Active coke preparation method and preparation device

A technology for preparing device and active coke, applied in the field of active coke, can solve the problems of low activity of active coke, limited application of active coke, small specific pore volume and specific surface area of active coke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

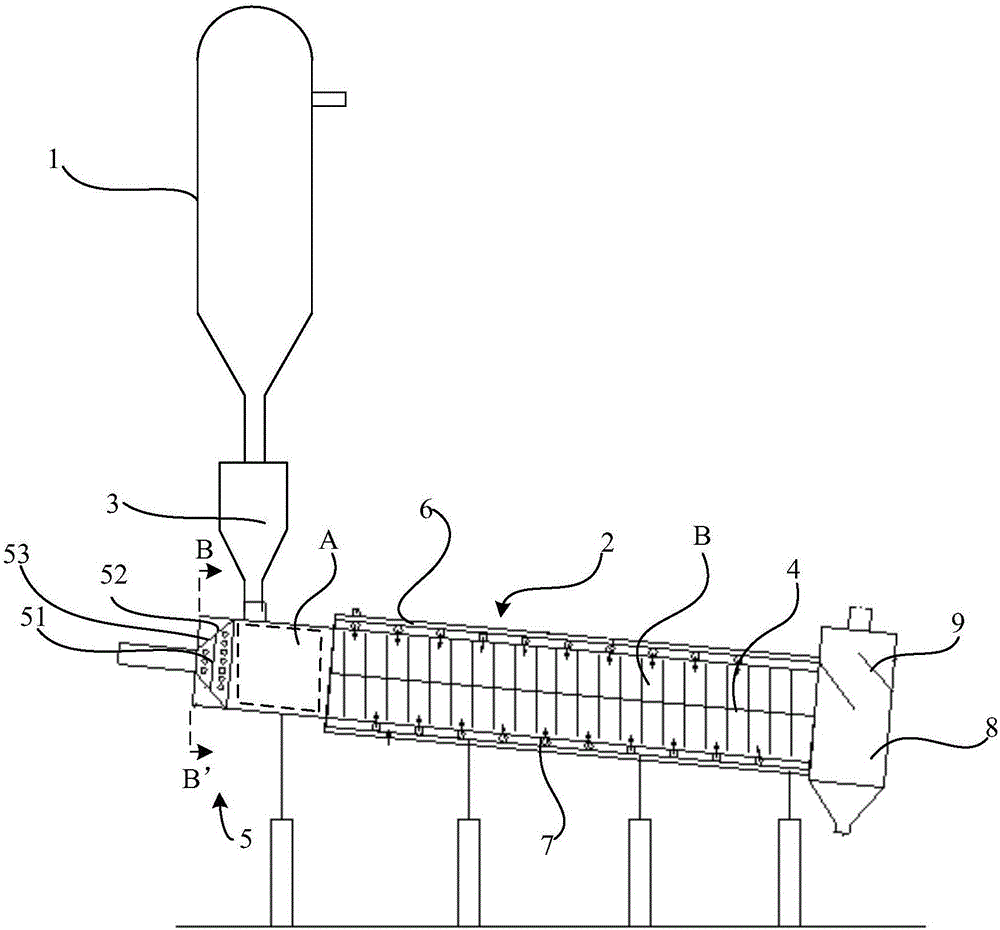

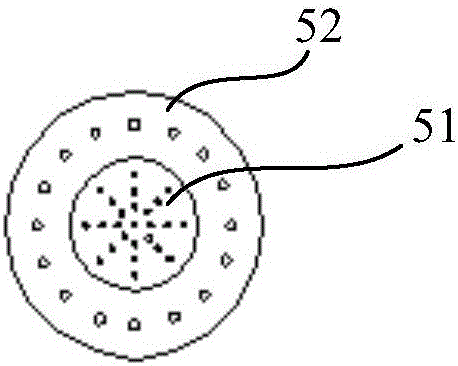

[0035] A method and device for preparing active coke provided in the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

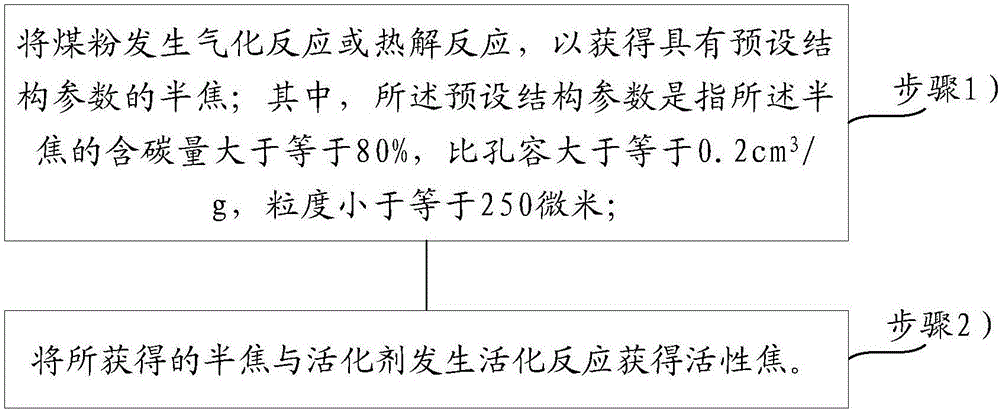

[0036] On the one hand, the embodiment of the present invention provides a method for preparing active coke, see figure 1 ,include:

[0037] Step 1) Gasify or pyrolyze the pulverized coal to obtain semi-coke with preset structural parameters; wherein, the preset structural parameter means that the carbon content of the semi-coke is greater than or equal to 80%, which is higher than The pore volume is greater than or equal to 0.2cm3 / g, and the particle size is less than or equal to 250 microns;

[0038] Step 2) Activating the obtained semi-coke with an activator to obtain active coke.

[0039] Among them, the gasification reaction refers to the process in which pulverized coal reacts with a gasification agent to generate methane, tar and semi-coke under the conditions of medium temperature (8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com