Tubular type annular channel double-sided heat-exchange large-flux microchannel fixed bed reactor

A technology of fixed bed reactor and annular channel, which is applied in chemical/physical/physicochemical fixed reactors, etc., can solve the problems of large fluid resistance, loss of control, and overheating reaction temperature, so as to improve safety, replace and Easy regeneration and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

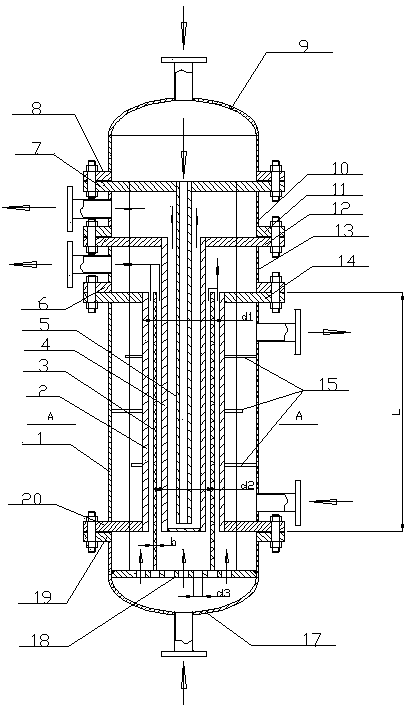

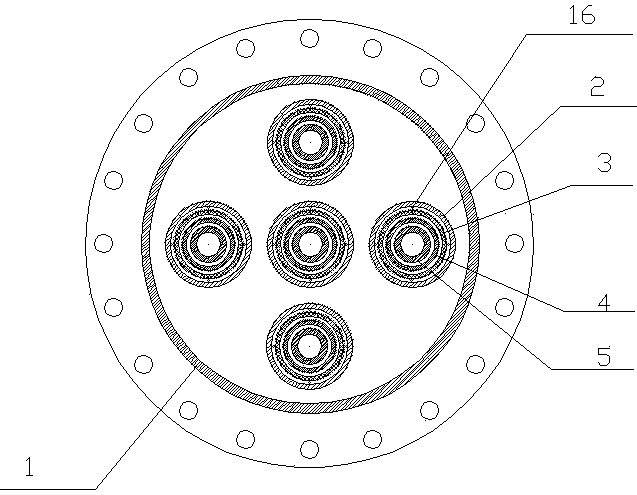

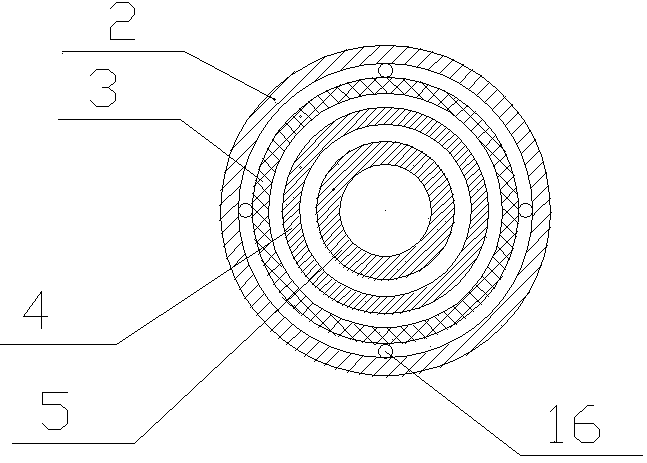

[0033] Such as Figure 1-3 As shown, the tubular annular channel double-sided heat exchange large-flux microchannel fixed-bed reactor includes: cylinder 1, column tube 2, catalyst tube 3, middle casing 4, inner casing 5, and No. 1 flange 6. No. 3 flange tube plate 7, No. 3 flange 8, No. 1 head 9, No. 2 tube box 10, No. 2 flange 11, No. 2 flange tube plate 12, No. 1 tube box 13, No. 1 Flange tube plate 14, baffle plate 15, fixed-distance round steel 16, No. No. 1 flange tube plate 14, the other end of cylinder body 1 is welded on No. Outlet of the medium, the tubes 2 are set in the cylinder body 1, one end of the tubes 1 is welded on the No. 1 flange tube plate 14, the other end of the tubes 1 is welded on the No. The inner wall of the end is welded with fixed-distance round steel 16, the catalyst tube 3 is set in the column tube 2, one end of the catalyst tube 3 is supported on the supporting flower plate 18, the other end of the catalyst tube 3 is flush with the No. 1 flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com