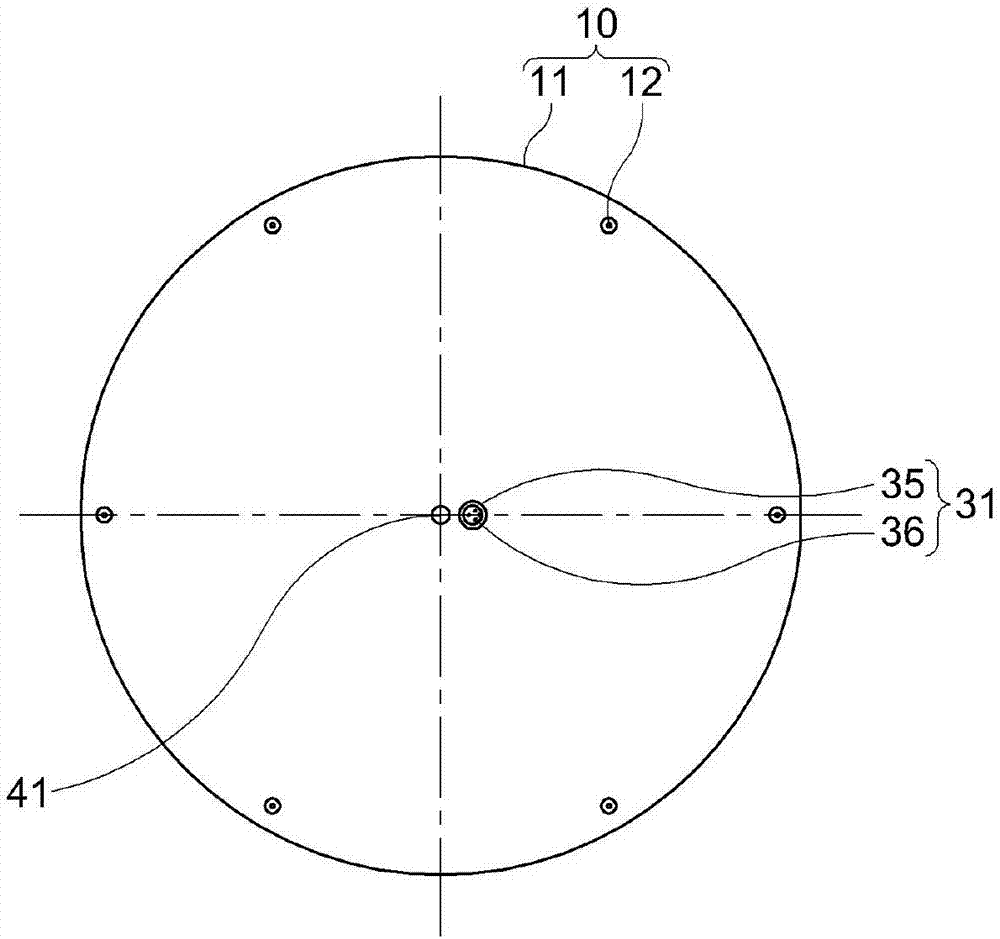

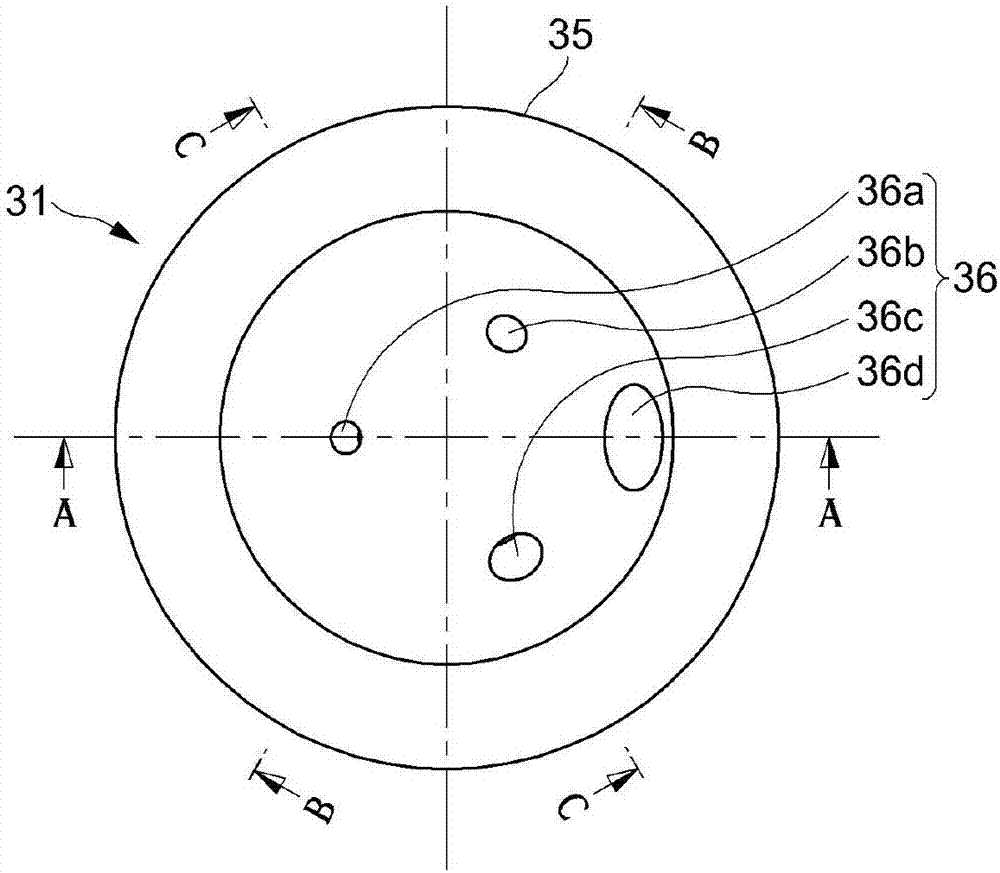

Non-sealing solid oxide fuel battery pack with double gas channels

InactiveCN101908637AUniform atmosphereEliminate reactivityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

The invention relates to a non-sealing solid oxide fuel battery pack with double gas channels, belonging to the field of electrochemical power generation. The non-sealing solid oxide fuel battery pack solves the problems that single batteries in a conventional single gas-chamber solid oxide fuel battery pack have nonuniform gas atmosphere, which affects the output voltage and output power of the battery pack. The battery pack is formed by connecting a plurality of single batteries in series or in parallel through connecting sheets, wherein a fuel-enriched vent pipe and an oxygen-enriched vent pipe are arranged relatively in parallel, the battery pack is arranged between the fuel-enriched vent pipe and the oxygen-enrich vent pipe, a plurality of fuel ports are arranged on the lateral wall of the fuel-enriched vent pipe with equal intervals, a plurality of oxygen ports are arranged on the lateral wall of the oxygen-enriched vent pipe with equal intervals, each fuel port corresponds to an anode of the single battery, each oxygen port corresponds to a cathode of the single battery, the anode and the cathode of the battery pack are respectively led out through an anode lead wire and a cathode lead wire, fuel-enrich gas is filled in the fuel-enriched vent pipe, and oxygen-enrich gas is filled in the oxygen-enriched vent pipe. The invention is mainly applicable to power generation.

Owner:HARBIN INST OF TECH

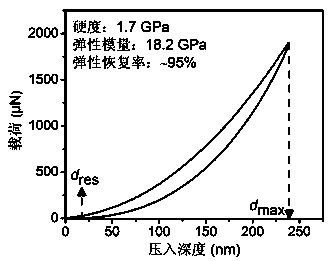

Preparation method of super-lubricity amorphous carbon film with nano-structure

InactiveCN103882376AReduce coefficient of frictionImprove wear resistanceVacuum evaporation coatingSputtering coatingNano structuringRadio frequency magnetron sputtering

The invention discloses a preparation method of super-lubricity amorphous carbon film with a nano-structure. The film is prepared by adoption of a radio frequency magnetron sputtering physical vapor deposition technology, and is silicon- aluminum- co-doped amorphous carbon film having super-lubricity performance in a high vacuum environment. The film has the nano netlike and fullerene-like compound nano-structure, and has excellent elastic recovery performance. In addition, even the nano hardness of the film is low and the film belongs to soft film, the film shows excellent frictional wear performance in the vacuum environment, the lowest friction coefficient is 0.001 and the wear rate is reduced to the order of magnitudes of 10<-19> m3 / N*m. The film is uniform and compact, and firmly combines metal based materials. The film is a solid lubrication and sealing material, and has a good application prospect with respect to various mechanical motion parts in the vacuum environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

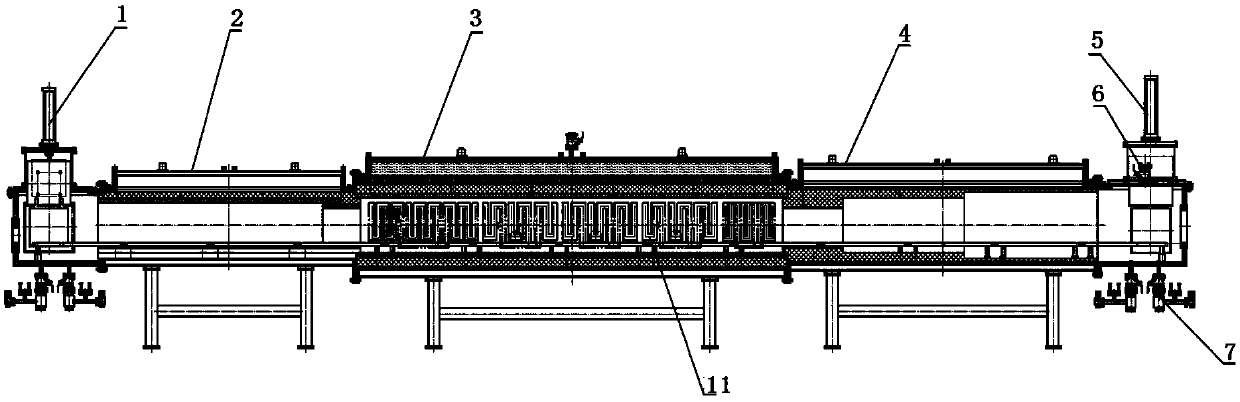

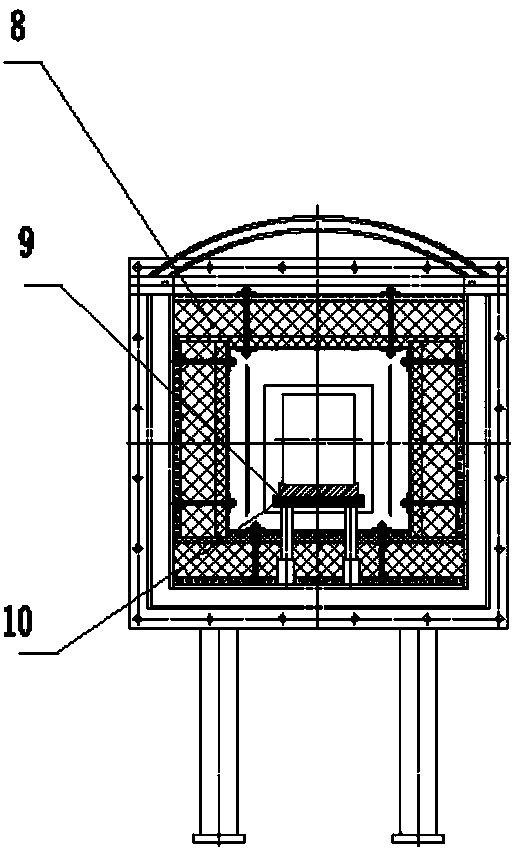

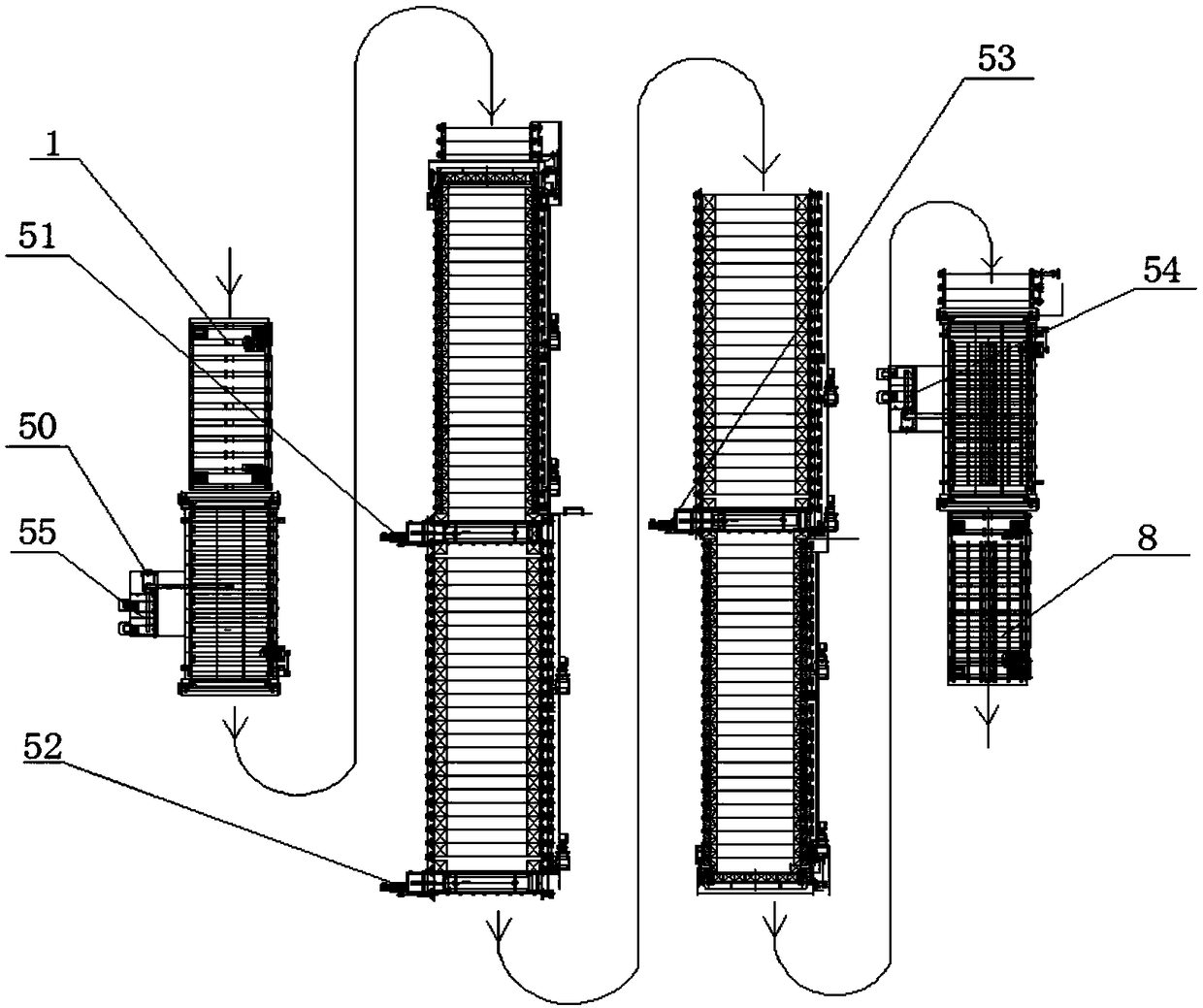

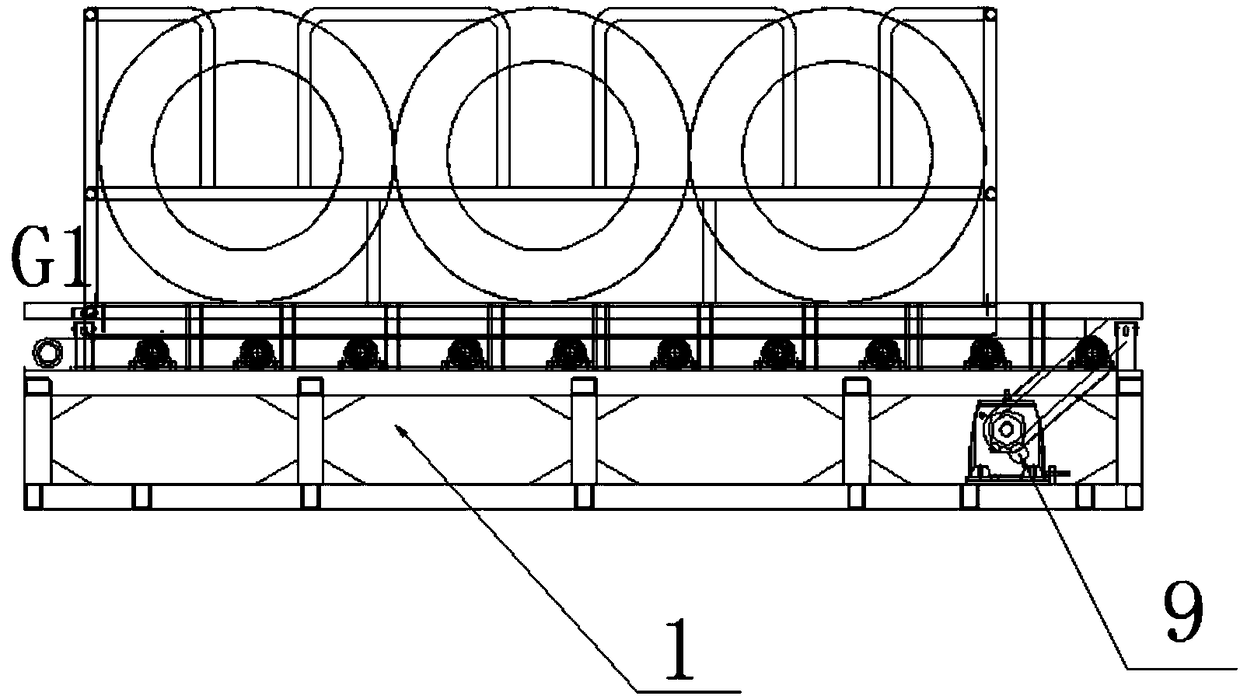

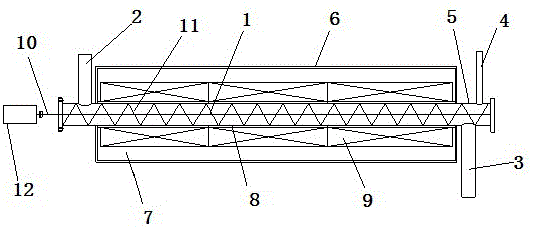

Ultra-high-temperature nitriding continuous tunnel furnace

ActiveCN108020081ASolve the problems of long length, large space occupation and large energy lossRealize fully automatic closed loopFurnace typesEngineeringOxygen

The invention discloses an ultra-high-temperature nitriding continuous tunnel furnace. The furnace comprises an aerobic charging area, a feeding area, a furnace body and a discharging area, wherein the areas are connected in sequence to form a rectangular loop structure, and the areas are independent from one another; the feeding area, the furnace body and the discharging area are of a sealed cavity structure, and the aerobic charging area is of a non-sealing structure; and rails are laid in all the areas, and the materials enter and exit from the areas in a one-way mode. The sintering temperature of the ultra-high-temperature nitriding continuous tunnel furnace can reach 2000 DEG C, and the unique annular structure layout realizes the full-automatic closed circulation of the materials ascompactly as possible, rapid cooling and independent feeding and discharging of the materials in the furnace can be realized, the size is small, and the atmosphere in the furnace is uniform; the circulating production process of discharging the material at one end and feeding the material at the other end can be realized, and the nitriding process of the batch materials is realized; hydraulic propelling is adopted, the whole process is controlled by computers, manual intervention is not needed, and automatic continuous operation is realized; and the furnace is stable and reliable in material running, high in safety performance and low in labor intensity.

Owner:钢研工程设计有限公司

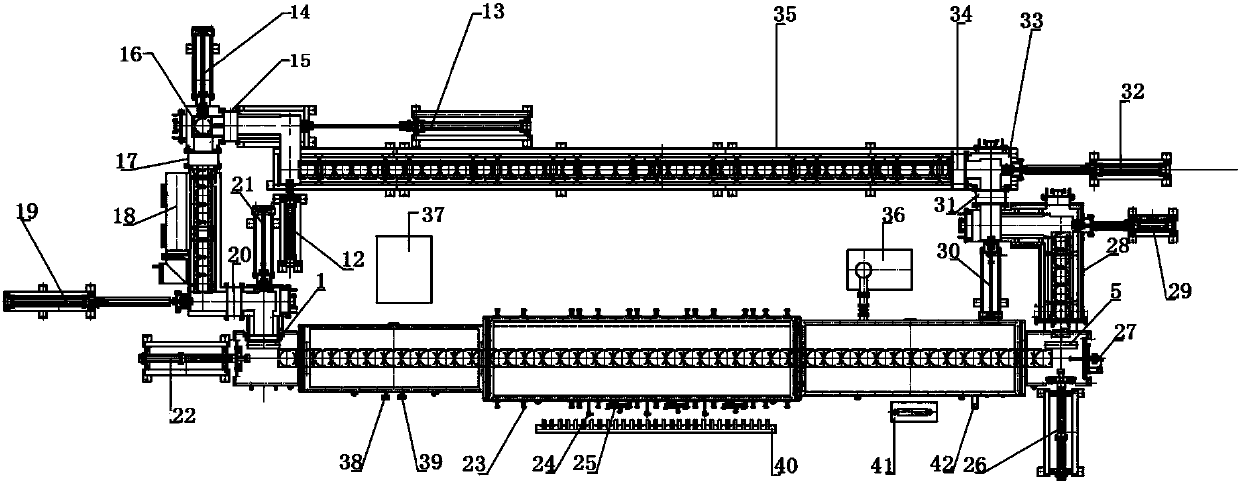

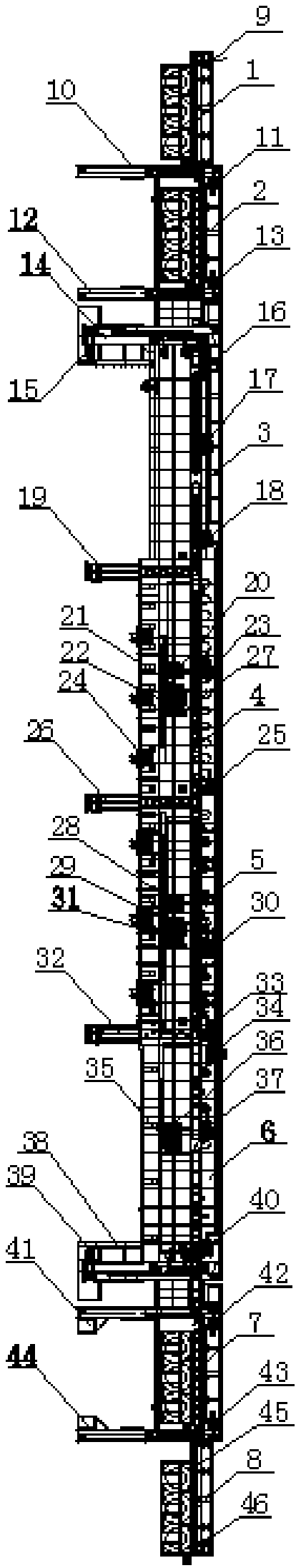

Protective atmosphere short-period roll bottom type continuous annealing furnace production line

InactiveCN108823374AMeet the standard of heat treatmentConvenient heat treatmentFurnace typesHeat treatment process controlAutomatic controlAtmosphere

The invention discloses a protective atmosphere short-period roll bottom type continuous annealing furnace production line. The protective atmosphere short-period roll bottom type continuous annealingfurnace production line comprises a feeding table, a feeding vacuum chamber, a pre-heating chamber, a heating chamber, a thermostable chamber, a slow cooling chamber, a discharging vacuum chamber anda discharging table. The protective atmosphere short-period roll bottom type continuous annealing furnace production line is mainly suitable for spheroidizing annealing, softening annealing, full annealing, distressing, normalization, carbon restoration and other heat treatment processes of low-carbon steel, low alloy steel, bearing steel and other wires, discs, bars, steel pipes and forged casting. The protective atmosphere short-period roll bottom type continuous annealing furnace production line is automatically controlled through a computer and a PLC program, so that all equipment is closely connected, and continuity of feeding is achieved. Meanwhile, the whole device is good in sealing performance, low in energy consumption and high in safety. Intellectualization and automation of production are achieved, and production efficiency and product quality are improved.

Owner:杭州赤热工业炉科技有限公司

Heat treatment method of perforating head

InactiveCN101012492AUniform temperatureUniform atmosphereFurnace typesHeat treatment process controlAlcoholPunching

The invention discloses a heat processing method of punching bow, which comprises the following steps: (1) heating furnace temperature to 850 deg.c; loading bow in the furnace; dripping alcohol in the furnace at 5-6ml / min; finishing dripping alcohol after 1h; starting dripping the composite liquid of alcohol and water with bulk rate at 1: 4; (2) heating to 1000 deg.c; insulating 4h; keeping pressure of furnace to 0.6-1.0Kpa; (3) cooling temperature to 850 deg.c; fetching bow out of furnace; transmitting bow through high-temperature fan; making the temperature in the furnace evenly.

Owner:耿志佳

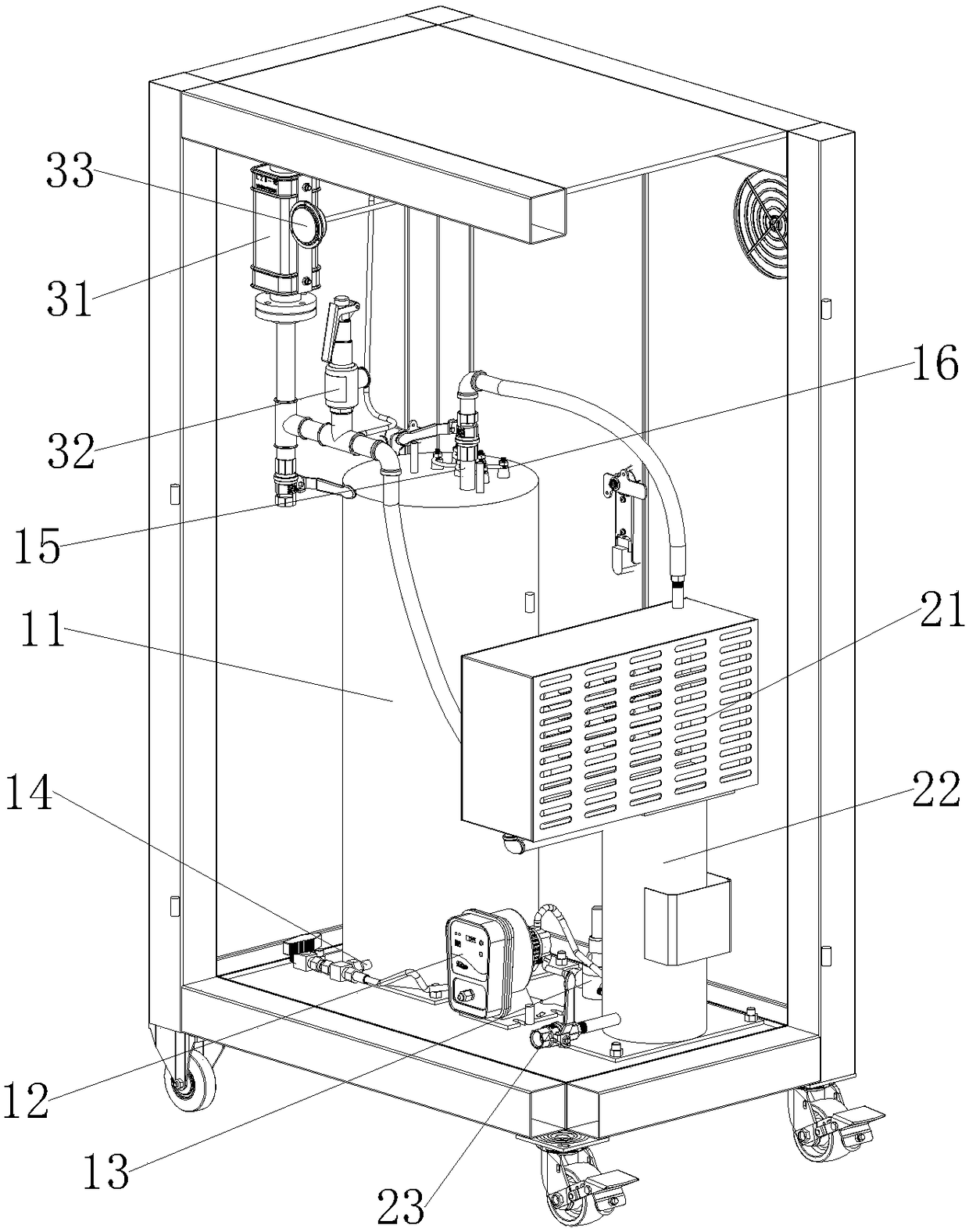

Methanol low temperature cracking device

InactiveCN109279575ASuitable for heat treatment protectionSimple structureHydrogenChemical industryHigh carbonShielding gas

The invention relates to a metal heat treatment protective gas preparation device, especially to a methanol low temperature cracking device. The device includes a cracking reactor and a condenser. A liquid inlet of the cracking reactor is connected to nitrogen and a methanol storage tank. A gas outlet of the cracking reactor is connected to the condenser. An outlet of the condenser is connected toan outlet-gas flowmeter. A heating device is mounted on the cracking reactor. The heating device is an electric heating tube. The electric heating tube is mounted on the top of the cracking reactor.A temperature sensor is also mounted on the cracking reactor. An inlet-liquid metering pump is mounted between the methanol storage tank and the liquid inlet. An inlet-gas flowmeter is mounted betweenthe nitrogen and the liquid inlet. The methanol low temperature cracking device provided by the invention has the advantages of simple structure, convenient use and maintenance, accuracy temperaturecontrol, large use temperature span, temperature cracking, high cracking efficiency, low energy consumption, uniform mixed atmosphere generated by cracking, wide application range, and high carbon potential of cracking gas which is up to 1.0%.

Owner:盐城科莱特电热机械有限公司

Ultralow-friction silicon-aluminum double-element mixed amorphous carbon film preparing method

ActiveCN103160779AReduce coefficient of frictionImprove wear resistanceVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringMagnetic memory

The invention discloses a silicon-aluminum double-element mixed amorphous carbon film preparing method with a radio frequency magnetron sputtering physical vapor deposition technology. An ultralow-friction silicon-aluminum double-element mixed amorphous carbon film has nano hardness of 9-15 Gpa and good tribology performance, the minimum friction coefficient can reach 0.0083, and the number of reciprocating times continuously in the ultralow friction coefficient can be 18000. The film is even and compact and is firmly combined with base materials, abrasion resistance is good, the film can be widely used in a magnetic memory optical disk, a micro electronic mechanical system (MEMS) and automobile parts and other fields.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

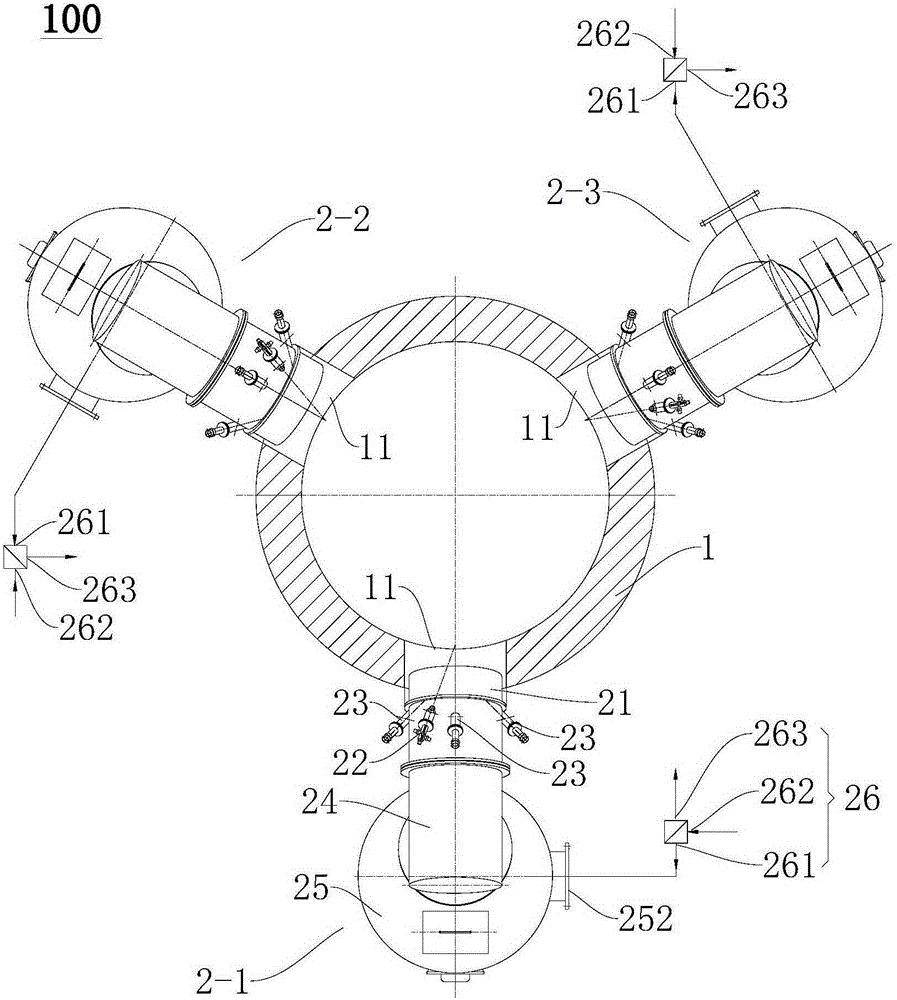

Smelting furnace

InactiveCN105300099AHigh thermal efficiencySmall pressure fluctuationsCrucible furnacesCombustorEngineering

The invention discloses a smelting furnace. The smelting furnace comprises a furnace body and three combustors. The cross section of the inner circumference of the furnace body is circular. The three combustors are arranged at intervals in the circumferential direction of the furnace body, and the center axes of the three combustors on the furnace body are located in the same plane. Each combustor is provided with an air inlet, at least one fuel gas inlet and a smoke exhaust opening. The three combustors are configured in the manner that when air enters any combustor from the corresponding air inlet and fuel gas enters the combustor from the corresponding fuel gas inlet for combustion, the rest two of the three combustors exhaust smoke through the corresponding smoke outlet openings. According to the smelting furnace, the three combustors which are arranged at intervals in the circumferential direction of the furnace body are arranged, when one combustor conducts combustion, the rest two of the combustors exhaust smoke, and therefore fluctuation of pressure in the furnace can be reduced, evenness of the atmosphere and the temperature in the furnace is improved, and the thermal efficiency of the smelting furnace is improved.

Owner:SHENWU TECH GRP CO LTD

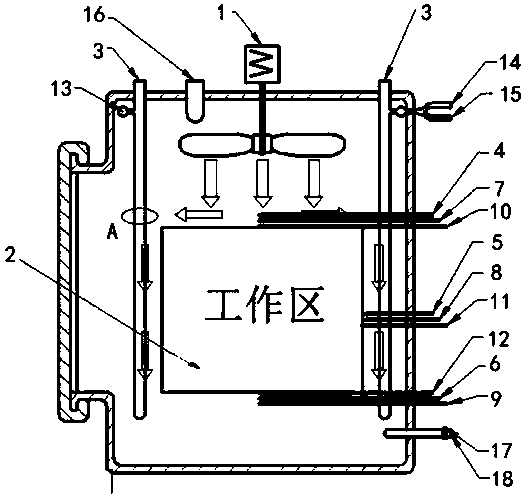

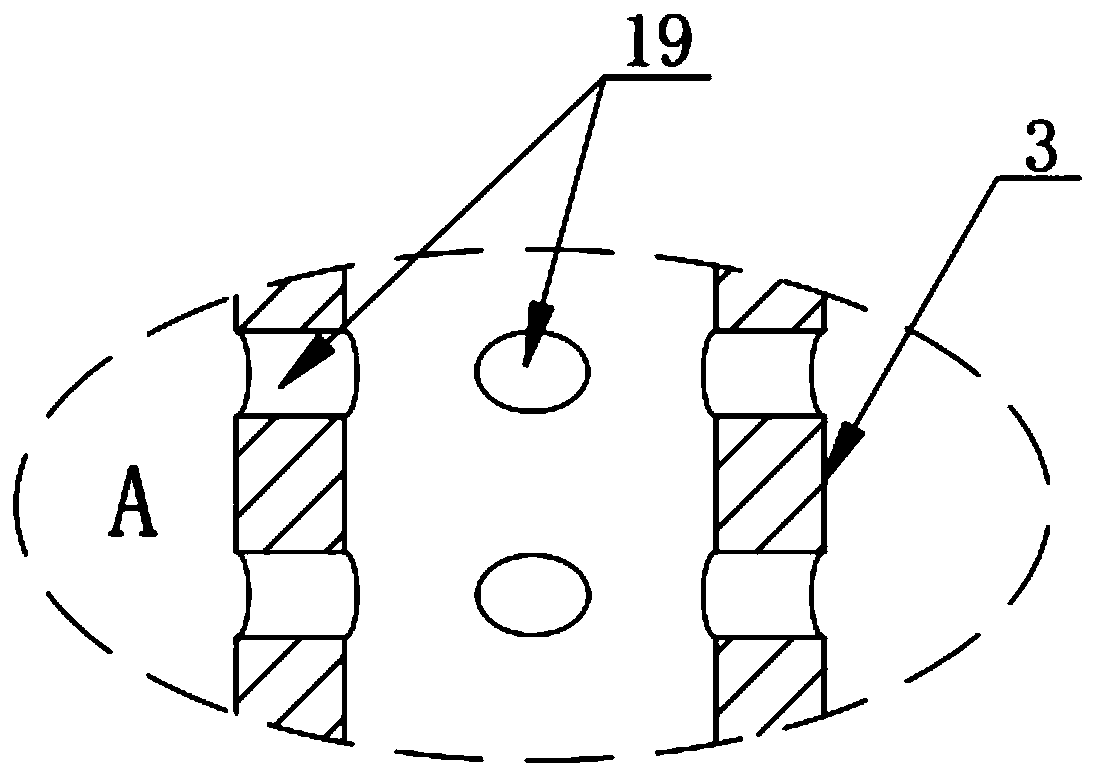

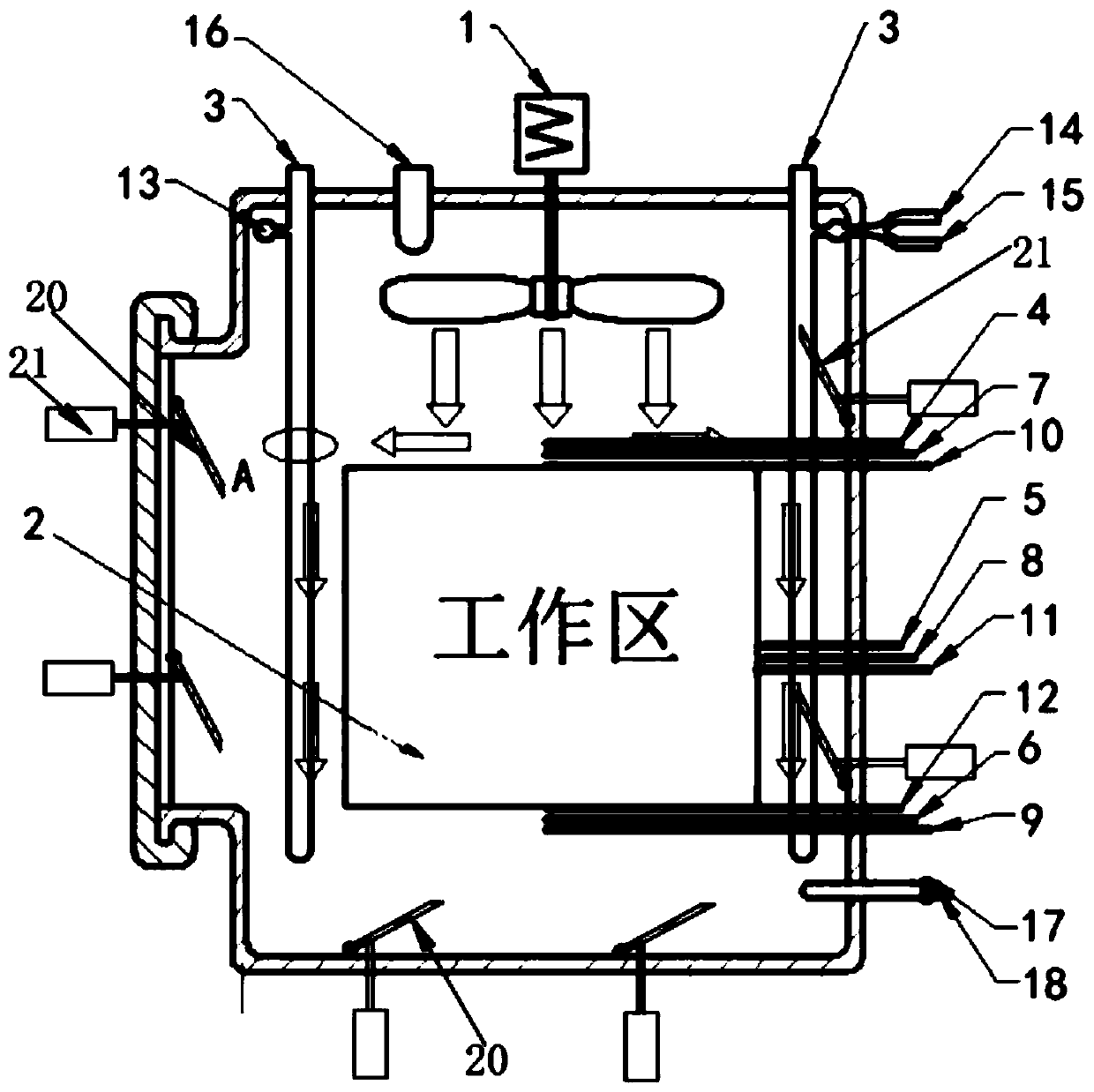

Variable frequency speed regulation device for vacuum carburizing process and speed regulating method thereof

PendingCN110144545AReduce distortionUniform atmosphereSolid state diffusion coatingComputer control systemEngineering

The invention discloses a variable frequency speed regulation device for a vacuum carburizing process and a speed regulating method thereof. The variable frequency speed regulation device comprises avacuum carburizing furnace and a plurality of radiant tubes, and further comprises a variable frequency speed regulation fan, a first thermocouple, a second thermocouple, a third thermocouple, a firstheat conduction probe, a second heat conduction probe, a third heat conduction probe, a fourth thermocouple, a fifth thermocouple and a sixth thermocouple, wherein the first thermocouple, the secondthermocouple and the third thermocouple are respectively arranged at the centers above, on the side of and below a working area; the first heat conduction probe, the second heat conduction probe and the third heat conduction probe are arranged at the centers of the upper surface, the side surface, and the lower surface of the working area; the fourth thermocouple, the fifth thermocouple and the sixth thermocouple are arranged at the centers of the upper surface, the side surface, and the lower surface of a workpiece in the working area. According to the variable frequency speed regulation device for the vacuum carburizing process and the speed regulating method thereof, the flow rate and pressure of carburizing gas in the vacuum carburizing furnace and the rotating speed of the variable frequency speed regulation fan are adjusted by a computer control system, so that the rate of temperature rise, heat diffusion, and / or cooling of the workpiece in the deep cooling process can be controlled.

Owner:SHANGHAI YIBAI IND FURNACES CO LTD

High temperature annealing air distribution system in orientation silicon steel strip coil bell type furnace

ActiveCN102534181AUniform atmosphereEliminate potential safety hazardsFurnace typesHeat treatment furnacesDistribution systemSteel belt

The invention provides a high temperature annealing air distribution system in an orientation silicon steel strip coil bell type furnace, which comprises an air supply pipeline, a water vapor channel and an air return pipeline. The air supply pipeline extends into the inside of the bell type furnace from a centre position of the bottom of the bell type furnace and is lifted to the top of the highest steel strip coil in the bell type furnace, and air outlet through holes are evenly drilled on the pipe wall in the radial direction and the axial direction. Water vapor through holes are arranged on a horizontal bearing support plate body used for bearing each layer of steel strip coils in the bell type furnace, and the air return pipeline is an annular pipeline arranged at the bottom in the furnace close to the inner wall of an outer cover. The air distribution system enables atmosphere in the furnace to be even, and maintains balance of air inlet and air outlet for a long time. When the cover is uncovered, hydrogen in the furnace is exhausted, and the air distribution system eliminates potential safety hazard, prevents steel strip surface to be oxidized, guarantees safety in the furnace, and is high in product quality.

Owner:无锡华精新材股份有限公司

Sintering adjusting method of porcelain insulator in strong reduction period

The invention provides a sintering adjusting method of a porcelain insulator in a strong reduction period. By the adjustment of the proportion of the amount of combustion-supporting wind and the amount of fuel gas in a furnace, the sintering adjusting method of the porcelain insulator in the strong reduction period is improved and ameliorated, and is applicable to sintering of large blanks of megavolt hollow insulator, rod types and the like, a unified norm is formed, and generating of crystallization, glaze bubbles and orange peel defects is effectively eliminated.

Owner:XIAN XD HIGH VOLTAGE PORCELAIN INSULATOR CO LTD +1

Fancy spiral electronic waste pyrolysis device

PendingCN106479531AAvoid stickingInhibit adhesionIndirect heating destructive distillationSpecial form destructive distillationInsulation layerSpiral blade

The invention relates to the technical field of waste treatment, in particular to a fancy spiral electronic waste pyrolysis device. The device comprises an electronic waste pyrolysis reactor and an electric heating system, wherein the electronic waste pyrolysis reactor comprises a material pyrolysis assembly and a reactor shell. The material pyrolysis assembly comprises a spiral sleeve and a fancy spiral. The fancy spiral is located inside a temperature section where tar is generated inside the spiral sleeve, and the fancy spiral comprises a spiral shaft and fancy spiral blades, and each fancy spiral blade is provided with a plurality of opening gaps with angles; the electric heating system comprises a heating module and an insulation layer, the insulation layer is located on the outer side of the spiral sleeve inside the closed space, and the heating module is arranged on the outer surface of the insulation layer. The device adopts the fancy spiral blades for conveying raw materials, the materials are stressed in the axial and tangential directions when passing through the fancy spiral blades, adhesion and hardening of the materials are avoided, and blockage is avoided.

Owner:SHENWU TECH GRP CO LTD

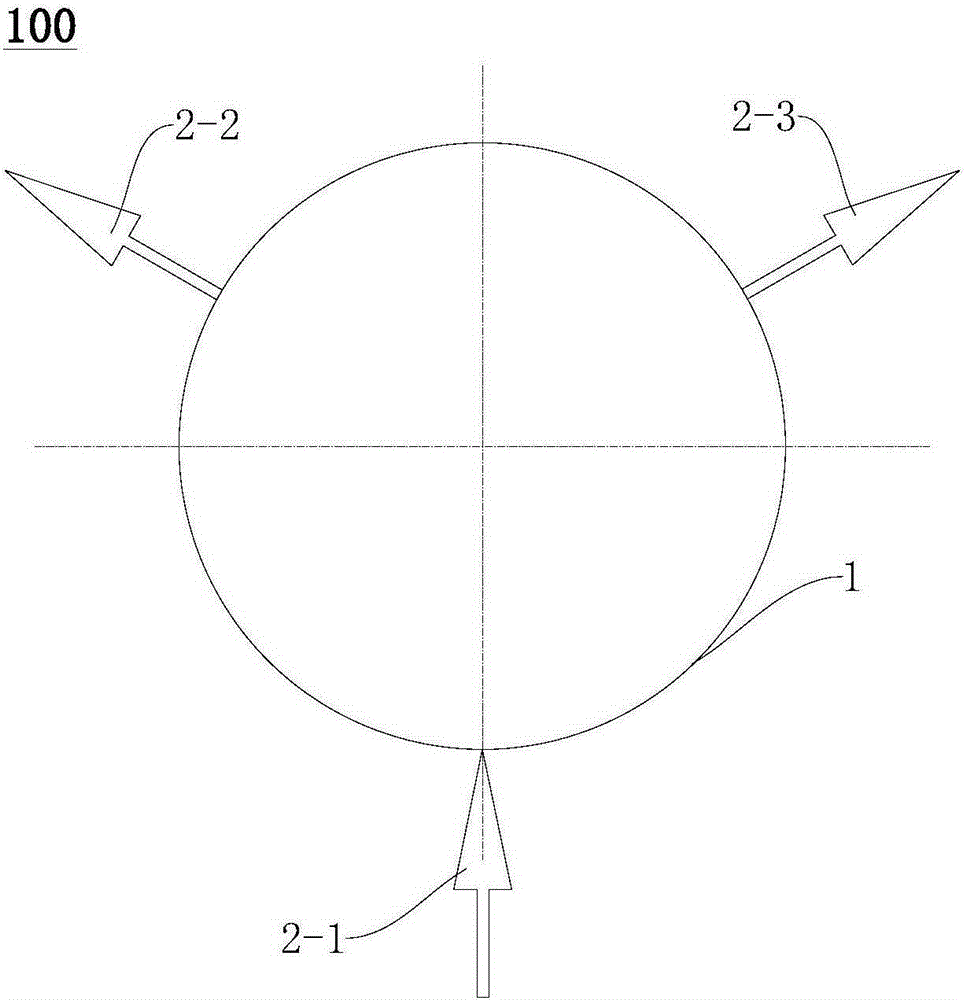

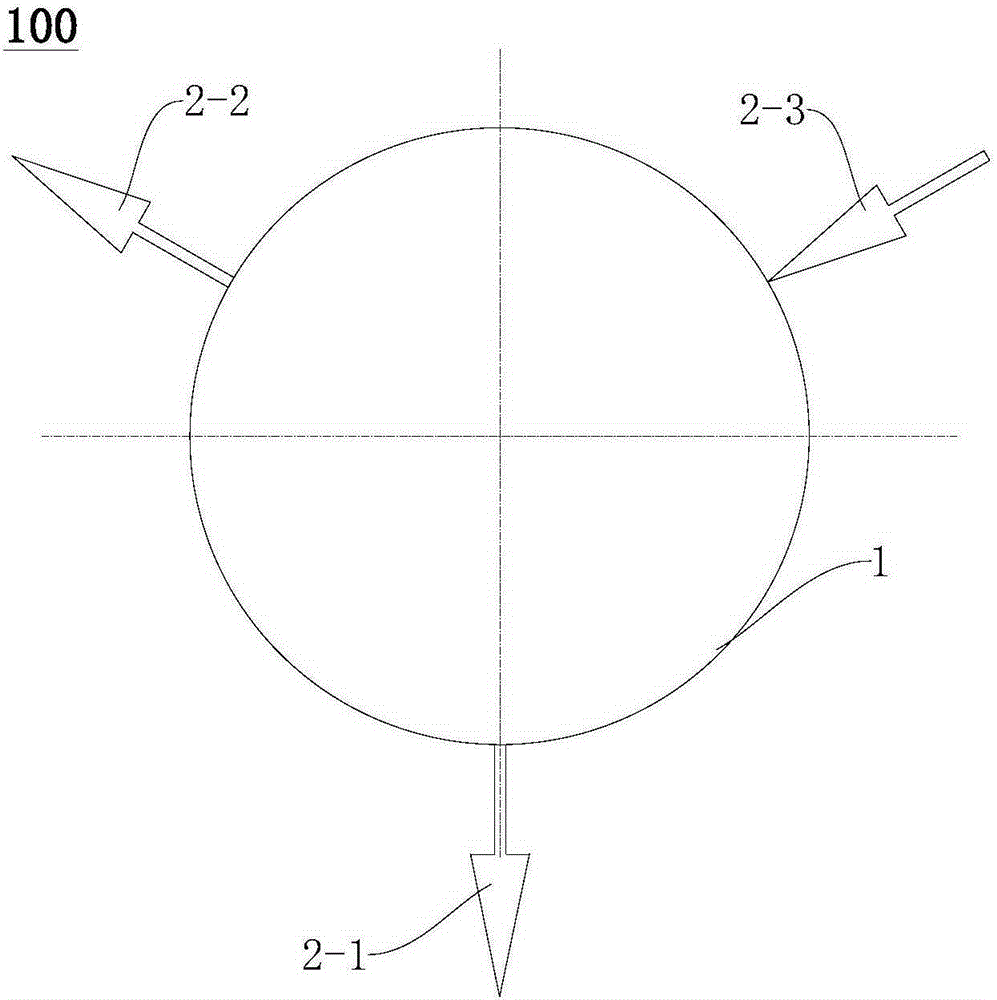

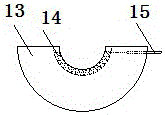

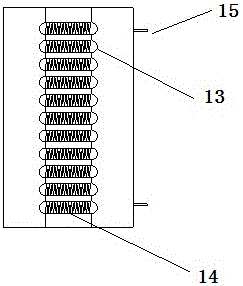

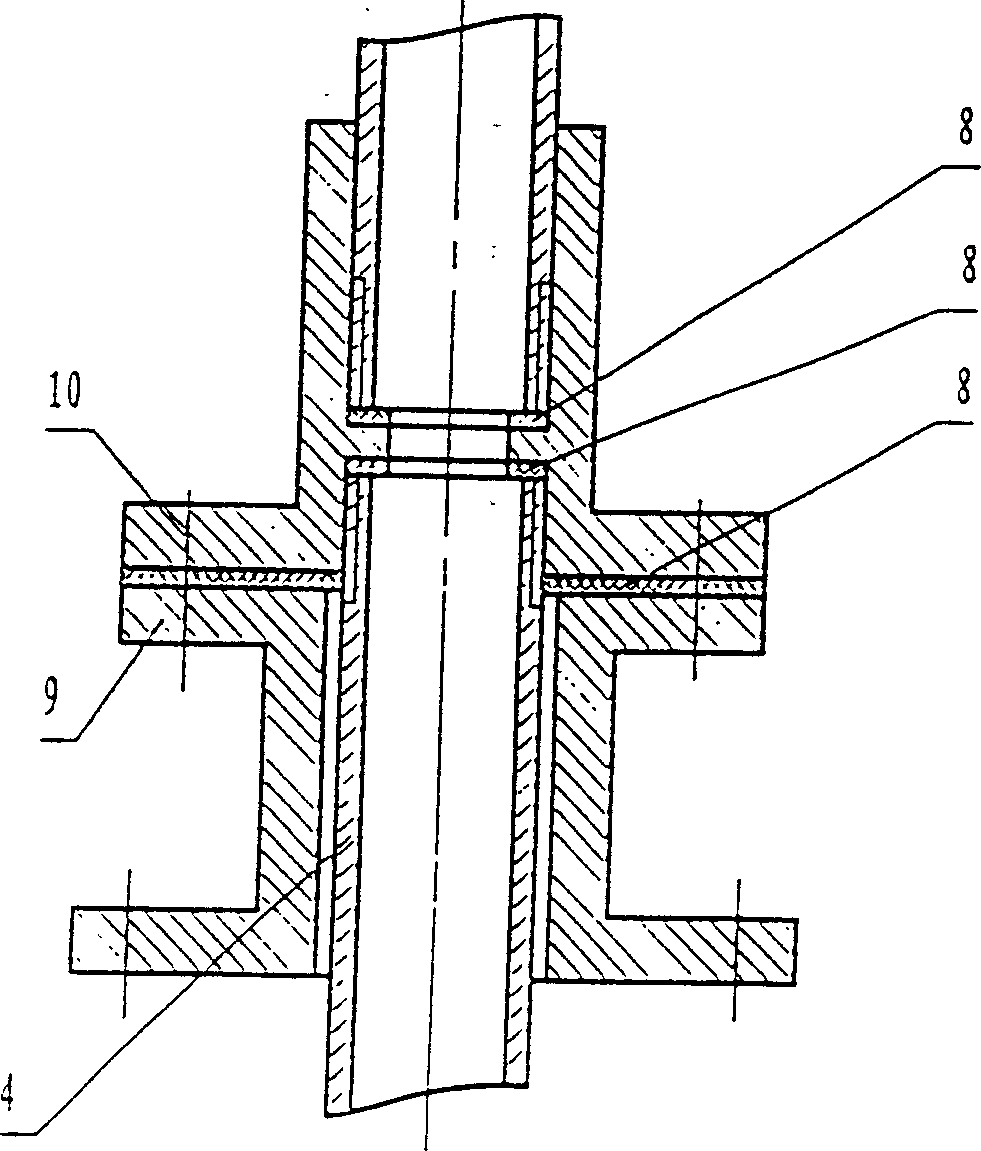

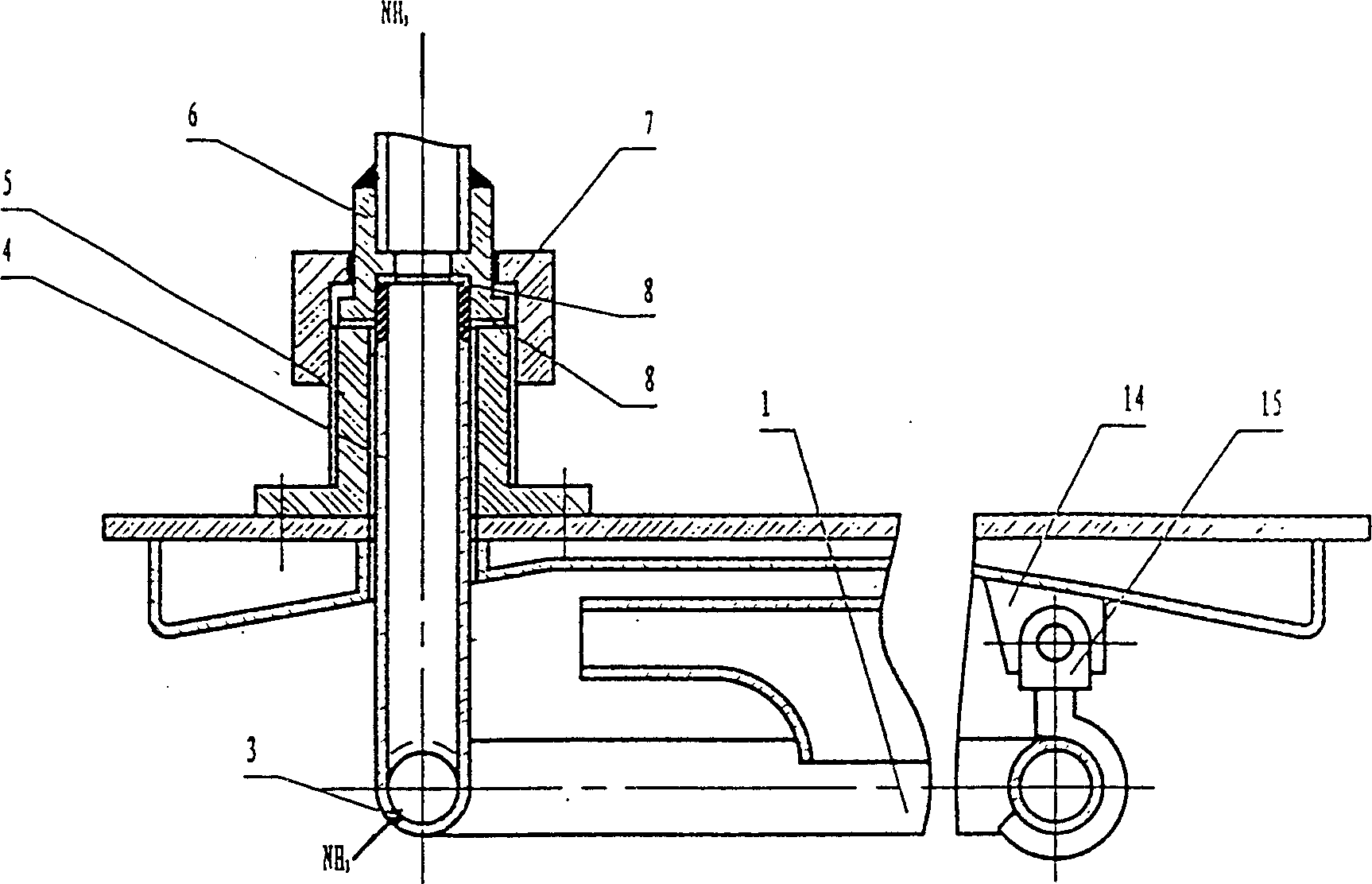

Demountable ring-shaped ammonia-feeding pipe equipped on nitriding furnace for making atmosphere homogeneous

The present invention is detachable and replaceable ring ammonia feeding pipe assembly for nitriding furnace to promote atmosphere homogenization, and belongs to the field of heat treating technology. The ring ammonia feeding pipe assembly includes ring ammonia feeding pipe and ammonia feeding pipe seat, and the detachable and replaceable ring ammonia feeding pipe is set horizontally below the furnace cover and has 45 deg outwards inclined lower part with small hole. The straight pipe welded to the ring ammonia feeding pipe is connected to the ammonia feeding pipe seat via pressing nut or flange. The present invention has no leakage of furnace gas, convenient detaching and replacing, less deformation, and long service life and can ensure homogeneous atmosphere inside the nitriding furnace and thus stable and high workpiece nitriding quality.

Owner:SHANGHAI JIAO TONG UNIV

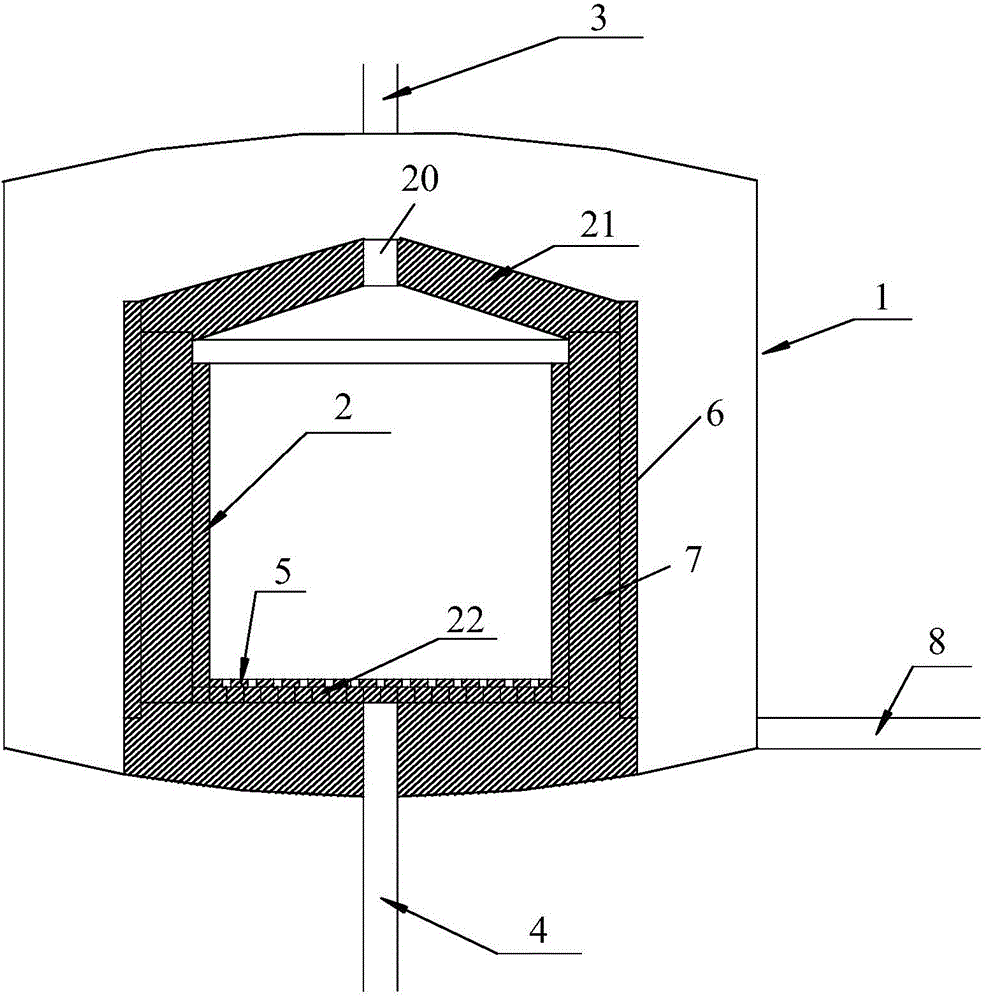

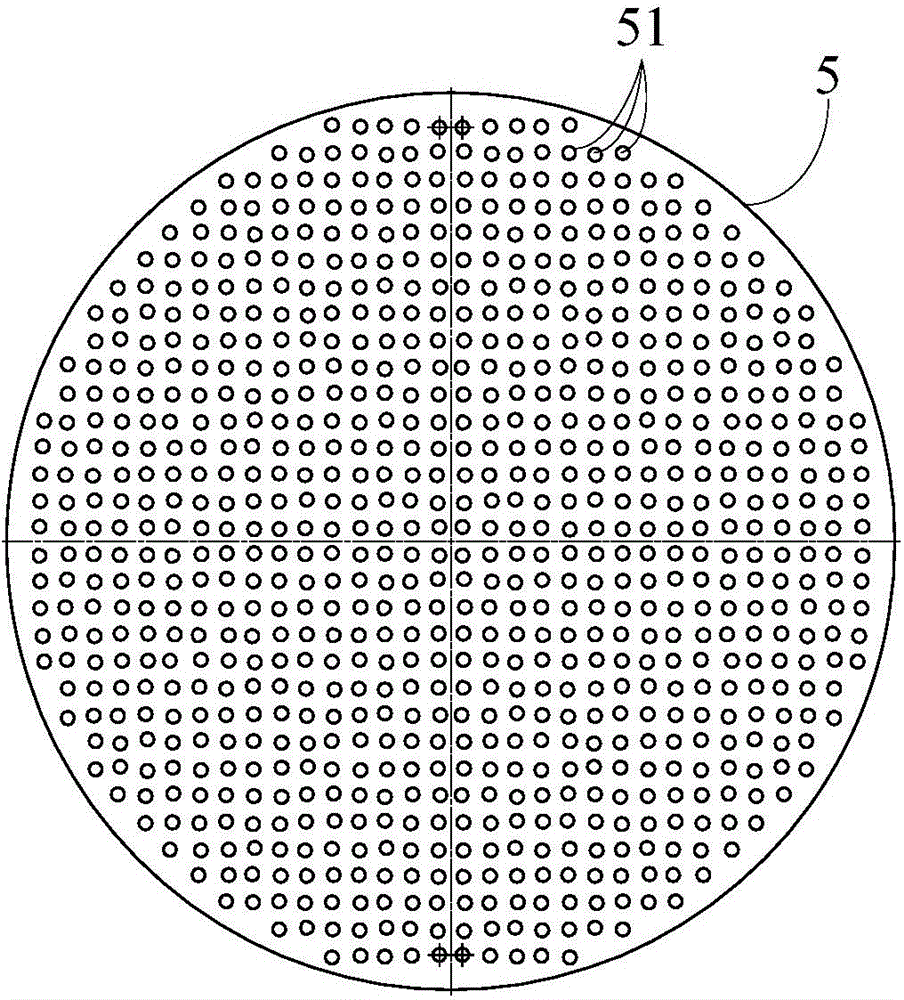

Intermediate frequency furnace for sintering various volatile substances

ActiveCN104457284AConsistent sintering effectHydrogen increasesMaintainance of heating chambersElectric heating for furnacesHydrogen atmosphereIntermediate frequency

The invention discloses an intermediate frequency furnace for sintering various volatile substances, and belongs to the field of intermediate frequency furnaces. The intermediate frequency furnace comprises a furnace body, a heating body, an upper air inlet and a tungsten rod, wherein the heating body is arranged at the upper end inside the furnace body and provided with an upper opening, the upper air inlet is formed in the upper end of the furnace body and communicated into the furnace body, the tungsten rod is arranged at the bottom inside the heating body, lower air inlets are formed in the bottoms of the furnace body and the heating body, and the lower air inlets communicate the space outside the furnace body with the space inside the heating body. Due to the fact that the lower air inlets communicating the space outside the furnace body with the space inside the heating body are formed in the bottoms of the furnace body and the heating body, air inside the furnace body can be exhausted by the upper air inlet, hydrogen enters the heating body through the lower air inlets and then enters the furnace body through the upper opening in the heating body to build a hydrogen protective atmosphere, the hydrogen passing through the surfaces of sintered materials can be increased, the hydrogen atmosphere in the furnace body can be more uniform, and the sintering effect of the sintered materials in the whole furnace is consistent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Non-sealing solid oxide fuel battery pack with double gas channels

InactiveCN101908637BUniform atmosphereIncrease the open circuit voltageFuel cells groupingFuel cell auxillariesGas chamberOxygen

Owner:HARBIN INST OF TECH

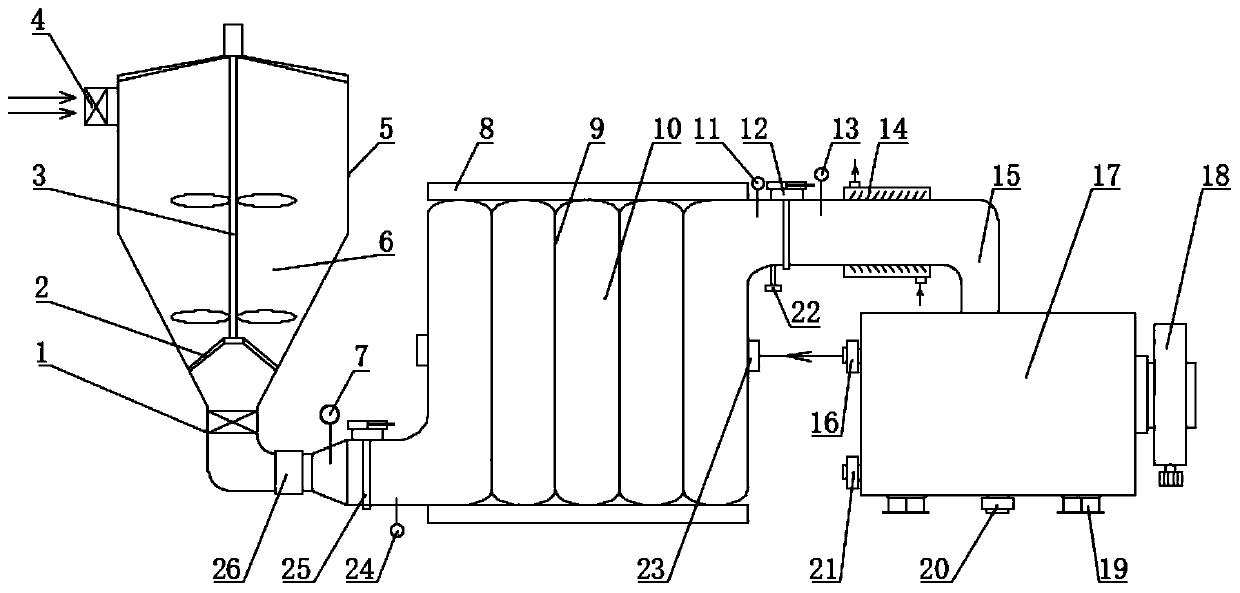

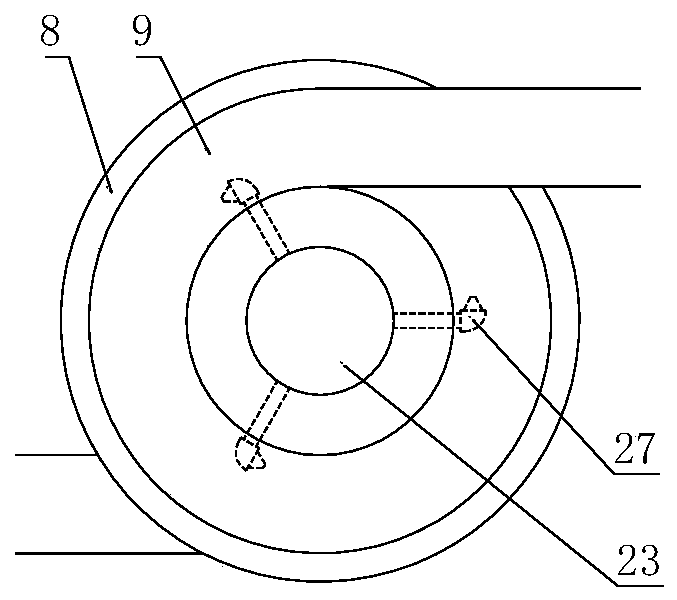

a co 2 Biomass continuous hydrothermal furfural preparation system and method under atmosphere

ActiveCN109621880BEfficient preparationImprove efficiencyOrganic chemistryChemical/physical/physico-chemical stationary reactorsSlurryFurfural

The invention discloses a system for preparing furfural from biomass through a continuous hydrothermal reaction in the atmosphere of CO2. The system comprises a raw material conveyor (6), a coil typereaction kettle (10) and a centrifugal machine (17); the raw material conveyor (6) comprises a feeding valve (4), a storage tank (5), a discharging valve (1) and a slurry conveyor (26); the coil typereaction kettle (10) is provided with a coil type reactor (9), a heating sleeve (8) sleeves the coil type reactor (9), and a CO2 pipeline (23) is arranged in the center of the coil type reactor (9); an exhaust port (16), a liquid outlet (21) and a solid phase outlet (20) are formed in the centrifugal machine (17), and the exhaust port (16) and the CO2 pipeline (23) are in butt joint. The continuous hydrothermal reaction is realized. The invention further discloses a method for preparing furfural from biomass through the continuous hydrothermal reaction in the atmosphere of CO2. The problems are solved that in an existing continuous reaction, operation is complex, and heating is not uniform, and product quality is improved effectively.

Owner:HUAZHONG UNIV OF SCI & TECH

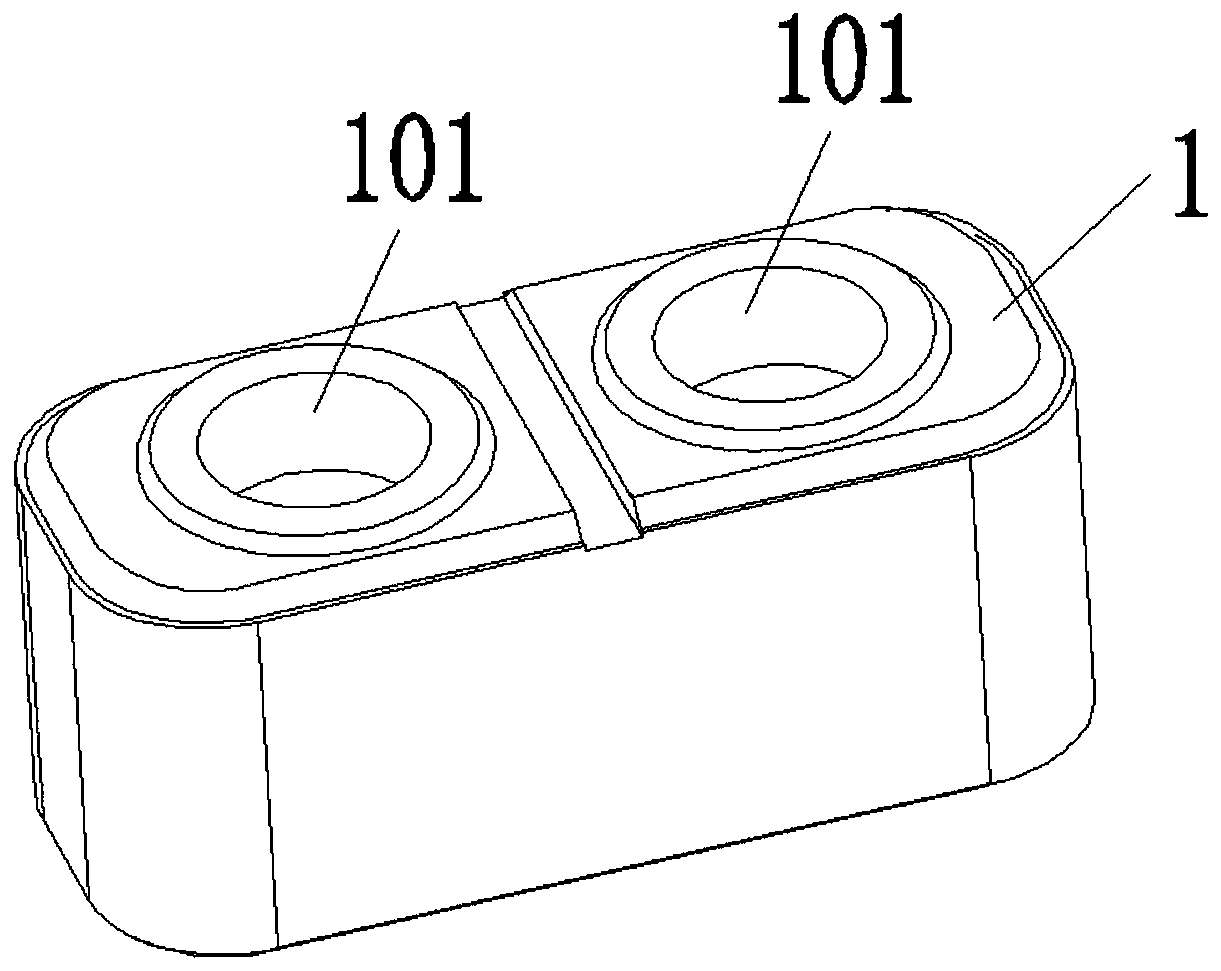

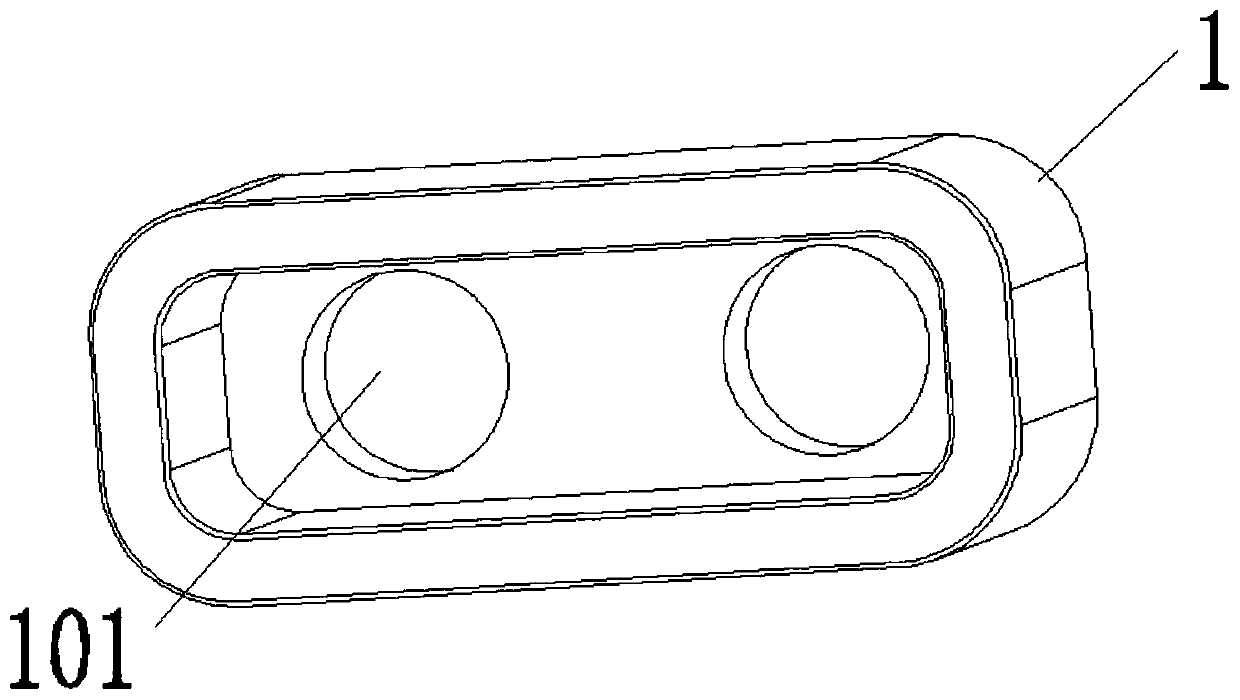

Molybdenum burning bowl and semiconductor ceramic semiconducting process

PendingCN111623637ANo deformationSkinnyFixed capacitor dielectricCharge supportsSemiconductorMolybdenum

The invention provides a molybdenum burning bowl and a semiconductor ceramic semiconducting process. The molybdenum burning bowl is of a cuboid structure, wherein three rows of air holes are evenly formed in the two side faces in the length direction. The semiconductor ceramic semiconducting process comprises the following steps that a closed furnace body is filled with 75% H2 + 25% N2 reducing gas, and heating molybdenum wires are electrified to heat the molybdenum wires to 1000-1100 DEG C; the molybdenum burning bowl is filled with products to be reduced, a furnace door on one side of the closed furnace body is opened on the premise of ensuring safety, and the molybdenum burning bowl is conveyed into a high-temperature-resistant furnace tube in the closed furnace body through a pushing mechanism for semi-conduction. Molybdenum has the characteristics of no deformation in a high-temperature reducing atmosphere, high temperature resistance, no discoloration in a reducing atmosphere, nopeeling and high strength, so that Al2O3 and a stainless steel burning bowl are replaced by the molybdenum burning bowl in the semiconductor ceramic semiconducting process, the process adaptability is obviously improved, and the economical efficiency of the molybdenum burning bowl is higher for a long time.

Owner:SHAANXI HUAXING ELECTRONICS DEV

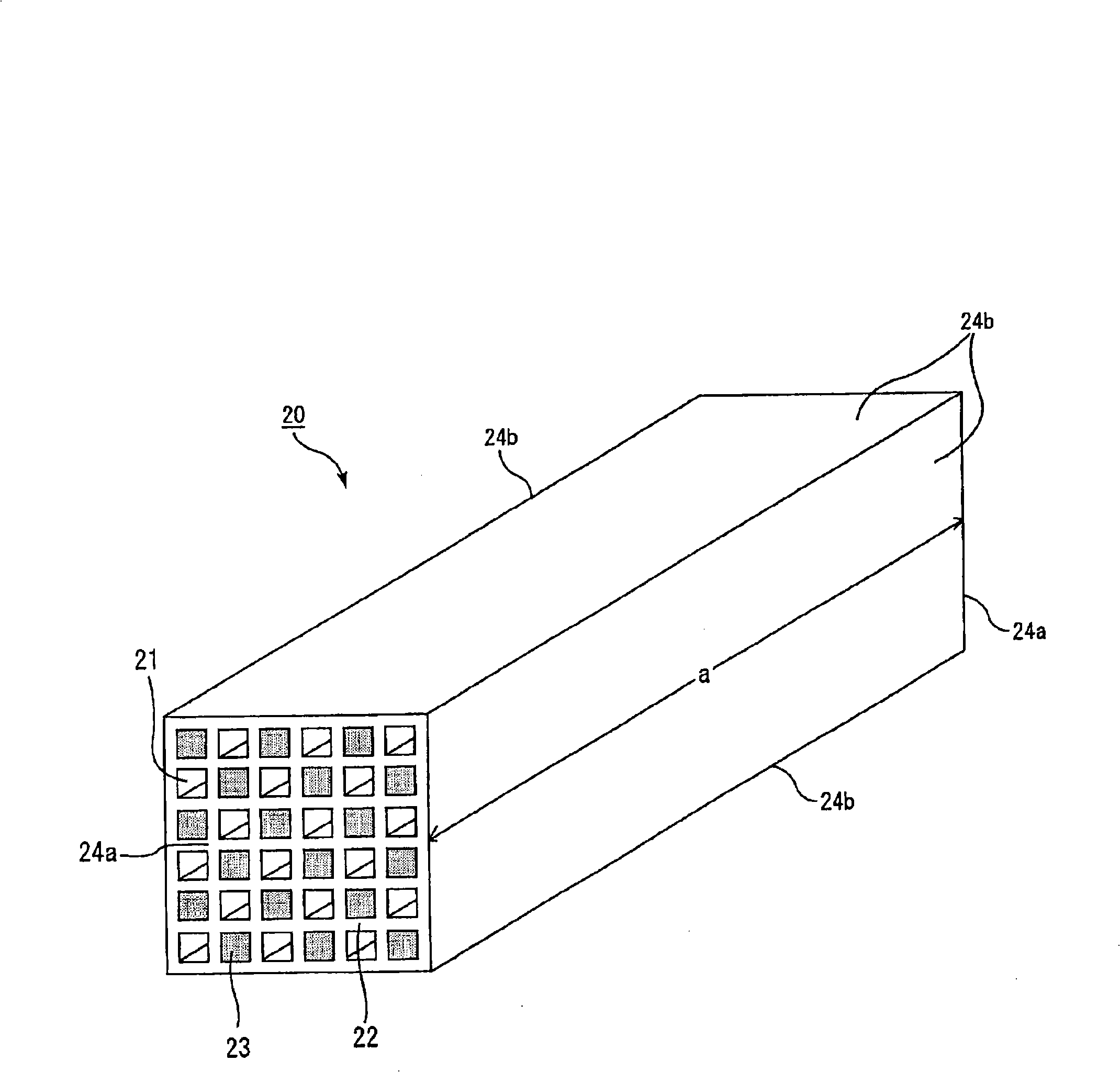

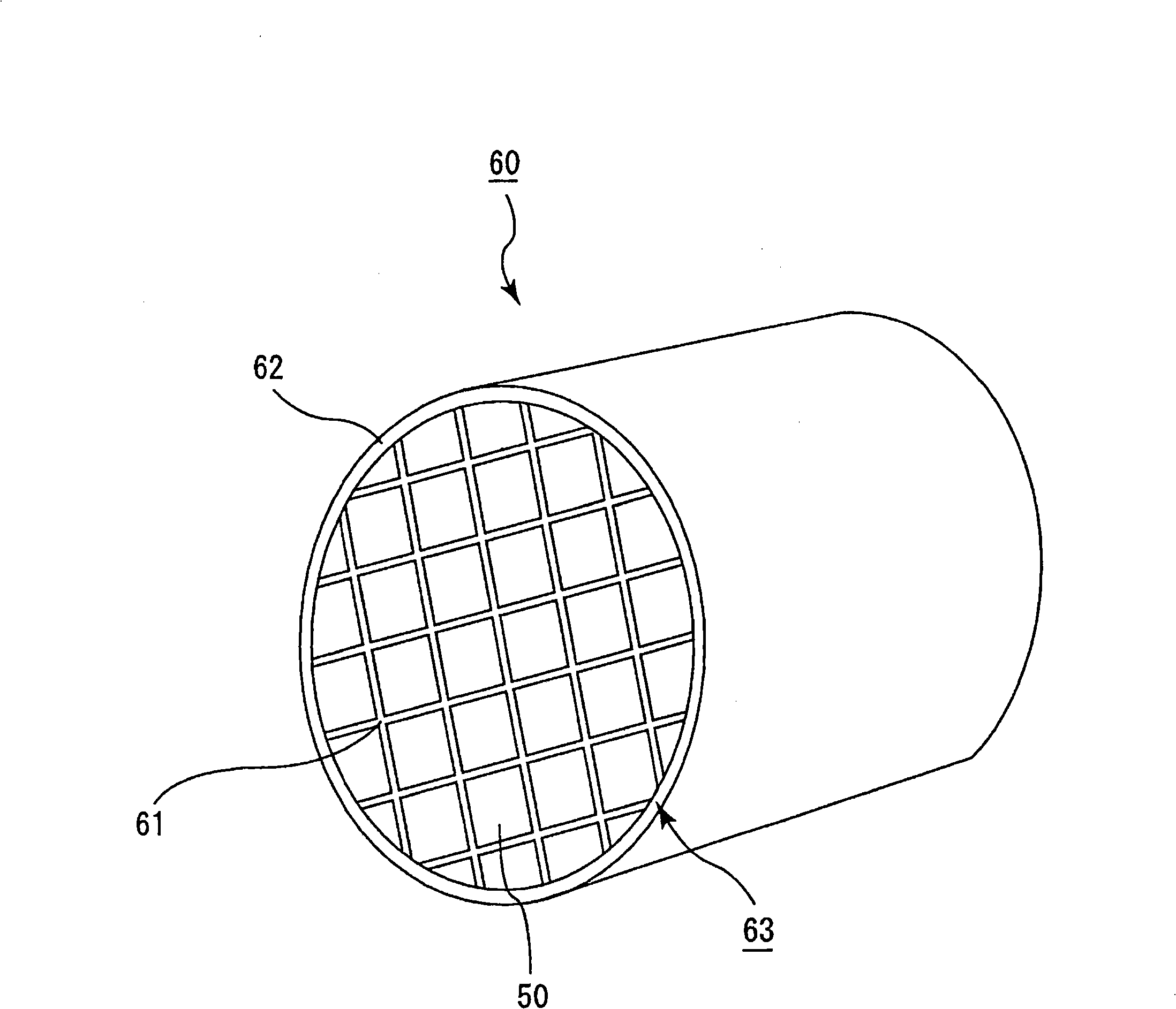

Firing jig and method for manufacturing honeycomb structured body

InactiveCN101318826AAvoid lostGuaranteed qualityCharge supportsThin material handlingHoneycomb structureMaterials science

Provided is a manufacturing method for a jig for firing and a honeycomb structural body. The jig for firing that even when repeatedly used in the firing of honeycomb molding while satisfactorily advancing the reaction of sintered body generation, is capable of preventing any coat layer detachment and is employable over a prolonged period of time to thereby attain reduction of running cost. The jig for firing is a jig for honeycomb molding firing including a housing for mounting thereon a columnar honeycomb molding composed mainly of silicon carbide with its side face laid down and including a coat layer provided on at least a face for honeycomb molding mounting of the housing, characterized in that the coat layer is composed mainly of silicon carbide, and that the arithmetic mean height of the coat layer determined in accordance with JIS B 0601(2001) is 10 mum or less.

Owner:IBIDEN CO LTD

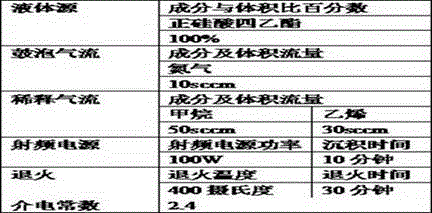

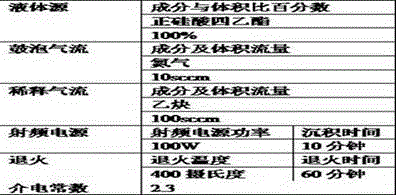

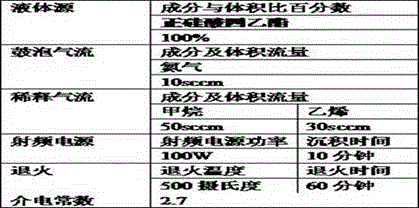

Manufacturing process of low dielectric constant film layer for microelectronic chip

ActiveCN103904026BImprove flatnessUniform chemical compositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen gasRadio frequency

The invention discloses a preparation method of a low dielectric constant thin film layer. When the vacuum degree in a furnace body is smaller than 10-30 Pa, a radio-frequency power supply and a matcher are started; after a second mass flow meter is started, exhaust nitrogen used for emptying residual gas in the furnace body is fed in; octamethylcyclotetrasiloxane and cyclohexane are mixed uniformly and injected into a pressure-proof stainless steel kettle, a baffle valve is shut down manually, bubbling nitrogen and inert gas are injected respectively from a first gas inlet pipe and a second gas inlet pipe, sequentially flow through a first pressure-proof gas mixing tank, the pressure-proof stainless steel kettle and a first nozzle and are fed into the furnace body, accordingly the octamethylcyclotetrasiloxane and the cyclohexane are brought into the furnace body, and the octamethylcyclotetrasiloxane, the cyclohexane, the bubbling nitrogen and the inert gas deposit on the surface of a substrate to form the thin film layer under the plasma condition. According to the method, the dielectric constant value of a thin film is adjusted and controlled conveniently and precisely, the thin film layer with a low dielectric constant value is obtained, chemical components of the thin film layer are more uniform, the thin film layer has good thermostability and hardness, and flatness of the thin film is improved.

Owner:佛山市萍枫机械设备有限公司

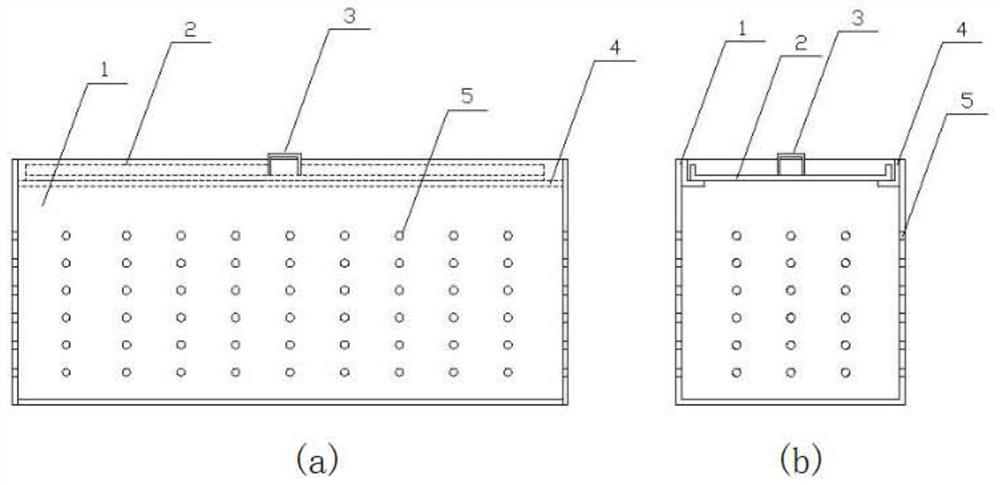

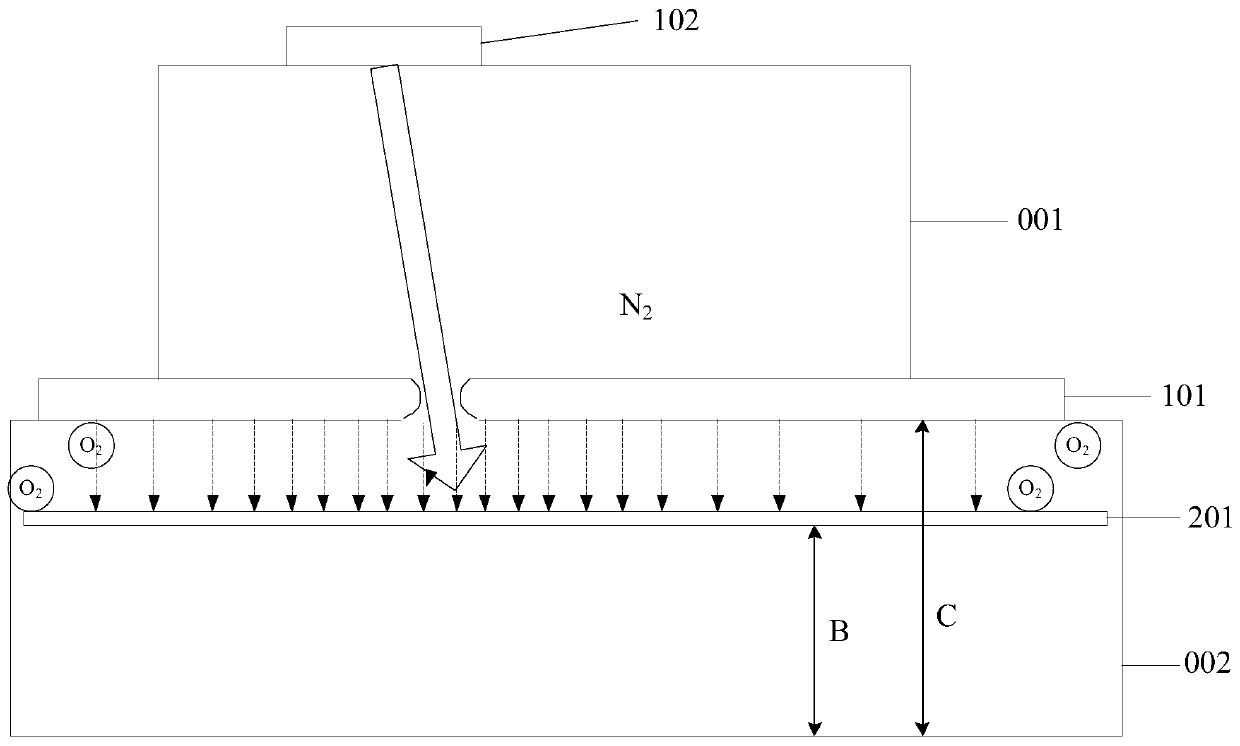

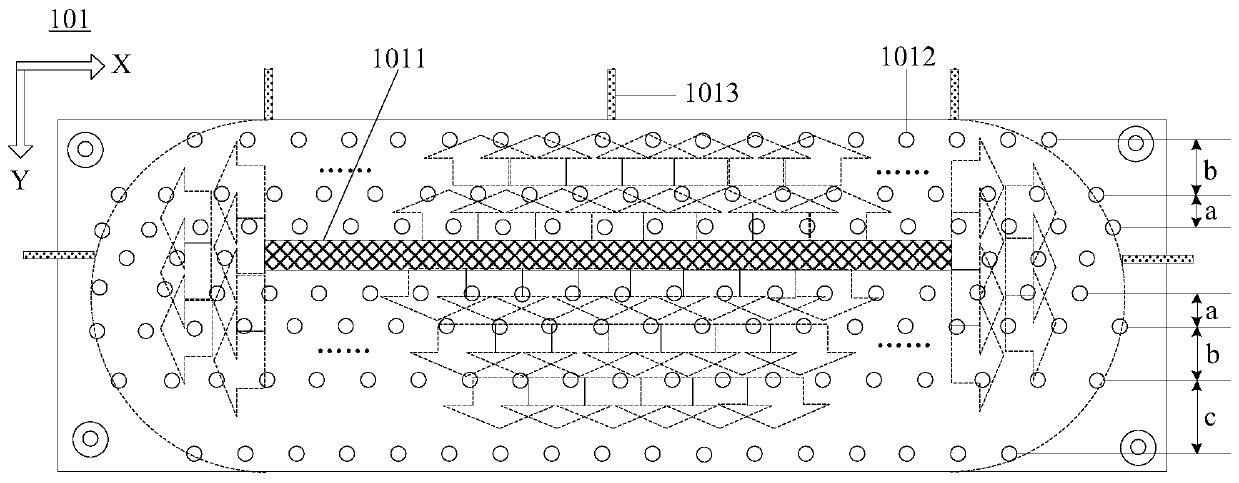

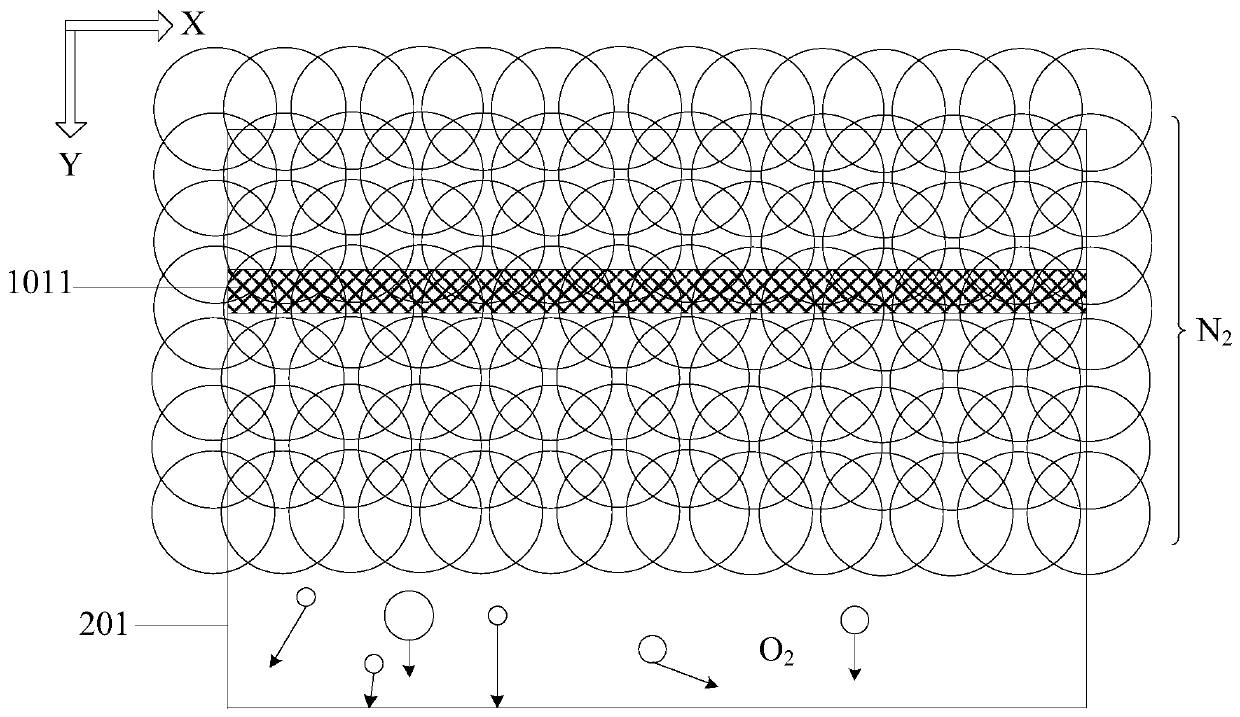

Laser annealing equipment

ActiveCN111446187AUniform atmosphereNo oxygen interferenceFinal product manufactureSolid-state devicesAmorphous siliconNitrogen atmosphere

The invention discloses laser annealing equipment which comprises a deoxidation chamber, an excimer laser generator located above the deoxidation chamber and an annealing chamber located below the deoxidation chamber. The annealing chamber comprises a bearing table used for bearing a substrate with an amorphous silicon film; the deoxidation chamber comprises a bottom cover plate, an annealing window and a nitrogen conveying pipe; the bottom cover plate comprises a laser exit slit and a plurality of gas diffusion holes distributed around the laser exit slit; nitrogen provided by the nitrogen conveying pipe fills the deoxidation chamber and diffuses to the bearing table through the laser exit slit and the gas diffusion holes; and a laser emitted by the excimer laser generator is emitted to the bearing table through the annealing window and the laser exit slit in sequence. The multiple gas diffusion holes are additionally formed in a periphery of the laser exit slit so that a nitrogen atmosphere blown to the surface of the bearing table by the laser exit slit and the gas diffusion holes is uniform, a melting recrystallization area is in a pure nitrogen environment, crystallization quality is improved, and then a product yield is increased.

Owner:BOE TECH GRP CO LTD +1

Heat treatment method of perforating head

InactiveCN101012492BUniform temperatureUniform atmosphereFurnace typesHeat treatment process controlAlcoholPunching

The invention discloses a heat processing method of punching bow, which comprises the following steps: (1) heating furnace temperature to 850 deg.c; loading bow in the furnace; dripping alcohol in the furnace at 5-6ml / min; finishing dripping alcohol after 1h; starting dripping the composite liquid of alcohol and water with bulk rate at 1: 4; (2) heating to 1000 deg.c; insulating 4h; keeping pressure of furnace to 0.6-1.0Kpa; (3) cooling temperature to 850 deg.c; fetching bow out of furnace; transmitting bow through high-temperature fan; making the temperature in the furnace evenly.

Owner:耿志佳

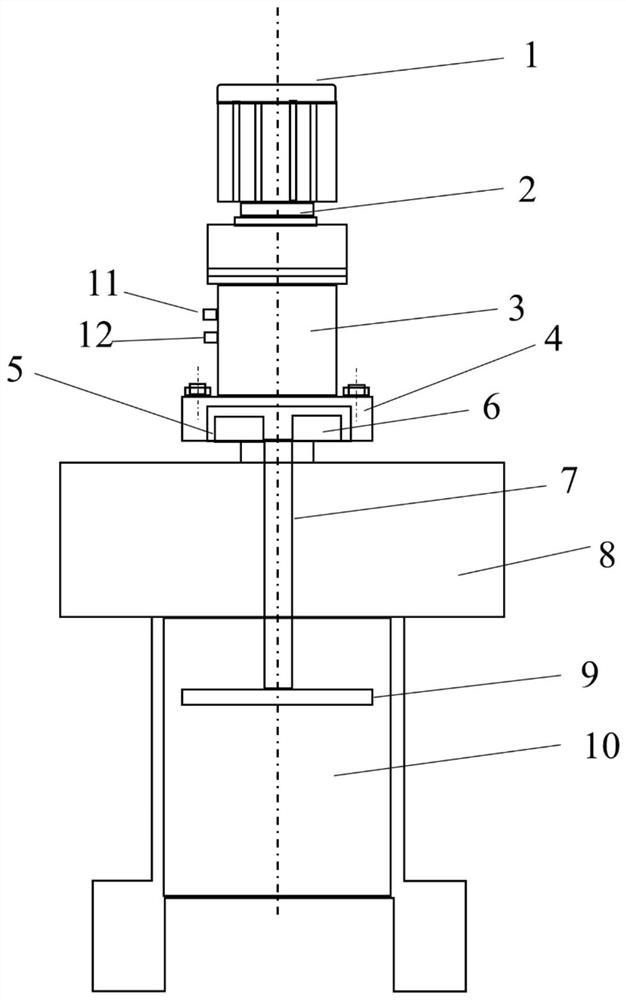

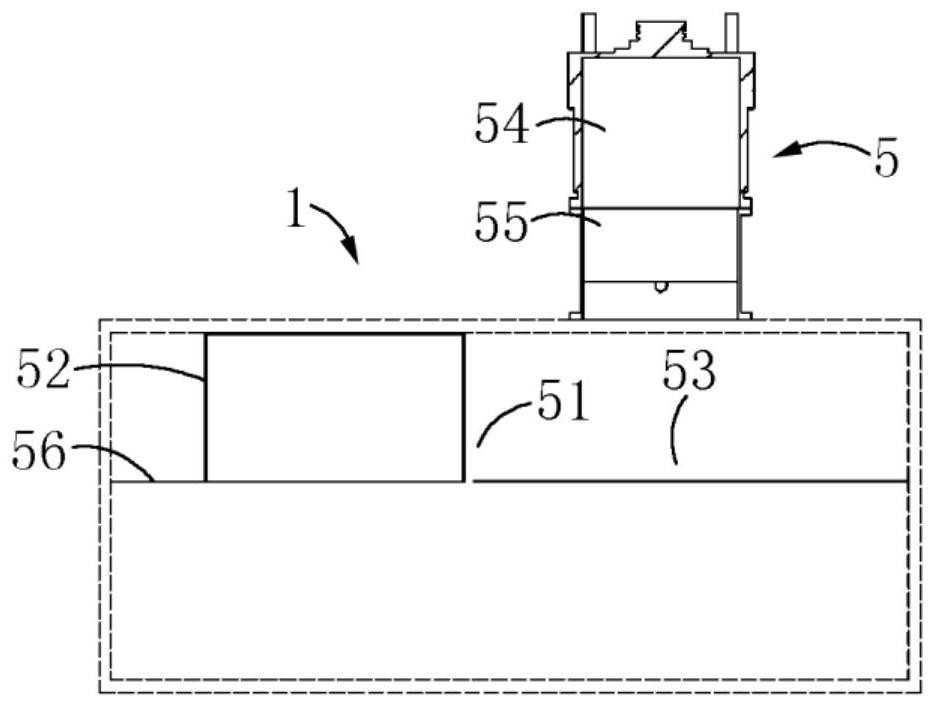

Magnetic rotary deposition device and high-temperature and high-pressure sintering furnace based on same

PendingCN113465363AAchieve perturbationPrevent leakageMuffle furnacesCharge treatment typeRotational axisElectric machine

The invention discloses a magnetic rotary deposition device and a high-temperature and high-pressure sintering furnace based on the magnetic rotary deposition device, and belongs to the field of material science equipment. The magnetic rotary deposition device comprises an explosion-proof motor, a cooling device and a magnetic coupling transmission system which are sequentially arranged from top to bottom; the magnetic coupling transmission system comprises a speed reducer, an outer magnetic rotor, an isolation sleeve and an inner magnetic rotor; the speed reducer is arranged between the explosion-proof motor and the cooling device; the isolation sleeve is arranged on the outer side of the inner magnetic rotor and separates the inner magnetic rotor from the outer magnetic rotor; the outer magnetic rotor is magnetically connected with the speed reducer through a coupler; the inner magnetic rotor is connected with a rotating shaft through a coupler; and the other end of the rotating shaft is connected with a rotary deposition substrate. According to the device, the magnetic coupling transmission system is matched with the rotary deposition substrate, so that the problem that the uniformity of a product is difficult to guarantee for chemical vapor deposition in which gas participates due to poor flowability of high-pressure gas in a furnace chamber of an existing high-temperature and high-pressure gas pressure furnace is solved.

Owner:XI AN JIAOTONG UNIV

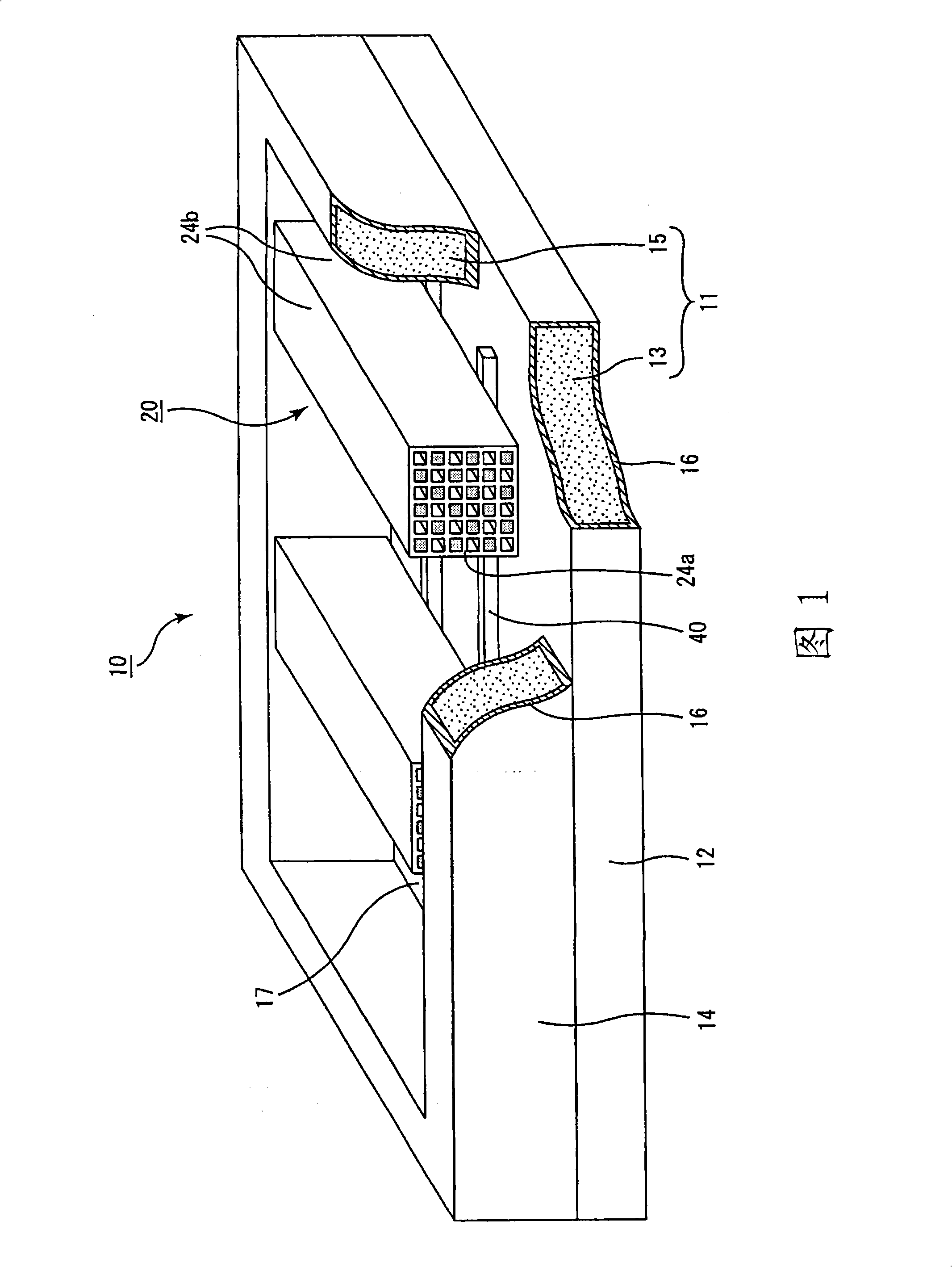

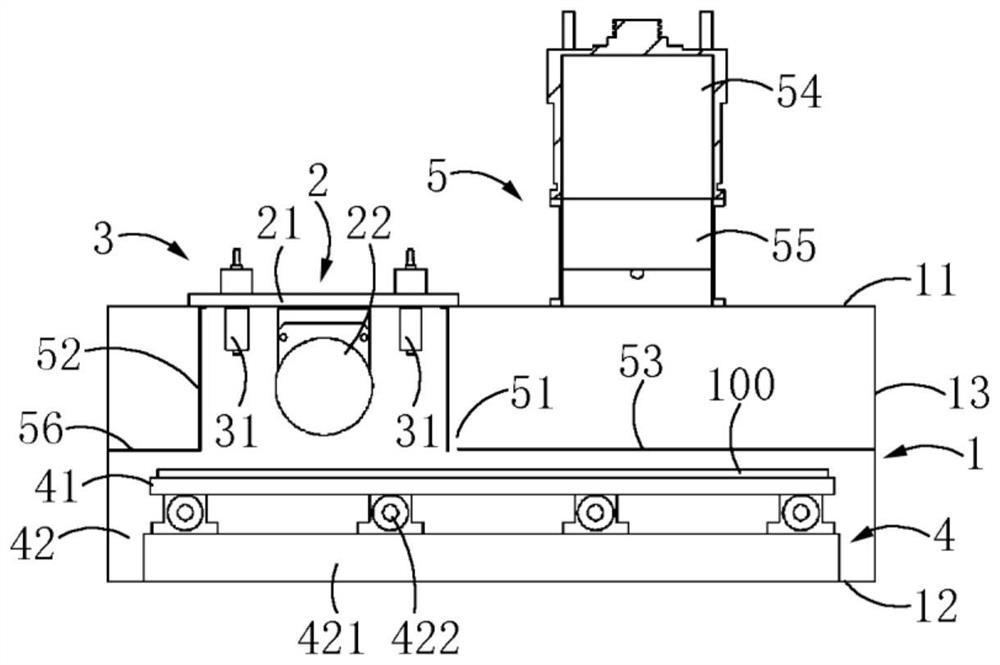

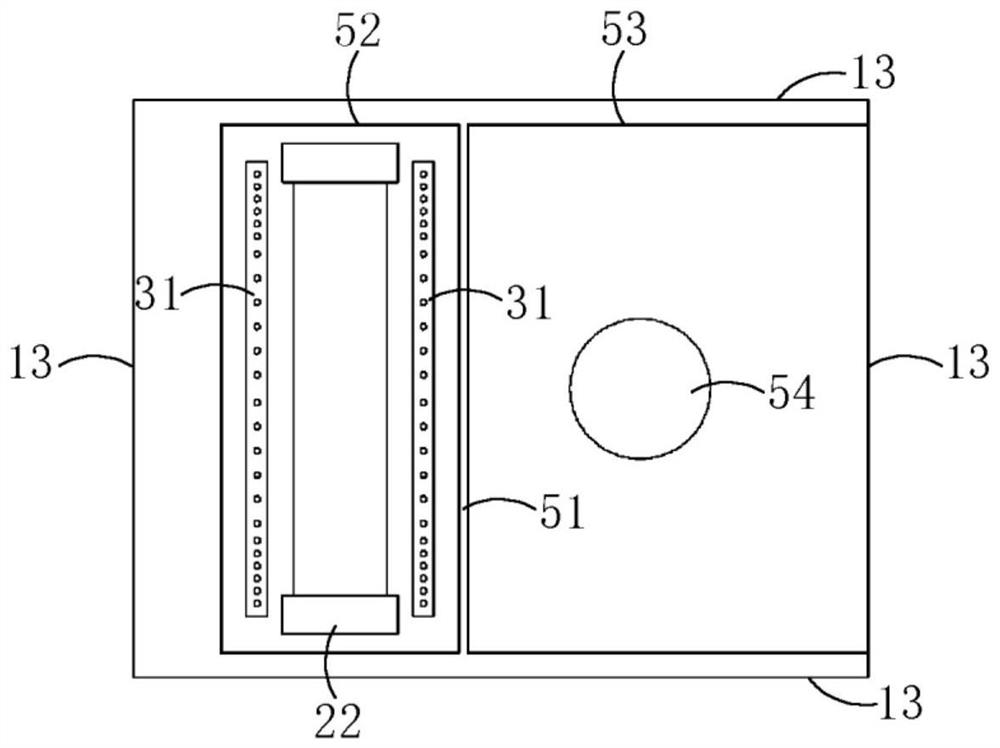

Semiconductor process equipment

ActiveCN112391597AUniform atmosphereEnsure coating uniformityVacuum evaporation coatingSputtering coatingPhysicsDeposition process

The embodiment of the invention provides semiconductor process equipment. The semiconductor process equipment is used for carrying out a rare earth deposition process on a substrate, and comprises anelectrode assembly and an air inlet mechanism which are arranged on the top wall of a process chamber and extend in a first direction; the air inlet mechanism is arranged around the electrode assembly; a moving mechanism is arranged at the bottom in the process chamber, extends in a second direction and is used for bearing and driving the substrate to move in the second direction, and the second direction is intersected with the first direction; and an air extracting mechanism is arranged on the top wall of the process chamber and communicates with the process chamber, the air extracting mechanism is located on one side of the electrode assembly, the air extracting mechanism is provided with an air extracting opening in the process chamber, and the air extracting opening extends in the first direction and is close to the air inlet mechanism and used for enabling process gas in the process chamber to evenly pass through the surface of the substrate. According to the semiconductor process equipment, the sputtering rate of the target material can be greatly improved while the coating uniformity is ensured, so that the production cost is greatly reduced.

Owner:北京七星华创集成电路装备有限公司

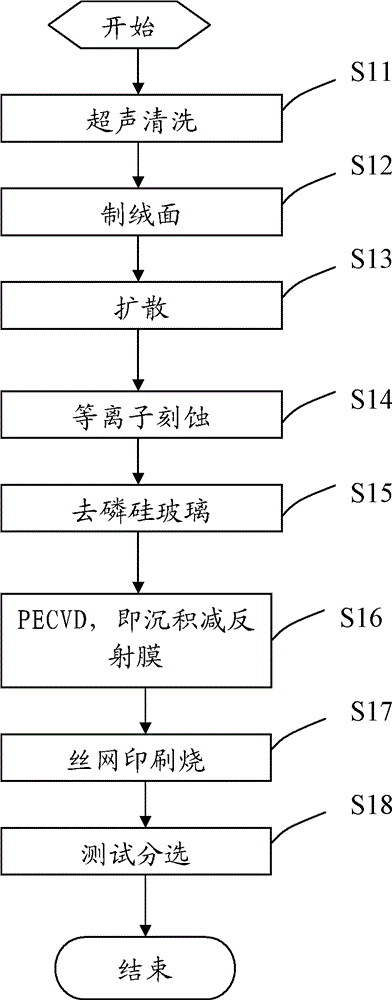

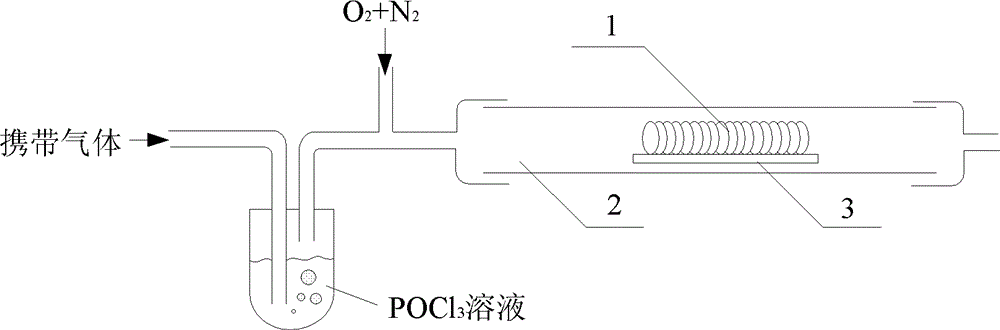

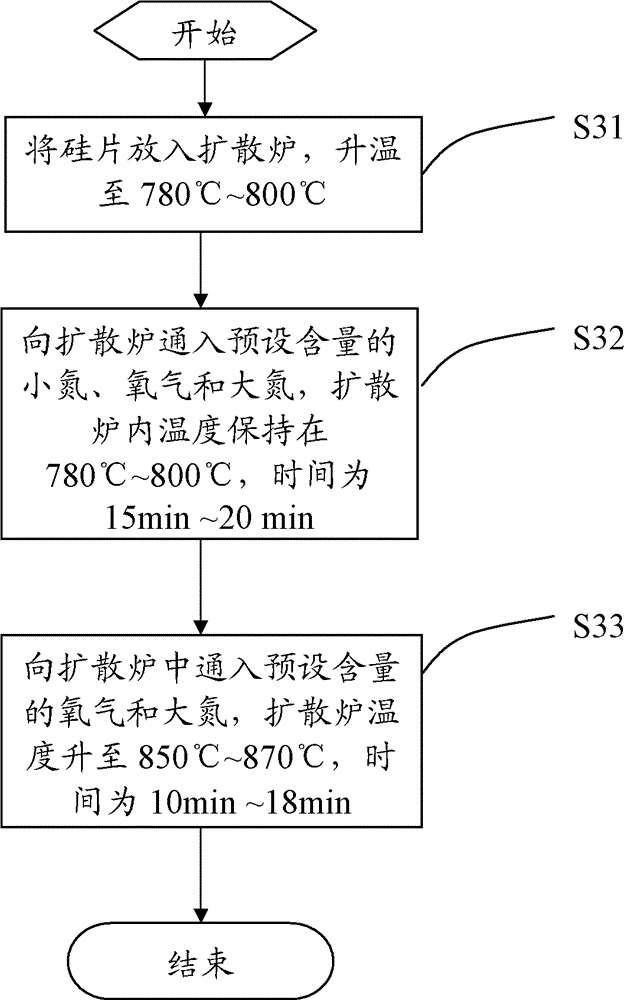

Crystalline silicon solar cell and diffusion method thereof

ActiveCN102254991BReduced activityReduce disturbanceFinal product manufacturePhotovoltaic energy generationDiffusion methodsMetallurgy

The invention discloses a crystalline silicon solar cell and a diffusion method thereof. The method comprises the following steps of: putting a silicon chip into a diffusion furnace and raising the temperature to 780-800 DEG C; introducing a preset amount of small nitrogen, oxygen and large nitrogen into the diffusion furnace through a diffusion furnace tube and keeping the internal temperature of the diffusion furnace at 780-800 DEG C for 15-20 minutes; introducing a preset amount of oxygen and large nitrogen into the diffusion furnace through the diffusion furnace tube and raising the internal temperature of the diffusion furnace to 850-870 DEG C for 10-18 minutes; and cooling the diffusion furnace and taking the silicon chip out, wherein the gas flow in the diffusion furnace tube is constant in the entire diffusion process. The depth of a PN junction of a solar cell produced with the method is small, the square resistance is more uniform, and the conversion efficiency of the solar cell is increased.

Owner:JETION SOLAR HLDG

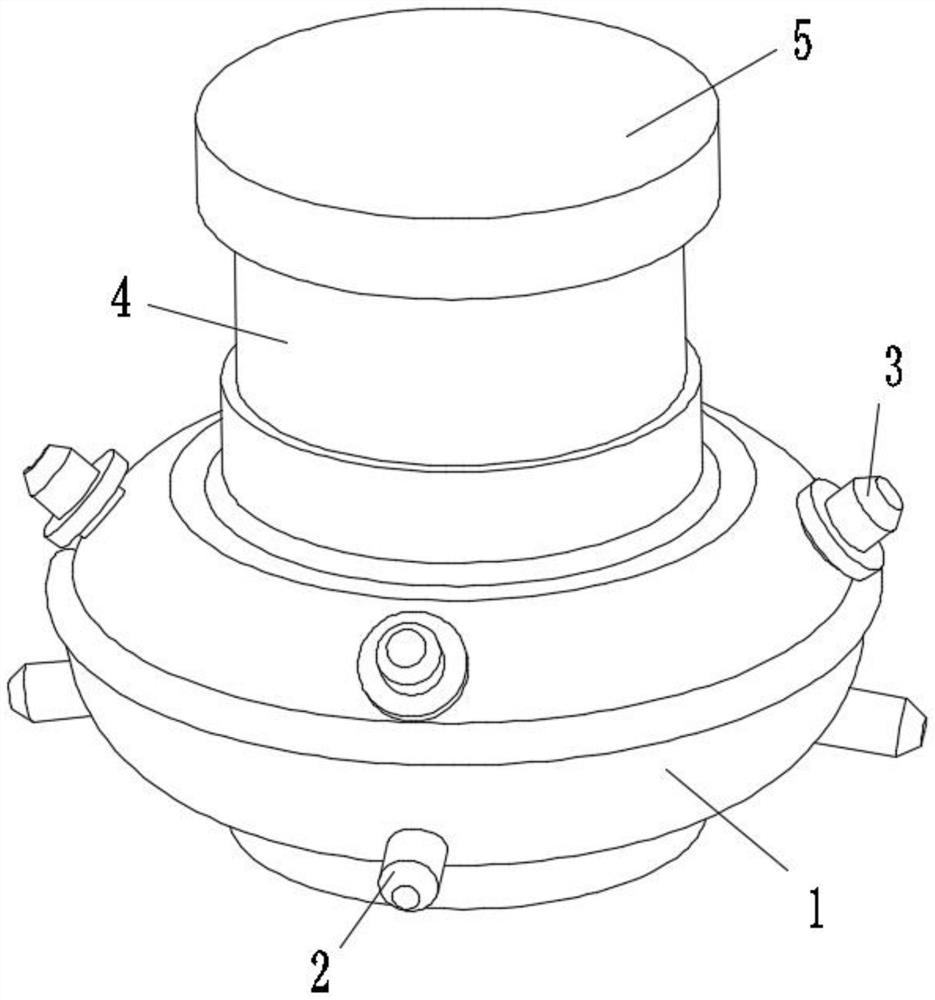

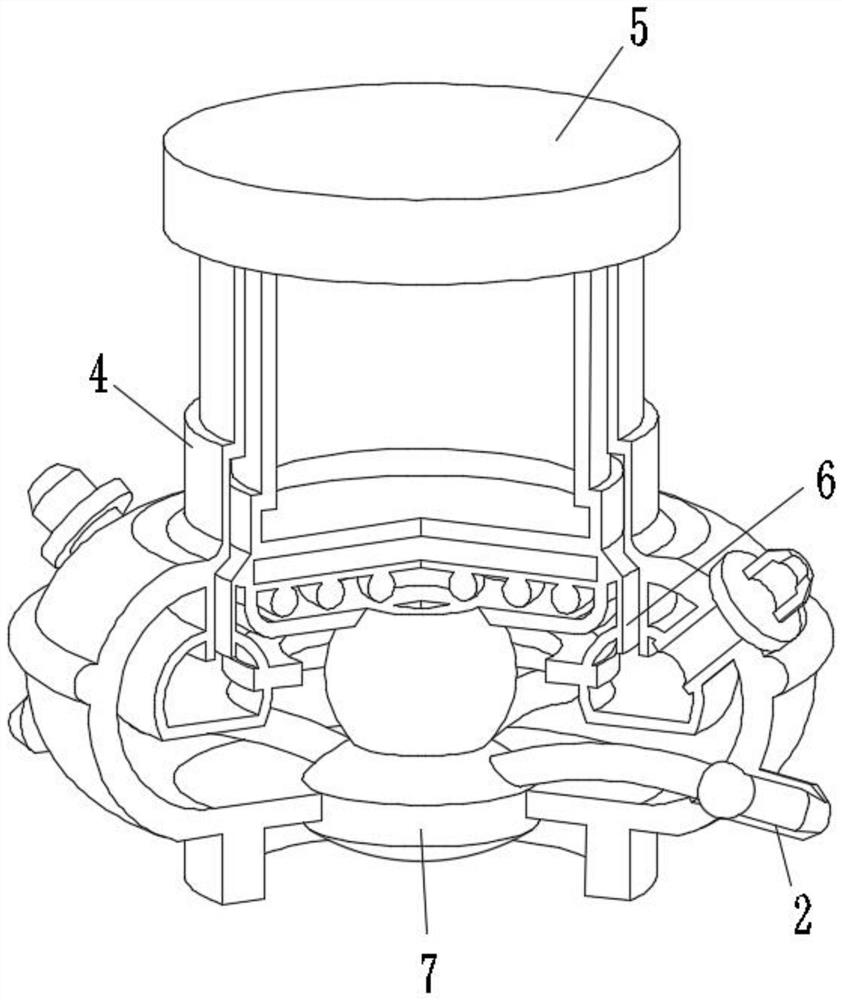

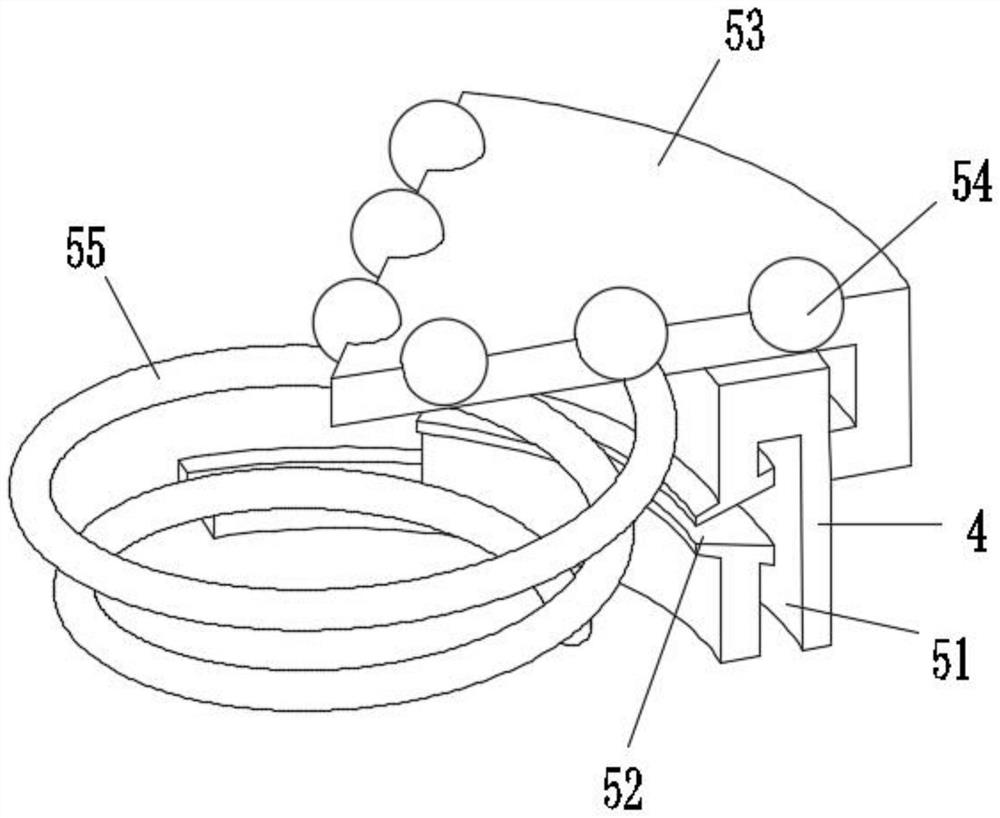

Gas medium homogenizer for high power laser diode sintering

ActiveCN104577705BImproving the quality of sintering infiltrationUniform atmosphereLaser detailsSemiconductor lasersHigh power lasersHigh power diode laser

The invention discloses a gas medium homogenization device for high-power laser diode sintering, which relates to the field of optoelectronic technology. The suction nozzles of the equipment are sealed and matched, and the support is provided with an intake passage and an exhaust passage that communicate with the intake pipe and the exhaust pipe, and the other ends of the intake passage and the exhaust passage communicate with the hollow area in the middle of the support. Install the bracket on the sintering table, so that the heat sink with solder is fixed to the connecting plate in the hollow area, a high-power laser diode is placed on the heat sink with solder, and the suction nozzle of the sintering equipment is adsorbed above the hollow area, reducing the gas Entering from the intake passage, it can fully cover the surface of the solder, which can fully restore the solder in the sintering area of the laser diode chip, and then use the exhaust passage to export the reduced exhaust gas to form a complete circuit. The invention has the advantages of simple structure, homogenization of reducing gas, and improvement of consistency of solder reduction.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Safety electric furnace utilizing waste heat

PendingCN113899206AEfficient removalAvoid cloggingCharge treatment typeIncreasing energy efficiencyGas passingMechanical engineering

The invention discloses a safety electric furnace utilizing waste heat, and relates to the technical field of waste heat utilization equipment. The safety electric furnace structurally comprises a tank body, wherein an energy-saving mechanism is fixedly connected to the bottom of the inner side face of the tank body, the energy-saving mechanism comprises a motor, the surface of the motor is fixedly connected with the bottom of the tank body, an air control mechanism is fixedly connected to the top of the motor, a water inlet pipe and a water outlet pipe are fixedly connected to the surface of the air control mechanism, and activated carbon is fixedly connected to the bottom of the inner side face of the tank body. According to the safety electric furnace utilizing the waste heat, the problem of how to effectively utilize the waste heat generated by the electric furnace is solved by designing the energy-saving mechanism, when residual gas reaches the connecting wall after passing through the air outlet, water flow is introduced into the connecting wall, and the speed direction of the water flow is perpendicular to that of air flow, so that the heat transfer efficiency is improved more efficiently, in the process, toxic gas generated by smelting is effectively adsorbed by the activated carbon.

Owner:石颖曈

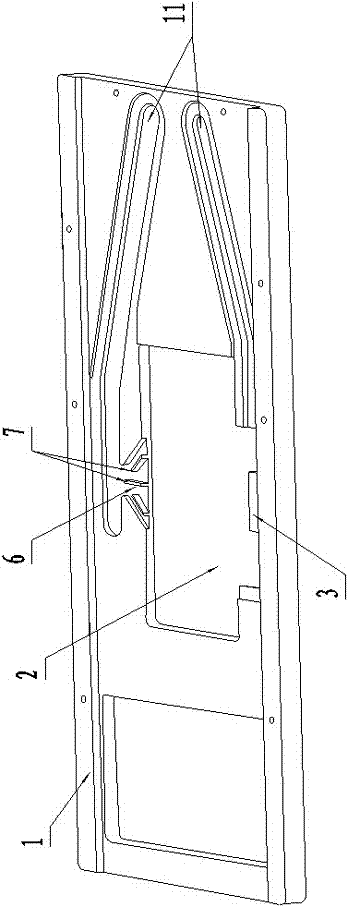

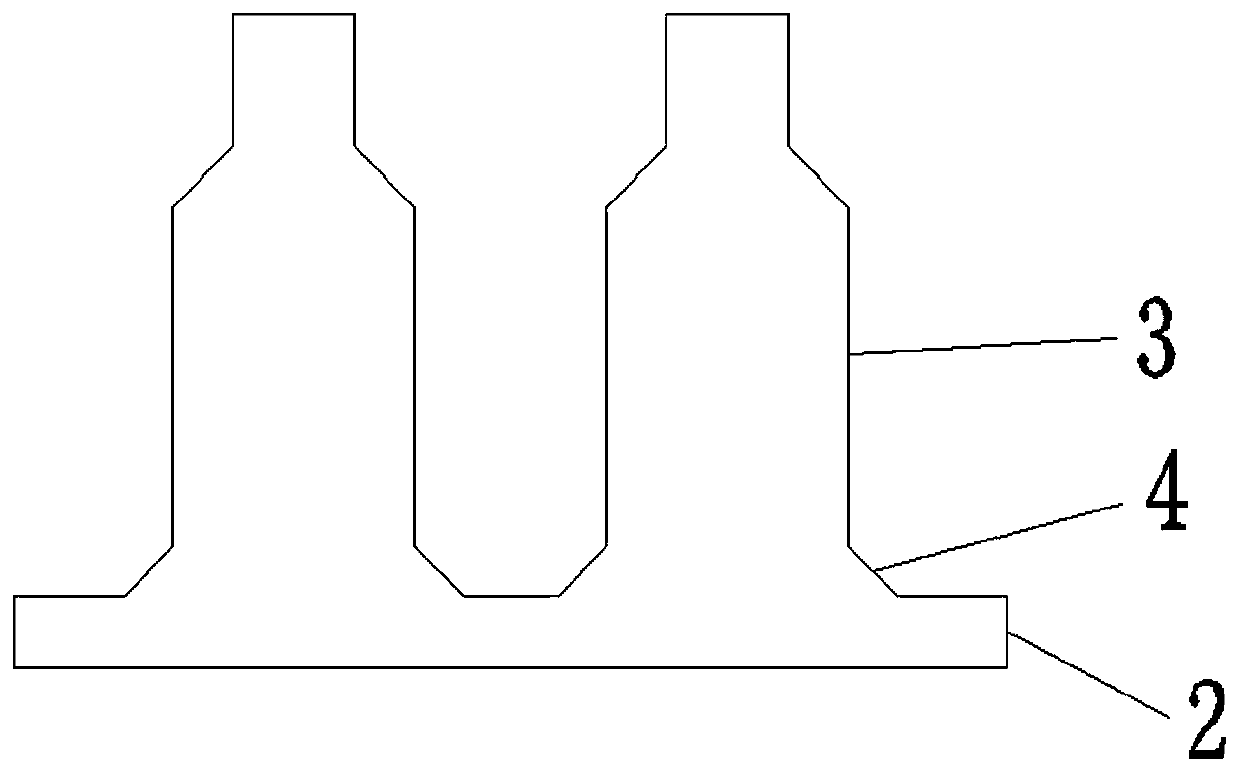

Load bearing pad for metallization sintering of high-voltage direct-current ceramic relay shell and sintering process

InactiveCN110931289AUniform atmosphereImproving Metallization Sintering QualityElectric switchesLower faceRelay

The invention discloses a load bearing pad for metallization sintering of a high-voltage direct-current ceramic relay shell. The relay shell is a cuboid with a hollow interior and an open bottom surface, two through holes are formed in the top surface of the cuboid, and the burning bearing pad comprises a bottom plate and support columns which are fixedly arranged on the bottom plate and used forbeing matched with the two through holes and supporting the relay shell. The invention further provides a metallization sintering process of the high-voltage direct-current ceramic relay shell, the load bearing pad is used as a supporting carrier, and a side sintering process is not adopted. The burning bearing pad is sleeved with the relay shell and makes line contact with the through hole of therelay shell, the phenomenon that the side wall sinks and deforms due to side burning is avoided, meanwhile, spaces are reserved in the upper face, the lower face and the side face of the relay shell,the atmosphere of the relay shell is more uniform in the metallization sintering process, and the metallization sintering quality of the relay shell is improved.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

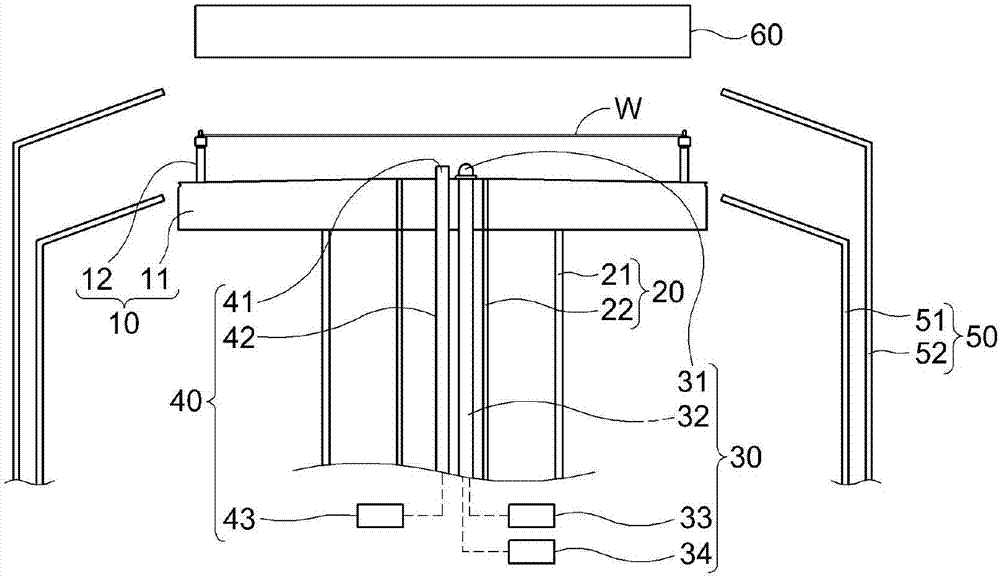

Substrate liquid processing apparatus and method

ActiveCN107078083AUniform atmosphereUniform supplySemiconductor/solid-state device manufacturingEngineeringMixed gas

The present invention relates to a substrate liquid processing apparatus which etches and cleans a substrate for a semiconductor. The substrate liquid processing apparatus comprises: a substrate supporting part for supporting a substrate on the top of a table being spaced apart from the substrate so that a surface to be processed is facing the bottom of the table; a rotational driving part for driving a rotation axis which rotates the table; and a processing liquid supplying part for supplying, in a processing space between the table and the substrate, processing liquid in a mist state in which gas is mixed or processing liquid in a steam state. According to the substrate liquid processing apparatus, it is possible to uniformize an atmosphere of the processing space between the substrate and the table, and to uniformly spray the processing liquid on the surface to be processed.

Owner:ZEUS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com