Production line of multi-axle multi-cutter stone-material thin, ultra-thin composite board

A composite board and production line technology, which is applied in stone processing tools, stone processing equipment, work accessories, etc. Ultra-thin stone composite panels, inability to process super-hard granite composite panels, etc., to reduce blade costs, reduce power consumption, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments are further described below in conjunction with the accompanying drawings.

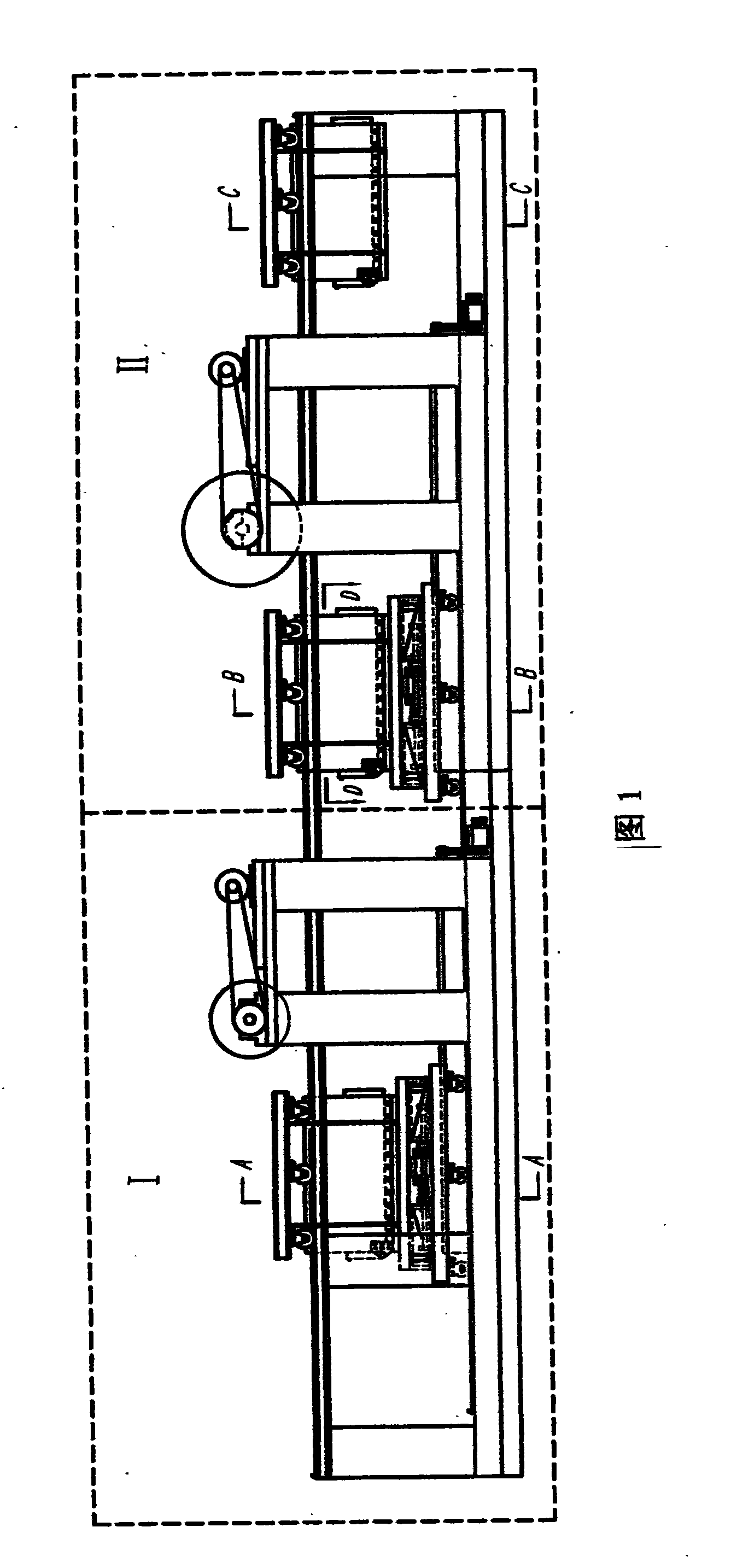

[0027] Referring to Figure 1, A-A, B-B, C-C, and D-D sectional lines are displayed in 2 areas I and II.

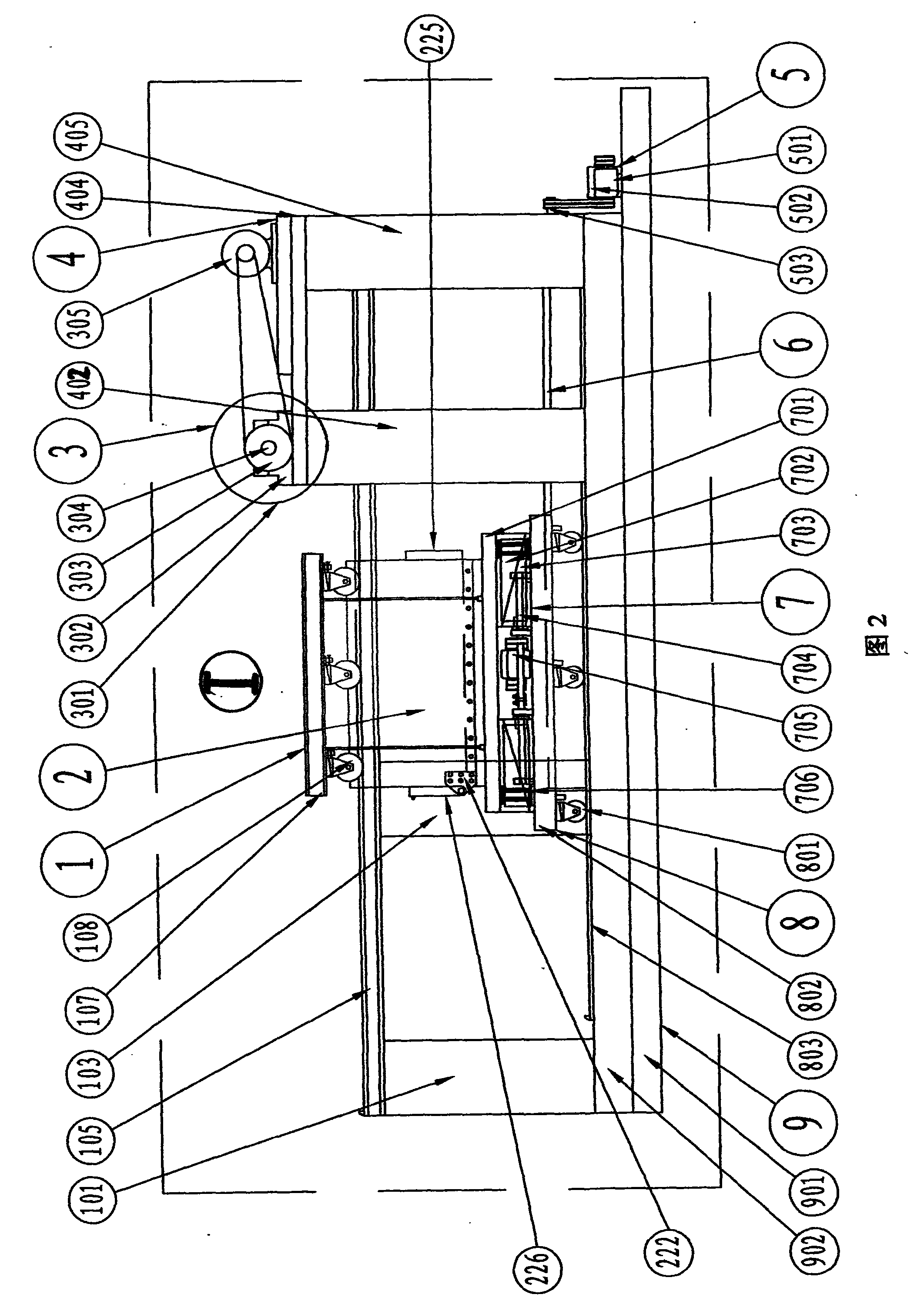

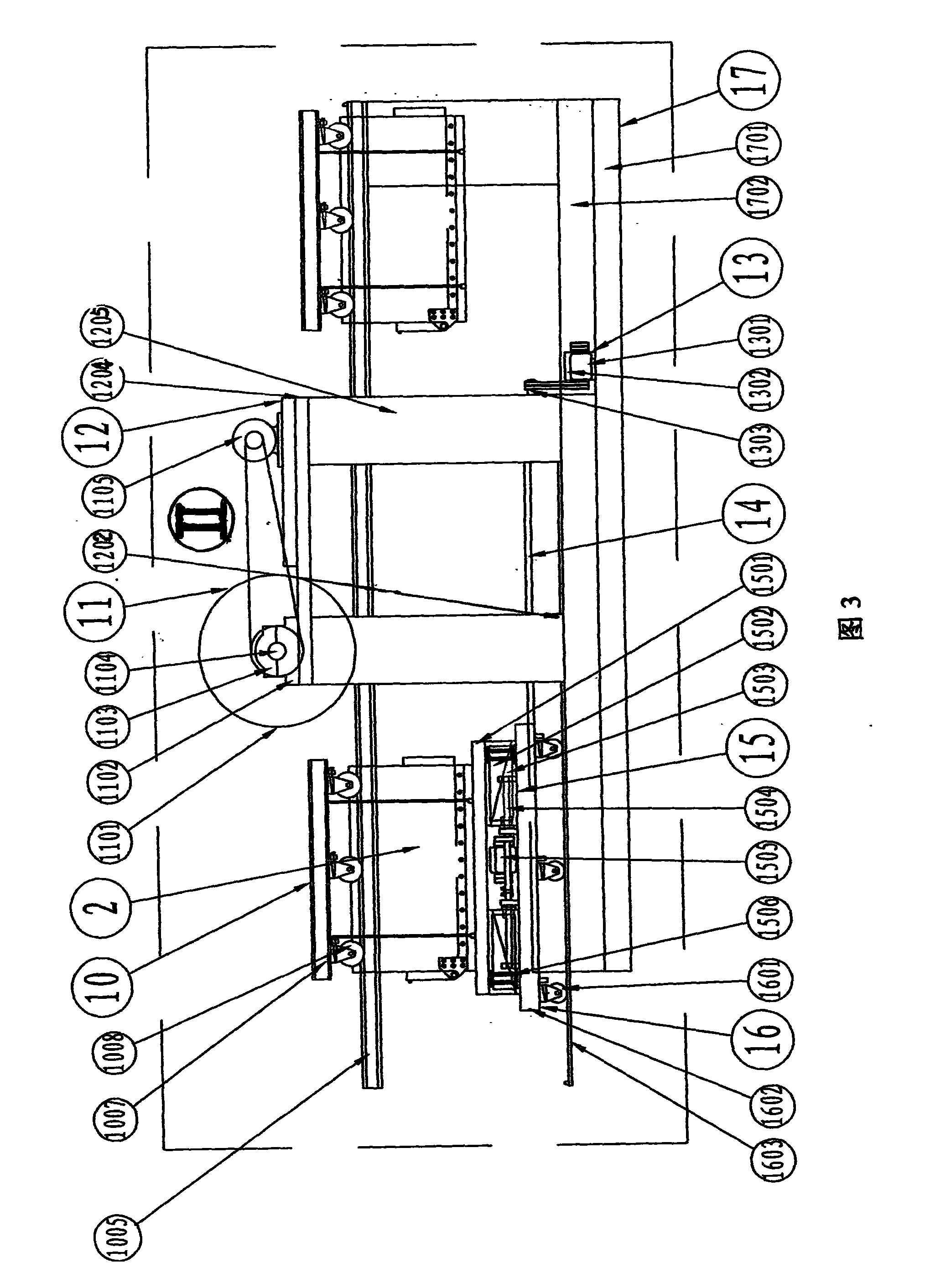

[0028] Referring to Figure 2, 1-travel crane assembly, 101, 103-travel crane load-bearing column, 105-travel crane wheel rail, 107-travel crane platform, 108-travel crane wheel group; 2-special fixture assembly, 222- Right side movable compression baffle loose-leaf board, 225-fixed right side compression baffle, 226-movable left side compression baffle; 3-knife shaft assembly, 301-saw blade group, 302- Cutter shaft bearing seat, 303-cutter shaft pulley, 304-cutter shaft, 305-main motor; 4-cutter shaft frame assembly, 402-cutter shaft frame main load-bearing column, 404-main load-bearing column connecting steel frame, 405-knife Pedestal auxiliary load-bearing column; 5-stroke transmission assembly, 501-stroke transmission motor, 503-stroke transmission gearbox, 503-stroke tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com