Two-dimensional transition metal disulfides monocrystalline, and preparation method and applications thereof

A technology of transition metal and dichalcogenides, which is applied in the field of two-dimensional transition metal dichalcogenide single crystals and its preparation, which can solve the problems of residues, difficulty in obtaining, and control, so as to avoid oxide residues and reduce nucleation points Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

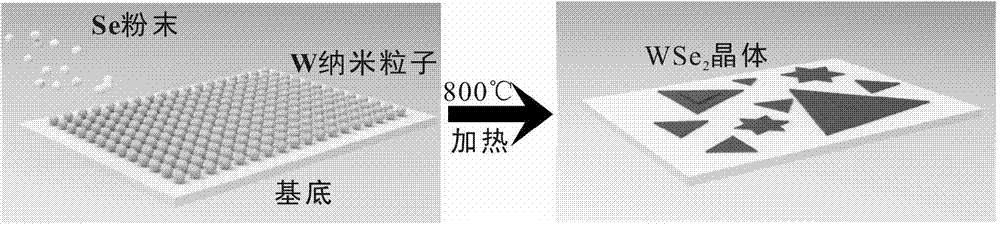

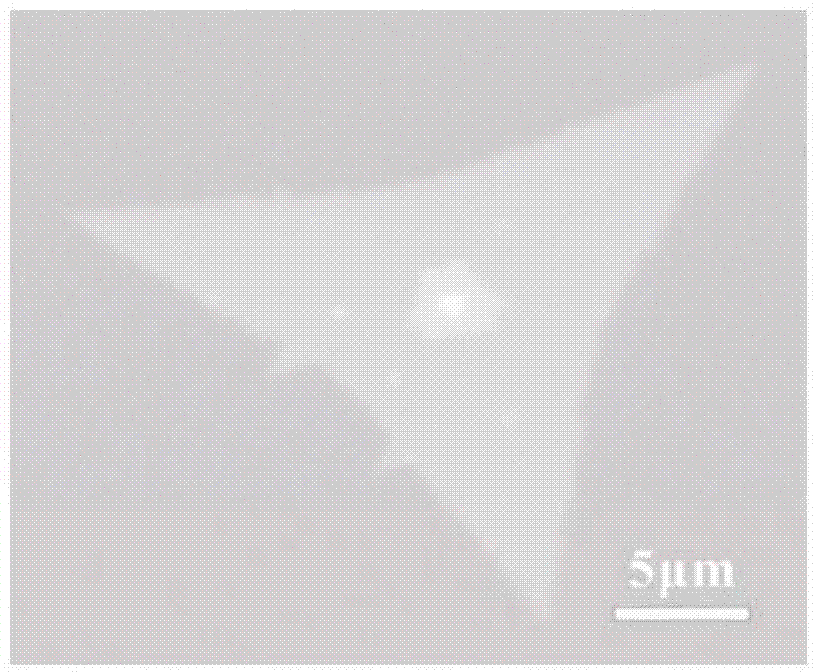

[0039] Example 1: Preparation of single-layer tungsten diselenide single crystal

[0040] (1) Cut the quartz plate into a square of 10×10 mm with a silicon knife, ultrasonically clean it in acetone, ethanol, and water for 20 minutes, then clean it with deionized water, and dry it with nitrogen.

[0041] (2) The cleaned quartz sheet is sputtered on the front side by magnetron sputtering, and the electron evaporator (ULVAC, ACS-4000-C4) is used for sputtering the tungsten layer under high vacuum, with a tungsten target with a purity greater than 99.95%. Shooting time is 7 seconds.

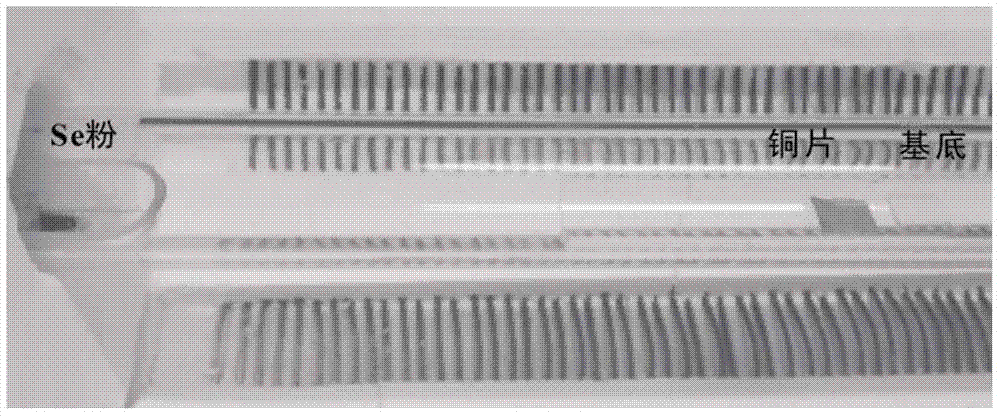

[0042] (3) be that 99.5% with purity, the selenium powder that quality is 0.03g is put into a new quartz boat, and this quartz boat is placed on the low temperature zone (a port position of CVD furnace) of one end of CVD furnace, as figure 1 shown.

[0043] (4) Put the quartz sheet sputtered with the tungsten layer into the quartz boat, and the quartz boat is pushed into the high temperature zone (...

Embodiment 2

[0050] Example 2: Preparation of double-layer tungsten diselenide

[0051] (1) Cut the quartz plate into a square of 10×10 mm with a silicon knife, ultrasonically clean it in acetone, ethanol, and water for 20 minutes, then clean it with deionized water, and dry it with nitrogen.

[0052] (2) The cleaned quartz sheet is sputtered on the front side by magnetron sputtering, and the electron evaporator (ULVAC, ACS-4000-C4) is used for sputtering the tungsten layer under high vacuum, with a tungsten target with a purity greater than 99.95%. Shooting time is 10 seconds.

[0053] (3) being 99.5% with purity, the selenium powder that quality is 0.05g is put into a new quartz boat, and this quartz boat is placed on the low temperature zone (a port position of CVD furnace) of one end of CVD furnace, as figure 1 shown.

[0054] (4) Put the quartz sheet sputtered with the tungsten layer into the quartz boat, and the quartz boat is pushed into the high temperature zone (the middle part ...

Embodiment 3

[0061] Example 3: Preparation of single-layer molybdenum disulfide single crystal

[0062] (1) Cut the quartz plate into a square of 10×10 mm with a silicon knife, ultrasonically clean it in acetone, ethanol, and water for 20 minutes, then clean it with deionized water, and dry it with nitrogen.

[0063] (2) The cleaned quartz sheet is sputtered on the front side by magnetron sputtering, and the electron evaporator (ULVAC, ACS-4000-C4) is used for molybdenum layer sputtering under high vacuum, and the molybdenum target with a purity greater than 99.95% is used for sputtering. Shooting time is 7 seconds.

[0064] (3) be that 99.5% with purity, the sulfur powder that quality is 0.08g is put into a new quartz boat, and this quartz boat is placed on the low-temperature zone (a port position of CVD furnace) of one end of CVD furnace, as figure 1 shown.

[0065] (4) Put the quartz sheet that has sputtered molybdenum layer into the quartz boat, and the quartz boat is pushed into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com