Cold starting system of alcohol fuel engine

An alcohol-based fuel, cold start technology, applied in combustion engines, internal combustion piston engines, charging systems, etc., can solve problems such as inability to preheat the engine, difficult flange configuration, and long heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

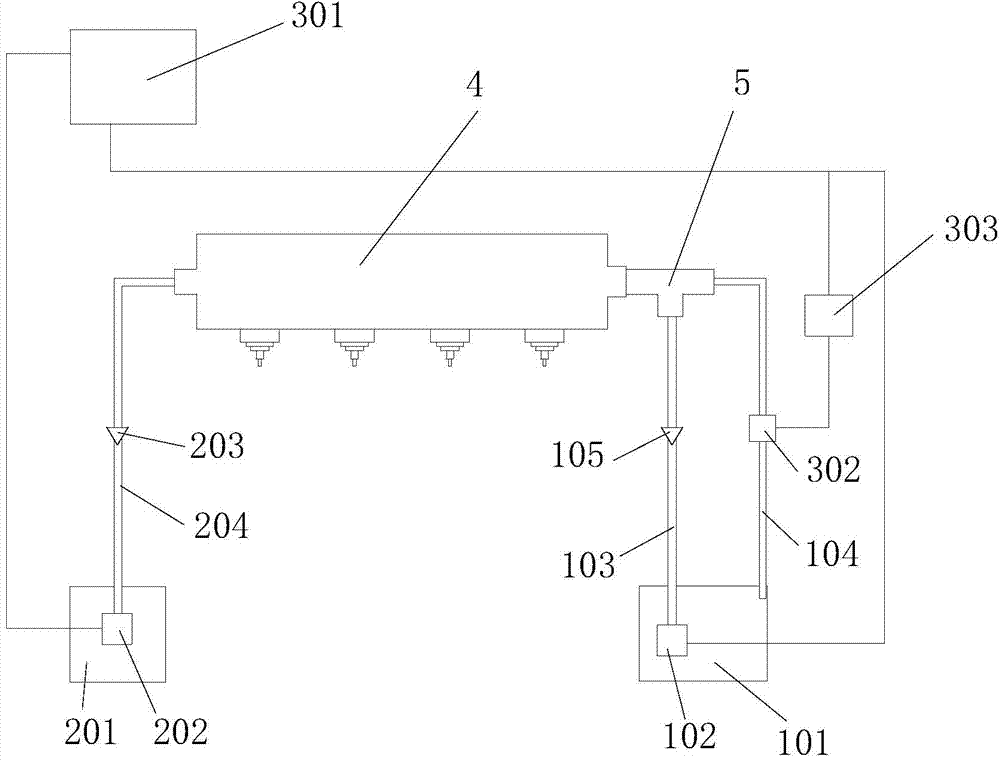

[0027] according to figure 1 As shown, the cold start system of the alcohol fuel engine of the present embodiment is illustrated, including an alcohol fuel supply system, a cold start auxiliary fuel supply system, an oil rail, a control system and a tee; the oil rail adopts an existing common oil rail That's it. The alcohol fuel supply system includes a fuel tank I, an alcohol oil pump, an oil inlet pipeline, an oil return pipeline, and a one-way valve I. The alcohol oil pump is fixed in the fuel tank I, and the inlet of the oil inlet pipeline is connected to the alcohol oil pump. connected, the outlet of the oil return line communicates with the oil tank I, and the one-way valve I is connected to the oil inlet line. The outlet of the oil inlet pipeline and the inlet of the oil return pipeline are both communicated with a port of the oil rail through the tee; The outlet of the pipeline is connected with the inlet of the oil return pipeline. The cold start auxiliary fuel sup...

Embodiment 2

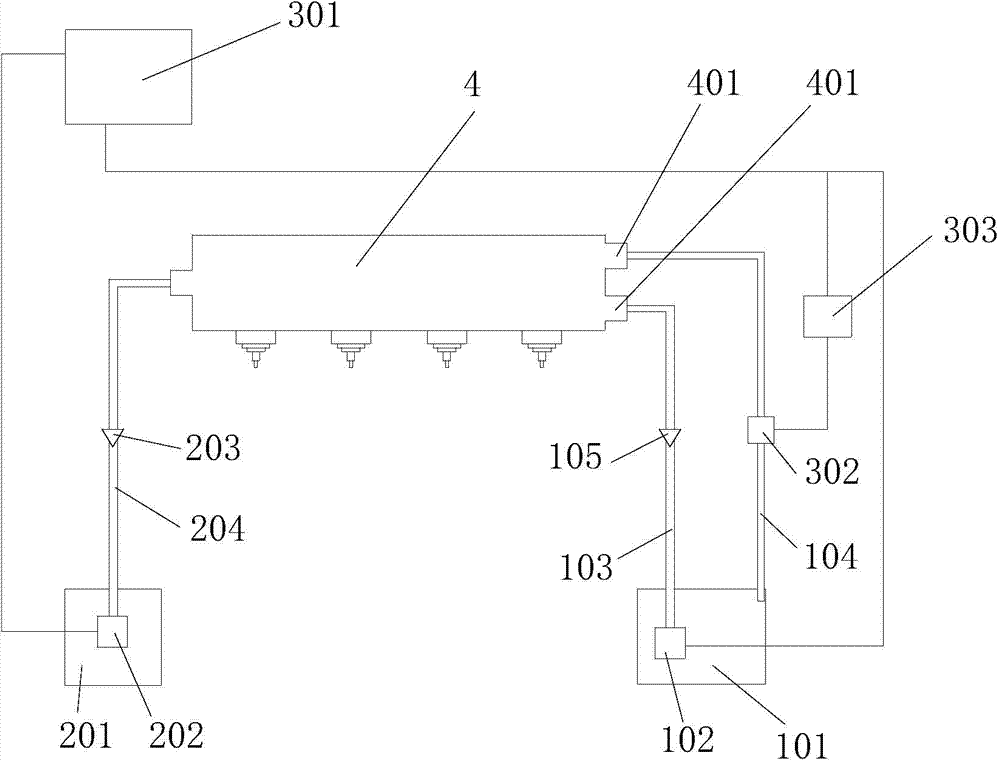

[0029] The difference between this embodiment 2 and embodiment 1 is that no tee is used, and an improved oil rail is adopted, such as figure 2 shown. The improved oil rail is an improved design of the port of the existing oil rail that communicates with the oil inlet pipeline and the oil return pipeline. The entrance is connected. Realize the oil inlet method of quick connection of two inlets and one outlet of oil rail.

[0030] The principle of the cold start system of the alcohol fuel engine of the above-mentioned embodiment 1 and embodiment 2 is as follows:

[0031] At low temperature, use the electronic controller in the control system to turn on the cold start auxiliary fuel supply system, that is, turn the switch of the electronic controller to the auxiliary fuel mode (gasoline mode), and at the same time control the delay breaker to turn on the alcohol fuel supply system. The solenoid valve on the oil return line in the engine performs a time-delayed closing control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com