Patents

Literature

75results about How to "Change the status quo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-dimensional transition metal disulfides monocrystalline, and preparation method and applications thereof

InactiveCN104846434AControl vulcanizationDegree of controlPolycrystalline material growthFrom chemically reactive gasesGas phaseSingle crystal

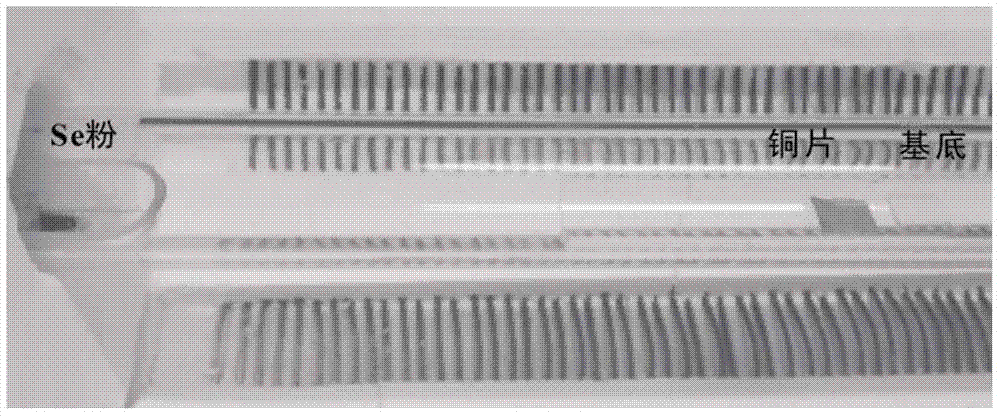

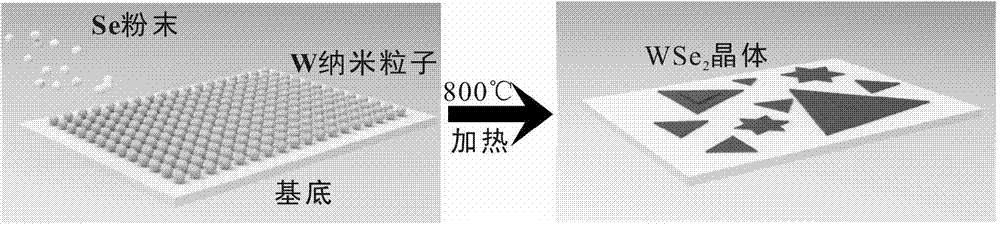

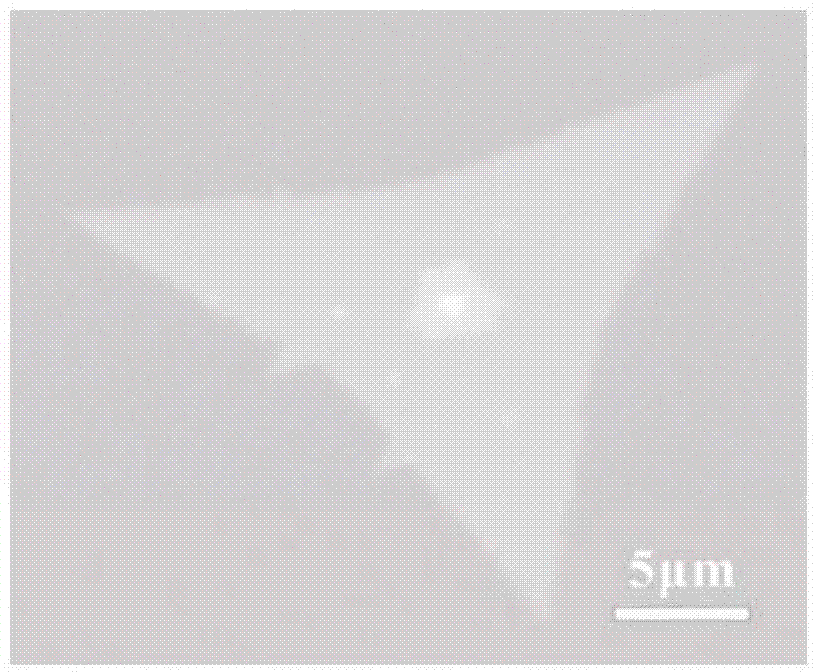

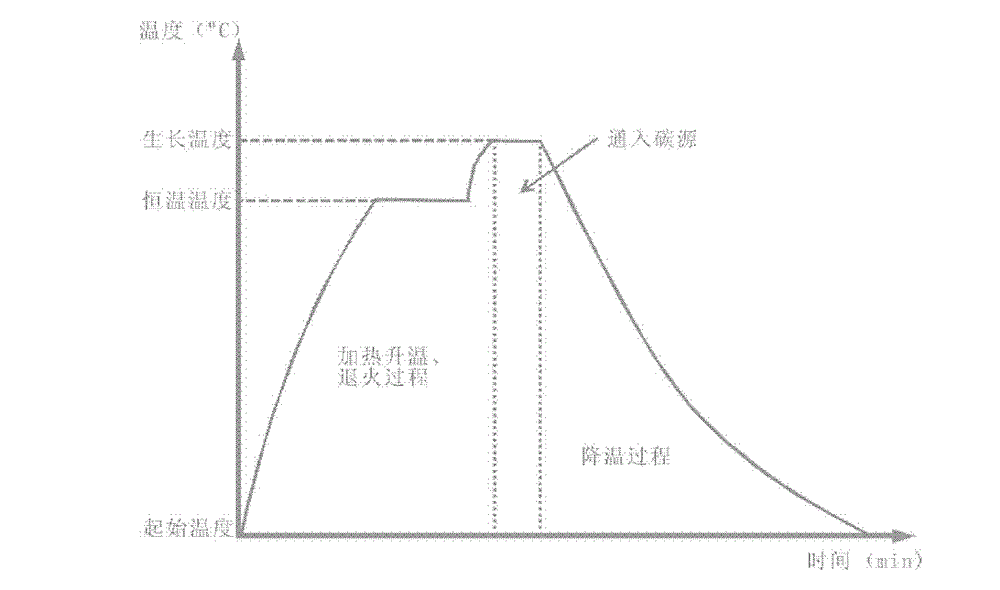

The invention discloses a two-dimensional transition metal disulfides (TMDs) monocrystalline, and a preparation method and applications thereof. According to the preparation method, in an inert atmosphere, assist control of the concentration of S or Se in a system is realized with common metal which is capable of reacting with sulfur family elementary substance (S, Se) and hydrogen so as to control sulfuration degree or selenylation degree of a transition metal layer, and controllable growth of TMDs monocrystalline is realized via chemical vapor deposition; deposition temperature is controlled to be 750 to 850 DEG C, and deposition time is controlled to be 5 to 15min so as to complete TMDs monocrystalline preparation; wherein, strict control on high-quality two-dimensional transition metal disulfides monocrystalline is realized via optimization of preparation parameters such as substrate sputtering treatment method, sulfur family elementary substance powder using amount, absorbed S / Se metal area and kinds, hydrogen concentration, growth temperature, and growth time.

Owner:WUHAN UNIV

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

Method for preparing mushroom culture medium by utilizing common water hyacinthes

InactiveCN1806493AChange the status quoChange the stance of extinctionHorticultureEutrophicationChemistry

The invention relates to a process for preparing mushroom culture medium by using common water hyacinths. The eutrophication makes the growth of common water hyacinths become ecological disaster, which blocks up shipping, and the invention is provided to restore water quality and make use of waste. The process employing common water hyacinths as raw material comprises the following steps: collecting, besting, dewatering, batching, pre-fermenting, and packing. The content of the product essential component of coarse protein, coarse fat, coarse fiber is as follows: 19.67%, 3.28%, and 18.03%, and for which size of mushroom and ear mushroom cultivated in mushroom medium is big and popular in market.

Owner:黎吉星

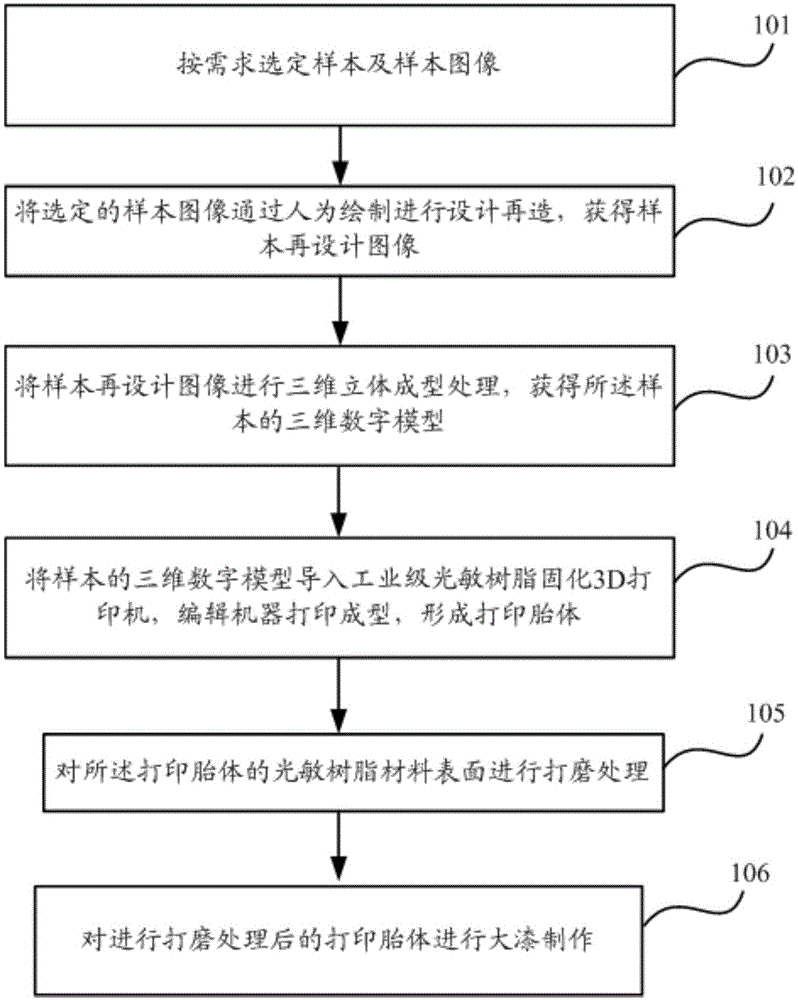

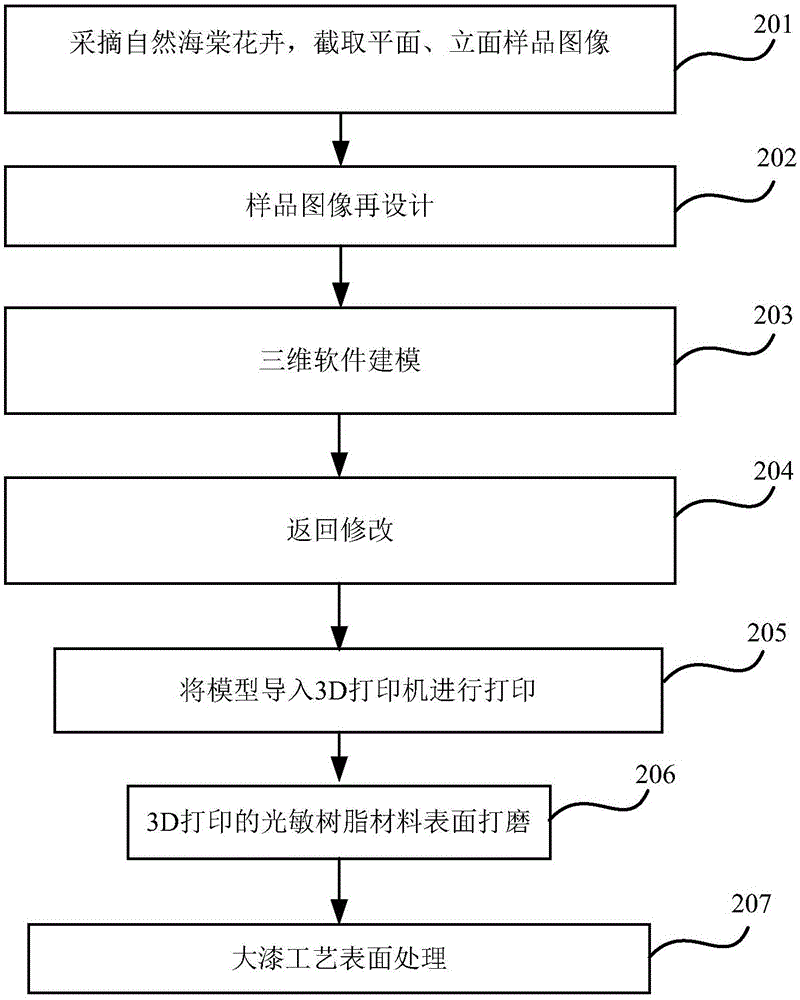

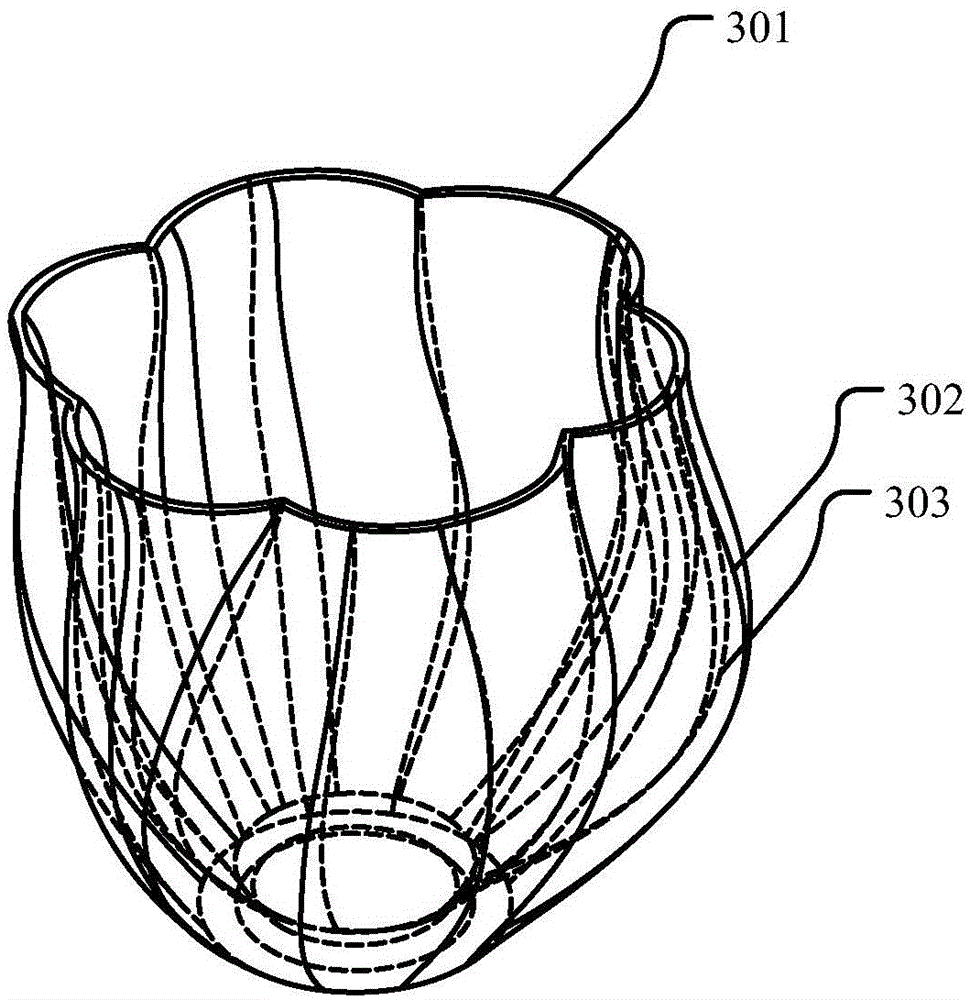

Method for manufacturing matrix by adoption of 3D printing technology

InactiveCN105058799AHigh degree of completionSmooth surfaceAdditive manufacturing apparatusSample imageLacquer

The invention provides a method for manufacturing a matrix by the adoption of a 3D printing technology. The method comprises the steps that a sample and a sample image are selected according to needs; the selected sample image is designed and remade through manual drawing, and a redesigned sample image is obtained; the redesigned sample image is subjected to three-dimensional forming treatment, and a three-dimensional digital model of the sample is obtained; and the three-dimensional digital model of the sample is guided into a 3D printer, the machine is edited for printing treatment, and a printed matrix is formed. The method provides a novel rapid lacquer matrix manufacturing mode, the defect occurring when a traditional matrix is manufactured is overcome, and as the photosensitive resin 3D printed matrix and paper matrix completeness is high and the surface is smooth, financial resource, material and labor consumption caused by matrix manufacturing in the earlier stage is greatly reduced and the technique processes are reduced. The matrix can be obtained only by slight polishing, priming and lacquer coating. Time and labor are saved, and more crafts and techniques can be tried.

Owner:BEIJING ZHONGHONG SHENGJING LANDSCAPE DESIGN CO LTD

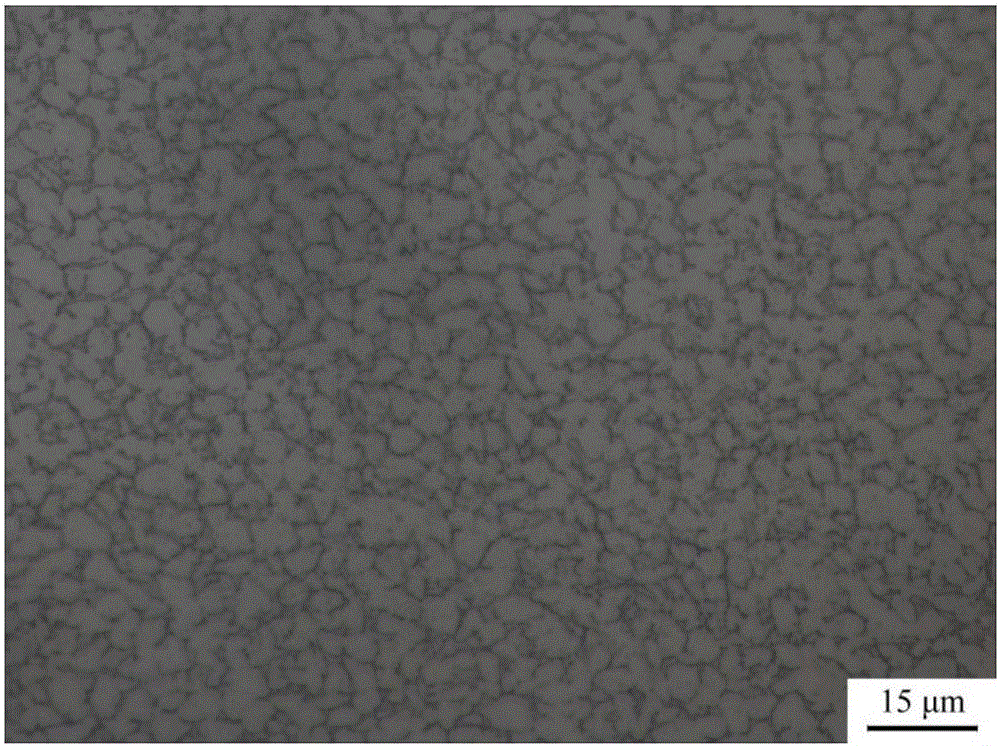

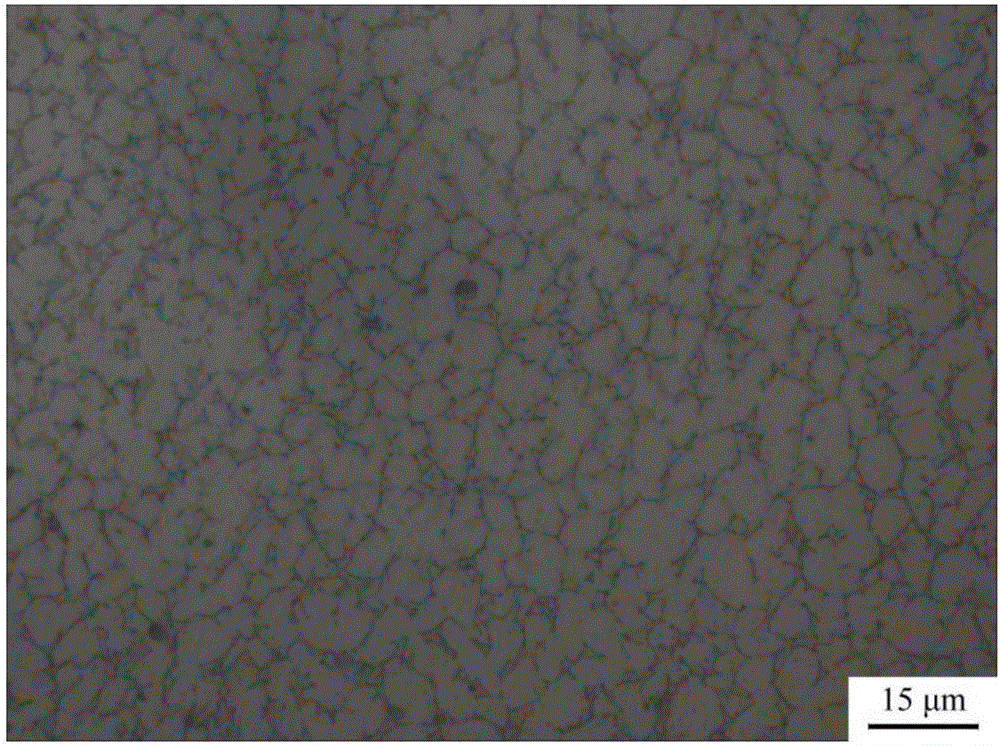

Method for controlling grain equi-axiation to improve plasticity of Ti20Zr6.5Al4V alloy

The invention relates to a method for controlling grain equi-axiation to improve plasticity of a Ti20Zr6.5Al4V alloy. The method mainly comprises the steps that a Ti20Zr6.5Al4V alloy bar is cut into a round ingot with the thickness being 16 mm, and the round ingot is cleaned up; the round ingot is put into a resistance furnace to be heated till the temperature ranges from 950 DEG C to 1,050 DEG C, heat preservation is carried out for 20 min to 40 min, and the round ingot is quickly placed in water for quenching after being taken out; then the alloy ingot is heated till the temperature ranges from 750 DEG C to 900 DEG C at the speed being 10 DEG C / min, the heat preservation time is shorter than 5 min, the alloy ingot is subjected to rolling deformation through a dual-roller mill after being taken out, the rolling speed ranges from 0.3 m / s to 0.6 m / s, and the reduction in single pass ranges from 0.5 mm to 2 mm; heating-rolling is repeated 5-20 times in the same way till deformation reaches 60% or above, and air cooling is carried out until the room temperature is obtained; and then the alloy is subjected to annealing treatment after being heated, the annealing temperature ranges from 750 DEG C to 850 DEG C, and furnace cooling is carried out until the room temperature is obtained after heat preservation is carried out for 1 h to 12 h. According to the method, operation is easy, and the production cost is low; and the plasticity of the alloy is remarkably improved while strength is guaranteed.

Owner:YANSHAN UNIV

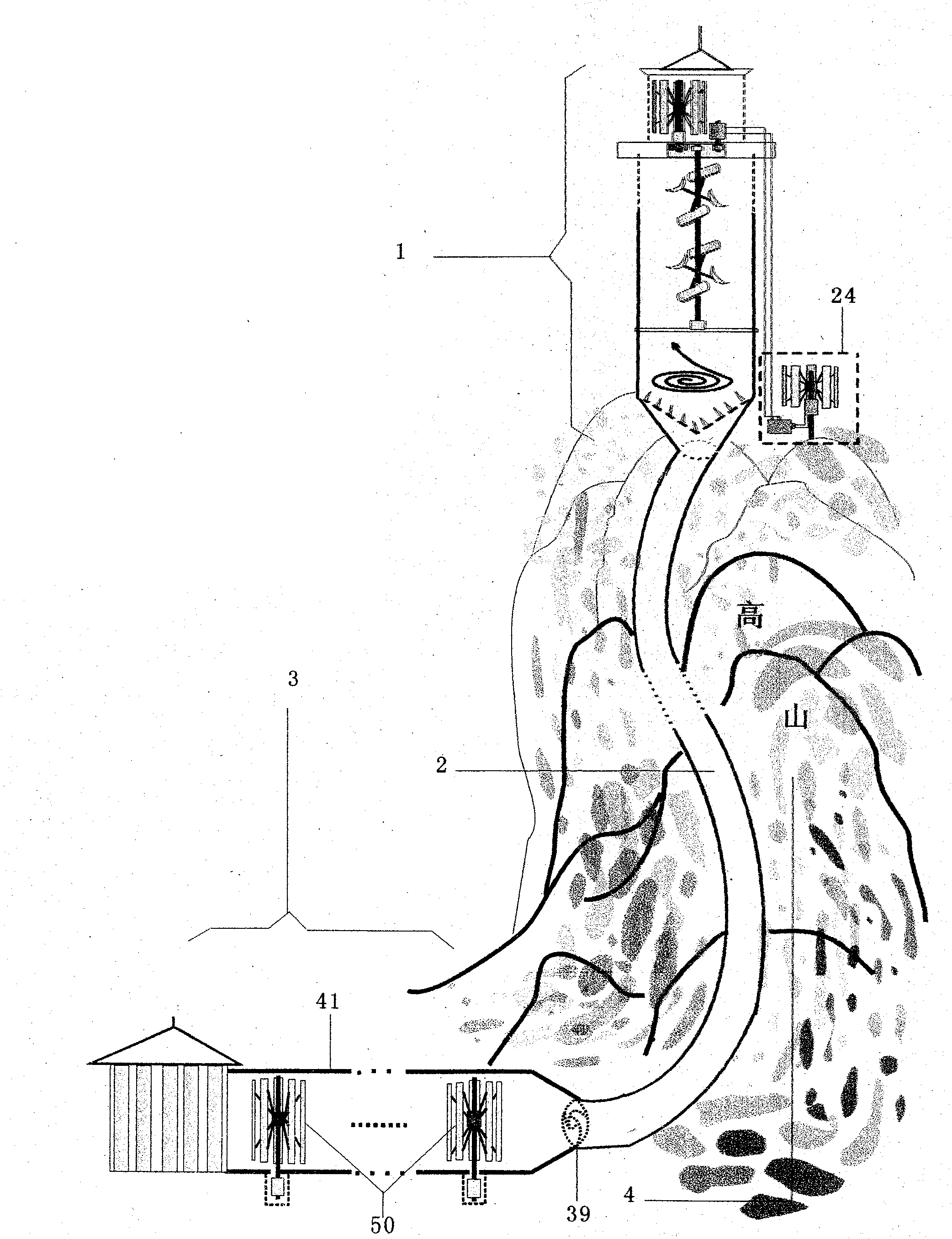

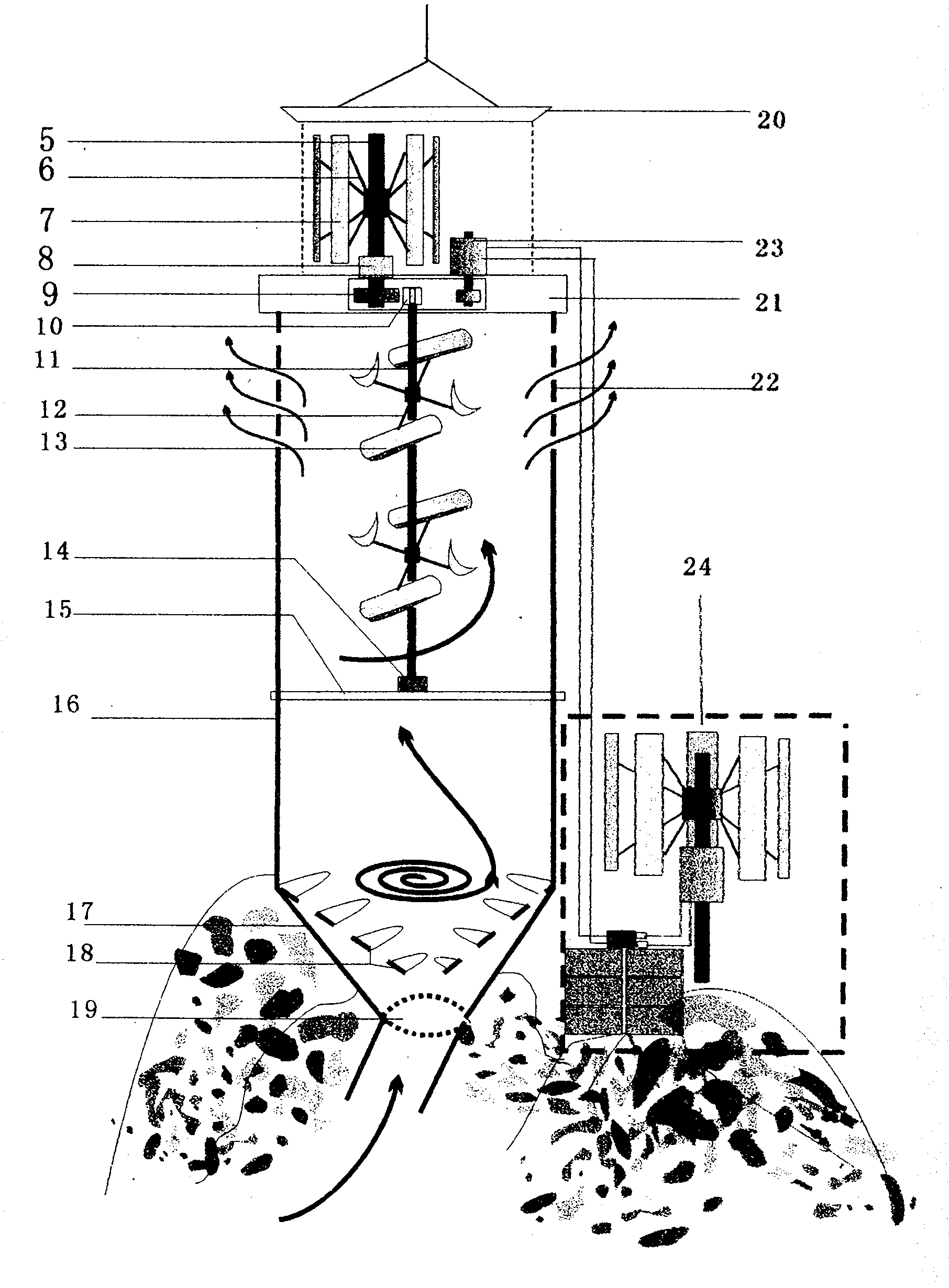

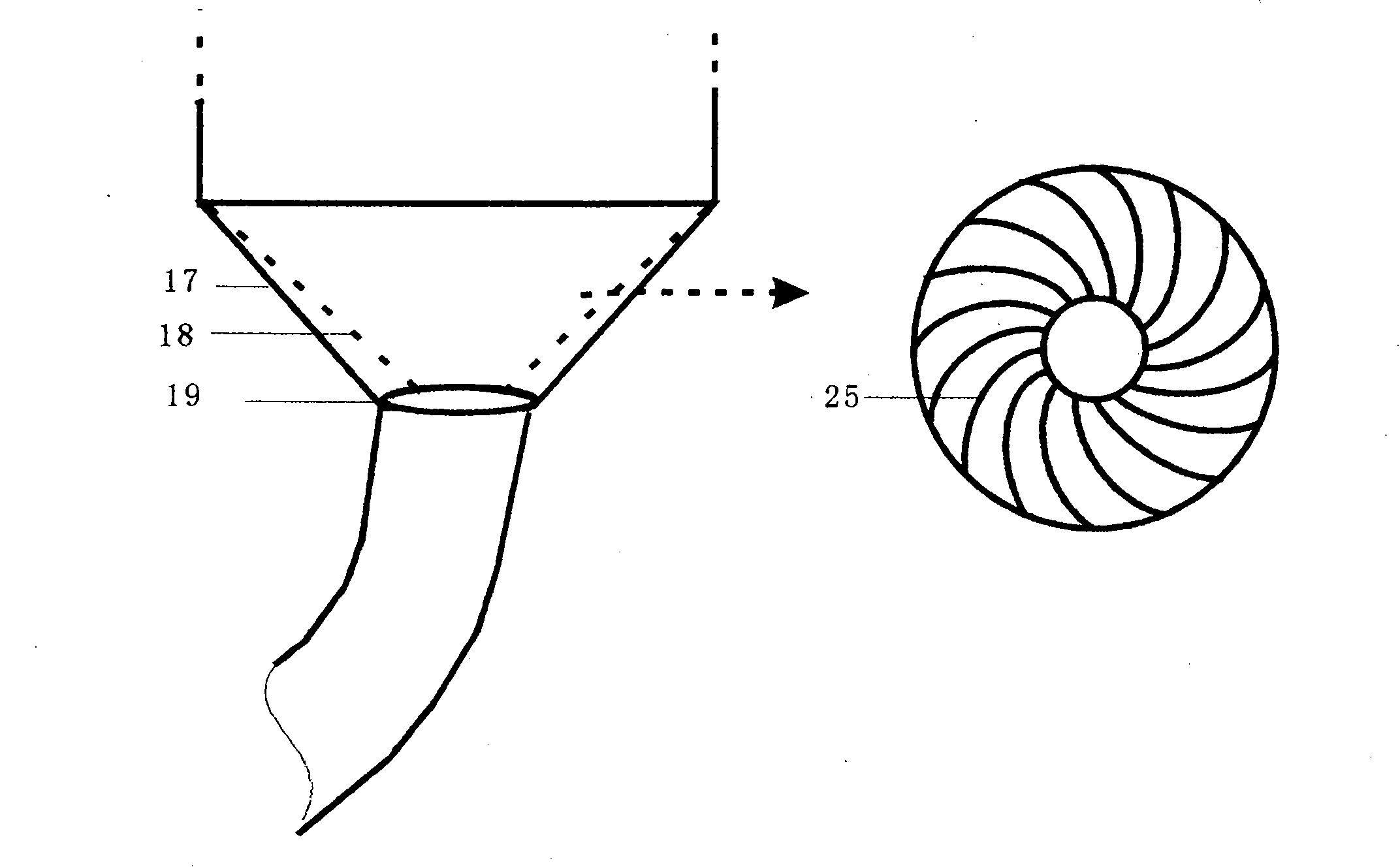

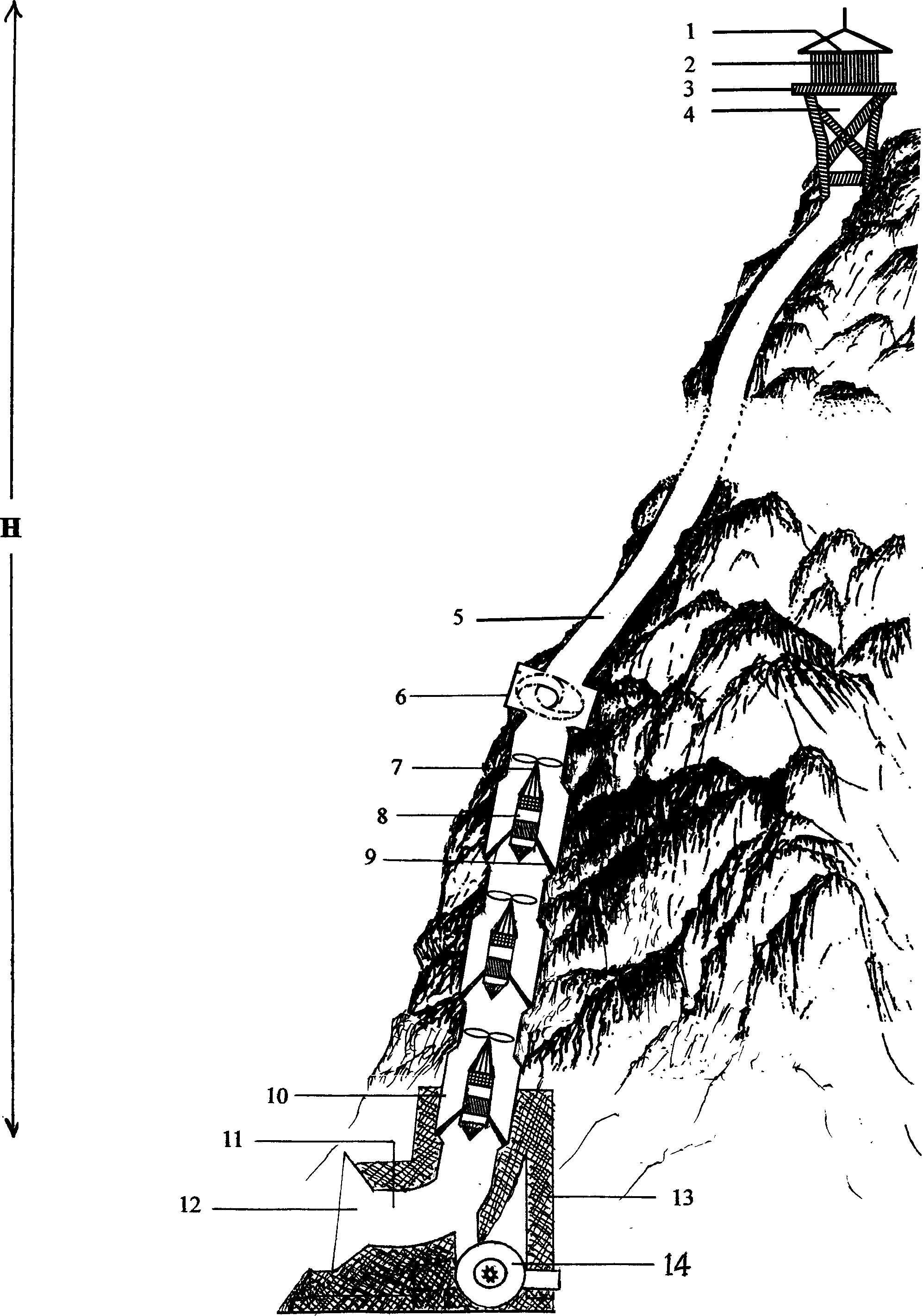

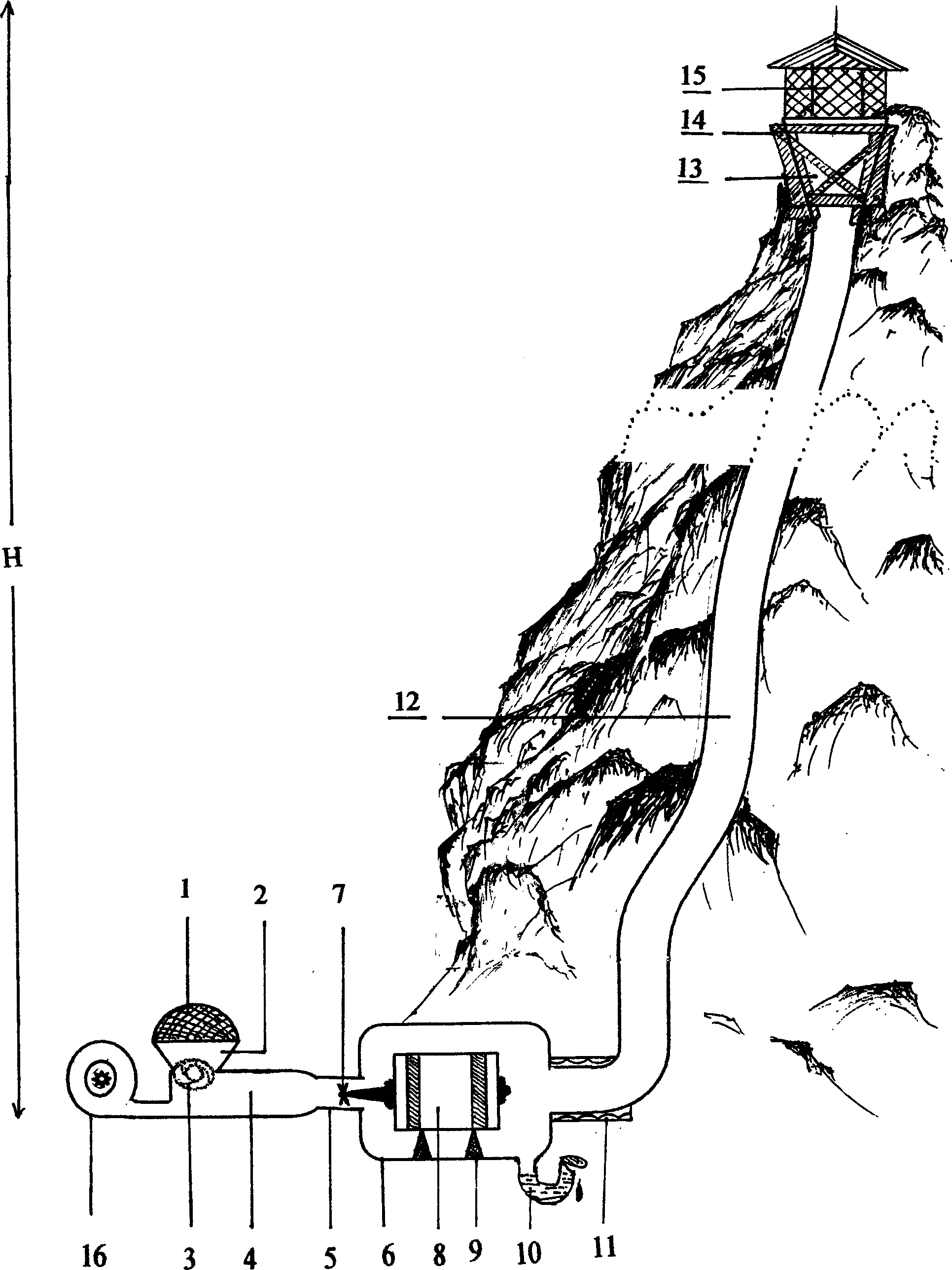

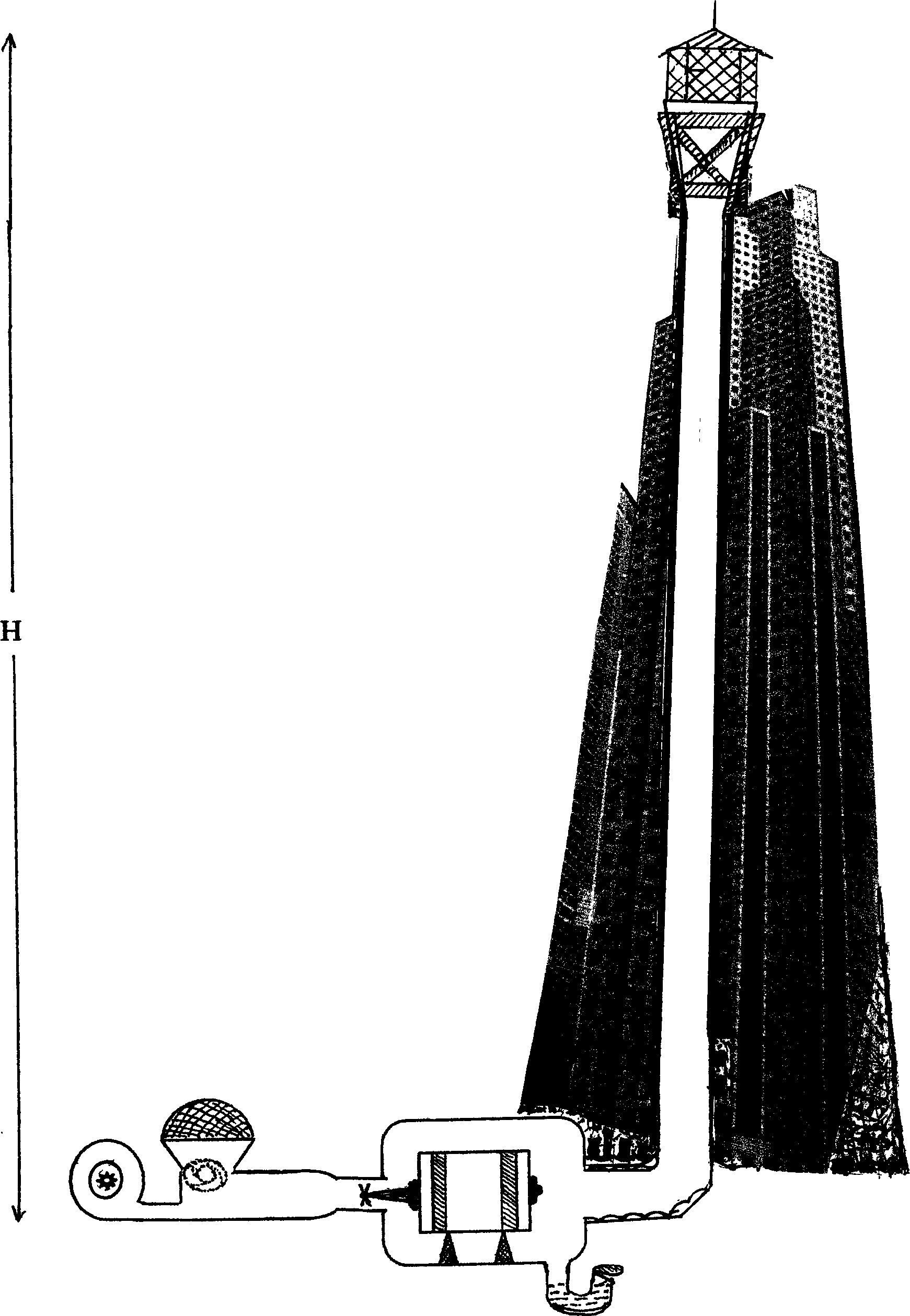

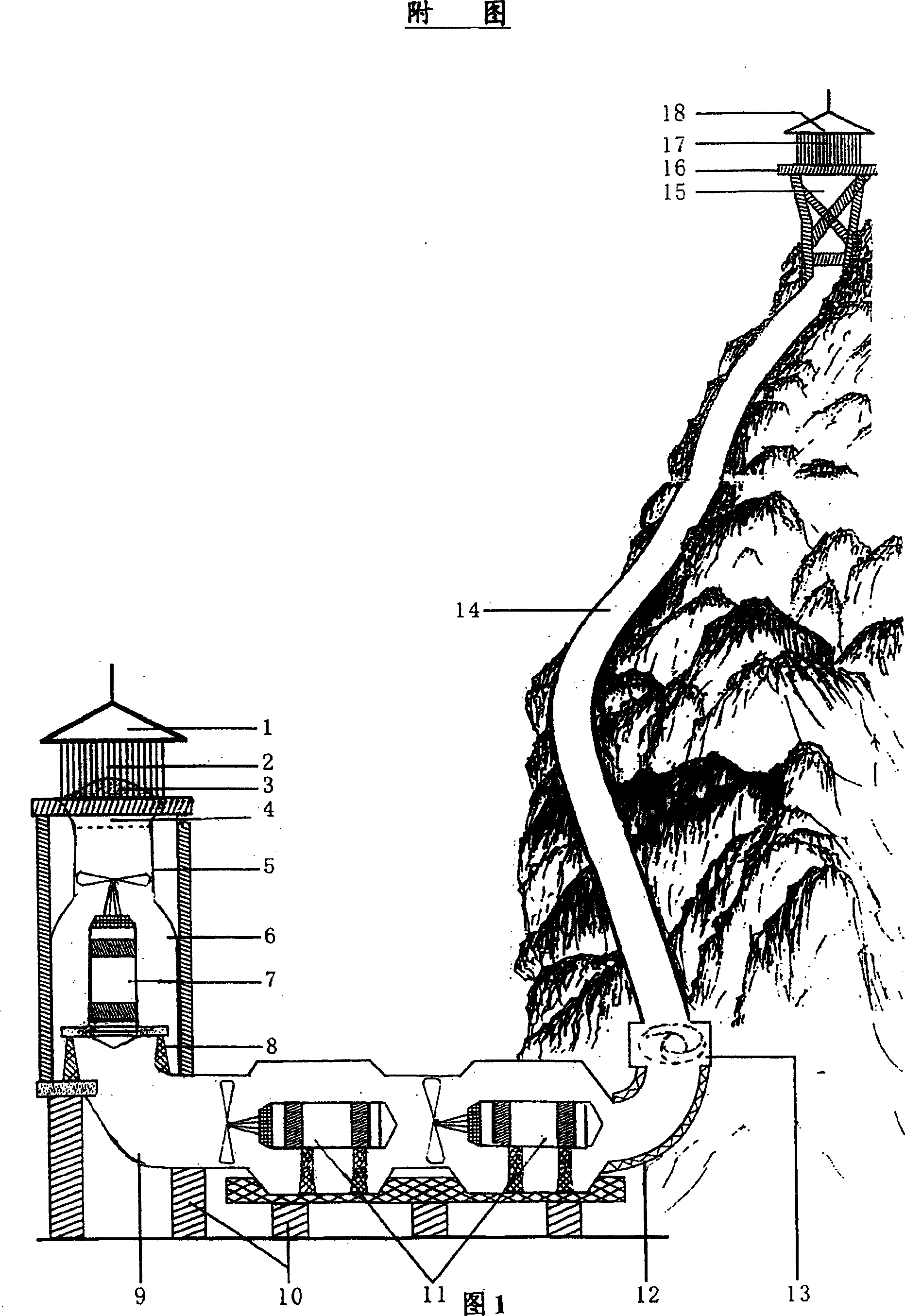

Comprehensive power generation device adopting atmospheric gradient temperature difference and artificial cyclone

InactiveCN102003346AGuaranteed energy supplySustained Wind PowerWind motor controlMachines/enginesCycloneAir volume

The invention relates to a comprehensive power generation device adopting atmospheric gradient temperature difference and artificial tornado. The device comprises a big-diameter ventilation duct (2), a tornado tower, a wind power machine, a tornado machine (1), a wind power input system (24), a wind machine roadway (41), a wind collection bin (42), a return air wall (49), an automatic gear regulating devices (37, 38) and an automatic wind volume regulating gate (49), wherein the big-diameter ventilation duct (2) is constructed along a high mountain (4) and used to obtain the atmospheric gradient temperature difference and the atmospheric gradient pressure difference; the tornado tower, the wind power machine, the tornado machine (1) and the wind power input system (24) are constructed on the top of the high mountain, the tornado tower is used to generate tornado; and the wind machine roadway (41), the wind collection bin (42) and the return air wall (49) are constructed at the foot of the high mountain. The comprehensive power generation device is characterized in that the outer wall (17) of the bottom of the tornado tower, and the wall of the high end pipe of the big-diameter ventilation duct are connected (19); the wall of the low end pipe of the big-diameter ventilation duct, and the pipe wall of the wind machine roadway are connected (39); the inlet (42) of the wind machine roadway is connected with the wind collection bin (42); the return air wall (49) is constructed on the both sides of the wind collection bin; the automatic gear regulating devices are arranged on the top cover part of the tornado tower; the automatic wind volume regulating gate is arranged at the joint of the wind machine roadway (41) and the big-diameter ventilation duct; and a generator set (50) is arranged in the wind machine roadway which is at the foot of the high mountain.

Owner:梁和平

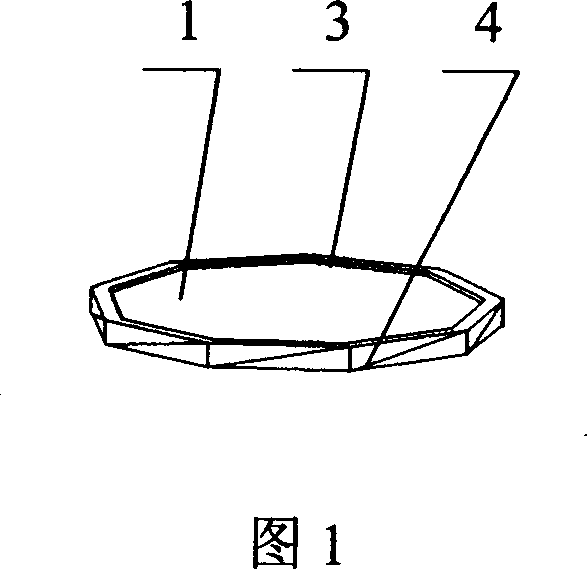

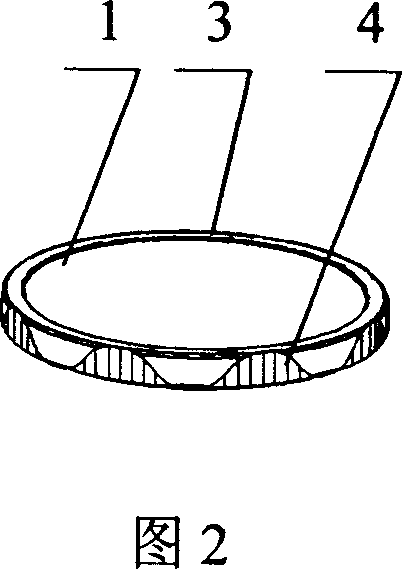

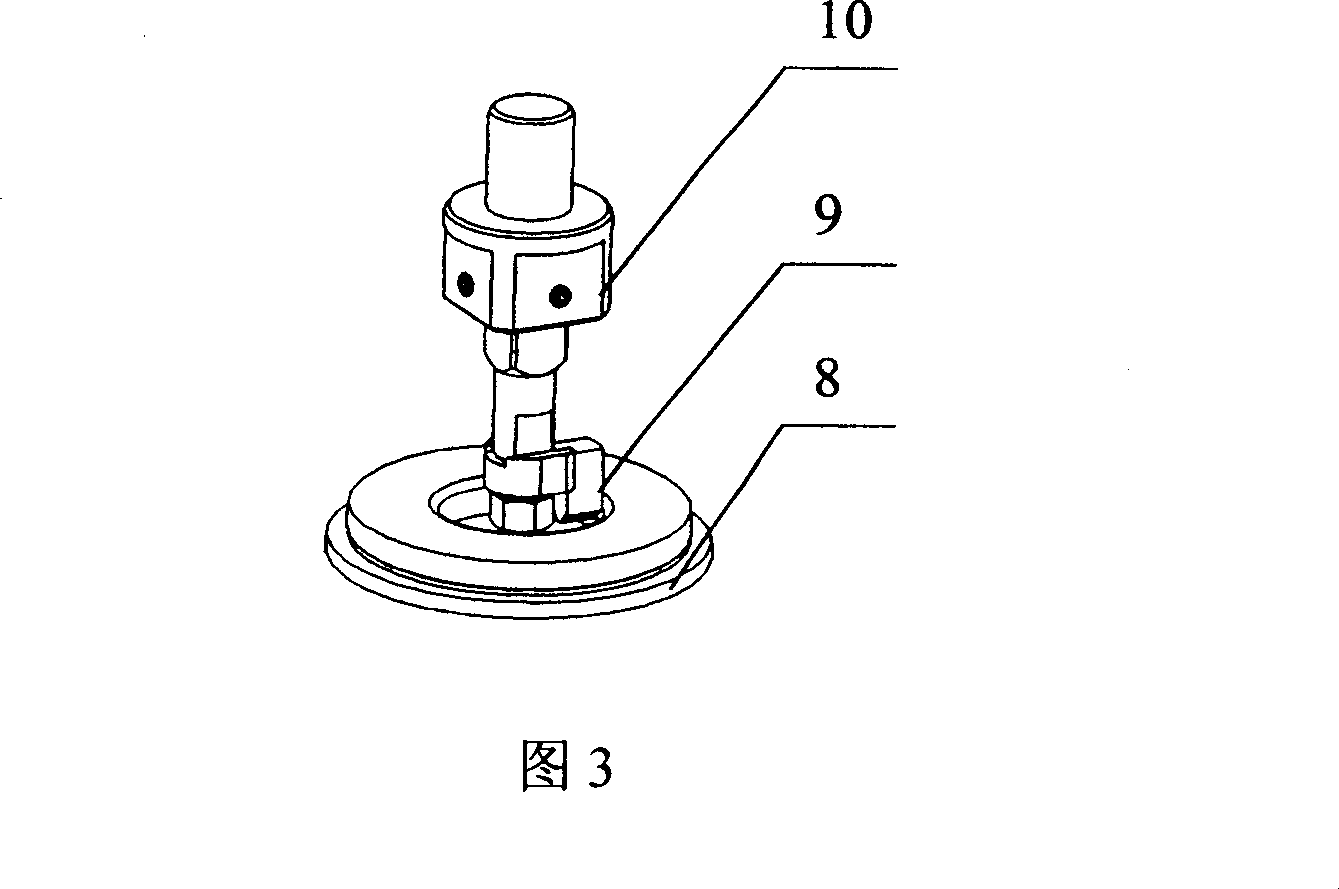

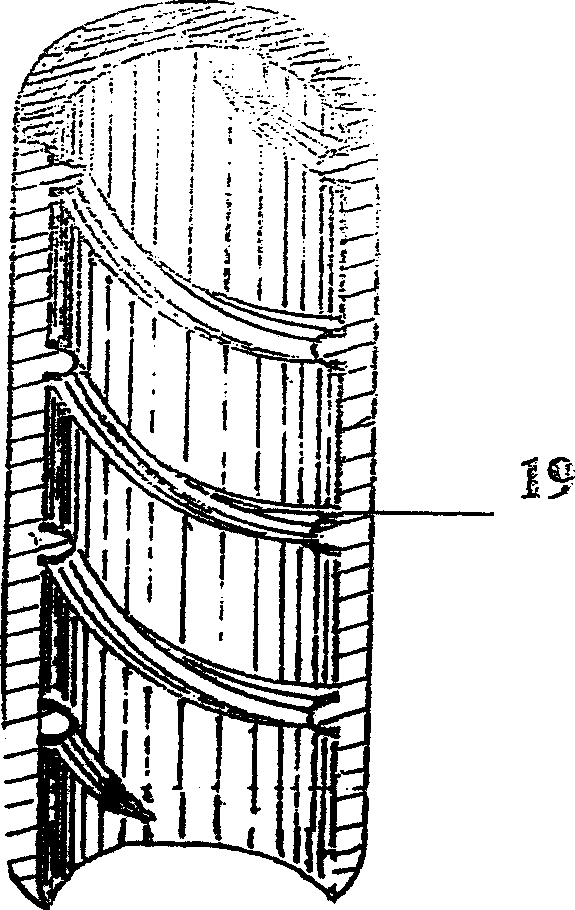

Coin with geometric pattern at edge and its preparing method

InactiveCN1943466AChange the status quoIncrease manufacturing difficultyCoinsEngineeringGeometric figure

The invention discloses a hard coin with edge part having geometric figure, characterized by side part of coin podium without said geometric figure, said figure height is same with coin thickness or thinner then thereto thickness; said coin is in the shape of circular, polygon or any there of; said geometric figure comprising shape of arc, ladder-shaped, triangular, hackle-shaped or mixture of them.

Owner:CHINA BANKNOTE PRINTING & MINTING

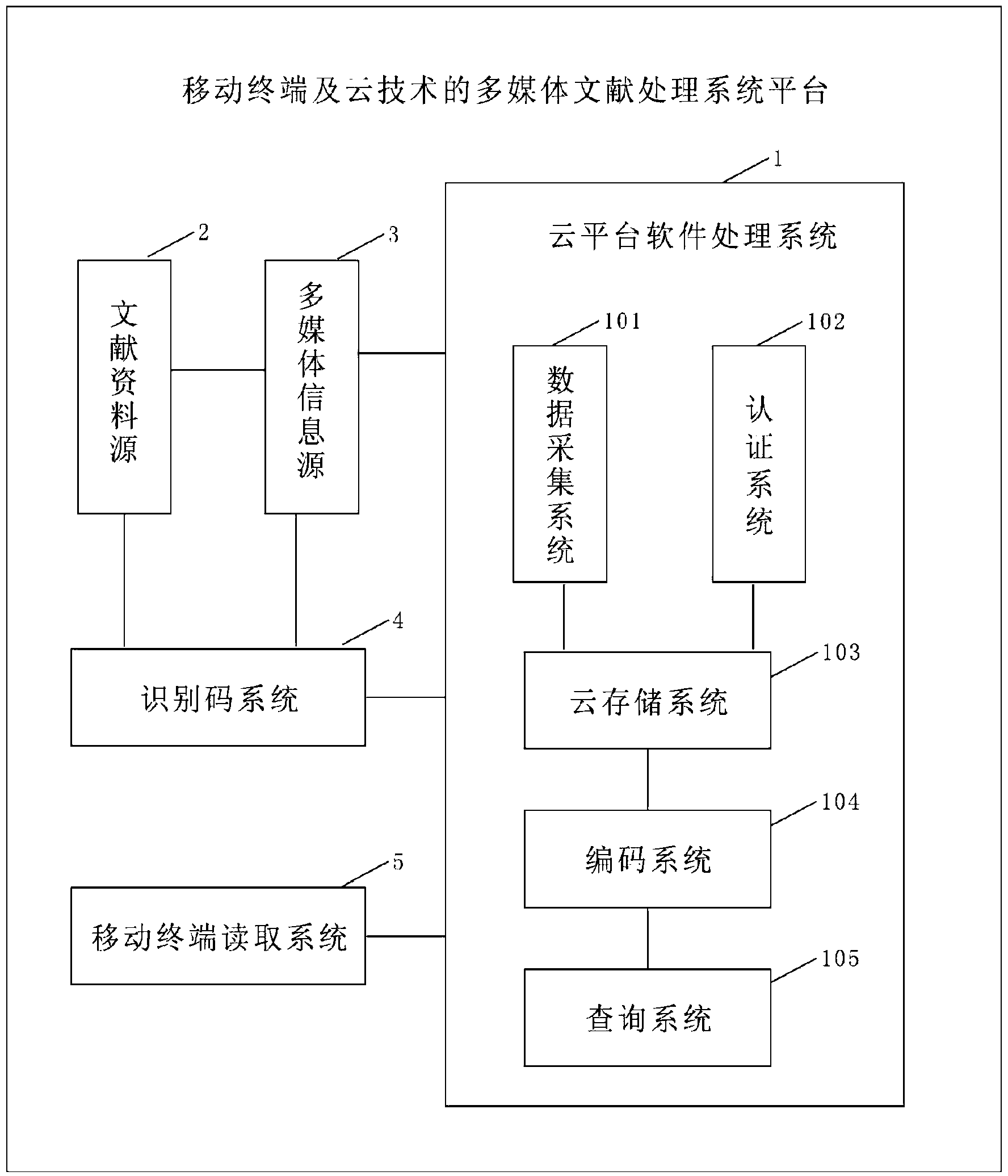

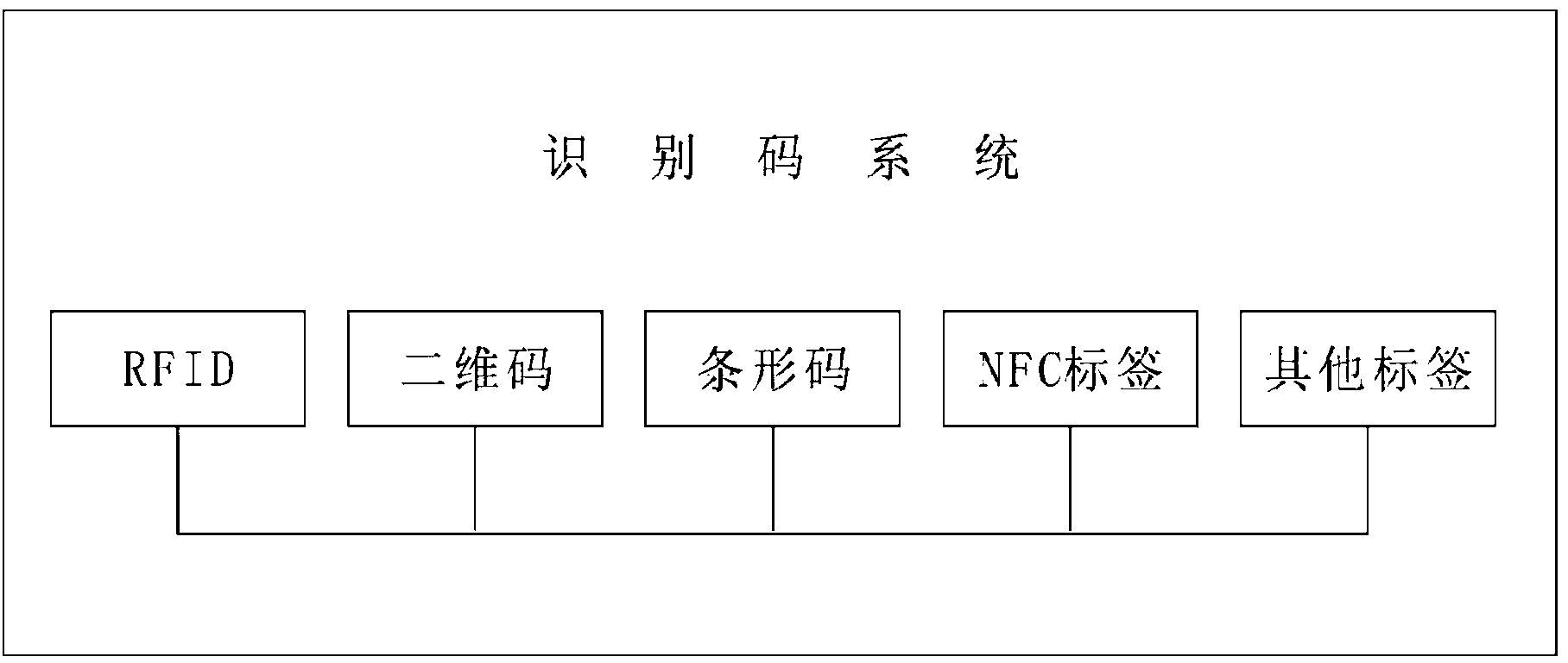

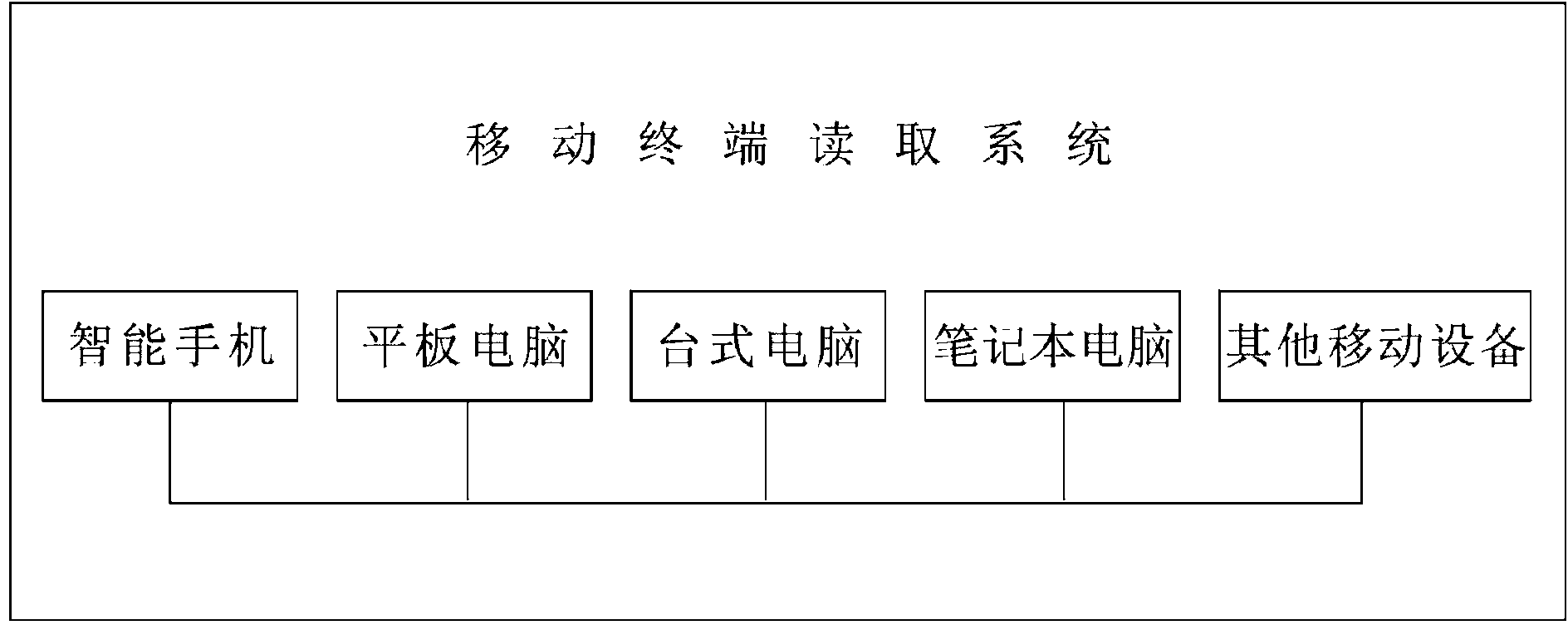

Multimedia document processing system platform and method based on mobile terminal and cloud technology

InactiveCN103970895ARealize cloud storage functionChange the status quoMetadata multimedia retrievalSpecial data processing applicationsInformation accessThe Internet

The invention discloses a multimedia document processing system platform and method based on a mobile terminal and a cloud technology. The multimedia document processing system platform comprises a cloud platform software processing system, a document source, a multimedia information source, an identification code system and a mobile terminal reading system. The method comprises the steps of utilizing the cloud platform software processing system to collect and store the document source and the multimedia information source, performing identification code certification after comprehensive treatment, utilizing the mobile terminal reading system to obtain information related to the document source from the identification code system, accessing an Internet cloud platform through the information, adopting one or several bindings in the identification code system, and enabling one or several of the mobile terminal reading system to perform cloud-to-end and end-to-cloud real-time interaction and man-machine interaction with documents and multimedia information obtained through one or several bindings of the identification code system. The multimedia document processing system platform is provided with software to read one or a plurality of labels, the distance between readers and writers is closer, a sales function is integrated, and the multimedia document processing system platform is favorable for popularization and propagation of the documents.

Owner:叶晓宇

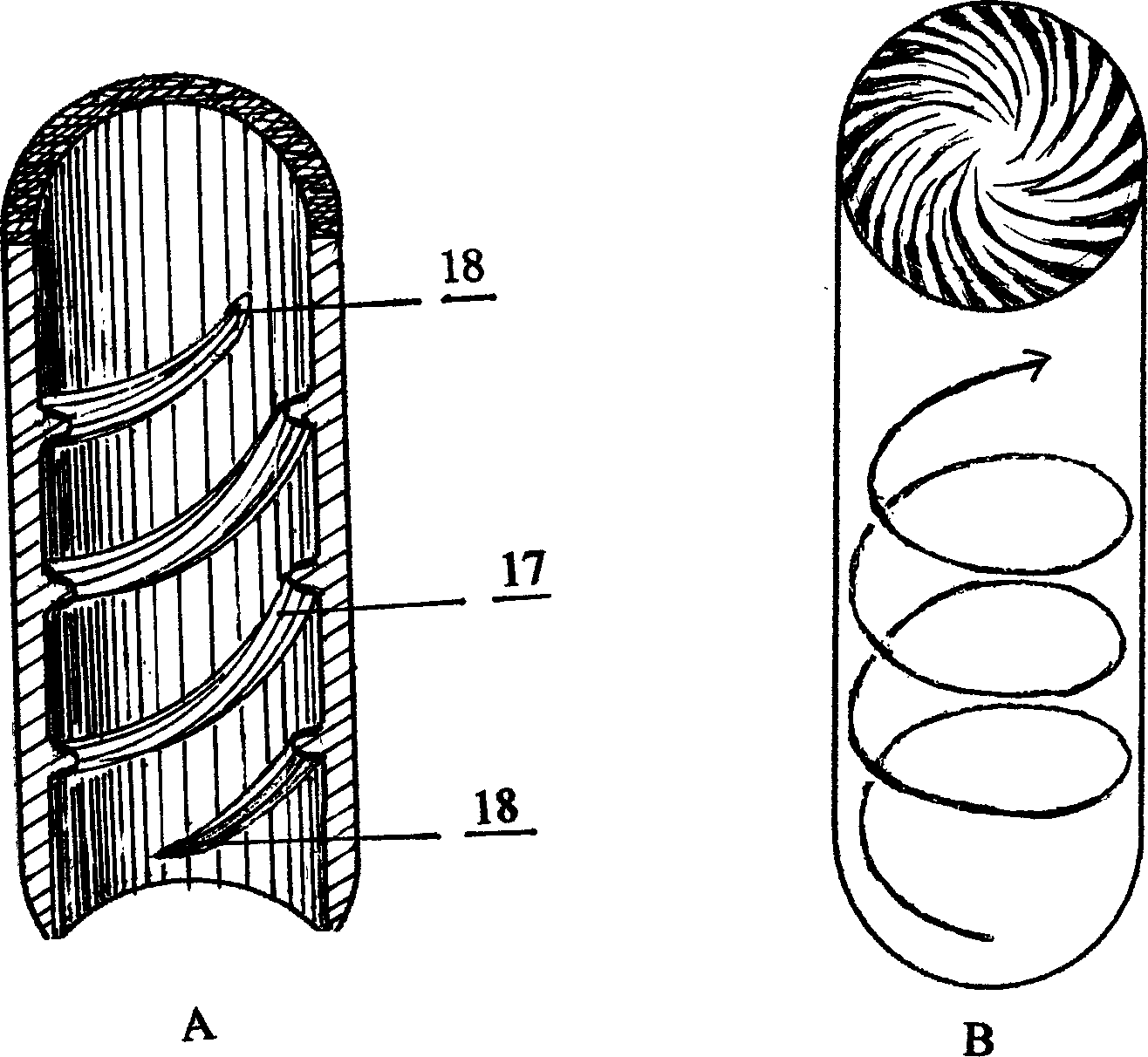

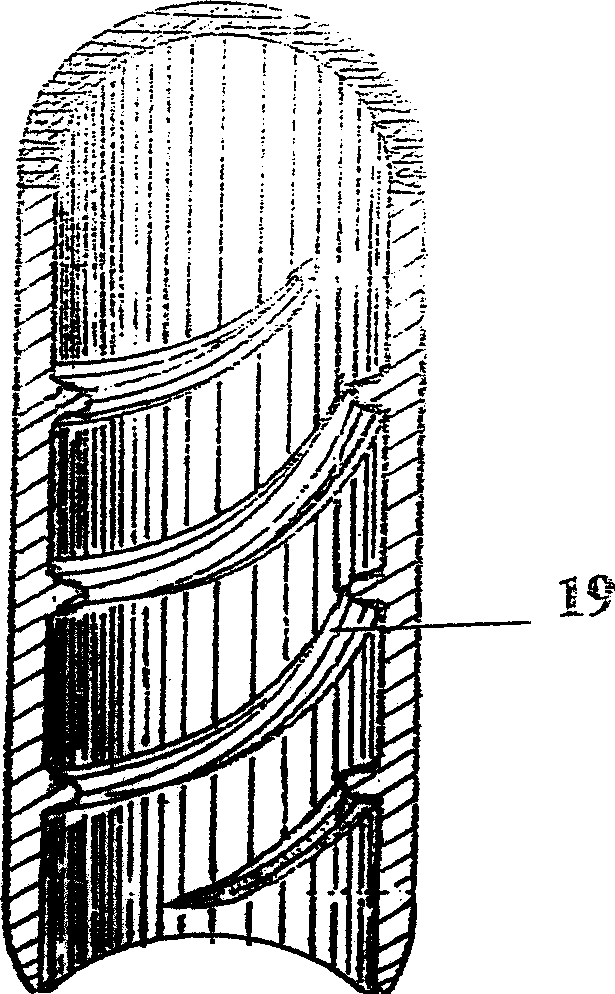

Down pulling artificial tornado-driven generating set and method

InactiveCN1811175AAvoid difficultiesAvoid security issuesWind motor supports/mountsMachines/enginesImpellerElectricity

The present invention discloses one kind of regenerable power source generating system, and is especially one kind of down pulling artificial tornado-driven generating set and method. The generating set includes mainly an intake gate, an air collecting pond, a spiral ridge air lowering pipeline, a wind regulating gate, a generator chamber, a vane wheel pipe, a wind exhaust pipe, an exhaust port and an exhauster. Principally, the present invention has large caliber spiral ridge air lowering pipeline to lead cold air downwards from steep mountain of 1000 m over height and rotate the downward airflow at high speed to form down pulling tornado and utilizes the powerful airflow to impact vane wheel of generator to produce electricity.

Owner:梁和平

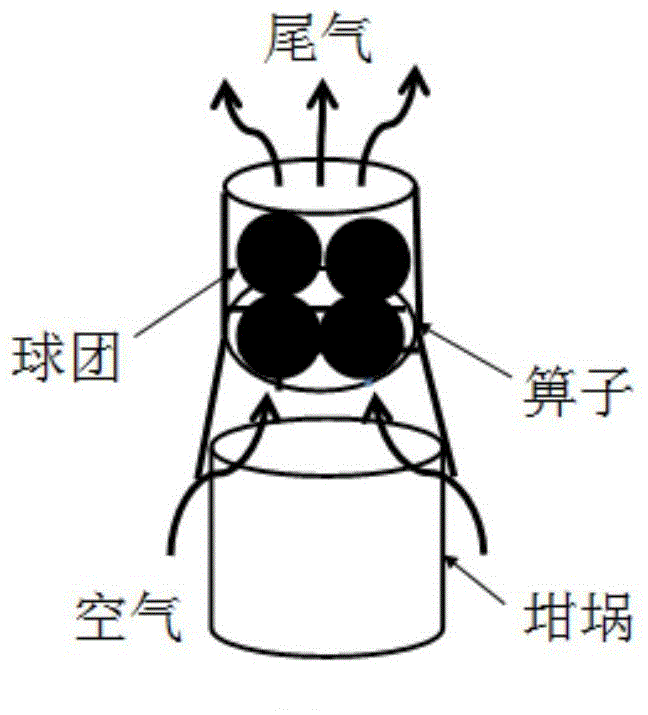

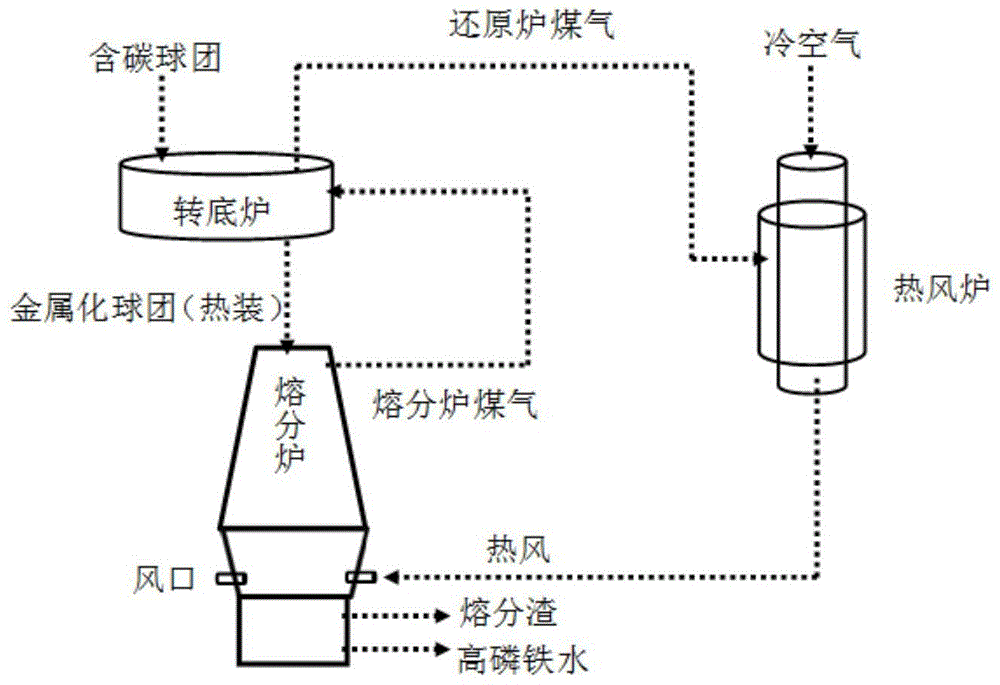

Pulverized coal melt separation and recovery method for low-grade iron resources

The invention relates to a pulverized coal melt separation and recovery method for low-grade iron resources and belongs to the technical field of ferrous metallurgy and environment protection. The pulverized coal melt separation and recovery method for low-grade iron resources comprises the steps that pulverized coal, raw materials containing iron and a fluxing agent are mixed to prepare carbon-containing pellets and are directly reduced rapidly; the metallized pellets are hot-charged in a melt separation furnace; heat required by melt separation is provided by hot air blown in from an air port and through combustion of hot coal left in the metallized pellets, and separation between slag and iron and recovery of iron are completed. The pulverized coal melt separation and recovery method for low-grade iron resources has the advantages that the heat utilization rate is increased, use amount of coke is reduced during melt separation, and energy consumption and production cost are reduced. Due to the fact that metallurgical solid waste and low-grade iron ore are high in slag content and low in iron grade, it is not economical if a traditional blast furnace technique is used for recovering iron; due to the fact that no coke layer exists in a traditional coal-based melt separation technique, molten iron carburization is not sufficient; in addition, due to the fact that the heat conductivity coefficient of a slag layer is low, iron melting is difficult. By the adoption of the technique, the high temperature and the high heat utilization rate which are required by molten iron melting are guaranteed; the technique is suitable for processing low-grade resources containing iron, and the current utilization situation of metallurgical solid waste and low-grade ore is greatly changed.

Owner:CENT IRON & STEEL RES INST +1

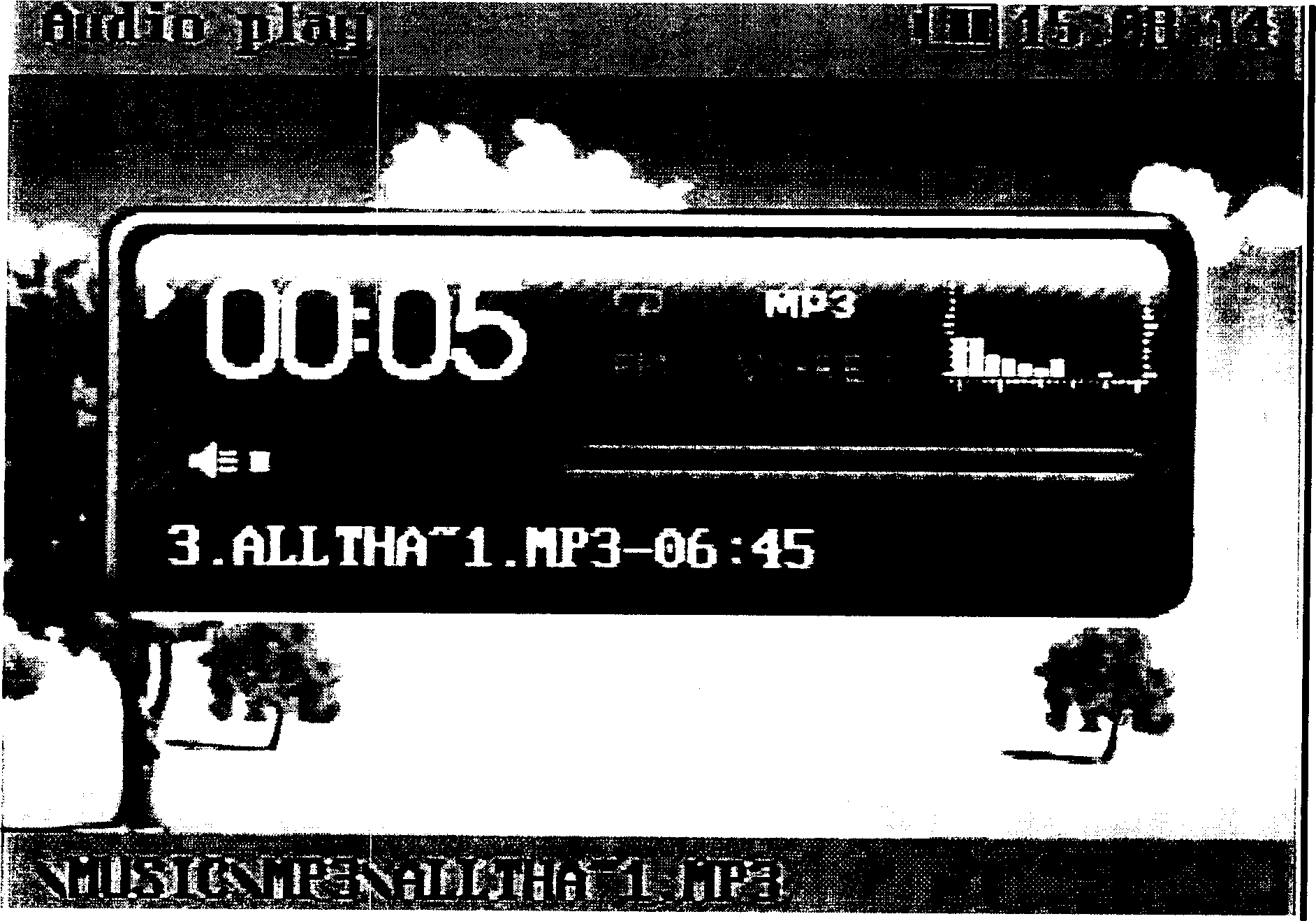

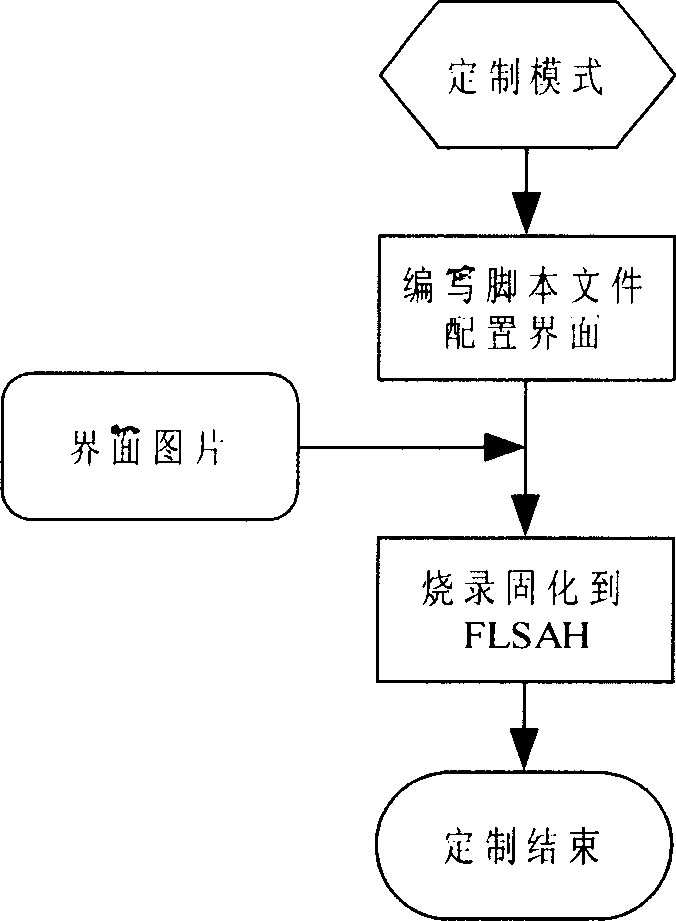

Portable multimedia player interface customizing method using script file configuration

InactiveCN1815444AIncrease variabilityEasy customizationExecution for user interfacesInput/output processes for data processingHuman–computer interactionXML

Through XML script file, user carries out configuration of script for interface. Parser for script file setup in PMP player parses information of script file customized by user, and reflects parsed result to final interface display. The invention discloses a fast and simple method to let user change interface according to own requirement.

Owner:HANGZHOU MICORUNIT TECH

Cleaning method for sewage pipe

The invention discloses a cleaning method for a sewage pipe. The cleaning method for the sewage pipe comprises the following steps: draining sewage in the sewage pipe, and washing away dirt in the sewage pipe by using clear water; ventilating the sewage pipe to discharge odor in the pipe, adding sterilizing powder in fed air, and killing bacteria by the sterilizing powder in the sewage pipe; afterthe sewage pipe is ventilated for a period of time, placing a pipe cleaning device in the sewage pipe, and cleaning the sewage pipe by the pipe cleaning device; and taking out the pipe cleaning device, and washing the sewage pipe again by the clear water to wash away the dirt cleaned from the inner wall of the sewage pipe by the pipe cleaning device. By the method, the dirt in the sewage pipe canbe cleaned effectively, the odor in the pipe can further be removed, thus, the current situation is changed, and influences of cleaning of the sewage pipe to a surrounding environment are greatly reduced.

Owner:宿州冬宇环保科技有限公司

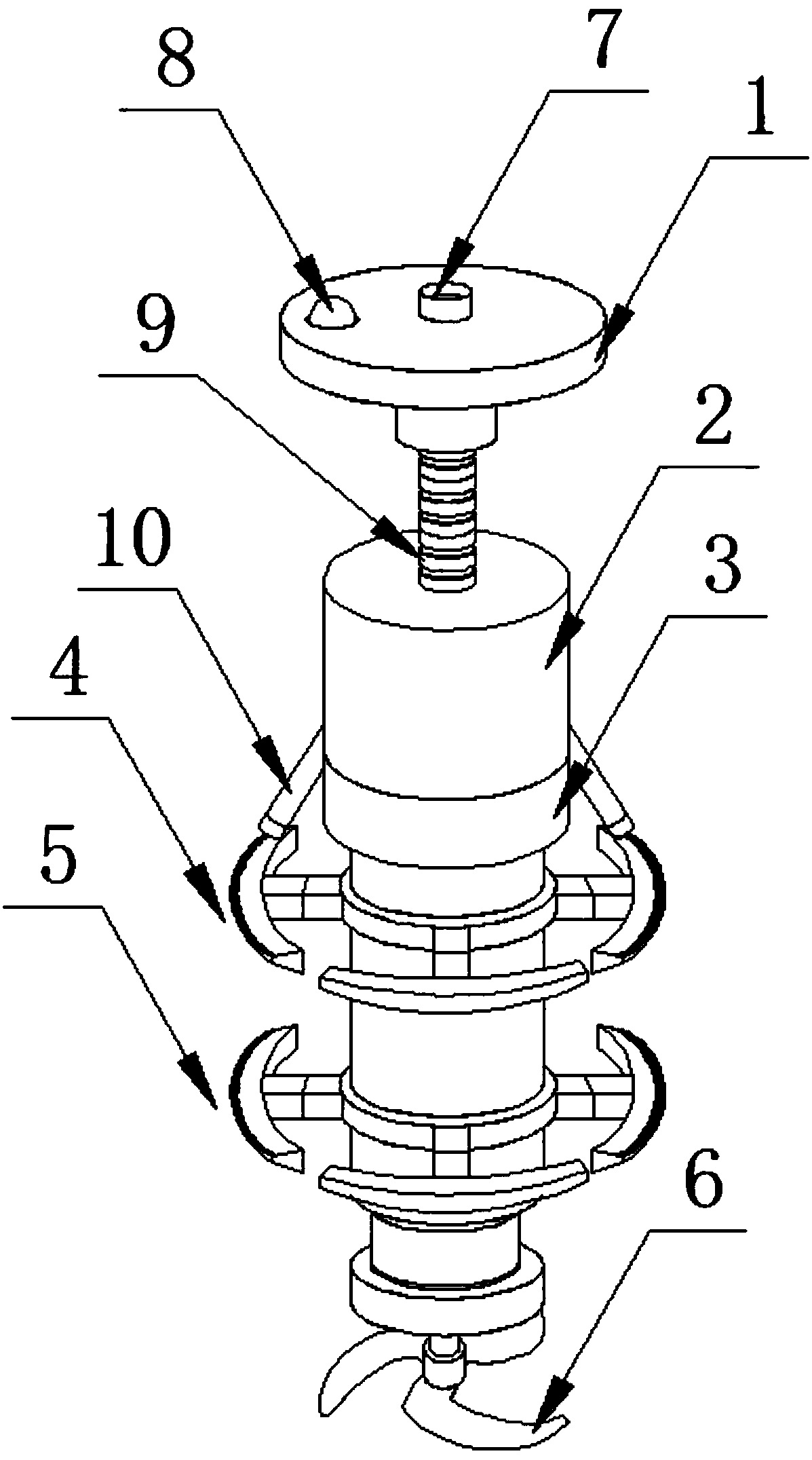

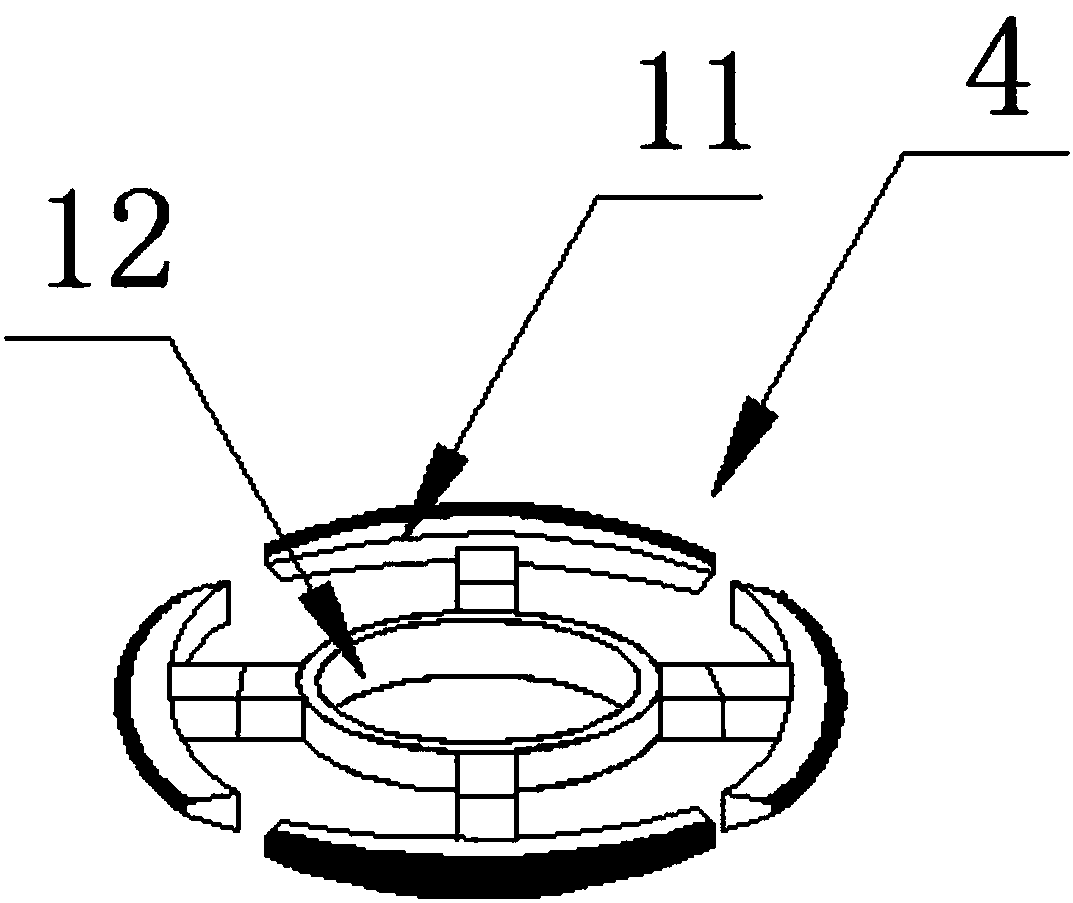

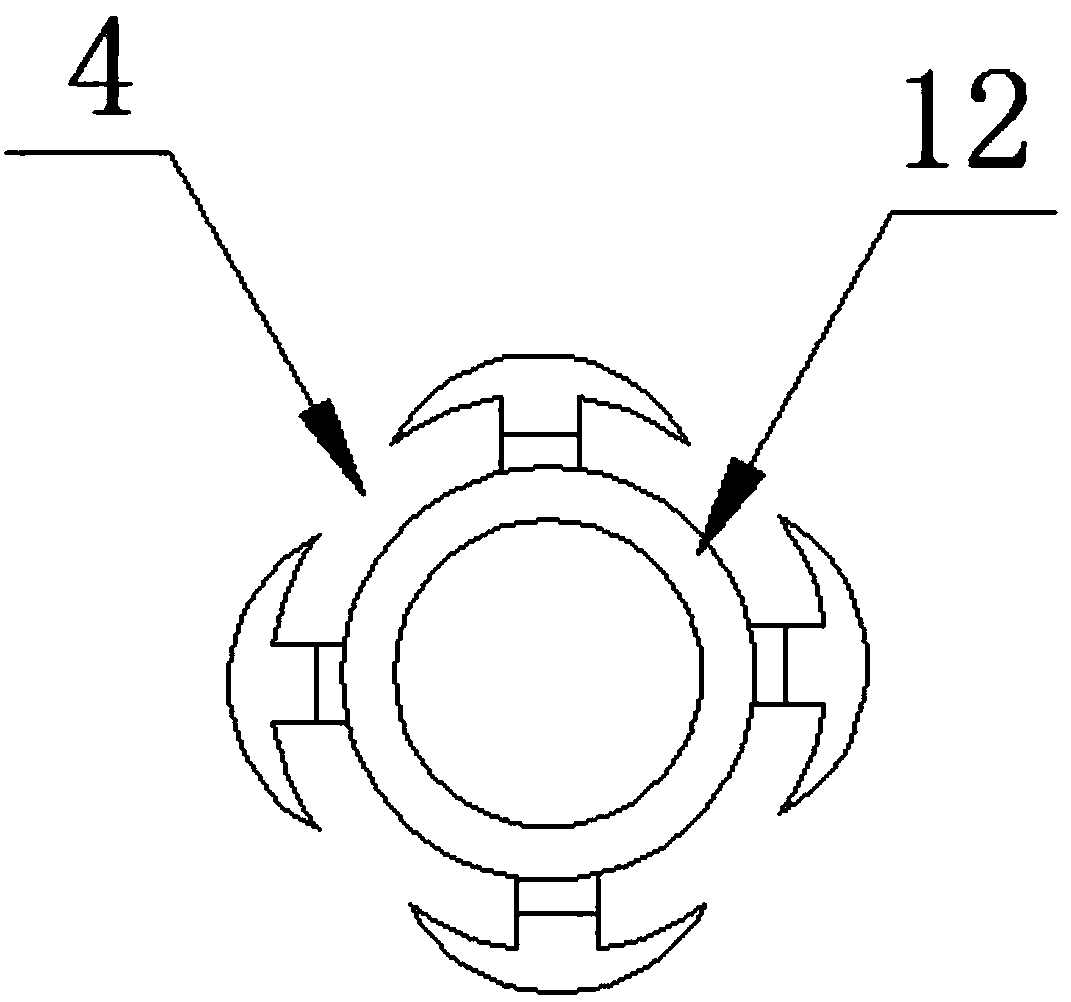

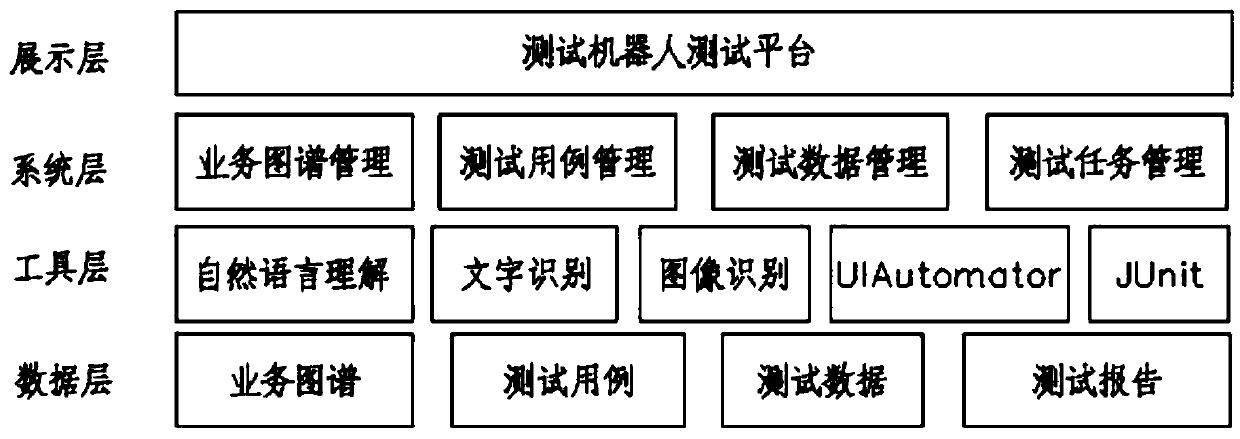

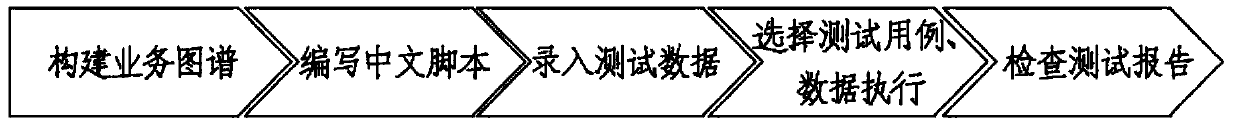

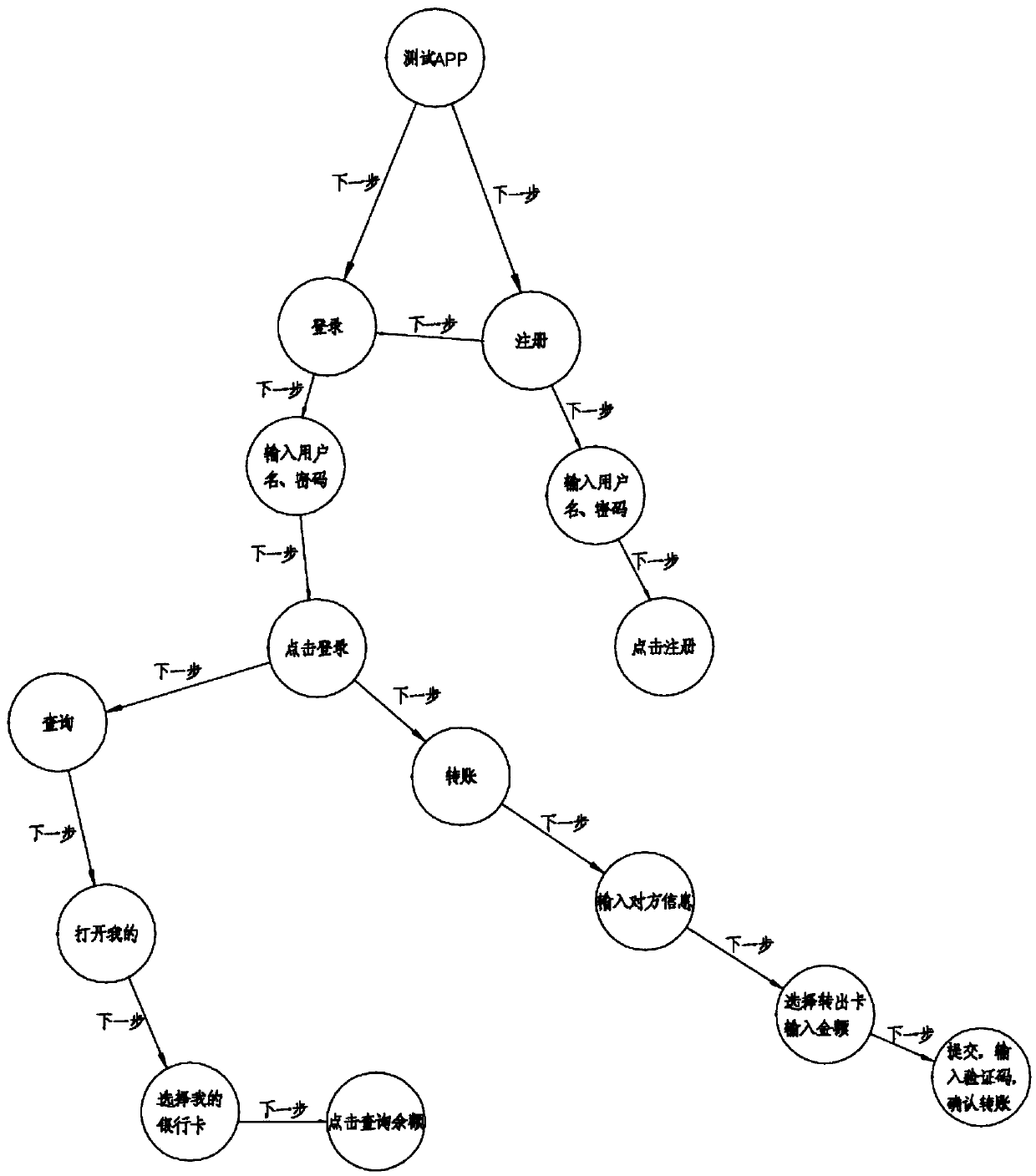

Robot using graph analysis to execute automated testing and use method thereof

ActiveCN108647147AChange the status quoLow technical requirementsSoftware testing/debuggingText recognitionNatural language understanding

The invention discloses a robot using graph analysis to execute automated tests and a use method thereof. The robot includes a display layer, a system layer, a tool layer and a data layer. The displaylayer is a test platform of the test robot. The system layer includes service graph management, test case management, test data management and test task management. The tool layer includes natural-language understanding, text recognition, image recognition, UIAutomator and JUnit. The data layer includes a service graph, test cases, test data and a test report. According to the robot, service process relationships of a software product are more intuitively displayed, current status of writing test cases by test engineers according to experience is changed, a test technology threshold is reduced, a test coverage rate is increased, technical requirements of script writers are reduced, and thus test lacking caused due to service changes and waste caused by full-quantity tests are reduced. A comprehensive data collection and analysis system comprehensively analyzes performance, function and compatibility problems of an application, and reports the same in time.

Owner:南京璇玑信息技术有限公司

Graphite fireproof binder and preparation method

InactiveCN109777305AGuaranteed stabilityEasy to prepareNon-macromolecular adhesive additivesInorganic adhesivesAdhesiveGraphite

The invention provides graphite fireproof binder. The binder is prepared from graphite powder, adhesive, curing agent, enhancer, dispersing agent, toughening agent and water. The invention further provides a preparation method of the graphite fireproof binder. Compared with the traditional graphite mending agent, the graphite fireproof binder not only can accomplish the mending on the graphite structural element, but also can guarantee the stability of the structure under a high-temperature working condition; the fireproof adhesive is simple in preparation method, non-harsh in condition, low in environment requirement, and strong in applicability. The graphite fireproof binder provided by the invention cannot react with the molten metal, and has more extensive application space on the graphite adhesion, and the current status that the high-temperature graphite mold can be formed only through the traditional machining process is changed.

Owner:珠海凯利得新材料有限公司

Artificial tornado generator and electricity generating method thereof

InactiveCN1769669ANo pollution in the processNo money to spendFrom solar energyEngine fuctionsElectricityCyclone

The invention discloses an artificial tornado generation device and generating method, which comprises the following parts: intermittent spiral spine extraction pipe, funnel-shaped pipe, air-flow heating pipe, motor chamber, neck tube, air-flow guiding pipe, vane-type adjustable gate, inlet bucket, air filter net and blower, wherein the intermittent spiral spine extraction pipe is composed of three spiral spine pipes of three fifths part paralleling cavity with 5-10 m length through encasing the joints, which takes the steep ridge with more than 45 deg slope as tapered carrier to pave or high architecture as adhesion to build vertically according to the need to design the length (height). The invention adapts the lifting flow of earth atmospheric tropospheric thermoelectric gradient as motive power to generate high speed cyclone due to the lifting flow of intermittent spiral spine, which forms strong tornado effect.

Owner:梁和平

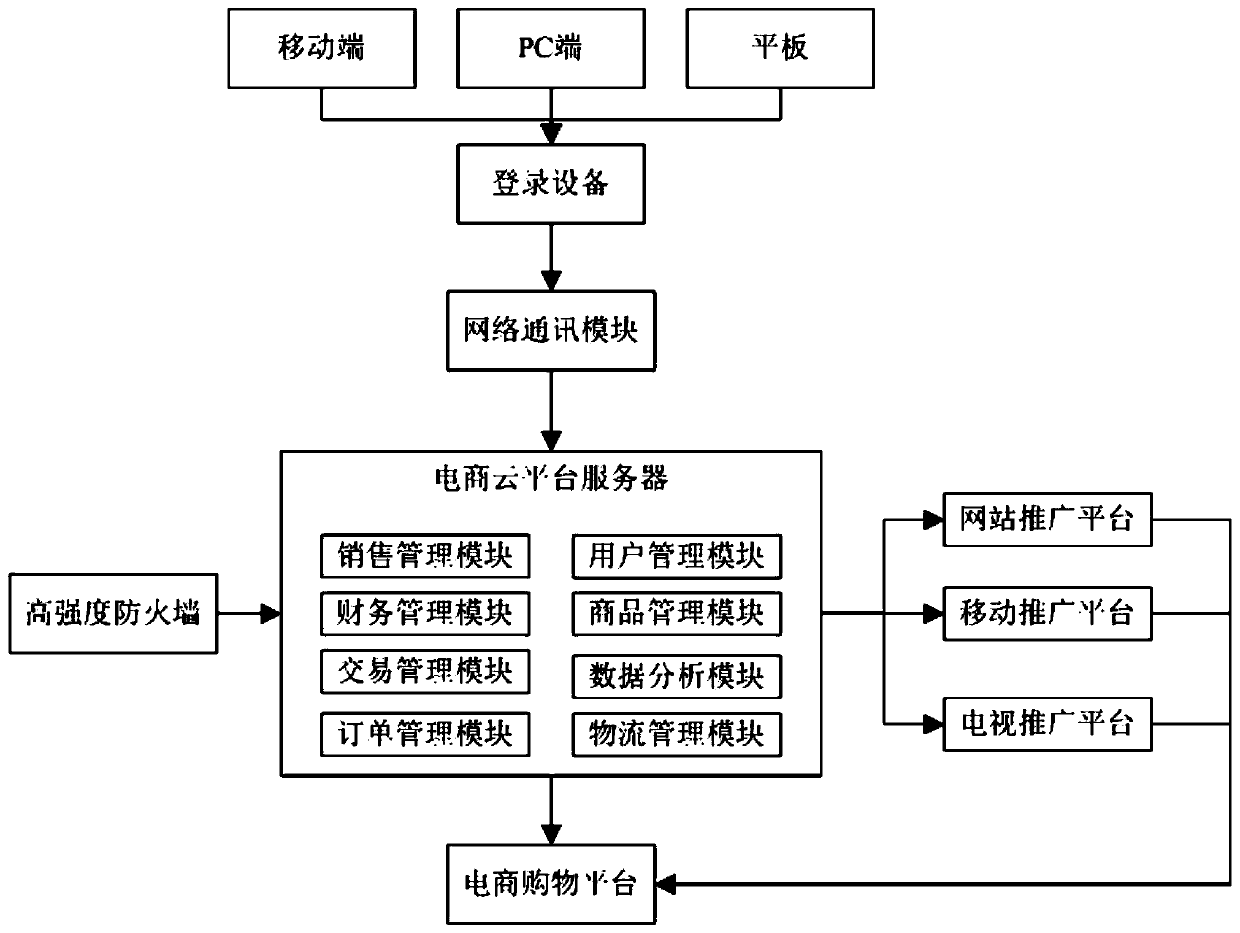

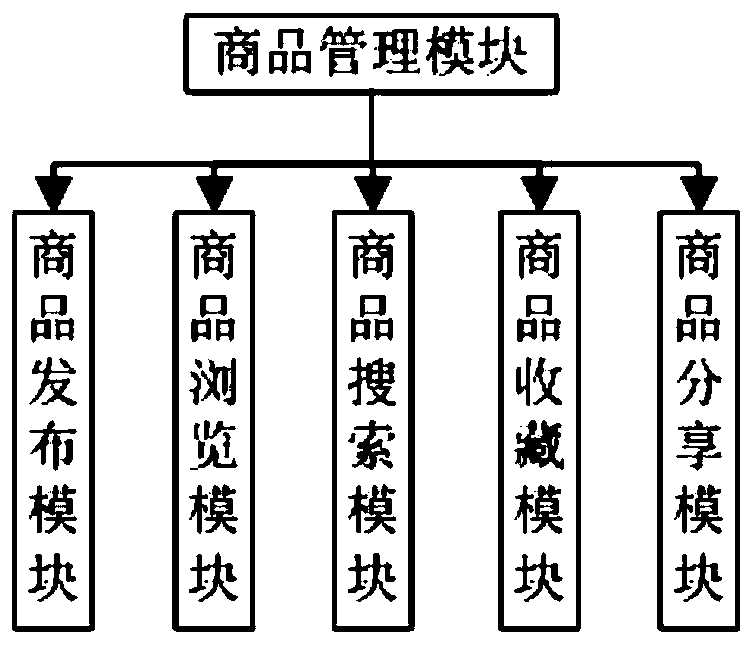

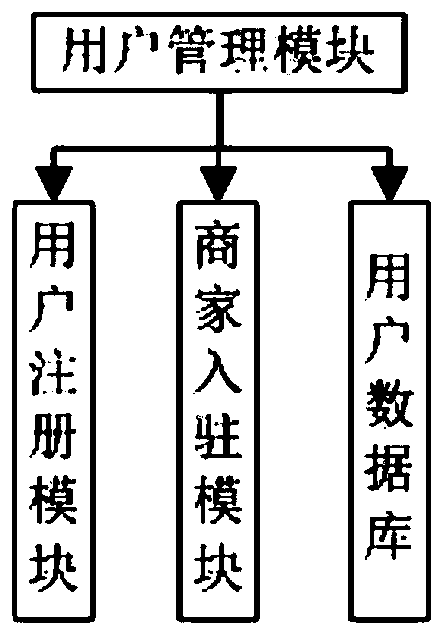

Shared e-commerce platform marketing promotion management system

InactiveCN111489187AChange the status quoImprove experienceFinanceBuying/selling/leasing transactionsNetwork communicationData store

The invention relates to the technical field of electronic commerce. The shared e-commerce platform marketing promotion management system comprises an e-commerce cloud platform server, login equipment, an e-commerce shopping platform, a website promotion platform, a mobile promotion platform and a television promotion platform; the e-commerce shopping platform is carried on the e-commerce cloud platform server, and the login equipment is in butt joint with the e-commerce cloud platform server through a network communication module. The e-commerce cloud platform server carries an e-commerce shopping platform, the data processing speed and the data storage speed are increased, and the working efficiency is improved; due to the portability of the mobile terminal, a user can browse, search, collect and share commodities anytime and anywhere and can obtain coupons; the spontaneous promotion enthusiasm of the user is effectively stimulated; the e-commerce shopping platform, the website promotion platform, the mobile promotion platform and the television promotion platform are mutually matched and added, the embarrassing situation that promotion is disordered and invalid nowadays is broken through, the requirement of a user is judged according to relevant information browsed by a user webpage, and promotion is conducted as required.

Owner:安徽西尔艾智能科技有限公司

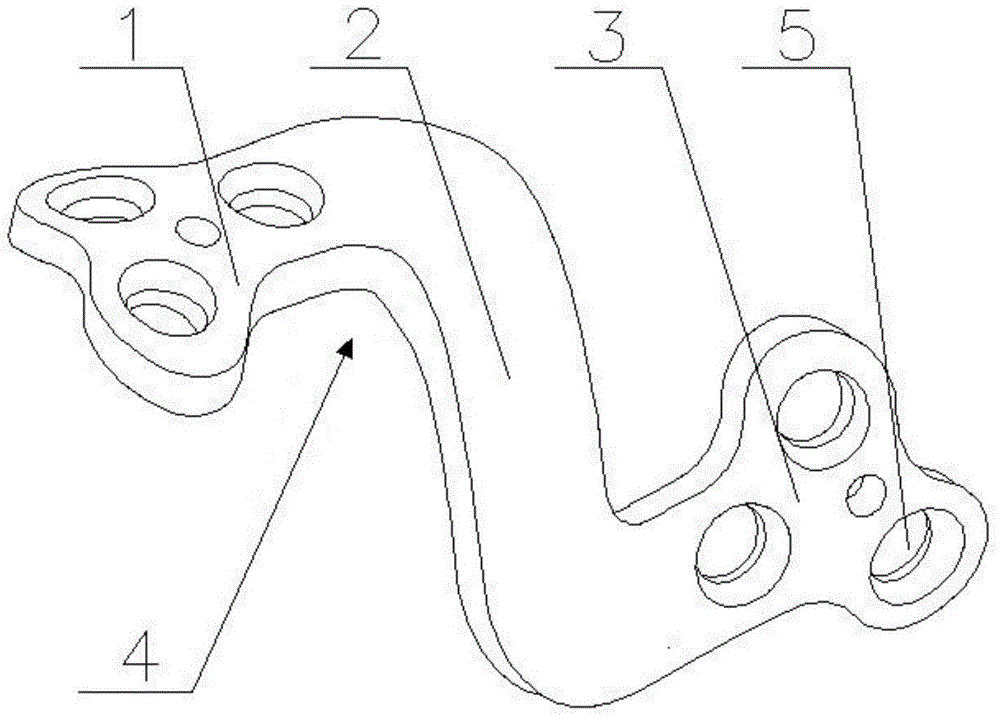

First metatar0sal far-end osteotomy plate

ActiveCN105726110AReduce stimulationChange the status quoBone platesSteel platesPostoperative recovery

The invention relates to the technical field of medical apparatuses and instruments, in particular to an inverted S-shaped osteotomy plate body.The osteotomy plate body comprises an osteotomy plate near end, an osteotomy plate far end and a transition section used for connecting the osteotomy plate near end with the osteotomy plate far end, and the osteotomy plate near end, the osteotomy plate far end and the transition section are integrally formed; the osteotomy plate body is provided with multiple fixing holes used for fixing an osteotomy plate on the first metatarsal bone, and the directions of the osteotomy plate near end and the osteotomy plate far end are in accordance with the direction of the first metatarsal bone.According to the first metatarsal far-end osteotomy plate, osteotomy fixing is stable and reliable, the steel plate design is adopted, the strength is high, early function rehabilitation is benefited, the postoperative recovery time is shortened, and a good fixing effect on osteoporosis hallux valgus is achieved; the concealed edge design is adopted, and stimulus to soft tissue is reduced; the anatomic design is adopted, anatomical replacement after the osteotomy is convenient, and prebending of the steel plate during the operation is not needed.

Owner:上海斯地德商务咨询中心

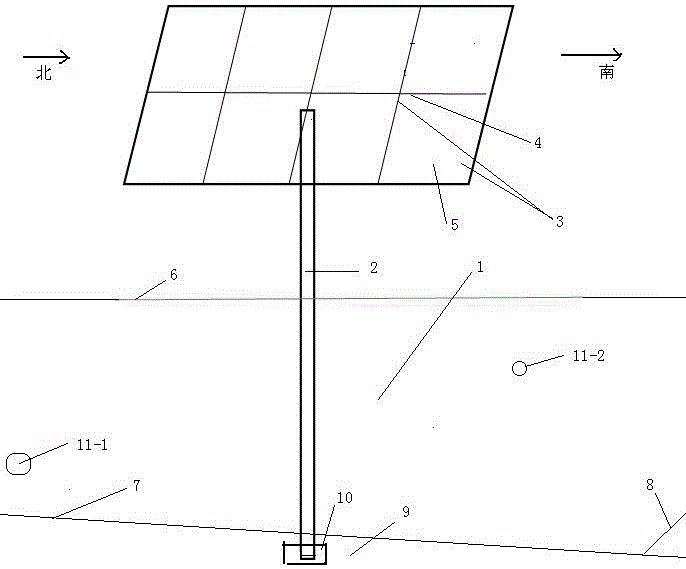

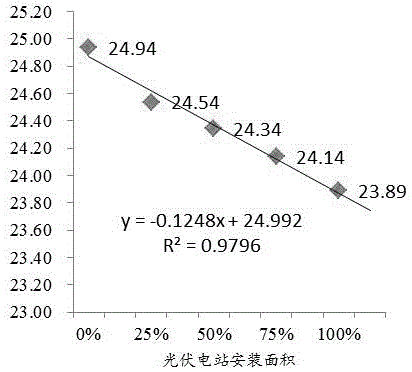

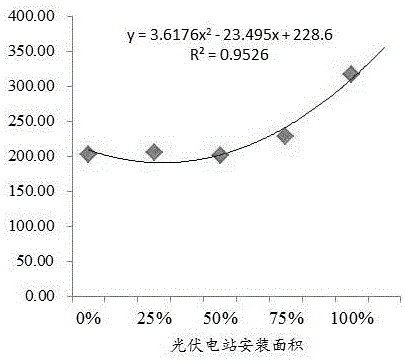

Pelteobagrus fulvidraco cultivating system and pelteobagrus fulvidraco cultivating method integrating fish farming and power generating

InactiveCN105104282AGrow fastReduce feed factorPV power plantsPisciculture and aquariaElectricityLand resources

The invention belongs to the field of aquaculture, and particularly relates to a pelteobagrus fulvidraco cultivating system and a pelteobagrus fulvidraco cultivating method integrating fish farming and power generating. The pelteobagrus fulvidraco cultivating system comprises a pond, supporting rods and photovoltaic modules, wherein the pond is provided with a pond bottom surface and a pond side surface; the photovoltaic modules are formed by photovoltaic module frames and photovoltaic panels; the photovoltaic module frames and the photovoltaic panels are mounted into a whole in a certain shape; one end of each supporting rod is fixedly arranged in soil or cement under the pond bottom surface; the other end of each supporting rod is higher than the water surface of the pond and is connected with the corresponding photovoltaic module frame; the number of the pond is greater than or equal to 1; the number of the supporting rods is greater than 1; the number of the photovoltaic modules is greater than 1; the photovoltaic panels have the functions of generating power and shading light. According to the pelteobagrus fulvidraco cultivating system disclosed by the invention, power generation is carried out by erecting the photovoltaic modules above the cultivating water surface, fish farming is carried out under the water surface, a mode of carrying out power generation above the water surface and carrying out fish farming under the water surface is formed, the land resource is saved, the environment is improved, and the income of each pond is increased.

Owner:TONGWEI

Intensive large-scale dairy farm cattle manure compressed high-density fuel and method thereof

InactiveCN102304407AWays to simplify resource utilizationSimplify the way to useBiofuelsSolid fuelsCooking & bakingLand resources

The invention relates to an intensive large-scale dairy farm cattle manure compressed high-density fuel and a method thereof, belonging to the field of environmental pollution abatement in livestock husbandry, waste recycling, new energy development and the like. The invention solves the environmental pollution caused by cattle industry, and can provide a new energy source substance-cattle manure compressed fuel. The method for preparing the high-density compressed fuel comprises the following steps: compressing pure cattle manure subjected to dry-wet separation, and baking. The invention changes the way of predecessors for utilizing the cattle manure resources, can also change the actual state of the scale of cattle industry in China, can maximize the centralized breeding, and saves abundant land resources and human resources.

Owner:徐武文 +1

Method for manufacturing high-density fuel from cow dung

InactiveCN107267244ASolve the shortageChange the status quoBiofuelsSolid fuelsHigh densityNew energy

The invention relates to a method for manufacturing high-density fuel from cow dung. The fuel comprises, according to a weight part ratio, 120-140 parts of fermented mature cow dung, 15-20 parts of crops straw, and 10-15 parts of sawdust powder. The method comprises: uniformly stirring and mixing fermented mature cow dung with crops straw and sawdust powder, performing compression moulding, performing natural air-drying for 3-5 days, and performing drying at 100 DEG C through a dryer, till the water content of the obtained product is less than 10%. According to the method, the utilization rate of cow dung resources is improved, pollution to a cattle farm is greatly reduced, and pollution to the environment is limited. The fermented cow dung is developed to be fuel, so that cost of a culture farm is reduced, development of cattle raising industry is promoted, and the problem of fuel shortage is overcome. The method provides a significant way for improving an environment energy utilization ratio. The biomass dung is developed into new energy, and an energy utilization mode is explored.

Owner:王运模

Method for promoting advancing maturity of navel orange No.52

The invention discloses a method for promoting advancing maturity of a navel orange No.52. According to the invention, the murcott orange with natural pollination has the special natural cross-pollination function; the murcott and the navel orange No.52 are planted in a hybrid mode, wherein the flowering phase of the murcott is identical with that of the navel orange No.52; and with natural pollination of mediums like bees, insects, and wind and the like, excellent characteristics of high glucose and high quality of the murcott orange are expressed and inherited by the navel orange No.52. Fifty navel oranges No.52 are planted per 666.7 square meters at an orchard and three murcott oranges are planted in a hybrid mode at equal distances; a box of bees are kept each 333.5 to 4000.2 square meters, small channels formed by iron gauzes are arranged at the inlet and outlet of the bee box, and newly-bloomed flowers of the navel oranges No.52 and the murcott oranges are placed in the channels, wherein the flowers are mixed with a little honey, so that signals for pollen collection of the navel oranges No.52 and the murcott oranges are sent to the bees. On the basis of the technical scheme, maturity of the navel oranges No.52 can be realized 30 to 40 days in advance and the soluble solid content of the fruit can reach up to over 15.4%. Therefore, the navel orange No.52 becomes the earliest one being on sale on the market and the one with the best quality; and the available price can be improved by 1.5 times.

Owner:建瓯市旭源农产品专业合作社

A kind of preparation method of bisphenol F and three, tetracyclic phenolic resins

InactiveCN102276425AImprove conversion rateAltered phenol residuesOrganic chemistryOrganic compound preparationSolventPhosphoric acid

The invention discloses a preparation method of bisphenol F and three- and four-ring phenolic resins, which is characterized in that it comprises the following steps: measuring phenol, formaldehyde and organic phosphoric acid catalyst; adding phenol, formaldehyde and organic phosphoric acid catalyst in sequence In the reaction kettle, the temperature is raised; after the reaction is completed, a large amount of crystals are precipitated after cooling down, suction filtered, and washed with water to obtain a mixture of crude bisphenol F and tricyclic and tetracyclic phenolic resins; place it on a suspended filter cloth, and in the oven Baking and drying, the obtained upper material of the filter cloth is crude bisphenol F, and the material filtered out of the filter cloth is tricyclic and tetracyclic phenolic resins; the filtered water phase is treated. The present invention adopts organophosphoric acid catalyst, can directly form crude bisphenol F without the step of solvent crystallization, greatly reduces the amount of solvent used, and reduces the complexity of later work; The tricyclic and tetracyclic phenolic resins produced by the reaction.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Paper mosquito coil and preparation method thereof

The invention discloses a paper mosquito coil and a preparation method thereof. The paper mosquito coil comprises a paper fragrant blank containing a mosquito repelling agent and a mosquito eradication agent, and comprises the following components in percentage by weight: 60 to 90 percent of waste paper, 0 to 25 percent of wood fiber, 8 to 33 percent of carbon powder and 2 to 7 percent of light calcium carbonate. The paper mosquito coil has the advantages of low cost, light weight, no pollution to hands and difficulty in fracture, is easy to ignite and cannot flame out. The preparation method comprises the following steps of: 1, crushing waste paper raw materials to form coarse pulp; 2, adding the wood fiber, the carbon powder and the light calcium carbonate into the coarse pulp, and uniformly mixing; 3, grinding the mixture by using a grinding disc to form waste paper pulp; 4, diluting the waste paper pulp by adding water, removing impurities, and manufacturing a mosquito coil paper board with the pulp; 5, punching the mosquito coil paper board, and drying to obtain a mosquito coil white blank; and 6, spraying the agents onto the white blank to obtain the paper mosquito coil. The method has the advantages of energy conservation, environment friendliness, high labor productivity and capability of production on a large scale.

Owner:HANGZHOU JIADEHAO COMMODITY

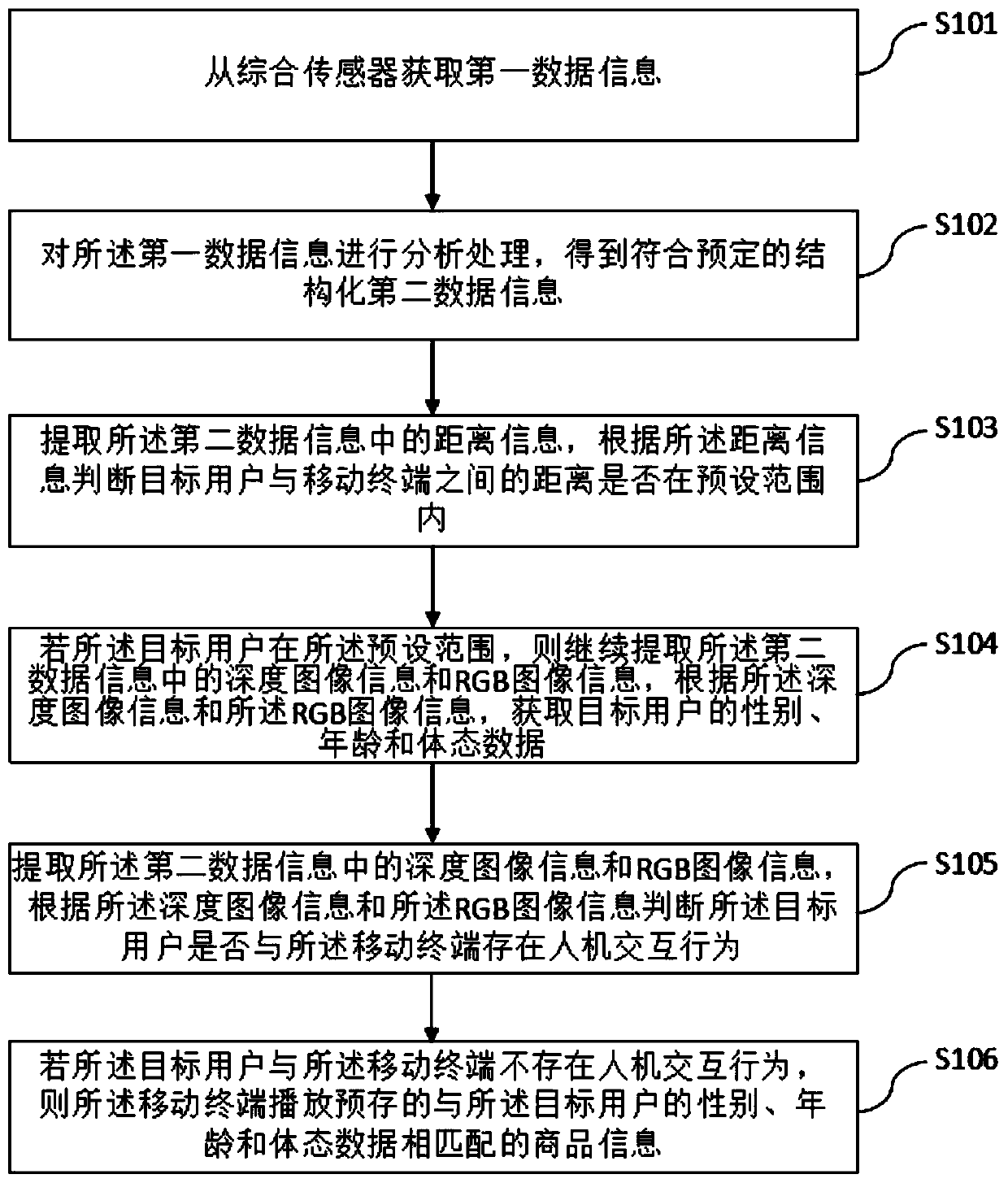

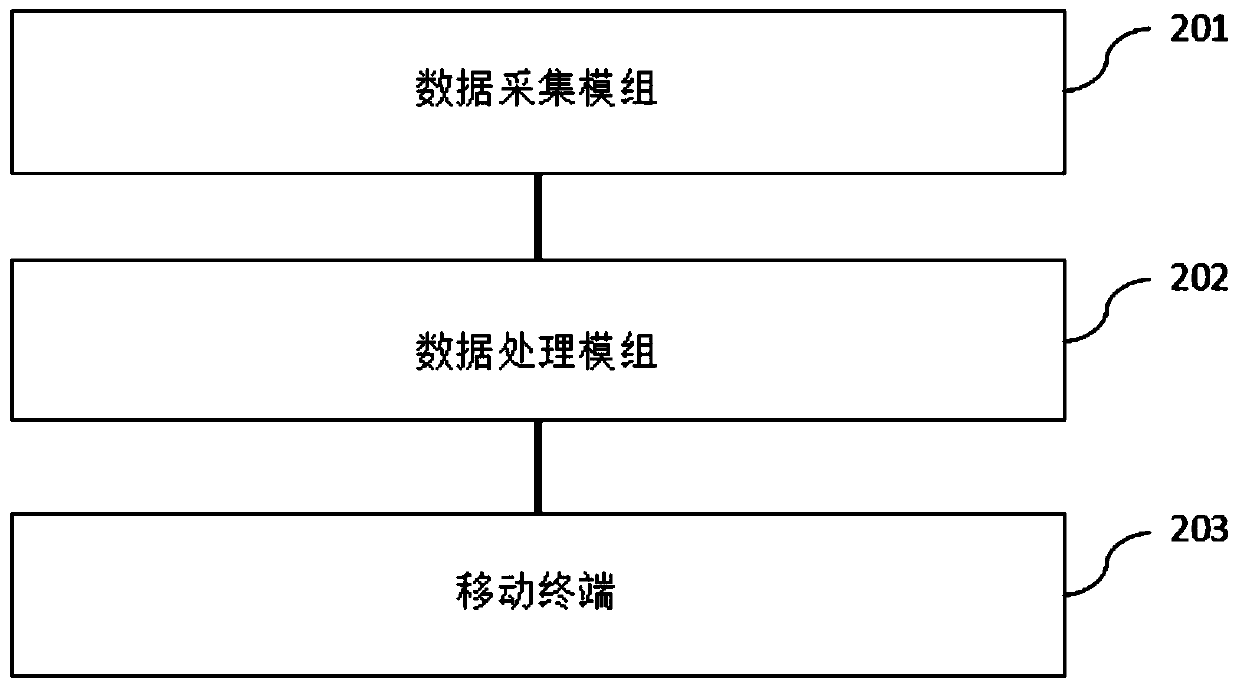

Multi-dimensional data acquisition application method and system

PendingCN111078014AAvoid stabilityAvoid using effectsInput/output for user-computer interactionGraph readingRgb imageData acquisition

The invention discloses a multi-dimensional data acquisition application method and system, and belongs to the technical field of information. According to the method, the comprehensive sensor is usedfor collecting the distance information, the depth image information and the RGB image information, the collected information is integrated into multi-dimensional data to be analyzed and processed, and whether the distance between the user and the mobile terminal is within a preset range or not is judged; if the user is in the preset range, the method includes extracting depth image information and RGB image information, and obtaining gender, age and posture data of the user according to the information; judging whether a human-computer interaction behavior exists between the user and the mobile terminal or not according to the depth image information and the RGB image information; and if the user and the mobile terminal do not have the human-computer interaction behavior, enabling the mobile terminal to play pre-stored commodity information matched with the gender, age and posture data of the user. The comprehensive sensor is composed of a distance sensor, an RGB camera and a depth camera. The method and system are convenient to configure, can improve the consumption experience, and is suitable for commercial popularization and application.

Owner:深圳数拓科技有限公司

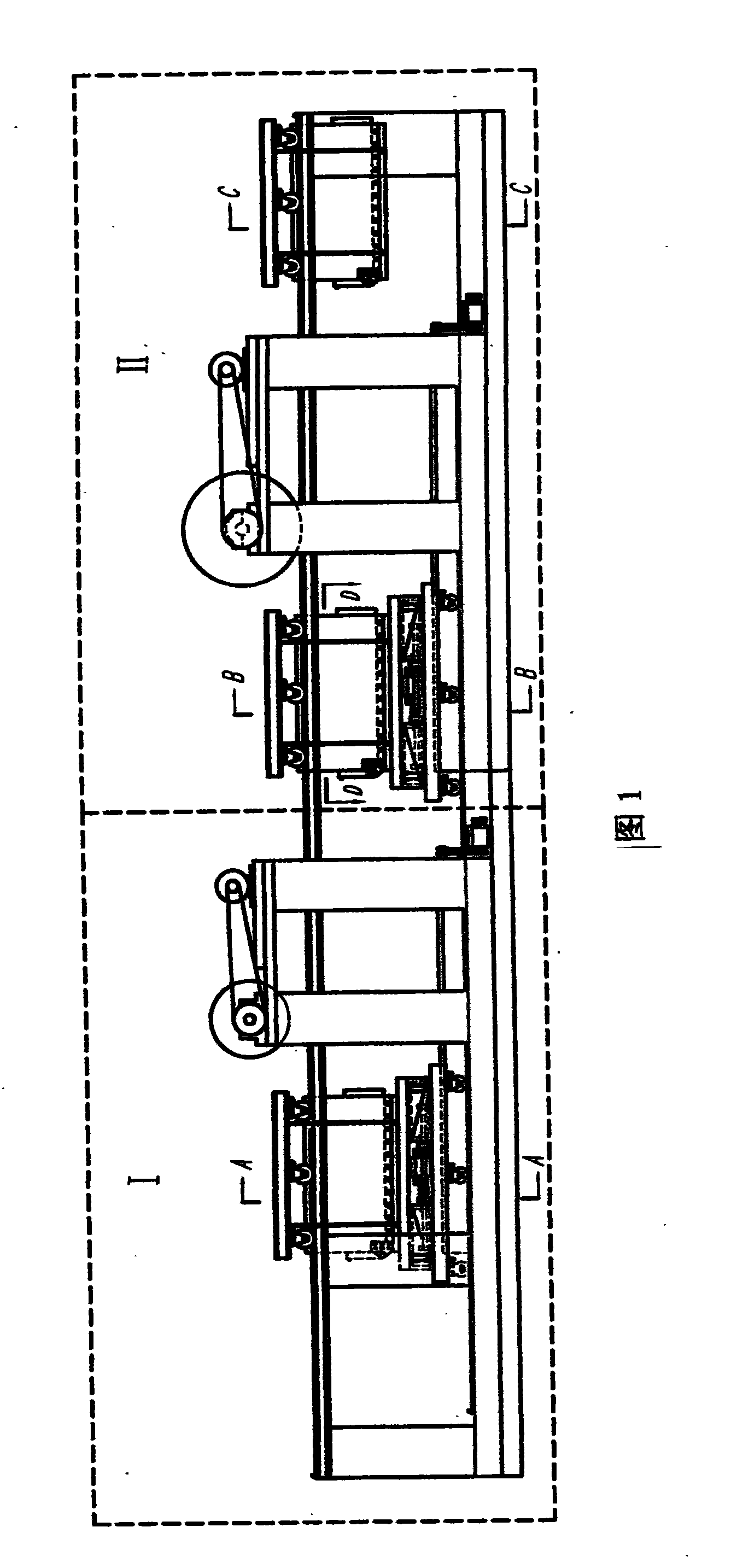

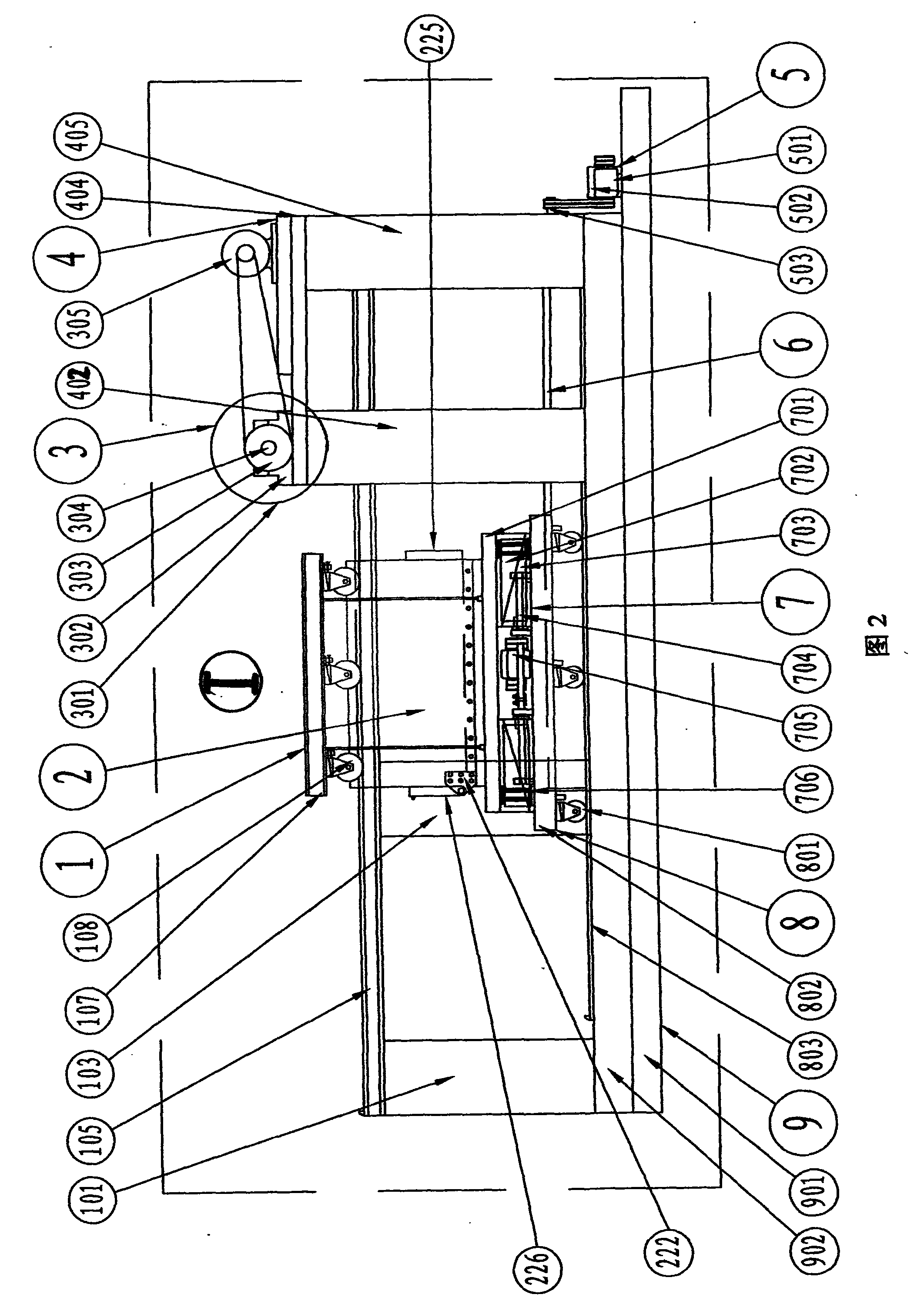

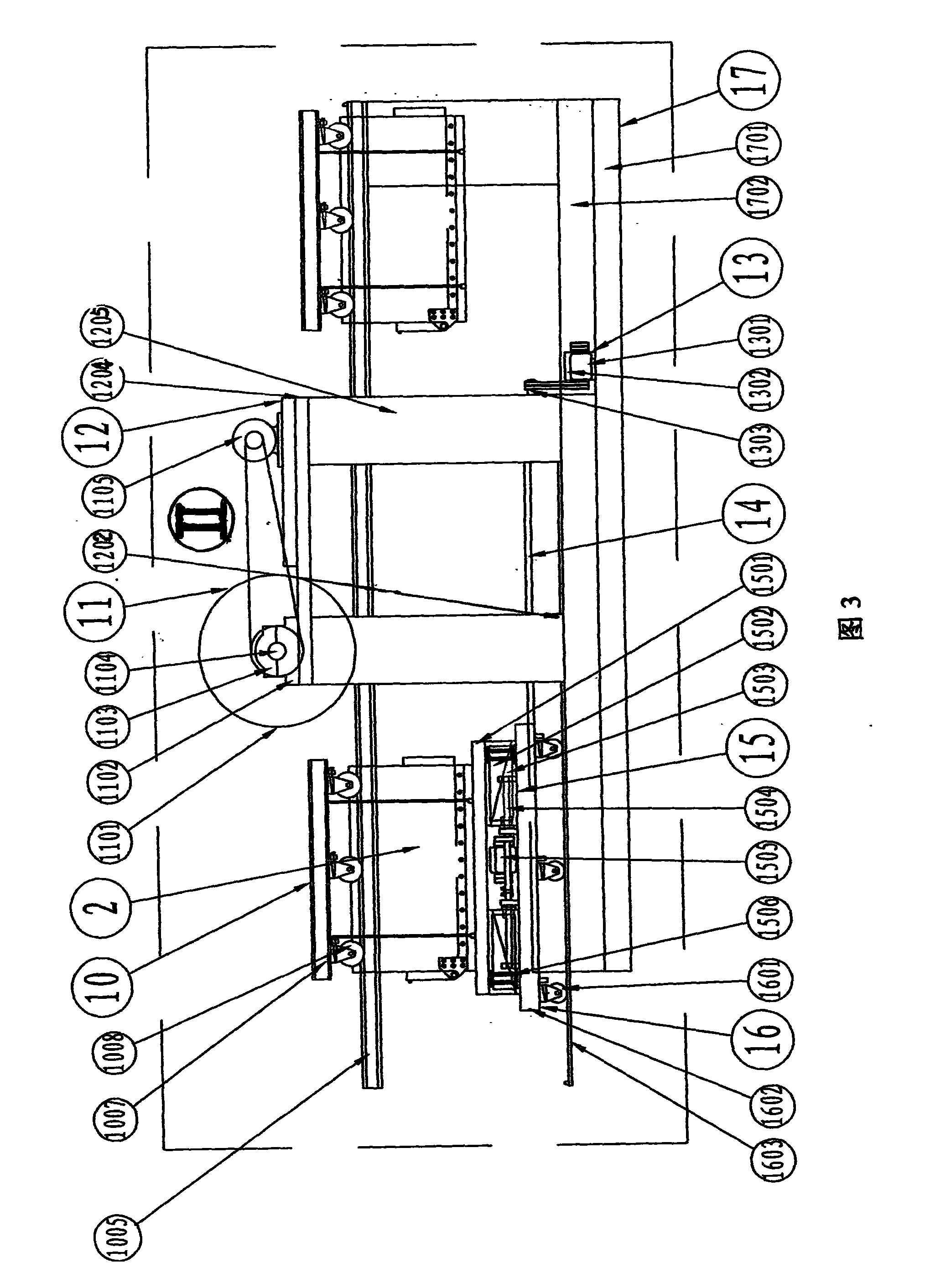

Production line of multi-axle multi-cutter stone-material thin, ultra-thin composite board

InactiveCN101491922ASolve world problemsChange the status quoWorking accessoriesStone-like material working toolsProduction lineSlide plate

The invention relates to a stone processing production line, in particular to a multi-shaft and multi-cutter production line for thin and ultrathin composite stone plates. The production line is characterized in that a plurality of cutter sets are arranged on a stand assembly to form a plurality of processing areas; each cutter set comprises each assembly of a traveling crane hoister, a special clamp, a cutter shaft, a cutter shaft rack, a stroke transmission, a planar guide rail, a lifting workbench and a stroke sliding plate; the lifting workbench achieves vertical cutting progress for a stone processed piece, and the stroke sliding plate is provided with the lifting workbench and is in transmission connection with the stroke transmission assembly to achieve horizontal cutting and reciprocating movement; and the special clamp clamps the processed piece and is hoisted on the traveling crane hoister which is arranged on a wheel track on a bearing column, the cutter shaft rack is also arranged on the bearing column and is provided with the cutter shaft, and the cutter shaft is in a fixed shaft mounting mode and is provided with a plurality of saw blades so as to achieve multi-cutter synchronous cutting to the stone to be processed. The whole production line achieves continuous processing, improves production efficiency greatly, and also improves management efficiency greatly.

Owner:陈正枢

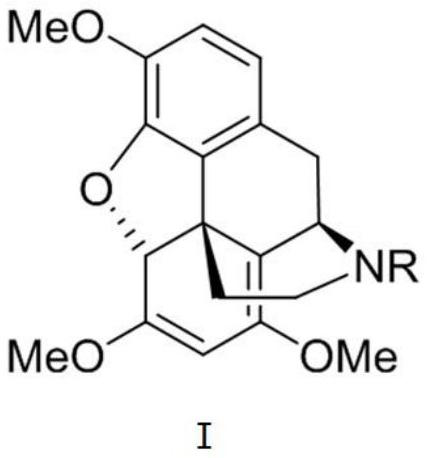

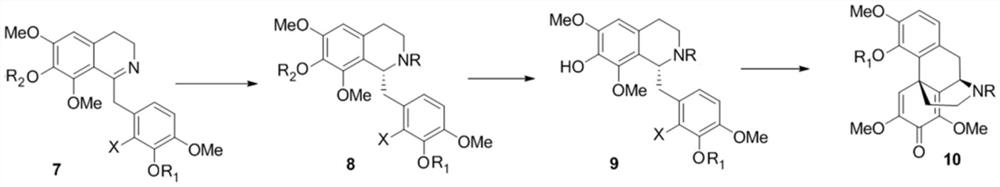

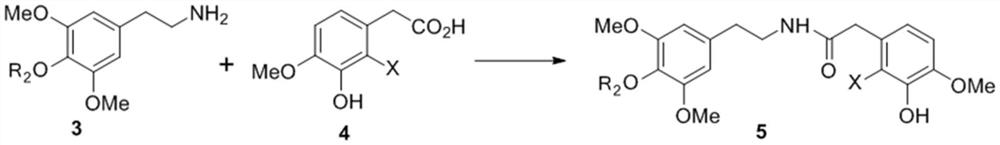

Intermediate as well as preparation method and application thereof

PendingCN114423764AHigh yieldGood choiceOrganic chemistry methodsBulk chemical productionPerylene derivativesEnantio selectivity

The invention relates to the field of drug synthesis, and discloses application of an intermediate or a preparation method thereof in total synthesis of morphine derivatives. A transition metal catalyzed asymmetric hydrogenation reaction and an intramolecular oxidation dearomatization Heck reaction in the process of preparing the intermediate are taken as key reactions of total synthesis, and efficient preparation of morphine derivatives, especially representative oxycodone and codeine is realized; the total synthesis method has the advantages of excellent chemical and enantioselectivity, high synthesis efficiency, simple operation and large-scale amplification; meanwhile, the prepared intermediate product can be used for preparing other various morphine derivatives only through simple modification and conversion, and the method has important practical significance for changing the current single industrial production mode of depending on artificial planting, extraction and semi-synthesis of morphine derivative drugs of poppy and guaranteeing supply of morphine drugs.

Owner:SICHUAN UNIV

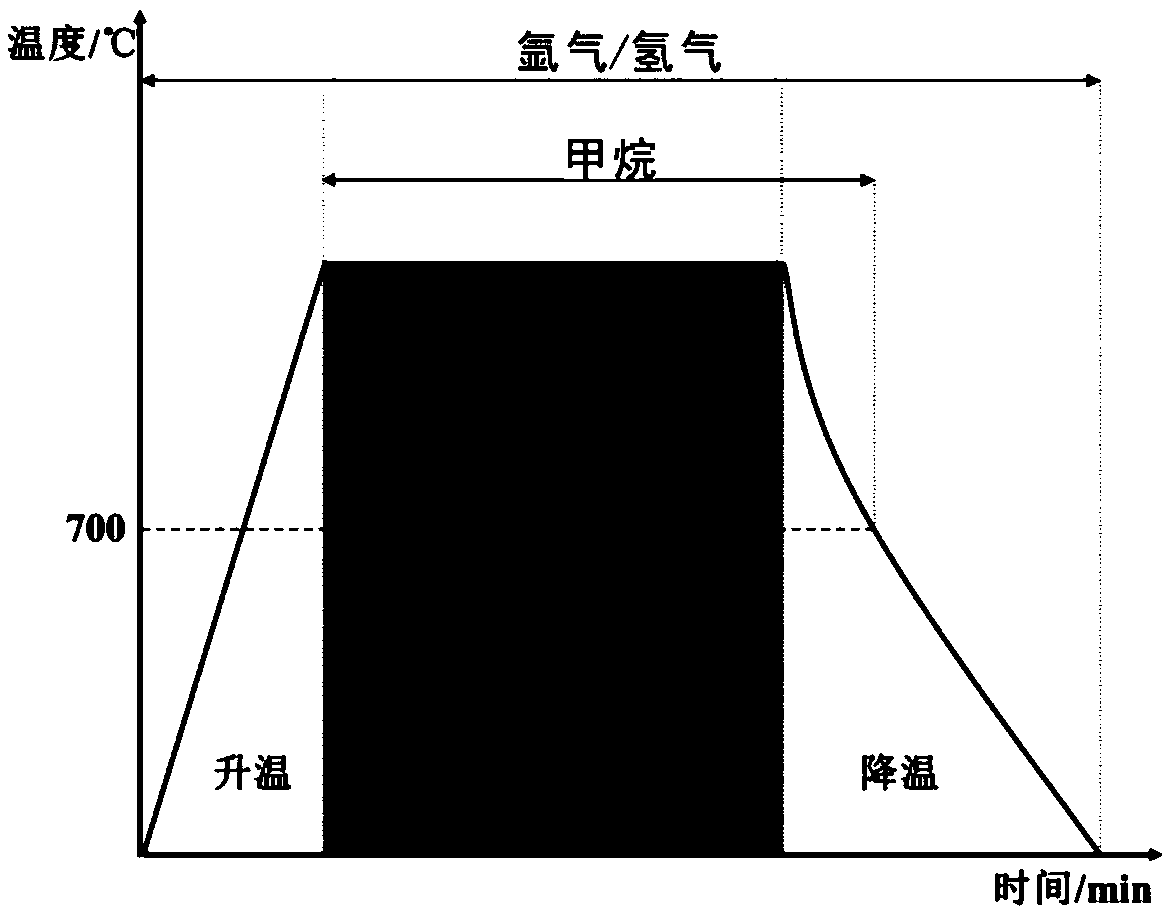

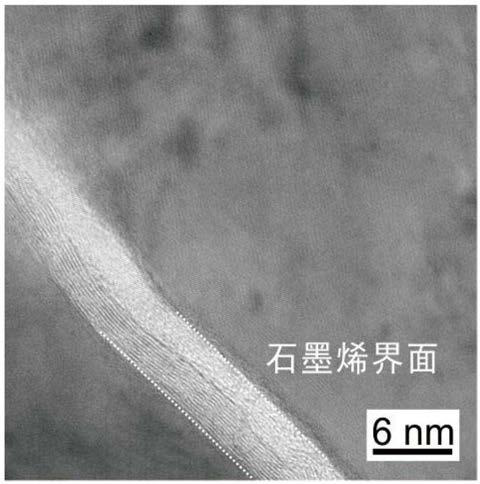

Method for preparing single-layer graphene

The invention discloses a method for preparing single-layer graphene. The method comprises the following steps of: 1) preparing an alloy substrate; and 2) in the hydrogen and inert atmosphere, catalyzing to grow graphene on the surface of the alloy substrate obtained in the step 1) by a chemical vapor deposition method, thereby finishing the preparation of the single-layer graphene. The method makes use of the characteristics of two or more alloy metals in the alloy substrate, realizes control on the decomposition, diffusion and precipitation processes of a carbon source, simply and efficiently restrains the precipitation process of carbon dissolved in the metal substrate to enable the graphene to be capable of growing in a surface catalytic manner to obtain the single-layer graphene with uniform layer distribution, and is suitable for industrial production and particularly for the controllable preparation of single-layer or few-layer graphene.

Owner:PEKING UNIV

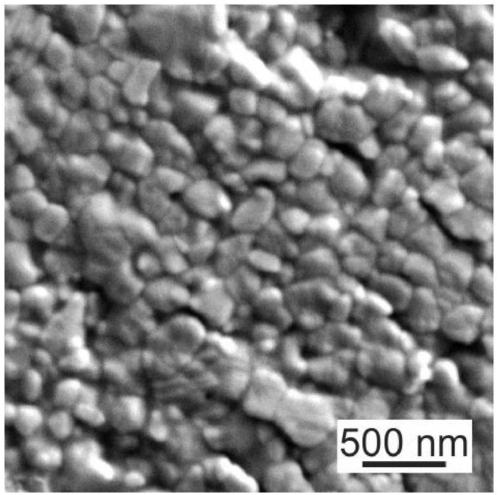

Preparation method of high-tolerance nanophase graphene composite ceramic

The invention relates to a preparation method of a high-tolerance nanophase graphene composite ceramic, and belongs to the field of composition of two-dimensional materials. A metal mixed ceramic nanopowder substrate is prepared first, then nanophase graphene is catalyzed to grow on the surface of the substrate through chemical vapor deposition so as to finish the preparation of the nanophase graphene; an obtained nanophase graphene composite ceramic powder is rapidly sintered by discharge plasma so as to finish the preparation of the nanophase graphene composite ceramic. The graphene ceramicmaterial prepared by the invention is excellent in electric conduction, heat conduction and chemical stability.

Owner:WUHAN UNIV

Method of increasing nobiletin content in Fujian tangerine peel

InactiveCN106416998AChange the status quoIncrease contentPlant genotype modificationTangerine FruitPollination

The invention discloses a method of increasing a nobiletin content in Fujian tangerine peel and belongs to of technical field of biology. The method takes a Murcott tangerine as a male parent and a Fujian tangerine as a female parent and increases the nobiletin content in the Fujian tangerine peel by a pollination method, and the pollination method is an artificial pollination method or a spontaneous pollination method. The method significantly increases the nobiletin content in the Fujian tangerine peel to 1710.0+ / -27.25 to 1998.18+ / -36.48 microgram / g; the content is 2.8 times of that in control Fujian tangerine peel; and the health-care quality character of fruit is further improved. In addition, the method is simple to operate, convenient to implement and low in cost and can be popularized rapidly.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com