Method for monitoring cracking reaction of dimethyldichlorosilance hydrolyzates

A technology of dimethyldichlorosilane and cracking reaction, applied in the directions of silicon organic compounds, measuring devices, instruments, etc., can solve the problems of inability to guarantee product quality, high safety risks, etc., so as to reduce the risk of safety accidents and reduce safety risks , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

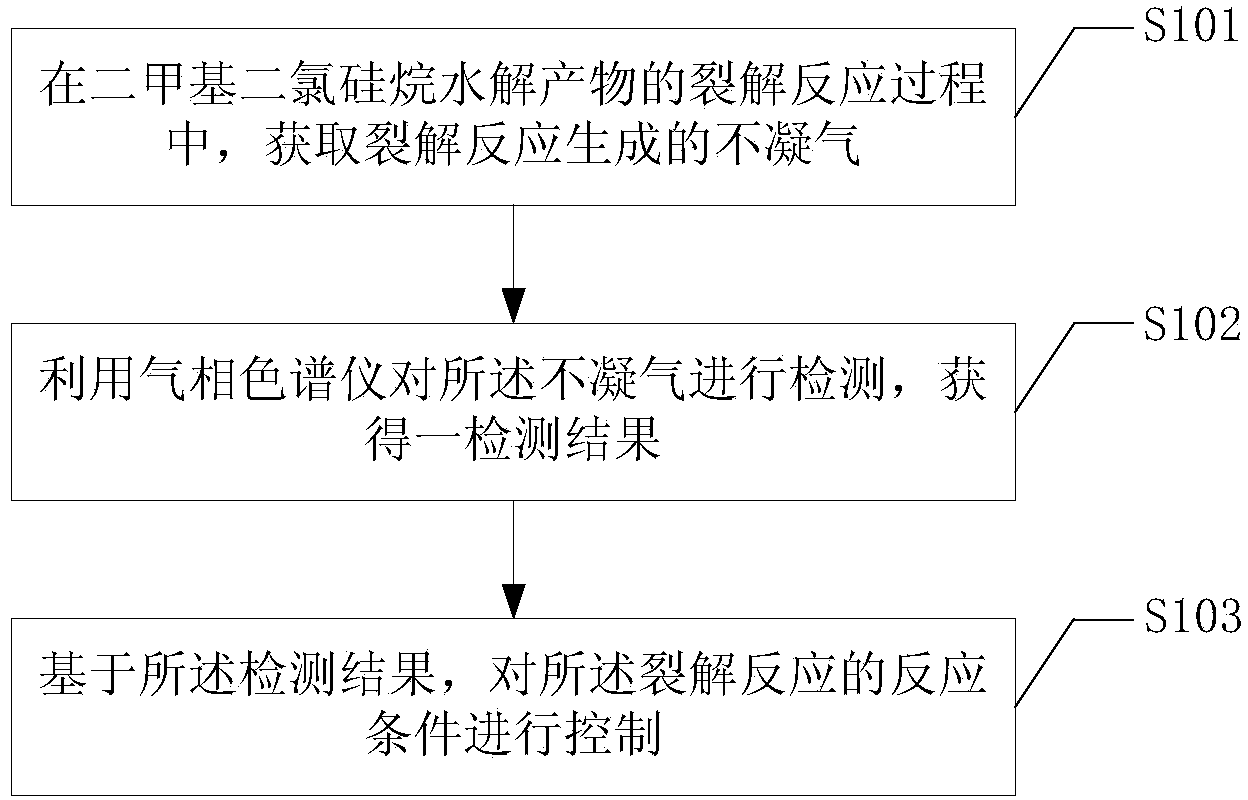

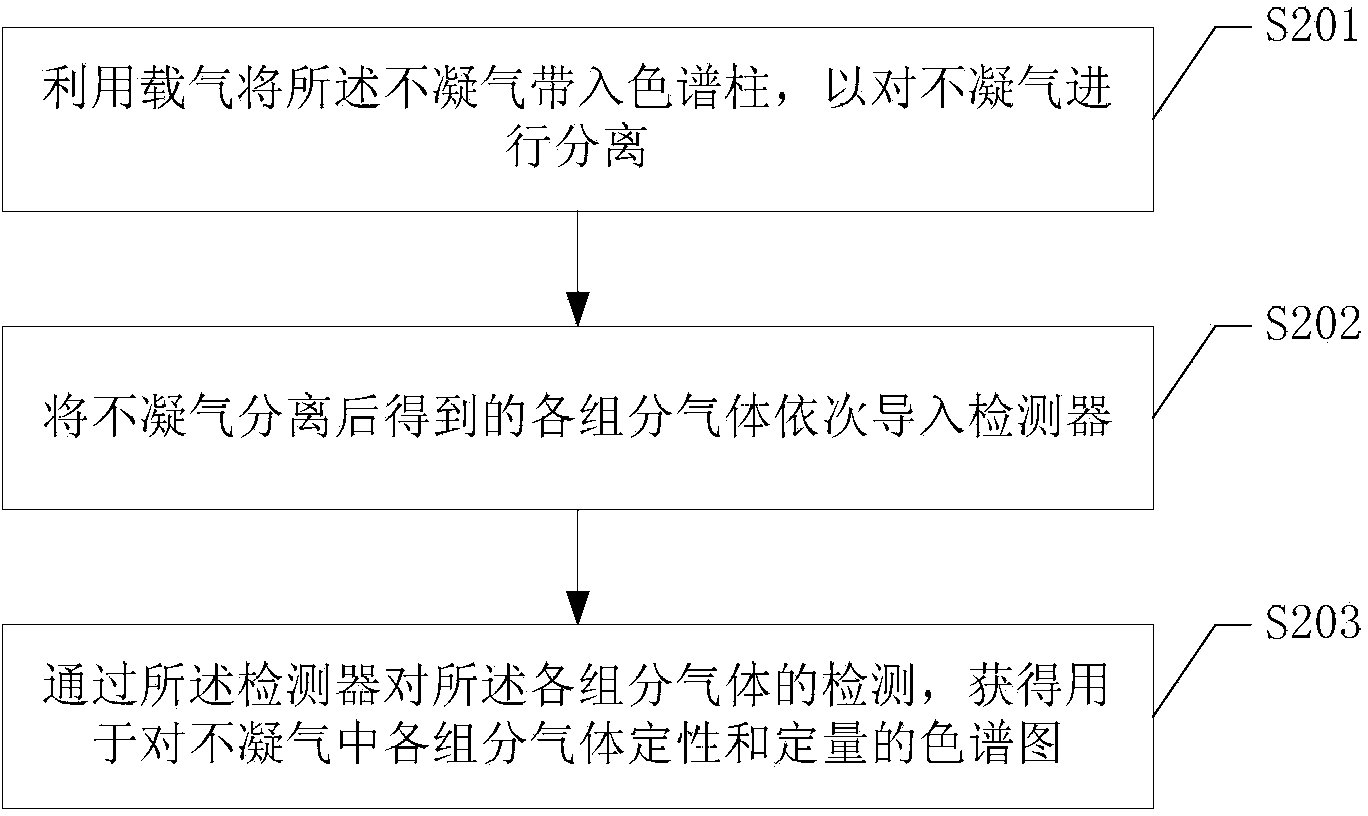

Method used

Image

Examples

Embodiment 1

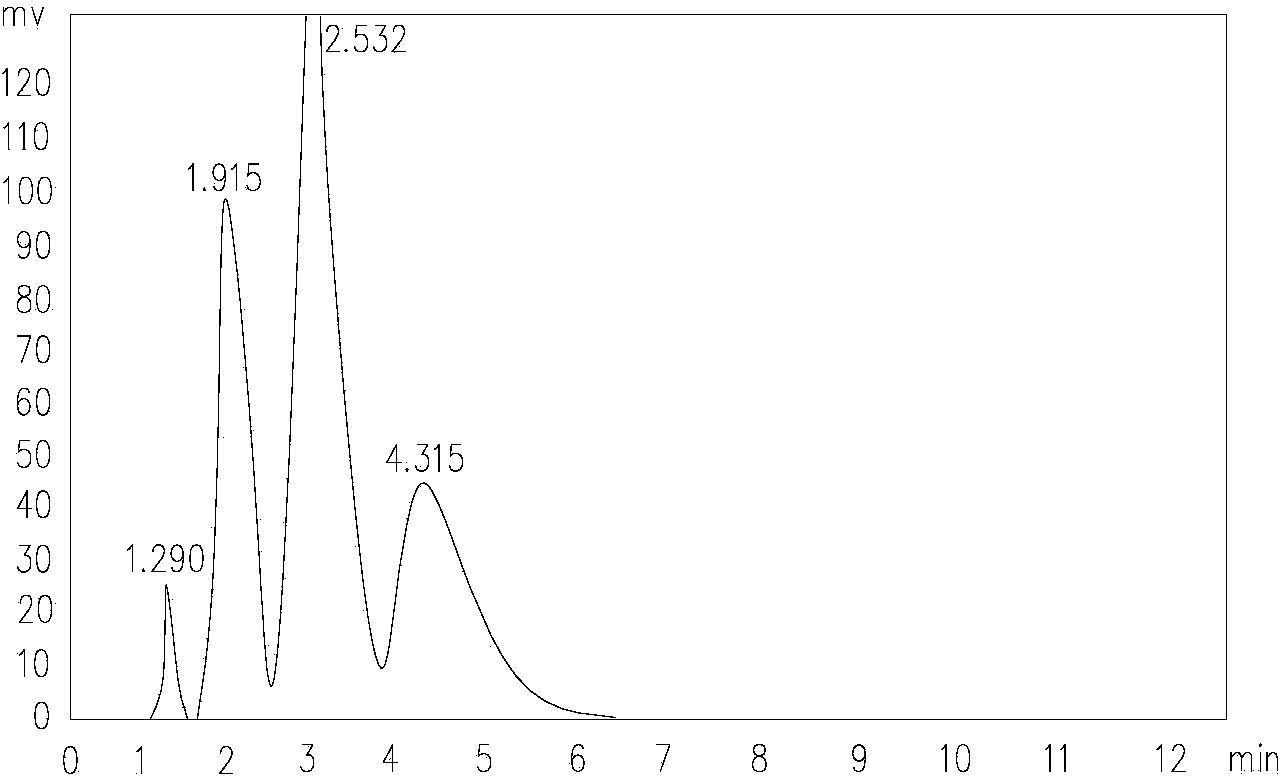

[0053] In practice, the non-condensable gas in the cracking system is monitored regularly or irregularly, and the monitoring targets are selectively on hydrogen, oxygen, nitrogen and methane gas. The SC-3000B gas chromatograph was used to analyze the non-condensable gas. The data integration method was the height external standard method, the detector was FID, the sampler was split flow, and the column temperature was programmed temperature rise, respectively at 128°C, 132°C and At 250°C, the chromatogram of non-condensable gas is obtained as Figures 3a-3c shown. However, depending on the retention time, Figures 3a-3c The components represented by each peak in turn are hydrogen, oxygen, nitrogen and methane.

[0054] Specifically, when the content of hydrogen and methane in the noncondensable gas of the cracking system is above the threshold value and below the upper limit value, the content of hydrogen and methane is reduced by adjusting the reaction temperature, catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com