Rose essence oil-modified starch compounded composite rice flour and a preparing method thereof

A technology for rose essential oil and starch, applied in the field of food processing, can solve the problems of long rehydration time, poor rehydration taste, single variety and the like of dry rice flour, achieve good water and oil absorption capacity, good reconstitution and taste, improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

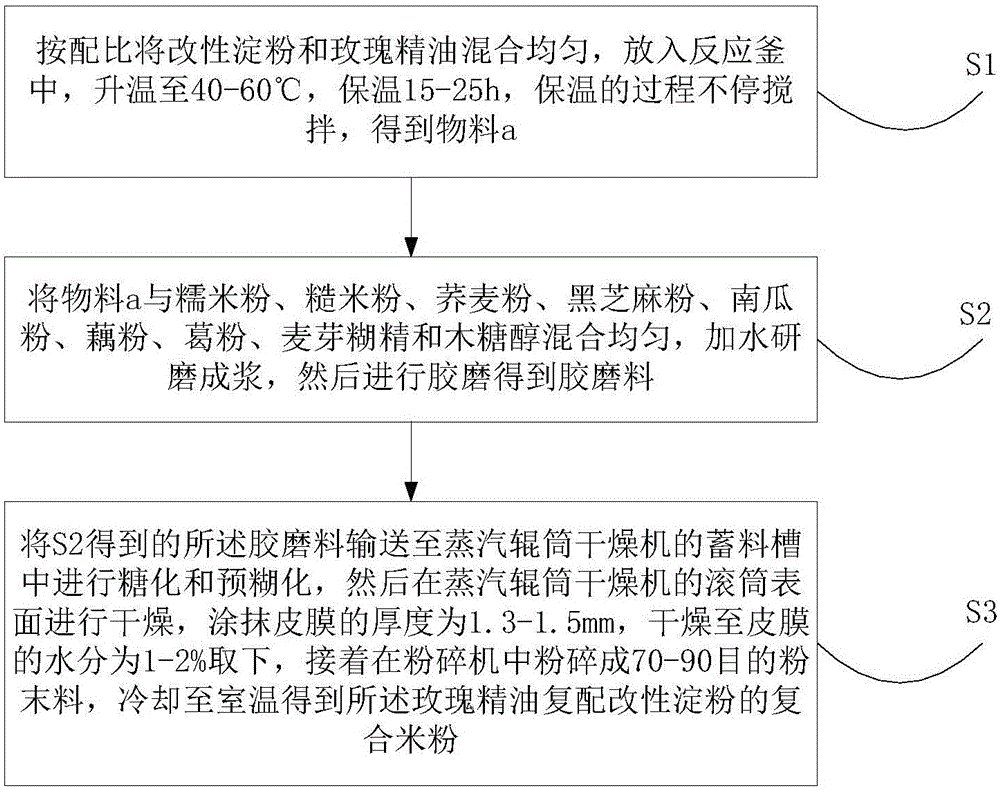

[0022] refer to figure 1 , the preparation method of the compound rice flour of a kind of rose essential oil compound modified starch that the present invention proposes, comprises the steps:

[0023] S1. Mix the modified starch and rose essential oil evenly according to the proportion, put it into the reaction kettle, heat up to 40-60°C, keep it warm for 15-25h, and keep stirring during the heat preservation process to obtain material a;

[0024] S2. Mix material a evenly with glutinous rice flour, brown rice flour, buckwheat flour, black sesame powder, pumpkin powder, lotus root starch, arrowroot starch, maltodextrin and xylitol, add water and grind it into a slurry, and then carry out rubber grinding to obtain rubber abrasive;

[0025] S3. The rubber abrasive obtained in S2 is transported to the storage tank of the steam roller dryer for saccharification and pregelatinization, and then dried on the surface of the roller of the steam roller dryer. The thickness of the coatin...

Embodiment 1

[0027] The compound rice flour of a kind of rose essential oil compound modified starch that the present invention proposes, its raw material comprises by weight: 100 parts of modified starch, 5 parts of rose essential oil, 10 parts of glutinous rice flour, 6 parts of brown rice flour, 6 parts of buckwheat flour, 6 parts of black sesame powder, 9 parts of pumpkin powder, 3.5 parts of lotus root starch, 5 parts of arrowroot powder, 4 parts of maltodextrin, and 3 parts of xylitol.

[0028] The modified starch is prepared according to the following process: put 10 parts of rice in a pulverizer by weight and grind it into a 120-mesh powder, then put the powder into a sodium acetate buffer solution, adjust the pH to 5, and preheat at 35°C for 10 minutes , then add 3.5 parts of compound enzyme and stir evenly, incubate at 35.5°C for 16h, then add a sodium hydroxide solution with a mass fraction of 4%, centrifuge, remove the supernatant, take the precipitate, remove the upper residue ...

Embodiment 2

[0035] The compound rice flour of a kind of rose essential oil compound modified starch that the present invention proposes, its raw material comprises by weight: 80 parts of modified starches, 8 parts of rose essential oils, 5 parts of glutinous rice flours, 9 parts of brown rice flours, 4 parts of buckwheat flours, 9 parts of black sesame powder, 4 parts of pumpkin powder, 5 parts of lotus root starch, 3 parts of arrowroot powder, 6 parts of maltodextrin, and 1 part of xylitol.

[0036] The modified starch is prepared according to the following process: Put 5 parts of rice into a pulverizer by weight and grind it into a 200-mesh powder, then put the powder into a sodium acetate buffer solution, adjust the pH to 4, and preheat at 40°C for 8 minutes , then add 5 parts of compound enzyme and stir evenly, keep warm at 33°C for 18h, then add a sodium hydroxide solution with a mass fraction of 2%, centrifuge, remove the supernatant, take the precipitate, remove the upper residue of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com