A honeycomb tio with microporous starch as template 2 Porous microsphere and its preparation method

A technology of microporous starch and porous microspheres, which is applied in the direction of microsphere preparation, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of high cost and unfriendly environment, achieve convenient recycling, reduce agglomeration, and produce short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

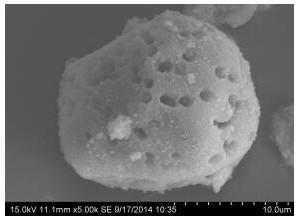

[0068] Example 1 A honeycomb TiO with microporous starch as template 2 porous microsphere

[0069] 1. Preparation method

[0070] (1) Weigh 75 g of cornstarch, add citric acid-sodium citrate buffer solution with a pH of 4.5, stir continuously with a magnetic stirrer, and prepare a cornstarch suspension with a concentration of 150 g / L;

[0071] (2) Add 4 g / L α-amylase and glucoamylase (α-amylase: glucoamylase = 3.2:1) to the cornstarch suspension in step (1), and place in a water bath at 55°C Stir and react in a pot for 9 h, filter the reaction solution and wash with distilled water for 3 times, dry the precipitate in an oven at 50°C, crush it and pass it through a 80-mesh sieve to obtain microporous starch;

[0072] (3) Weigh 1.5 g of P25 powder (commercial nano-TiO 2 ) into 500 mL of distilled water, adding 0.75% polyvinylpyrrolidone (based on P25 mass percent) as a dispersant, magnetic stirring for 30 min, and ultrasonic dispersion for 30 min to obtain nano-TiO 2 dispers...

Embodiment 2

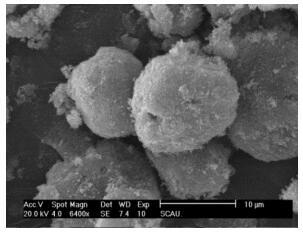

[0077] Example 2 A honeycomb TiO with microporous starch as template 2 porous microsphere

[0078] 1. Preparation method

[0079] (1) Weigh 50 g of cornstarch, add citric acid-sodium citrate buffer solution with a pH of 4.5, stir continuously with a magnetic stirrer, and prepare a cornstarch suspension with a concentration of 100 g / L;

[0080](2) Add 3 g / L α-amylase and glucoamylase (α-amylase: glucoamylase = 2:1) to the cornstarch suspension in step (1), and place in a water bath at 50°C Stir and react in a pot for 9 h, filter the reaction solution and wash with distilled water for 3 times, dry the precipitate in an oven at 50°C, crush it and pass it through a 80-mesh sieve to obtain microporous starch;

[0081] (3) Weigh 1.5 g of P25 powder and dissolve it into 500 mL of distilled water, add 0.5% polyvinylpyrrolidone (based on the mass percentage of P25) as a dispersant, stir magnetically for 30 min, and disperse ultrasonically for 30 min to obtain nano-TiO 2 dispersion e...

Embodiment 3

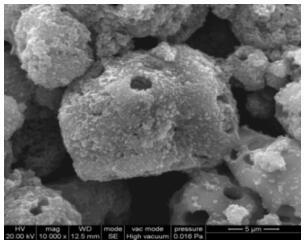

[0086] Example 3 A honeycomb TiO with microporous starch as template 2 porous microsphere

[0087] 1. Preparation method

[0088] (1) Weigh 25 g of cornstarch, add citric acid-sodium citrate buffer solution with a pH of 4, stir continuously with a magnetic stirrer, and prepare a cornstarch suspension with a concentration of 100 g / L;

[0089] (2) Add 1 g / L α-amylase and glucoamylase (α-amylase: glucoamylase = 1:1) to the cornstarch suspension in step (1), and place in a water bath at 50°C Stir and react in a pot for 6 hours, filter the reaction solution and wash with distilled water for 3 times, dry the precipitate in an oven at 50°C, crush it and pass it through a 80-mesh sieve to obtain microporous starch;

[0090] (3) Weigh 1 g of P25 powder and dissolve it into 500 mL of distilled water, add 0.5% polyvinylpyrrolidone (based on the mass percentage of P25) as a dispersant, stir magnetically for 30 min, and disperse ultrasonically for 30 min to obtain nano-TiO 2 dispersion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com