Patents

Literature

69results about How to "Easy to ream" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength hot-rolled complex phase steel plate and steel strip with good bending and broaching performance and manufacturing method thereof

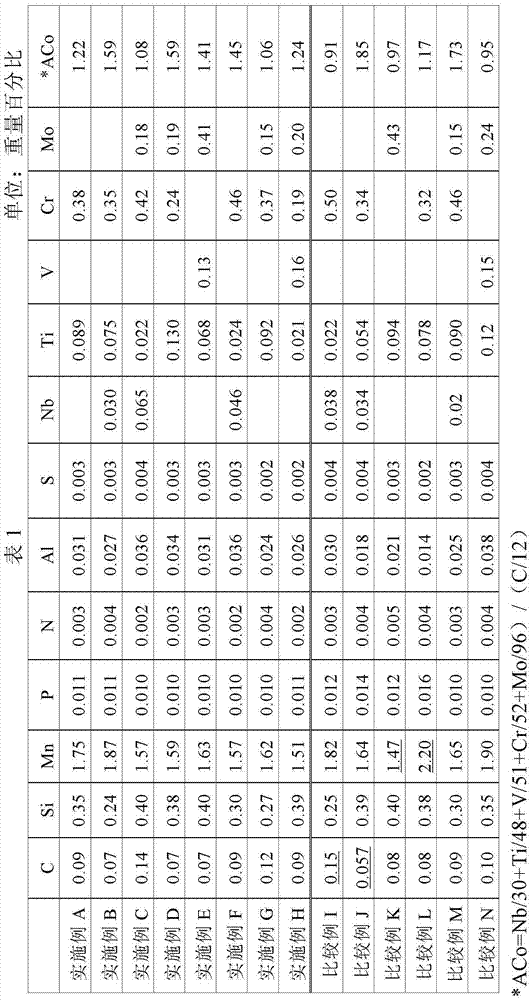

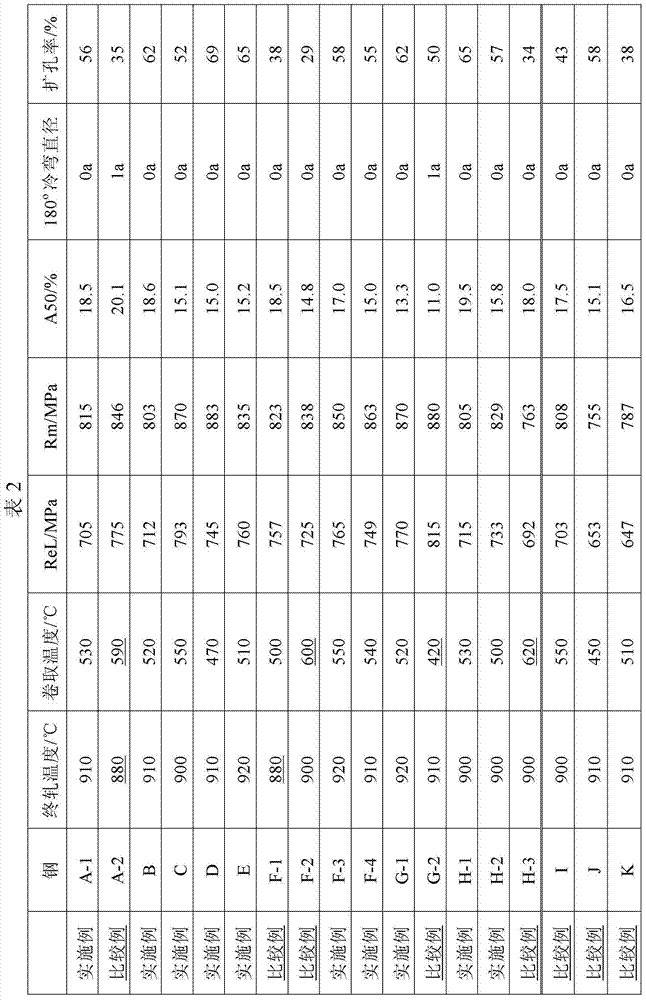

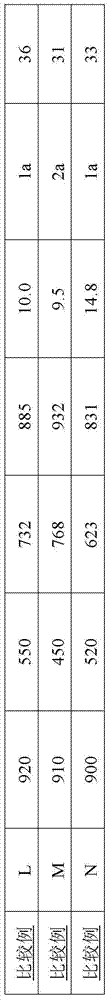

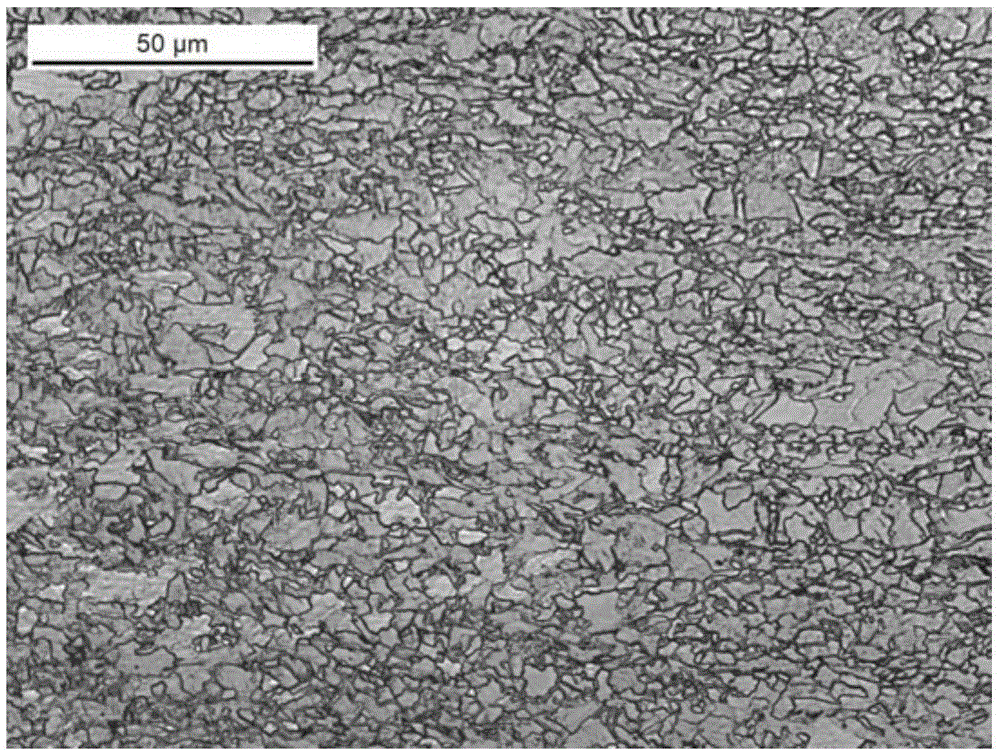

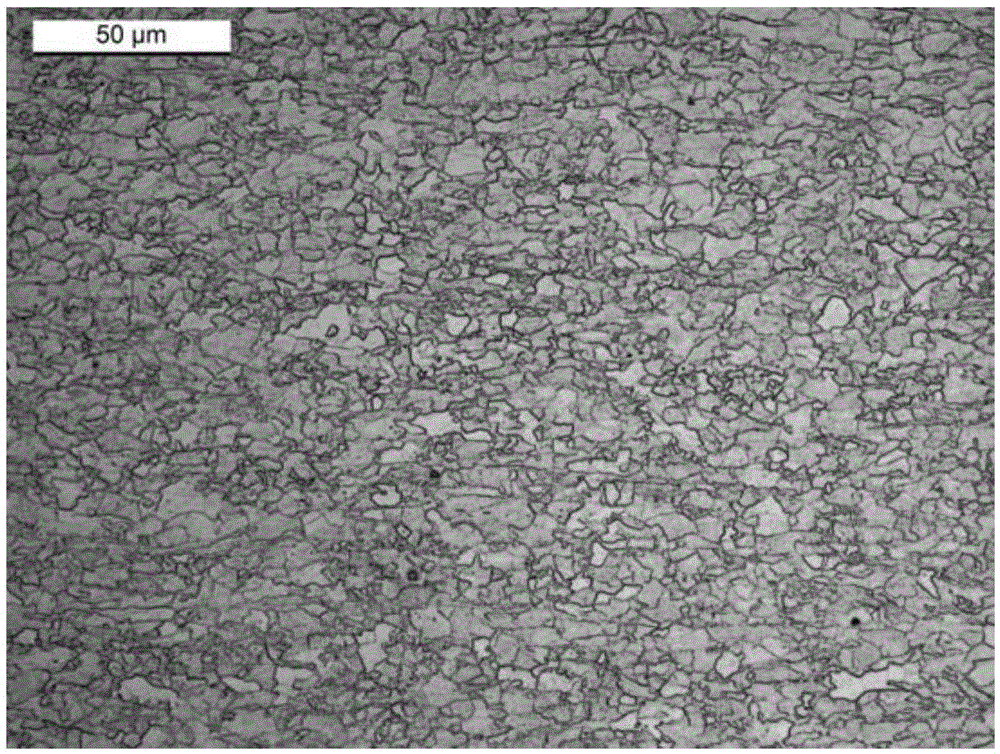

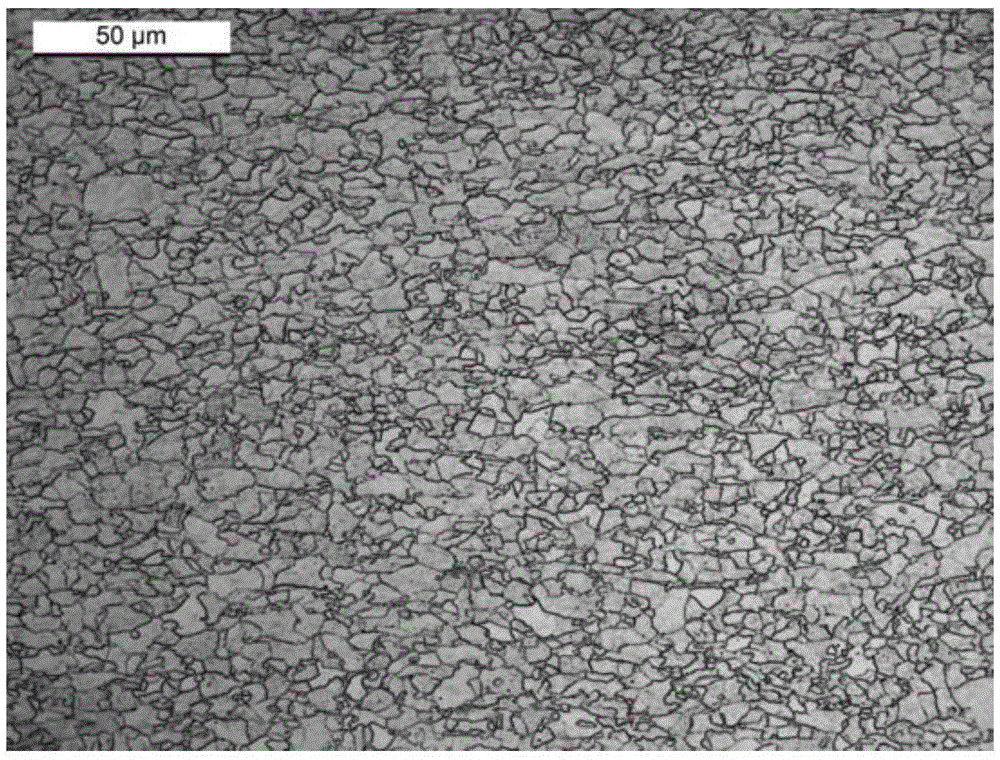

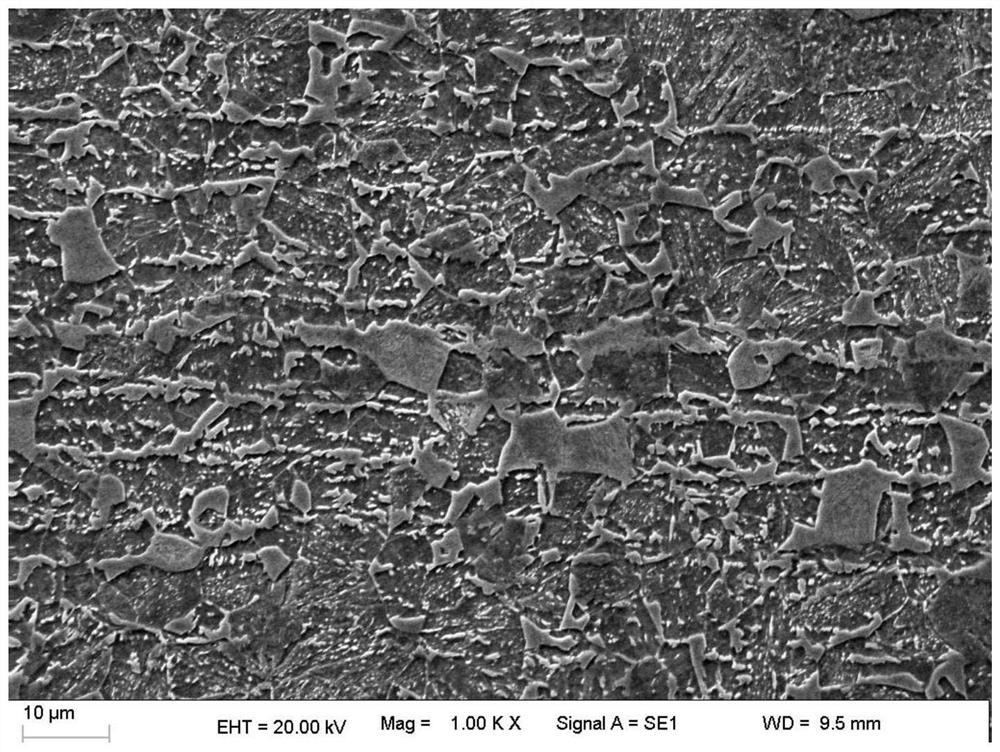

The invention discloses an ultrahigh-strength hot-rolled complex phase steel plate and steel strip with good bending and broaching performance and a manufacturing method thereof. The ultrahigh-strength hot-rolled complex phase steel plate and steel strip comprise the following components in percentage by weight: 0.07-0.14% of C, 0.1-0.4% of Si, 1.55-2.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.004% of S, 0.01-0.05% of Al and less than or equal to 0.005% of N, and further comprises at least one of alloy elements of less than or equal to 0.07% of Nb, 0.02-0.15% of Ti and 0.10-0.20% of V, at least one of alloy elements of 0.15-0.50% of Cr and 0.15-0.50% of Mo, and the balance of Fe and inevitable impurities. The ultrahigh-strength hot-rolled complex phase steel has the tensile strength of above 800 MPa, the yield strength of above 700 MPa, the cold bending performance of 0a at 180 DEG C, the broaching rate of above 50%, and the microstructure of bainite (at least 80%) and a small amount of ferrite, martensite and retained austenite, wherein the bainite is mainly lower bainite. The ultrahigh-strength hot-rolled complex phase steel can be applied to manufacture of an automobile chassis, a hanging component, a bumper and other products.

Owner:BAOSHAN IRON & STEEL CO LTD

780 MPa hot-rolled high-strength steel with high hole expansion ratio and manufacturing method thereof

The invention provides a 780 MPa hot-rolled high-strength steel with high hole expansion ratio and a manufacturing method thereof. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio comprises the following chemical components in percentage by mass: more than or equal to 0.03 percent and less than or equal to 0.07 percent of C, less than or equal to 0.2 percent of Si, more than or equal to 1.0 percent and less than or equal to 2.0 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, more than or equal to 0.02 percent and less than or equal to 0.05 percent of Al, less than or equal to 0.005 percent of N, more than or equal to 0.08 percent and less than or equal to 0.20 percent of Ti, more than or equal to 0.15 percent and less than or equal to 0.25 percent of Mo, less than or equal to 0.003 percent of O and the balance of Fe and inevitable impurity elements, wherein Ti / Mo is more than or equal to 0.25 and less than or equal to 1.5, and (Ti-3.42N) / 4+Mo / 8 is more than or equal to 0.03 percent and less than or equal to 0.07 percent. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio is obtained through smelting, casting, high-temperature heating, hot rolling and reeling processes, and is more than or equal to 750 MPa in yield strength, more than or equal to 780 MPa in tensile strength, more than or equal to 20 percent in extensibility, more than or equal to 70 percent in hole expansion ratio when the thickness is 3-6 mm.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

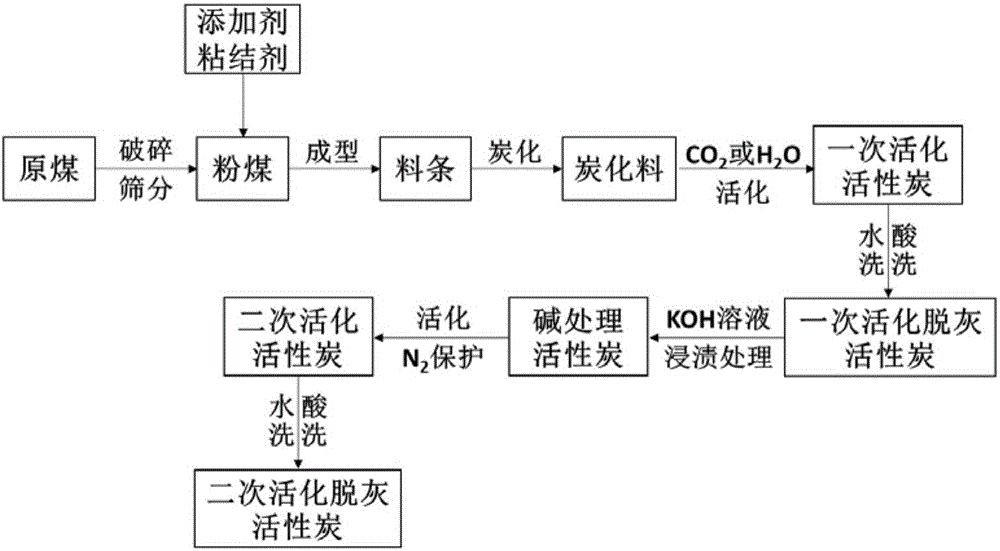

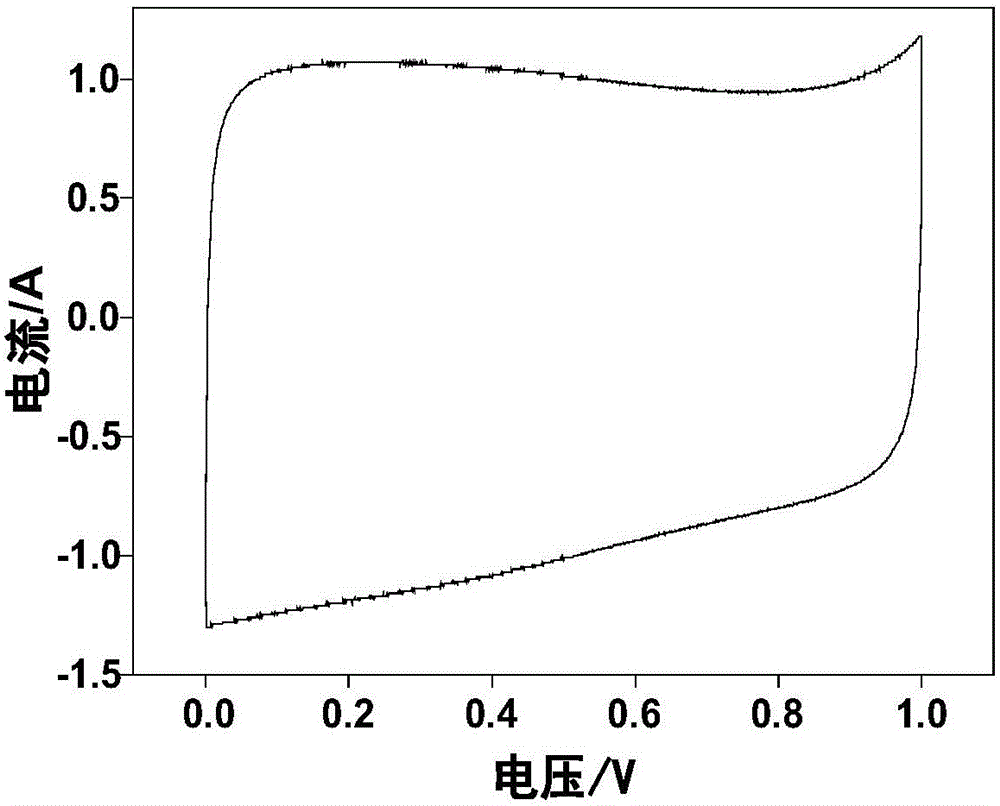

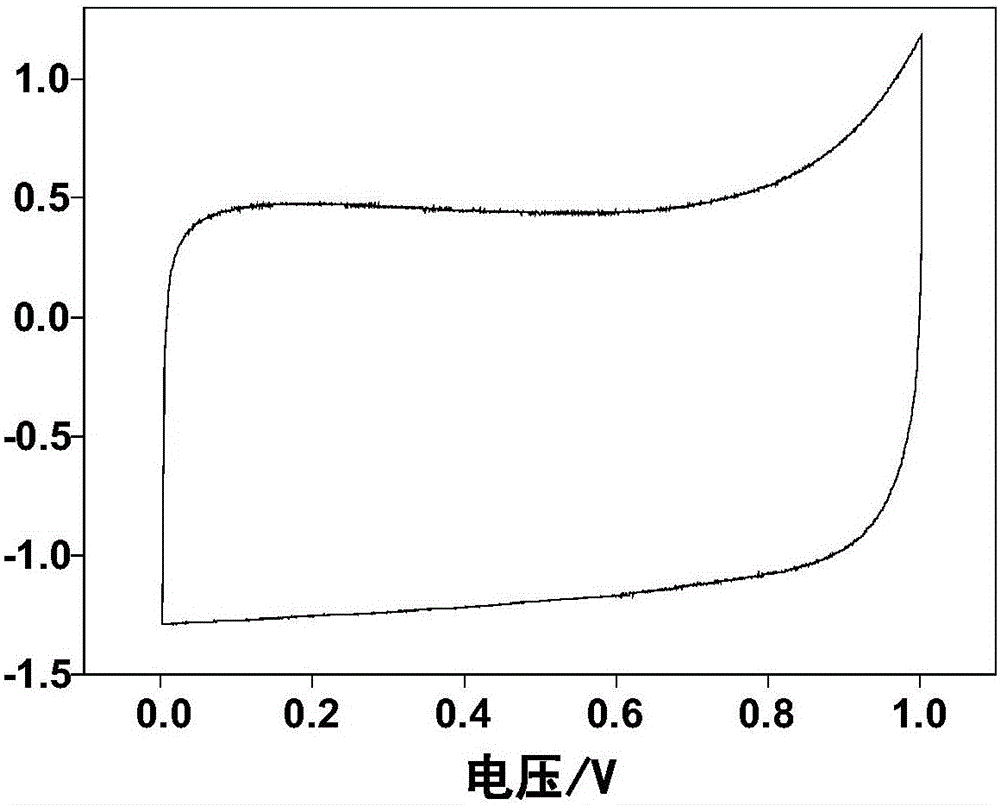

Two-step activation preparation method of activated carbon and application thereof in supercapacitor

The invention discloses a two-step activation preparation method of activated carbon and application thereof in a supercapacitor. The method comprises the following steps that blind coal is smashed and sieved, and an additive and a binder are added to be stirred; the mixture is added into a muffle furnace to be carbonized and then, shifted into a tubular activating oven, activated gas is introduced to be activated; diluted hydrochloric acid is used for acid pickling, filtering is performed, then, distilled water is used for washing, and a KOH solution is used for dipping; one-time activated carbon is placed into the activating oven, and protective gas is introduced to be activated; diluted hydrochloric acid is used for acid pickling, filtering is performed, then, distilled water is used for washing till pH is 7, and then drying is performed; reactivated de-ashing activated carbon is uniformly mixed with ethylene and polytetrafluoroethylene after being ground, the mixture coats foamed nickel, and after drying is performed, tabletting is performed to prepare the supercapacitor. Blind coal is adopted as a raw material, reaction conditions are mild, on the basis of the conventional activated carbon production technology, reactivation and de-ashing are performed, the synthesis cost is greatly lowered, and the huge application and popularization potential is achieved in the field of activated carbon for the high-performance supercapacitor.

Owner:CHINA UNIV OF MINING & TECH

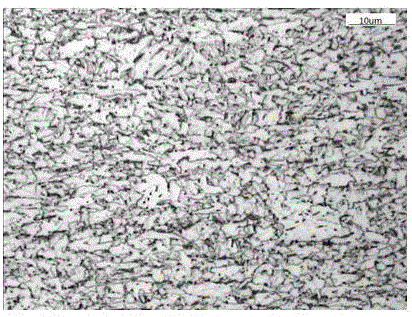

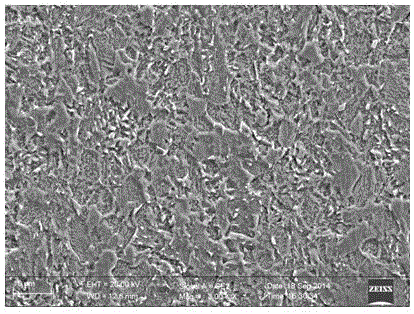

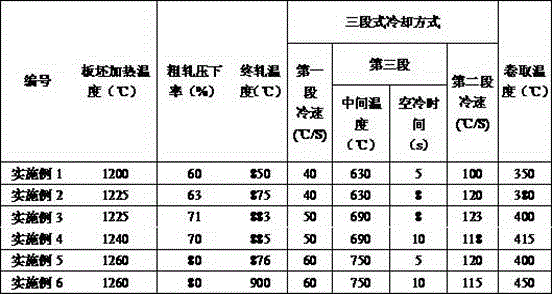

800MPa-level hot-rolled high strength chambering steel and production method thereof

The invention discloses 800MPa-level hot-rolled high strength bainite chambering steel and a production method thereof. The 800MPa-level hot-rolled high strength bainite chambering steel consists of the following chemical components in percentage by mass: greater than or equal to 4 percent and less than or equal to 0.08 percent of C, greater than or equal to 0.5 percent and less than or equal to 0.8 percent of Si, greater than or equal to 0.5 percent and less than or equal to 1.6 percent of Mn, less than or equal to 0.005 percent of P, less than or equal to 0.004 percent of S, less than or equal to 0.004 percent of N, greater than or equal to 0.15 percent and less than or equal to 0.18 percent of Ti, greater than or equal to 0.15 percent and less than or equal to 0.25 percent of Cr, greater than or equal to 0.03 percent and less than or equal to 0.05 percent of Nb, and the balance of Fe and inevitable impurity elements. The high strength bainite chambering steel with yield strength greater than or equal to 680 MPa, tensile strength greater than or equal to 800 MPa and ductility greater than or equal to 17 percent is obtained by processes of smelting, refining, slab continuous casting, slab heating, hot rolling, three-section type laminar cooling and rolling; a steel plate with the thickness of 2.8 to 6 mm has the chambering rate over 85 percent.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

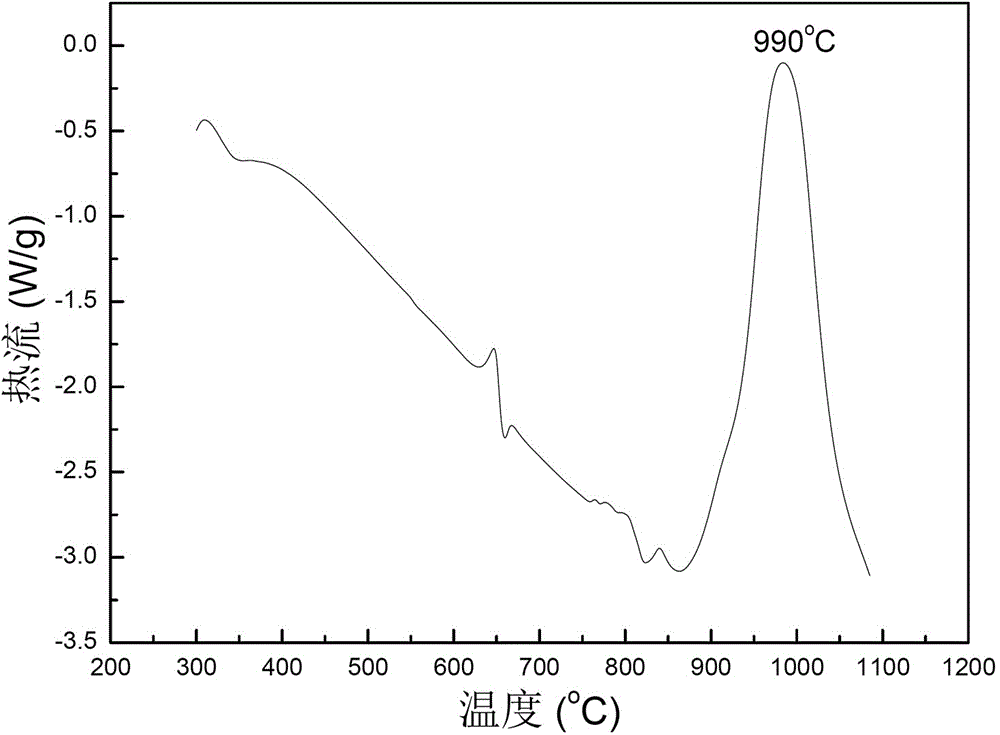

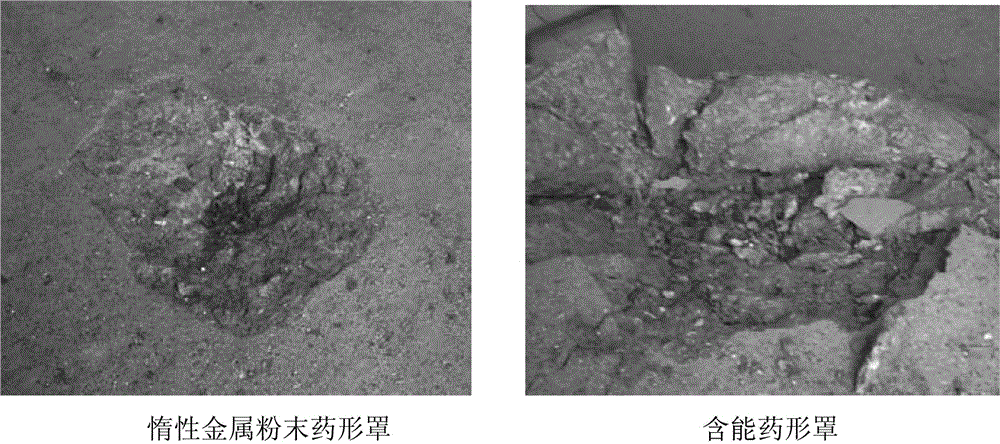

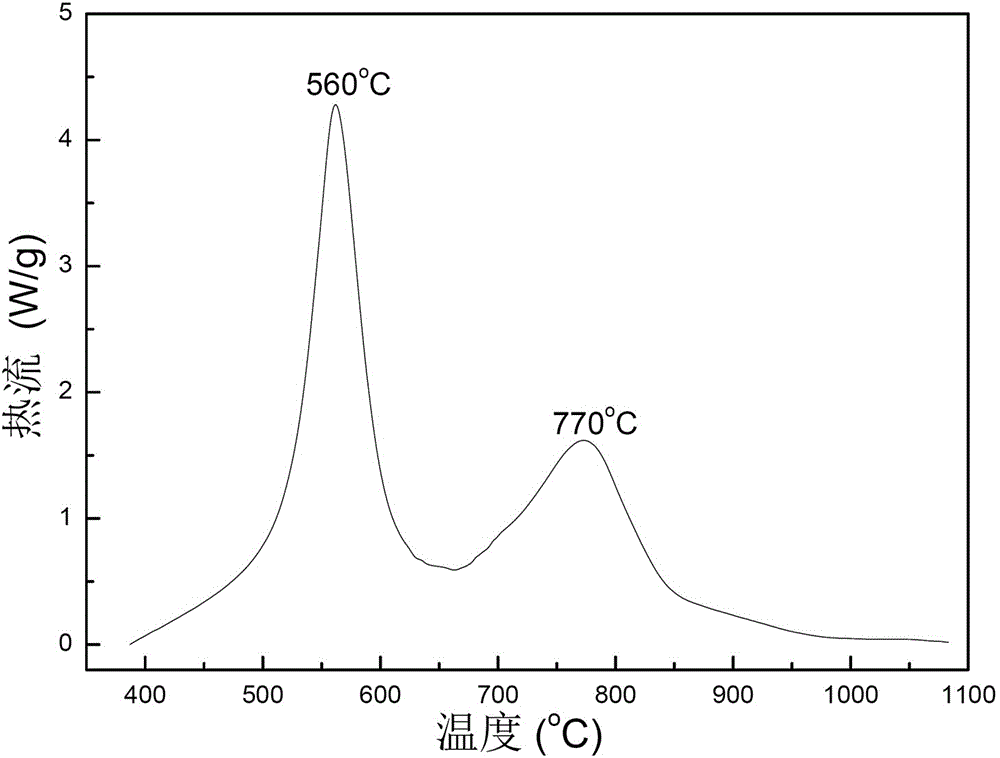

Energy-contained shaped charge cover with micro-nano thermite as material

InactiveCN105642880AIncrease energy densityEasy to masterExplosive chargesTransportation and packagingMicro nanoChemical reaction

The invention relates to an energy-contained shaped charge cover with micro-nano thermite as a material. The shaped charge cover is formed by mixing and pressing raw materials including, by mass percent, 15% to 35% of aluminum powder, 55% to 80% of metallic oxides, 1% to 5% of dicyclopentadienyl iron and 1% to 8% of a binding agent; the binding agent is a fluororubber and polystyrene compound system; and the energy-contained shaped charge cover is high in energy density and high in safety performance, and a reaction cannot be carried out immediately during explosive driving; however, in the penetration process, a strong chemical reaction can start, and extremely-high heat can be sent out, so that a high-temperature incandescence reaction product is generated. The energy-contained shaped charge cover can be combined with a conventional shaped charge cover in a matched manner for use, the effects of properly expanding the diameter of a shooting hole and successively setting on a fire can be achieved, and the damage or killing effect can be enhanced.

Owner:ZHONGBEI UNIV

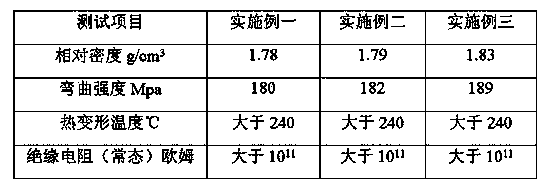

Injection moulded phenolic moulding plastic for communtator

The invention discloses an injection moulded phenolic moulding plastic for a commentator. The injection moulded phenolic moulding plastic comprises the following components in parts by weight: 15-24 parts of phenolic resin, 3-8 parts of a curing agent, 1-3 parts of a curing accelerator, 25-33 parts of reinforced fibers, 0.5-2 parts of a releasing agent, 10-45 parts of inorganic filler and 1-5 parts of a flexibilizer. The phenolic moulding plastic can be used for an injection moulding machine, so that the moulding efficiency is greatly improved. The mould is not sticky, the bending strength of the moulded product reaches up to over 180Mpa, the thermal deformation temperature is greater than 240 DEG C, and the insulation resistance is greater than 1011 ohms.

Owner:广西信和新合成材料有限公司

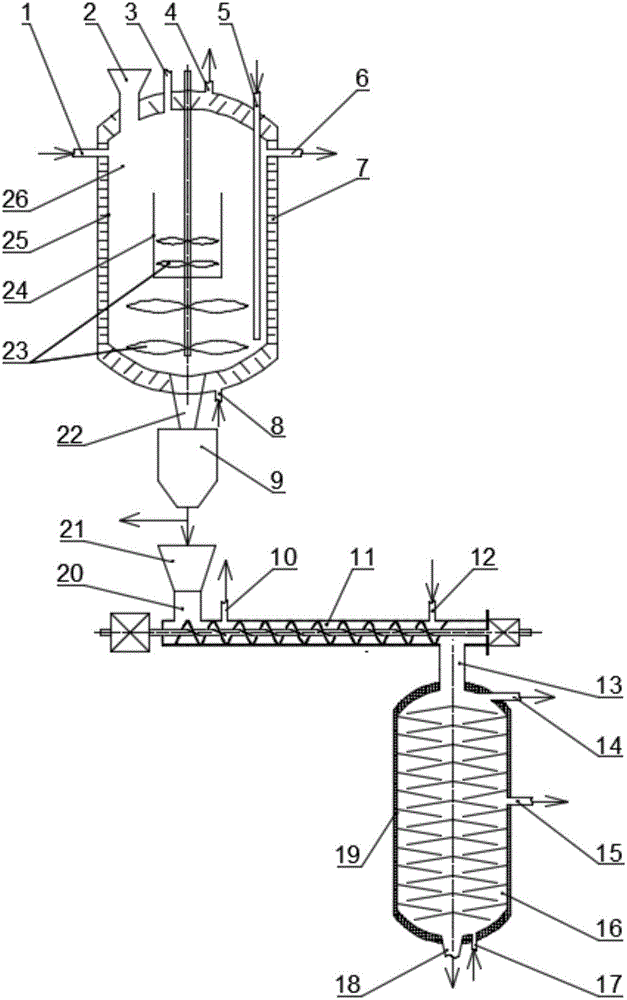

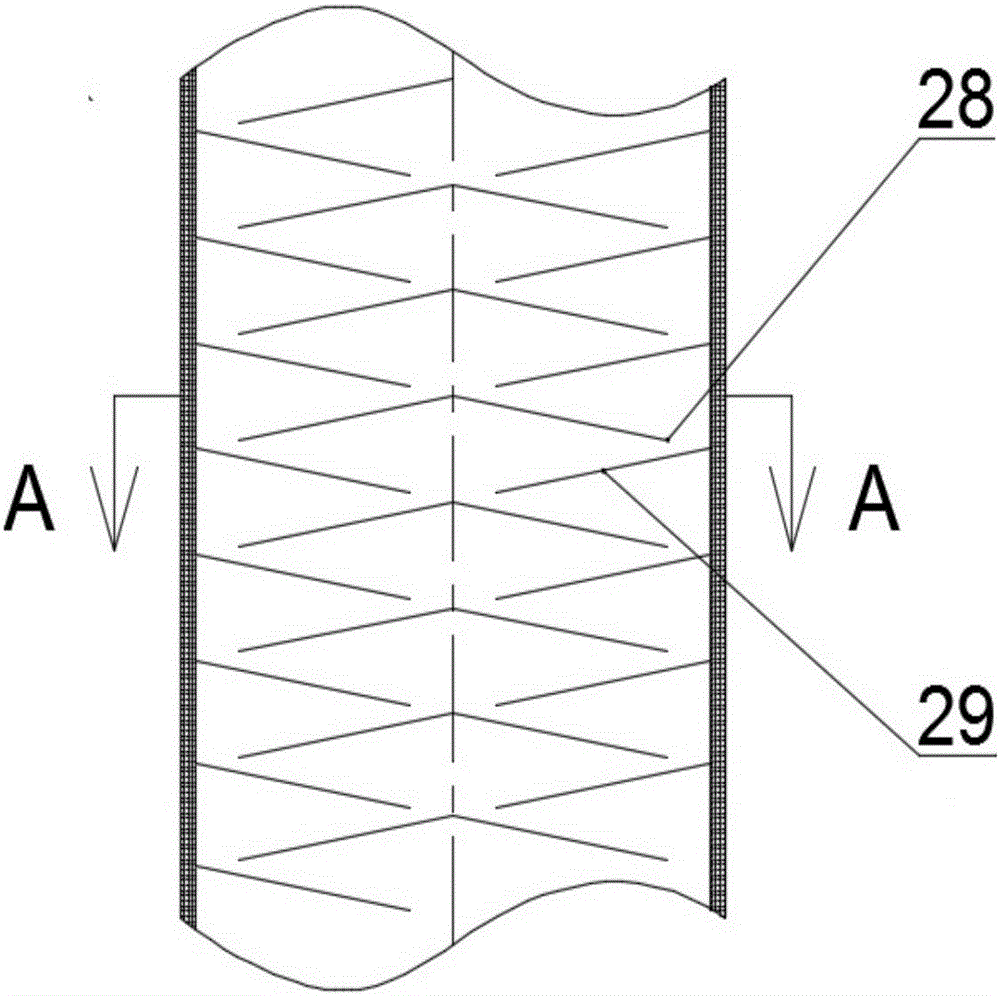

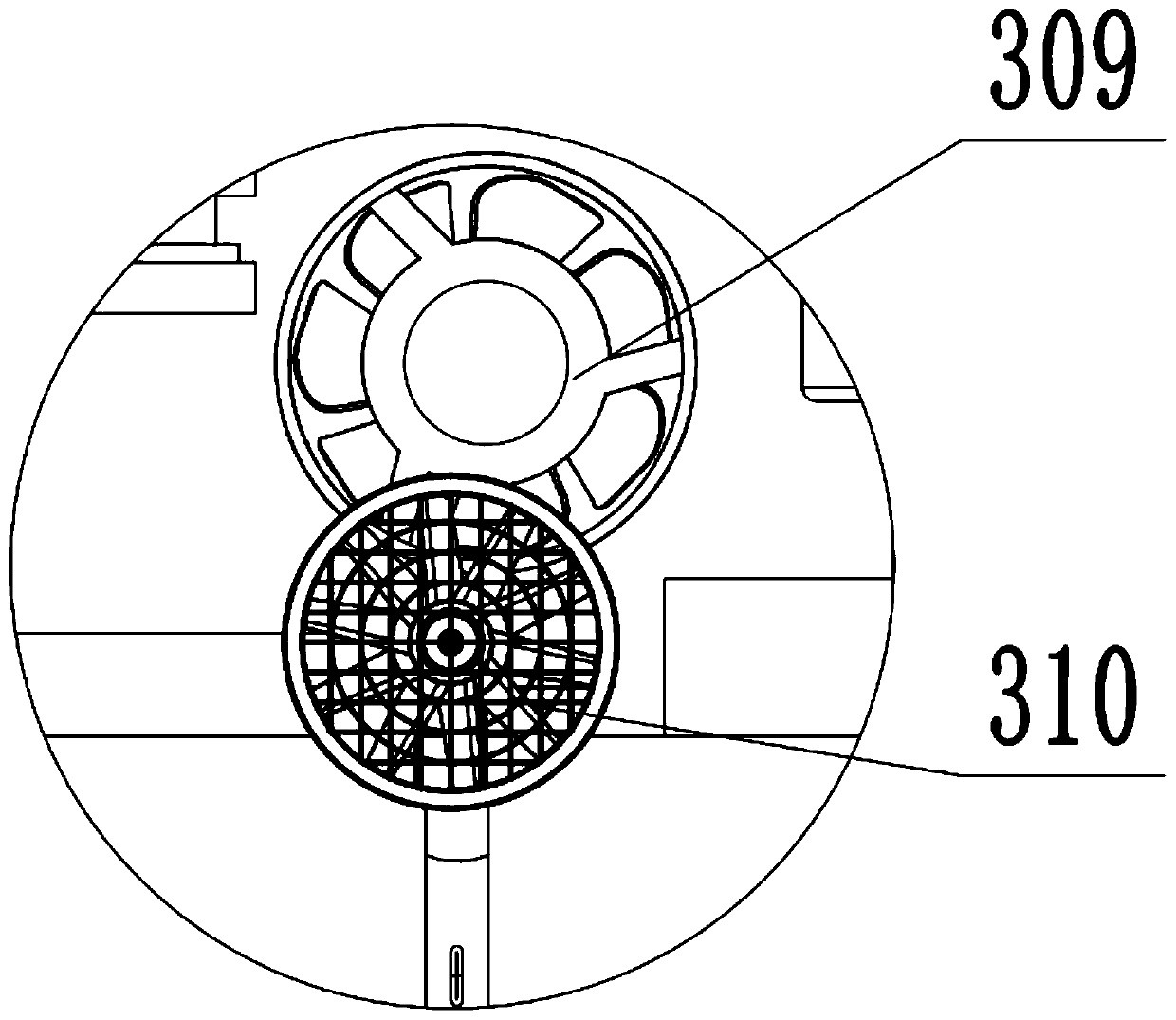

Two-stage biomass hydrothermal catalytic activation reaction device

InactiveCN106824001AEfficient catalytic decompositionEasy to openCarbon compoundsLiquid hydrocarbon mixture productionLiquid productBiological activation

The invention discloses a two-stage biomass hydrothermal catalytic activation reaction device and belongs to the field of a biomass hydrothermal technology. The device comprises a biomass high-pressure reaction kettle reactor and a vertical type activation furnace reactor which are communicated with each other through a packing auger drying bed; the biomass high-pressure reaction kettle reactor comprises a hydrothermal reaction cylinder, an additive loading tank and a biomass feeding pipe; under the condition of a carbon dioxide aqueous solution, the additive reacts with hydrogen ions in the aqueous solution to generate metal cations, so that biomass thermal decomposition is catalyzed to generate a high-quality liquid product; the biomass high-pressure reaction kettle reactor is also used for performing initial activation on hydrothermal coke; the vertical type activation furnace reactor comprises an activation reaction cylinder, a high-temperature activation gas nozzle, a round drainage plate and a ring-shaped drainage plate, and is used for preparing super activated carbon from the hydrothermal coke. The device is clever in design, can prepare supercapacitor electrode carbon and high-quality liquid products simultaneously by utilizing two-stage biomass hydrothermal catalytic activation reaction, and is high in energy utilization rate and high in production efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

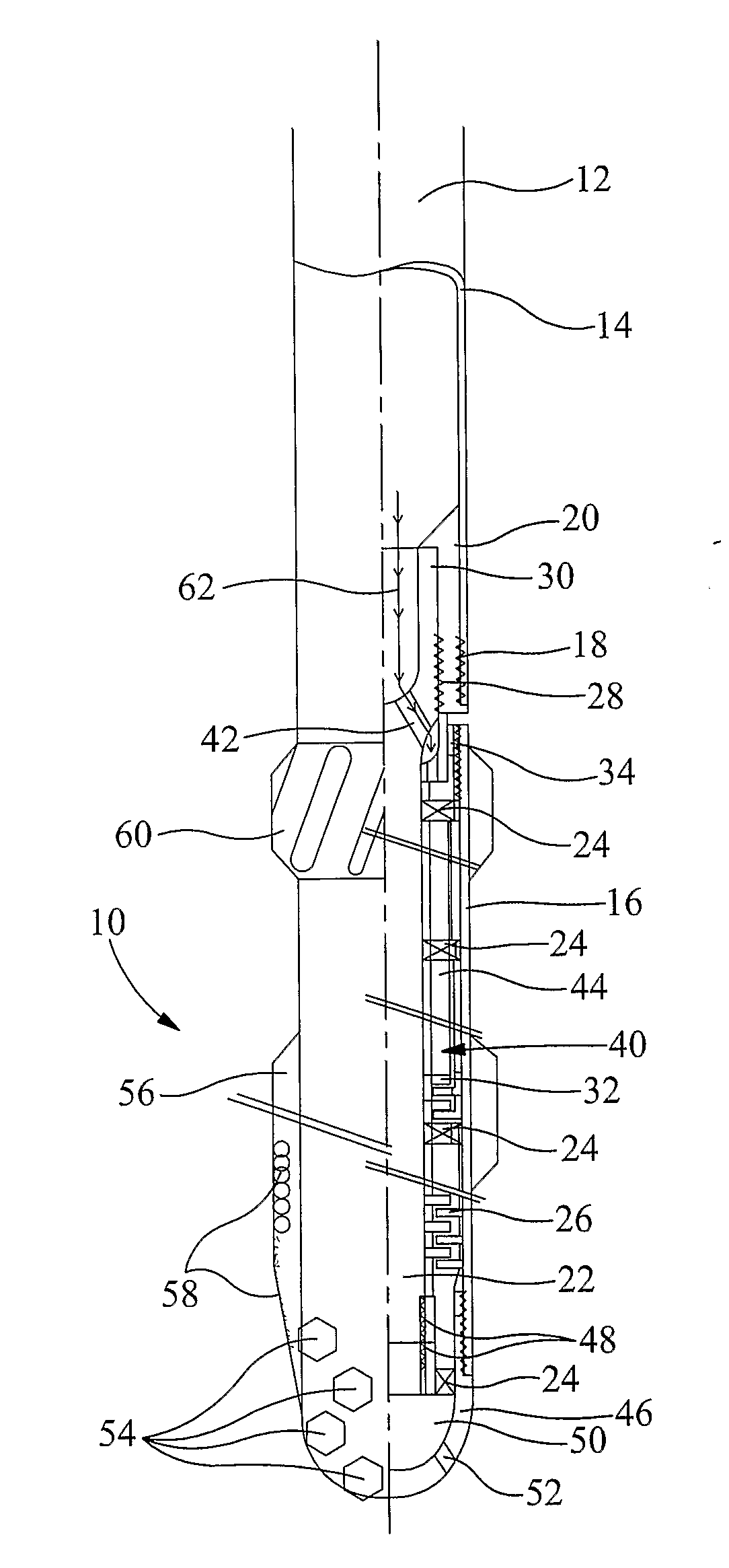

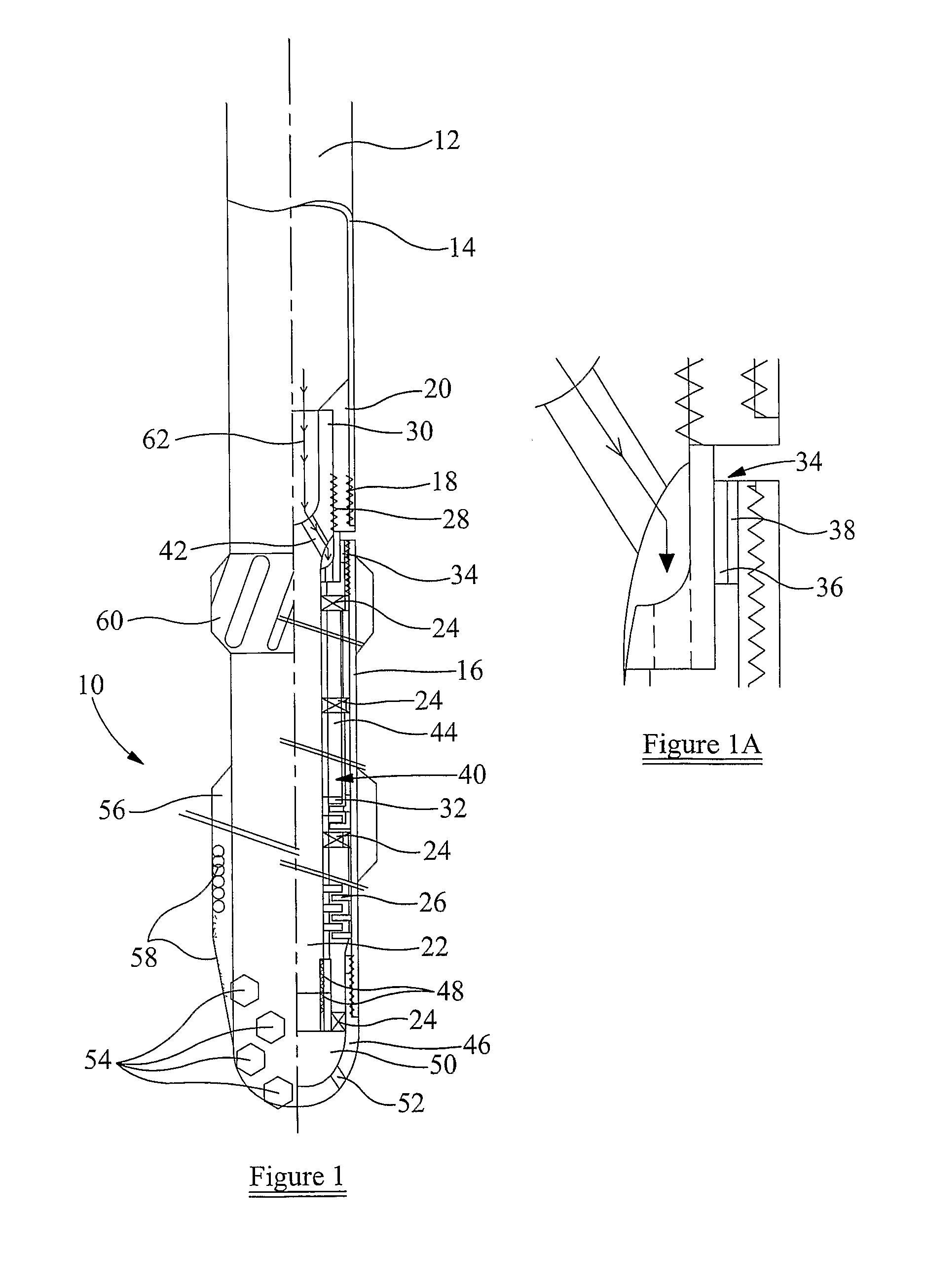

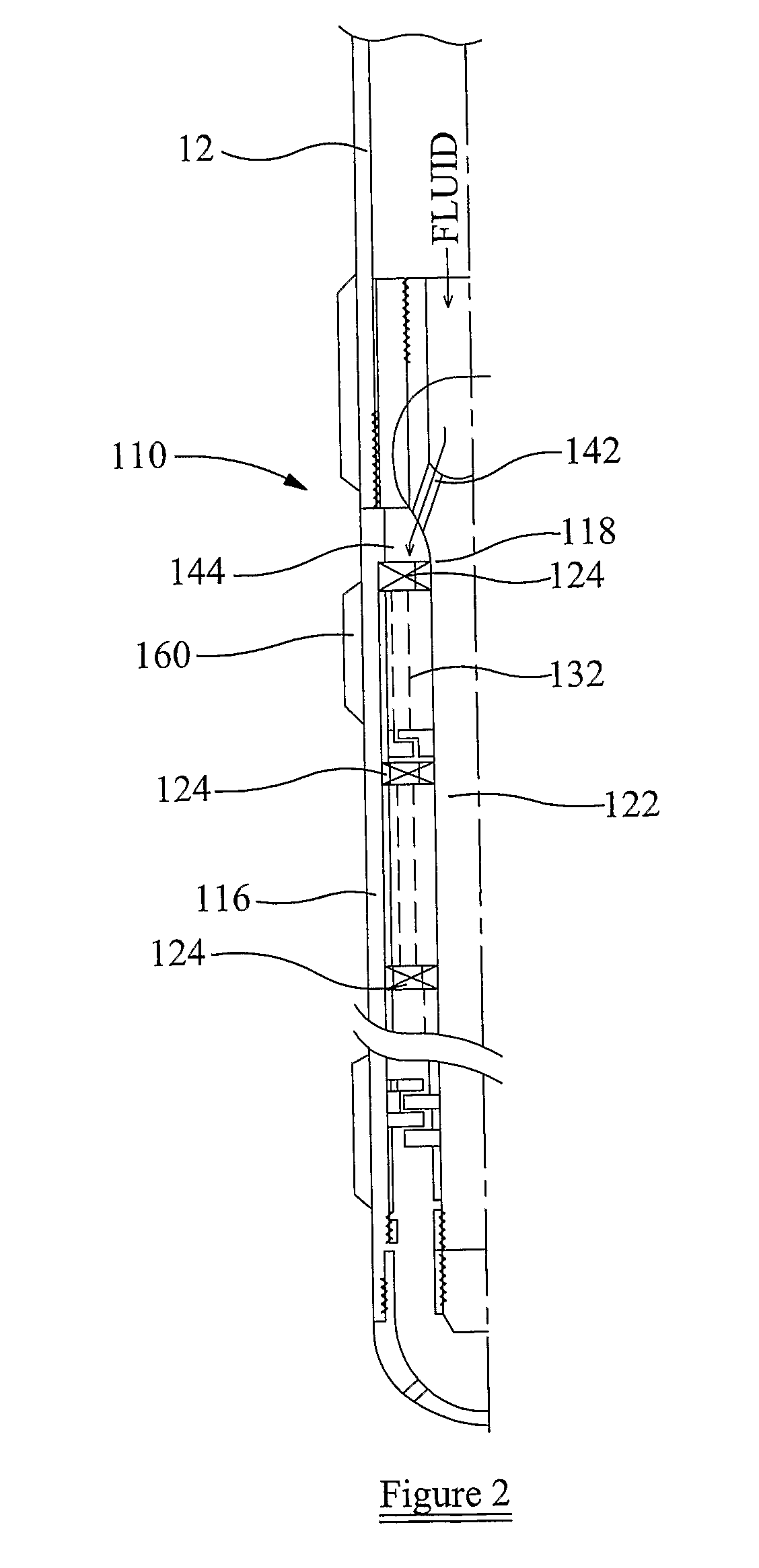

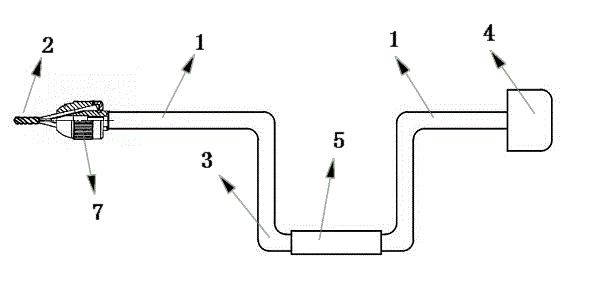

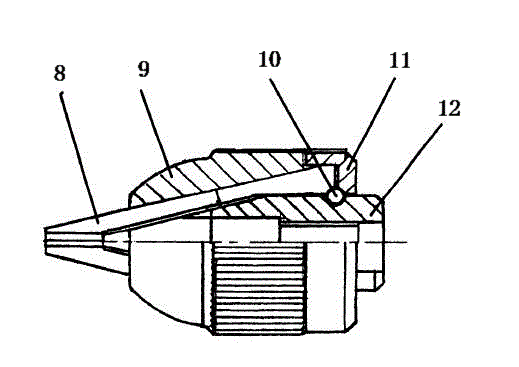

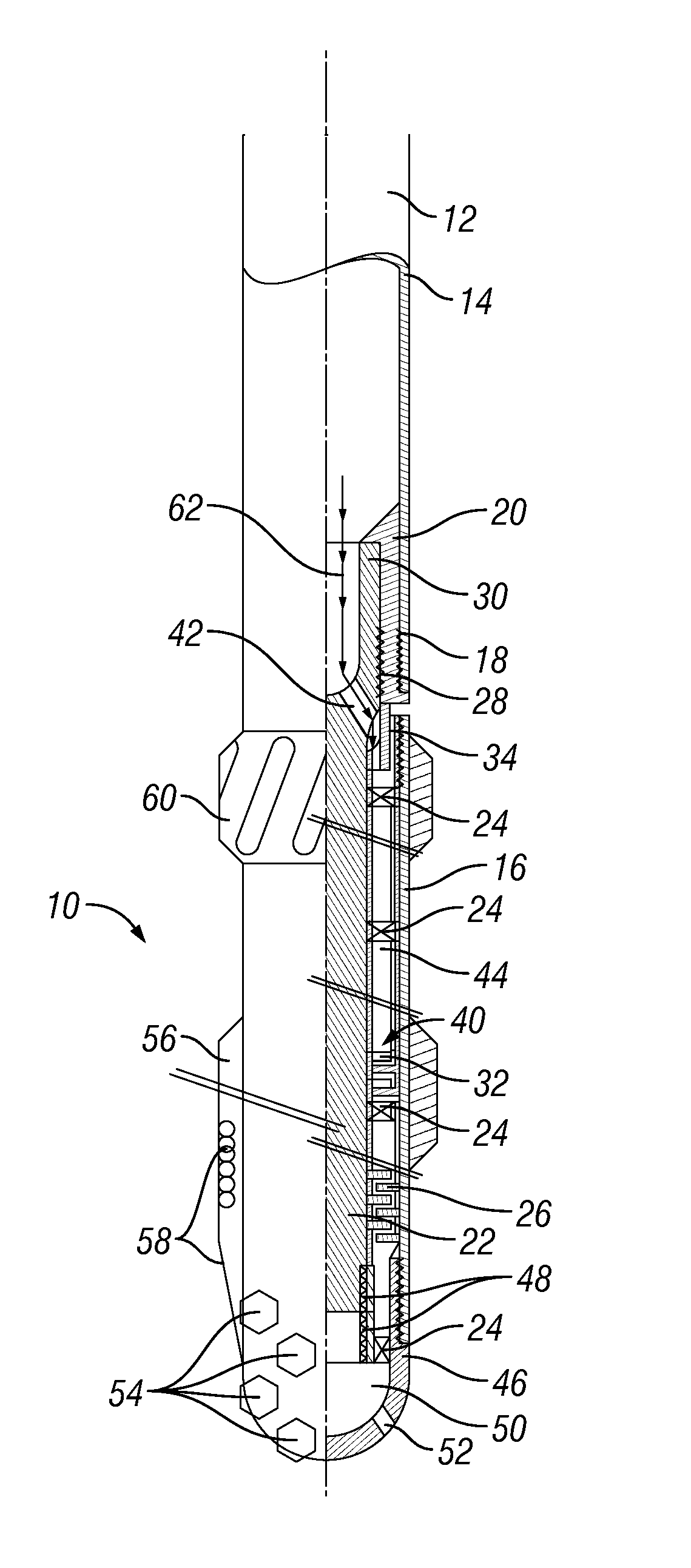

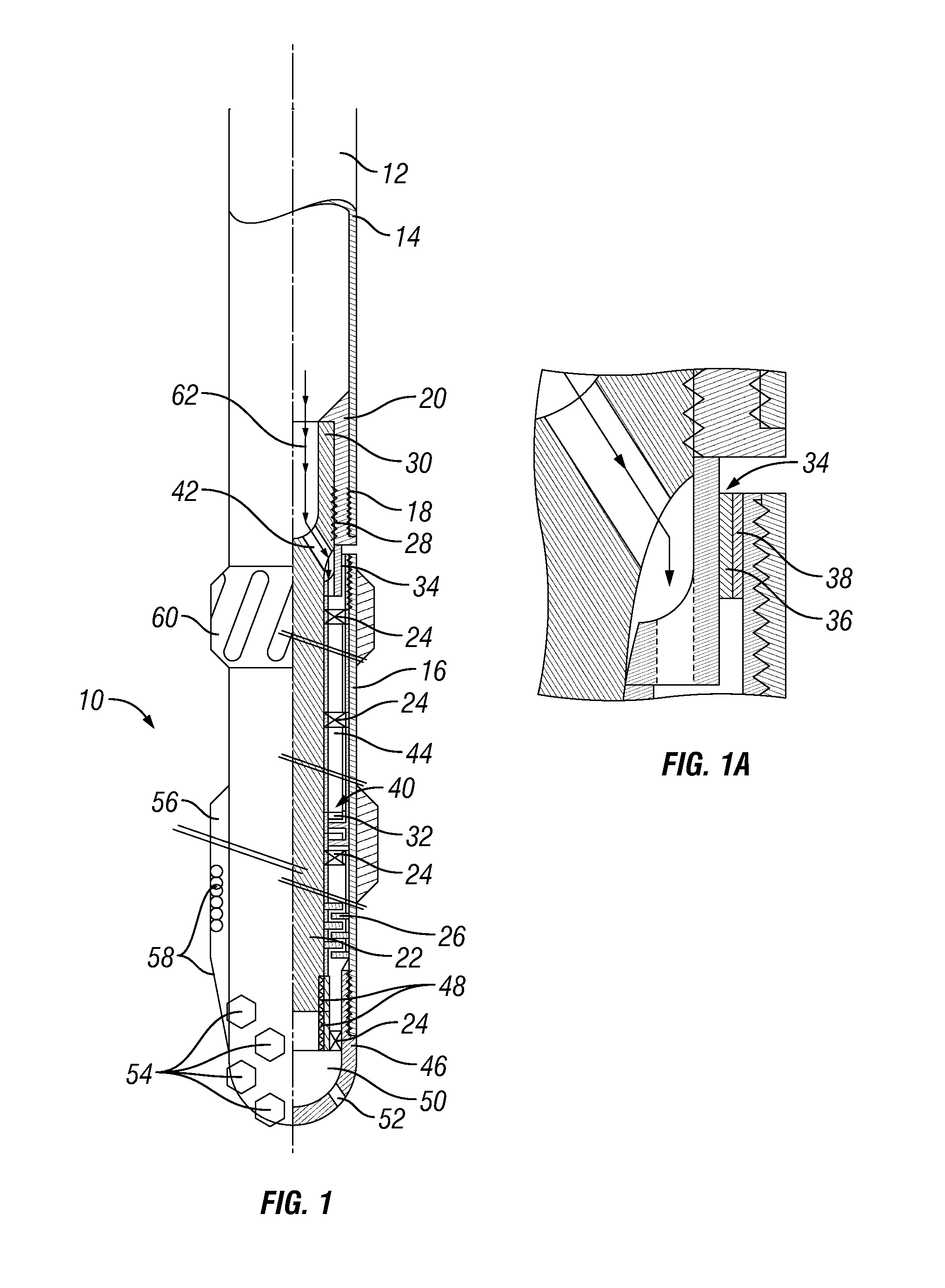

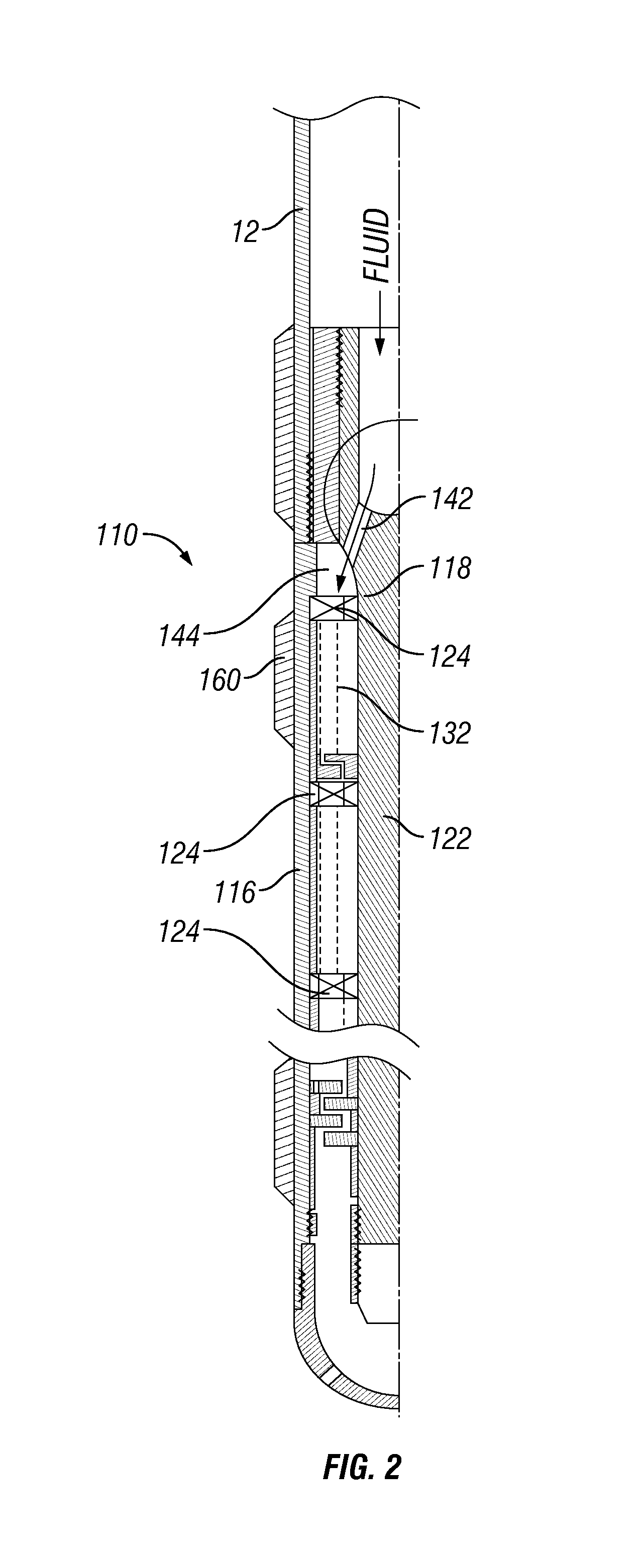

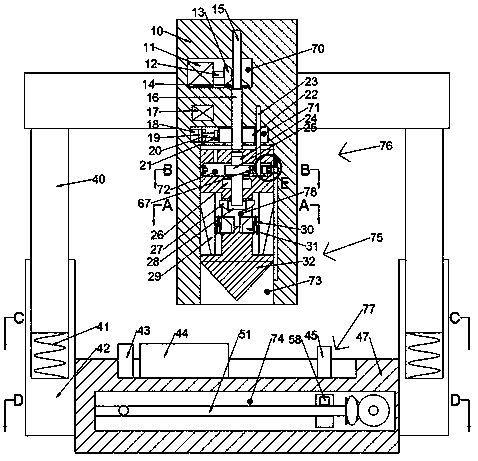

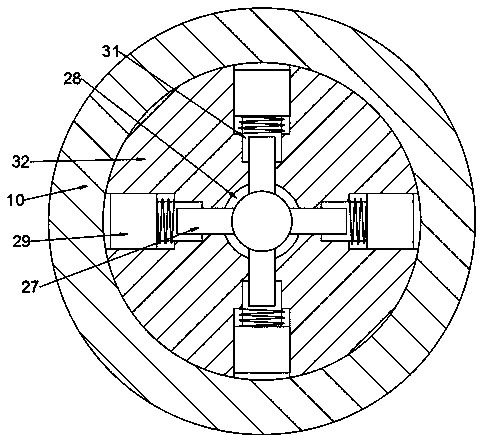

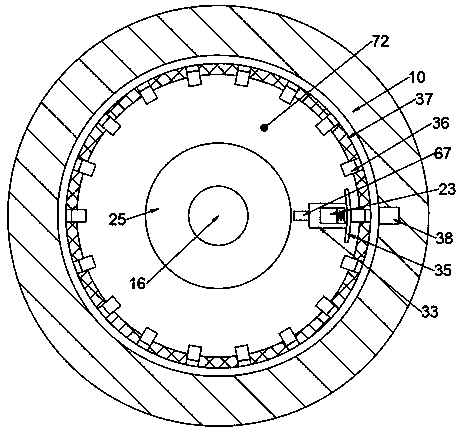

Reaming tool

A reaming tool for use in reaming a bore includes a body adapted for location in a bore. The body defines a rotor of a rotary drive arrangement. A shaft adapted for location is disposed in the body. The shaft defines a stator of the rotary drive arrangement. A seal element is disposed between the shaft and the body. The seal element defines a bearing surface for permitting sealed relative rotation of the rotary drive arrangement. The tool includes a reaming member, wherein relative rotation between the body and the shaft facilitates reaming of the bore by the reaming member.

Owner:DEEP CASING TOOLS LTD

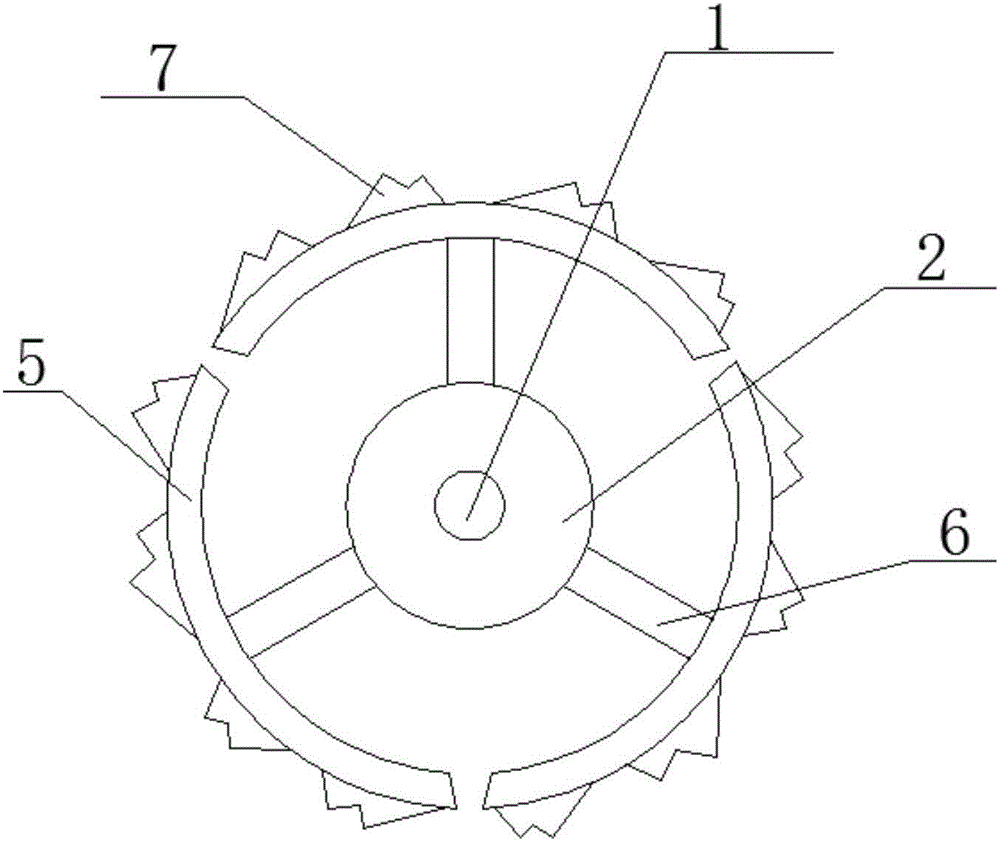

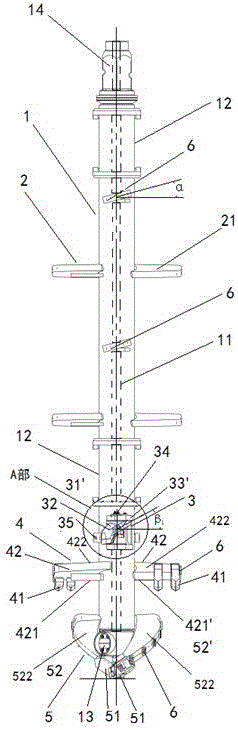

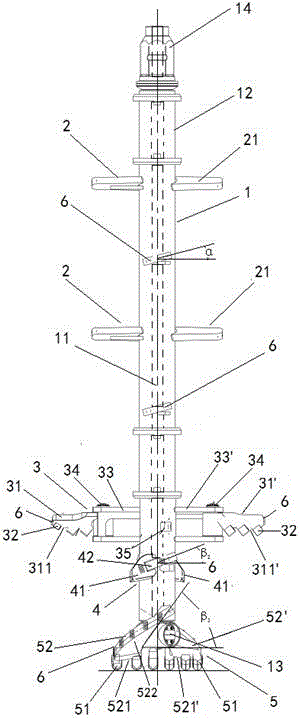

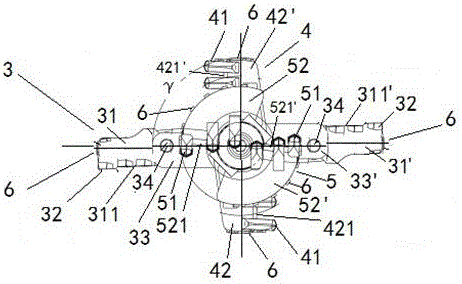

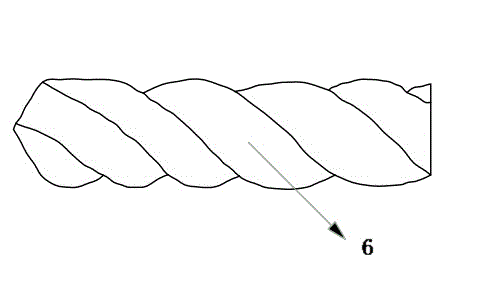

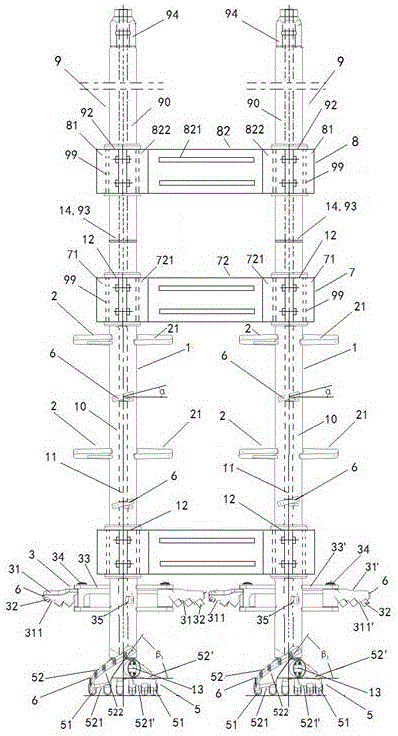

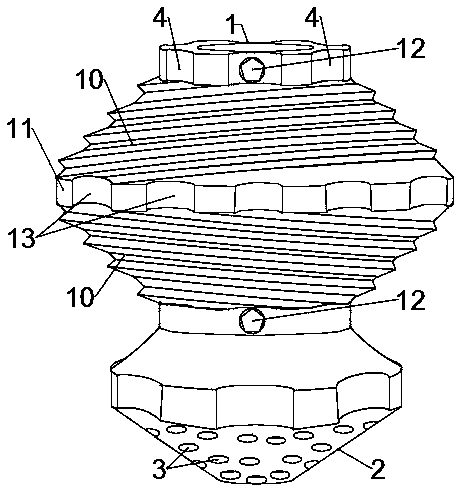

Multifunctional reamer for geological prospecting

InactiveCN106194032AImprove hole reaming efficiencyReaming speed is fastDrilling rodsDrilling casingsReamerEngineering

The invention discloses a multifunctional reamer for geological prospecting. The reamer comprises a drill pipe, a drill bit, three spiral reamer plates and a fixing band; an impactor is fixed on the upper portion of the drill pipe, the fixing band is fixed on the lower portion, close to the drill bit, of the drill pipe, three rotating shafts are uniformly fixed on the edge of the fixing band, each spiral reamer plate is rotatably connected with the fixing band through the corresponding rotating shaft, the portions, close to the fixing band, of the upper portion and the lower portion of the internal surface of each spiral reamer plate are connected with the drill pipe through telescopic cross rods, a compression spring is installed in each telescopic cross rod, protruding blocks are uniformly welded to the outer surface of each spiral reamer plate, and a dust cover is rotatably connected to the portion, above the impactor, of the drill pipe through a thread. According to the multifunctional reamer for geological prospecting, the structure is simple, the reaming effect is rapid and significant, time and labor are saved, the functions of achieving reaming and discharging mud and gravel to prevent blocking and dust are achieved simultaneously, and the multifunctional reamer is worthy of popularization.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

High-density graphite battery negative electrode material and preparation method thereof

ActiveCN106299258AImprove discharge capacityImprove stabilityCell electrodesSecondary cellsGraphite carbonHigh density

The present invention discloses a high-density graphite battery negative electrode material and a preparation method thereof. The graphite battery negative electrode material comprises the following raw materials: graphite carbon material supported modified quartz sand and a graphite carbon material, wherein a mass ratio of the graphite carbon material supported modified quartz sand to the graphite carbon material is 1:20-25. The preparation steps comprise: preparing modified quartz sand and graphite carbon material supported modified quartz sand, and adopting the graphite carbon material supported modified quartz sand and a graphite carbon material as raw materials to prepare the graphite battery negative electrode material. According to the present invention, the first discharge capacity is not less than 450 mAh / g (the irreversible capacity is less than 15 mAh / g), the first charge and discharge efficiency is more than 97.0%, and more than 90% of the first capacity is still retained after cycle 500 times; and the graphite battery negative electrode material has advantages of high capacitance, low irreversible capacity, stable cycle performance, high yield and simple process, and has broad application prospects in the applications in lithium-ion batteries and other negative electrode materials.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Steel for superhigh-strength hot rolling automobile structure and preparation method thereof

The invention relates to steel for a superhigh-strength hot rolling automobile structure and a preparation method thereof, belonging to the field of alloy steel production processes. The steel comprises the following components: 0.08 percent to 0.12 percent of carbon, 0.10 percent to 0.50 percent of silicon, 1.5 percent to 2.50 percent of manganese, less than 0.02 percent of phosphorus, less than 0.01 percent of sulfur, 0.02 percent to 0.05 percent of aluminum, 0.08 to 0.25 percent of vanadium, 0.03 percent to 0.06 percent of nitrogen and the balance of Fe and other inevitable impurities. The production process comprises the following steps of: converter smelting; external refining; continuous casting; hot rolling and reeling. The main process parameters are as follows: the heating temperature of continuous casting slabs is between 1,150 and 1,220 DEG C, the reeling temperature is between 500 and 650 DEG C, and the hot rolling total reduction ratio is more than 85 percent. According to the steel, vanadium-nitride micro alloying is adopted, vanadium precipitation is promoted by enhancing nitrogen, grains are refined, and precipitation strengthening and fine-grain strengthening are used as main strengthening measures, so that the yield strength is more than 700 MPa, the tensile strength is more than 800 MPa, the total elongation rate after fracture is more than percent, and the steel is used for high-strength automobile structures with high plasticity and good cold bending properties.

Owner:UNIV OF SCI & TECH BEIJING +1

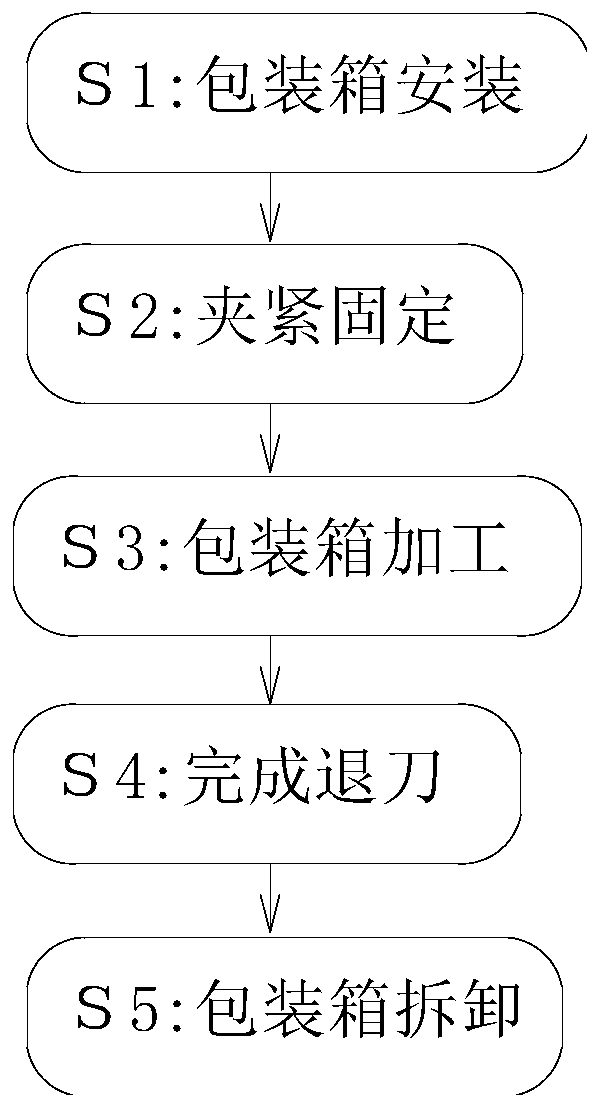

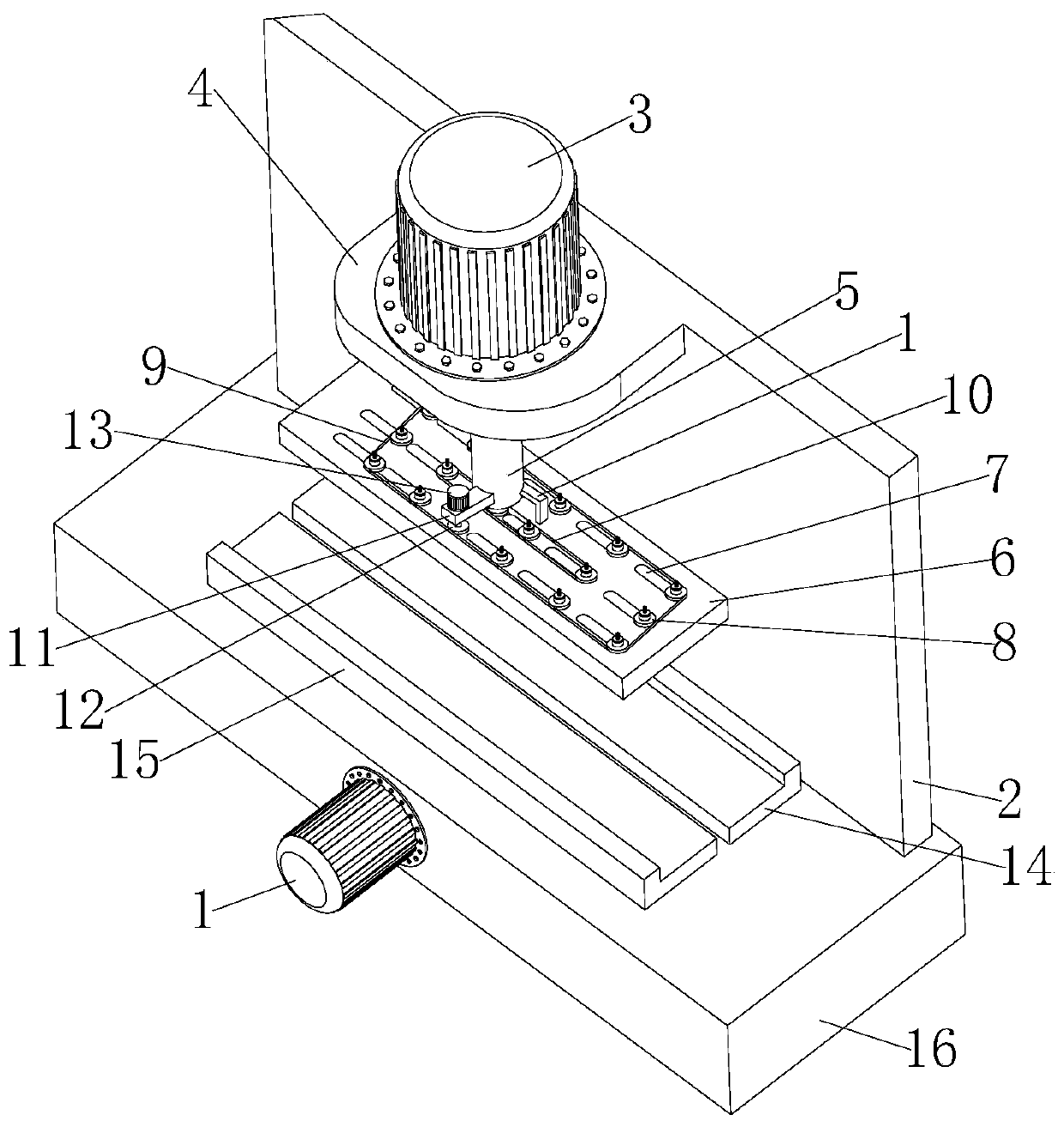

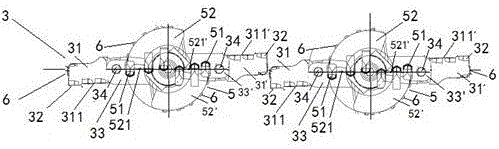

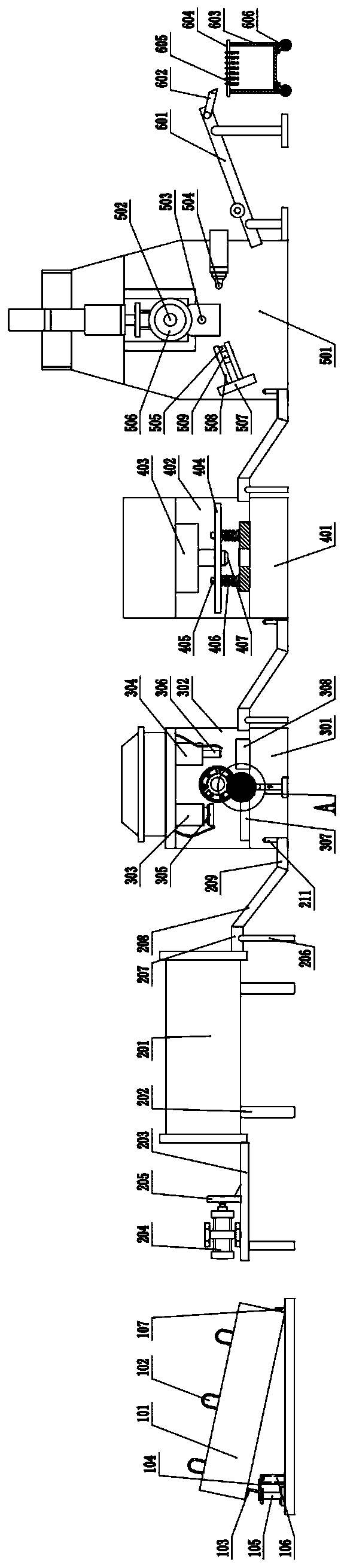

Fresh product foam plastic packaging box manufacturing and processing technology

ActiveCN111516046AImprove hole reaming efficiencyEasy to reamMetal working apparatusPlastic packagingIndustrial engineering

The invention discloses a fresh product foam plastic packaging box manufacturing and processing technology, and relates to the technical field of plastic foam processing. The fresh product foam plastic packaging box manufacturing and processing technology adopts a fresh product foam plastic packaging box manufacturing and processing device for cooperation. The fresh product foam plastic packagingbox manufacturing and processing device includes a bottom support plate which is horizontally fixed to the ground, and the top end of the bottom support plate is provided with side support ribbed plates vertically fixed to the top end of the bottom support plate. Several reaming cutters are engaged and driven through a first toothed belt and a second toothed belt and rotate synchronously in the same rotation direction, a base is vertically raised and lowered above the bottom support plate through an electric push rod, thus, the reaming cutters extend into slotted holes of a foam plastic packaging box and ream the slotted holes of the foam plastic packaging box, and the slotted holes of the foam plastic packaging box are reamed into slotted holes applicable to holding fresh fruits.

Owner:湖南君志达保温材料有限公司

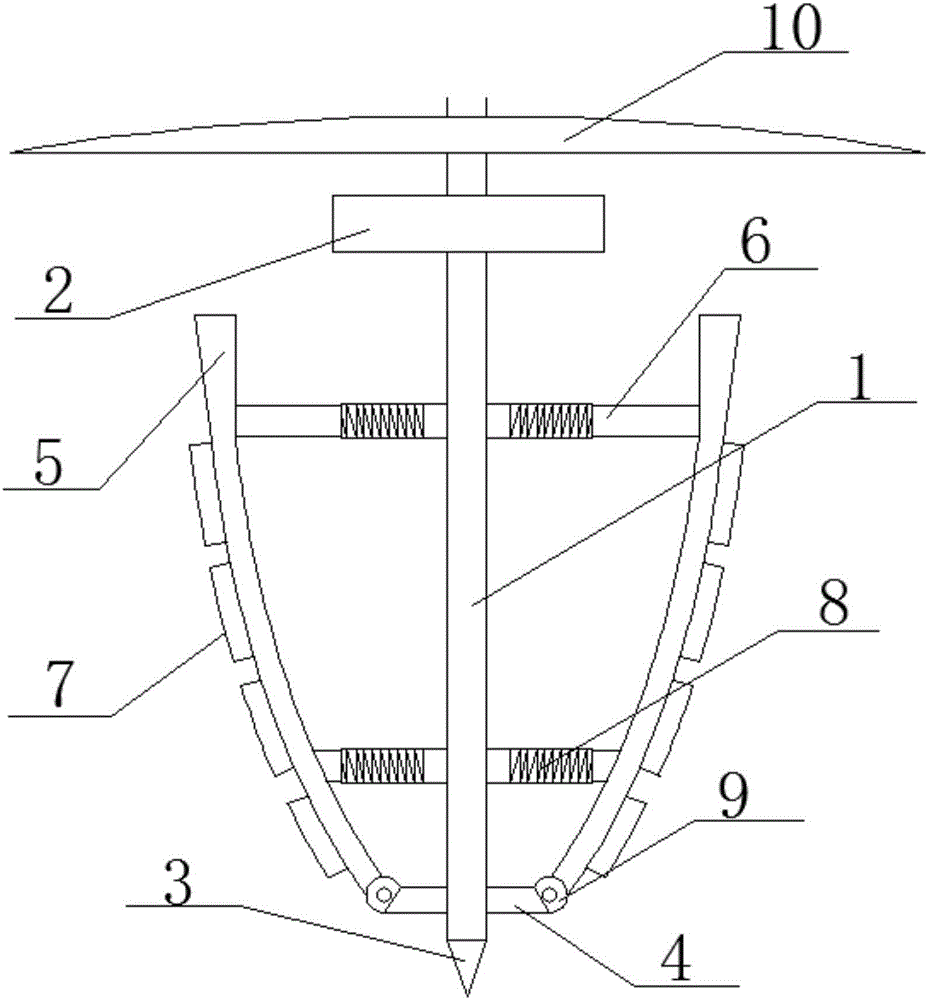

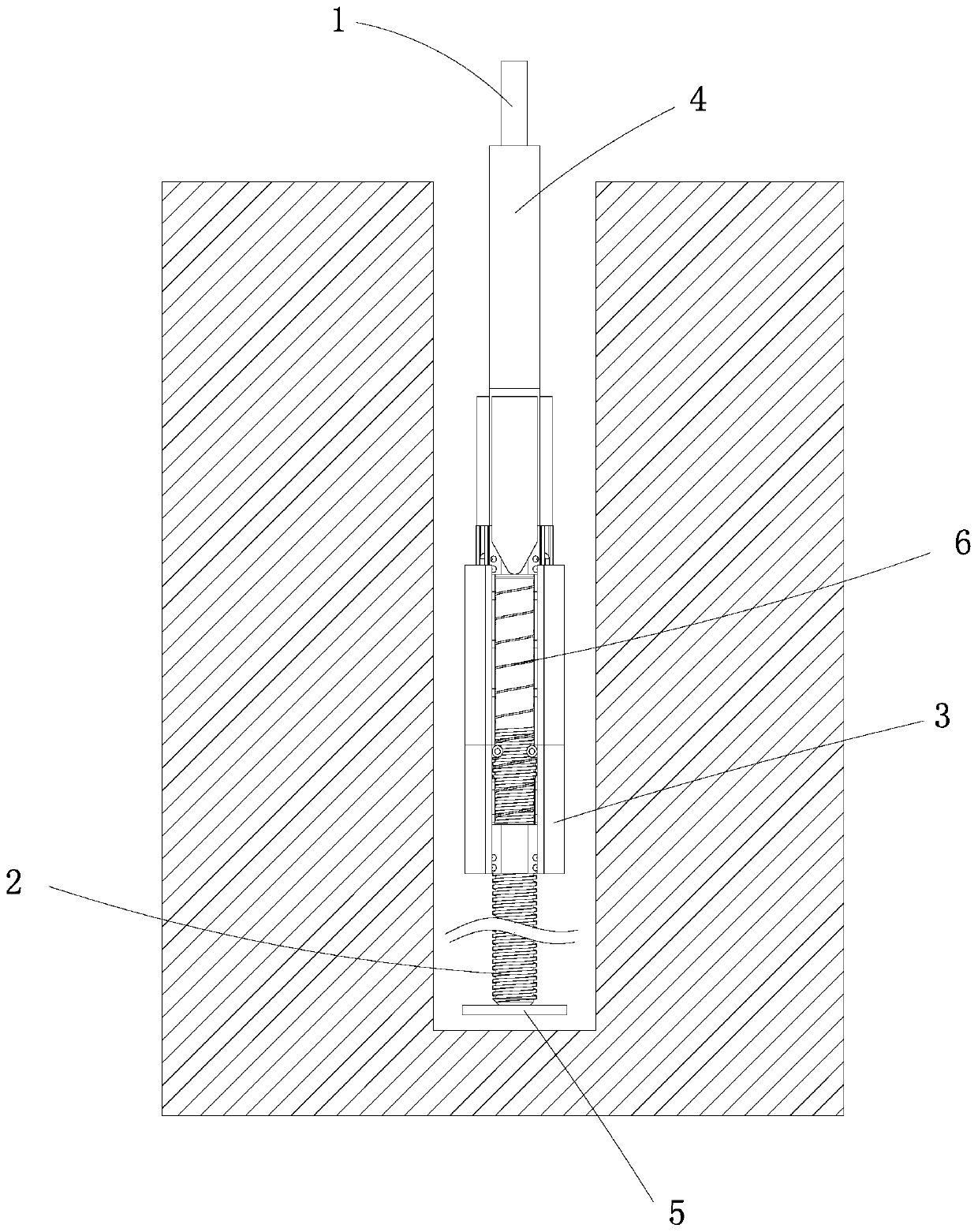

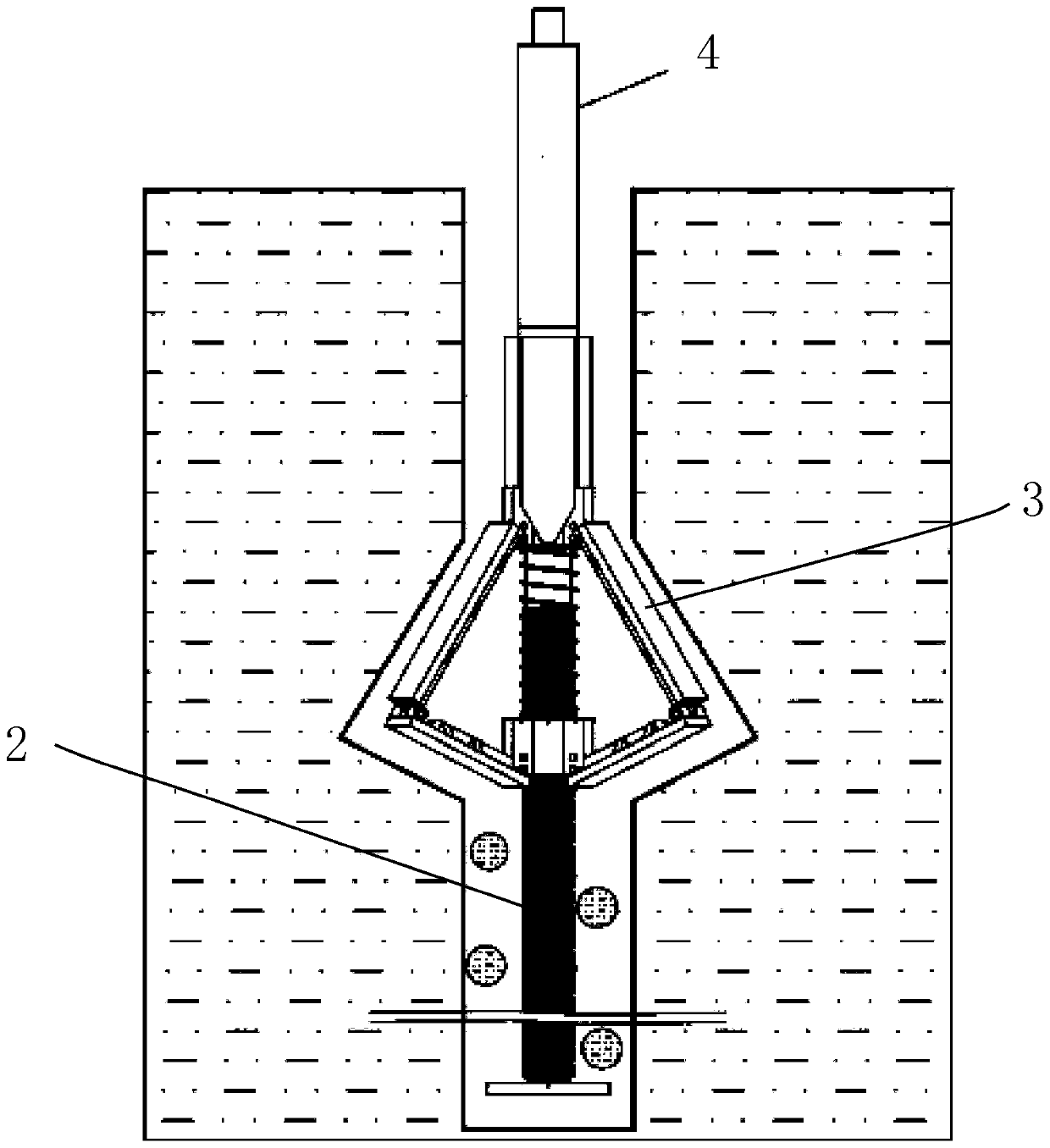

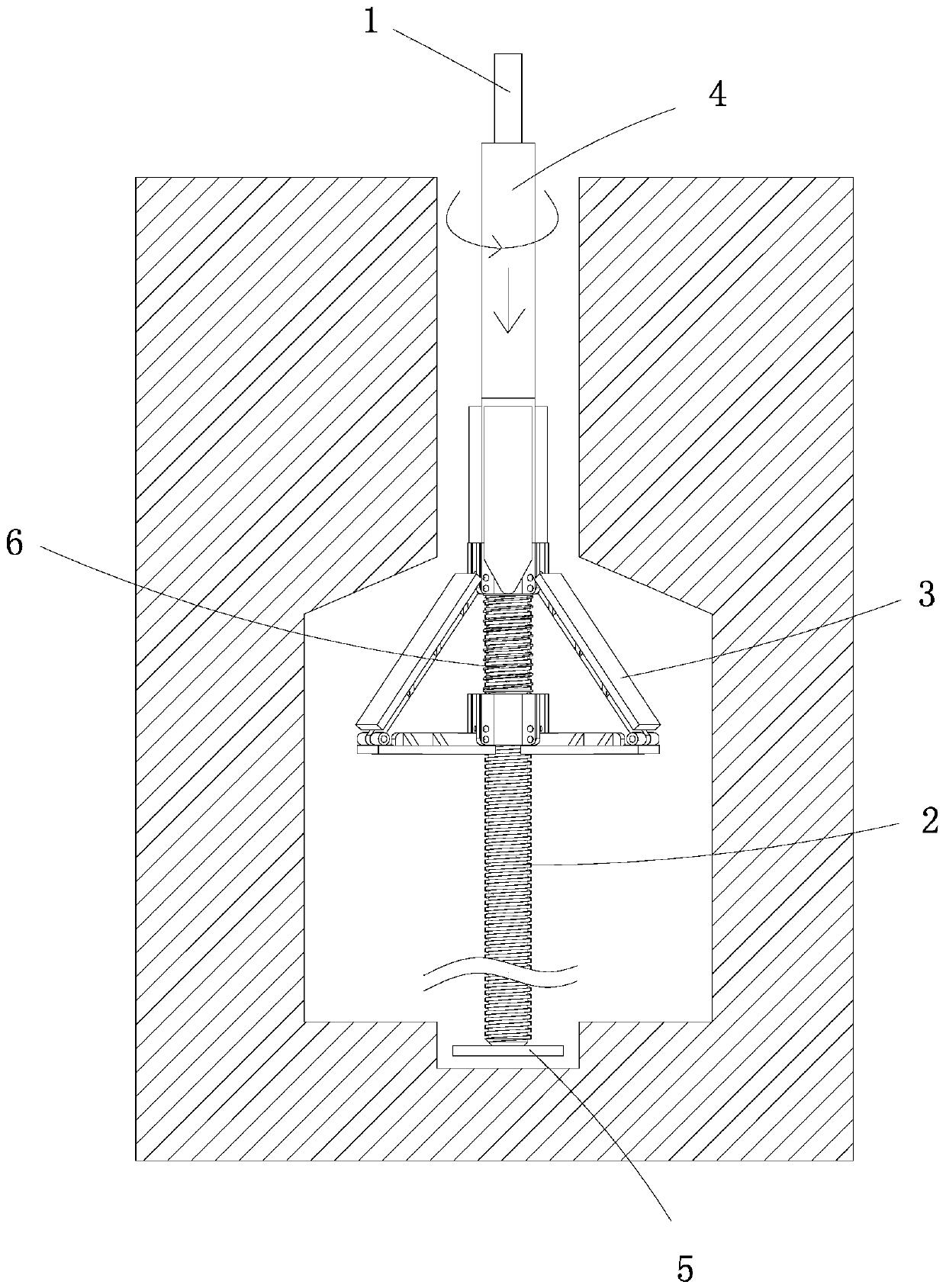

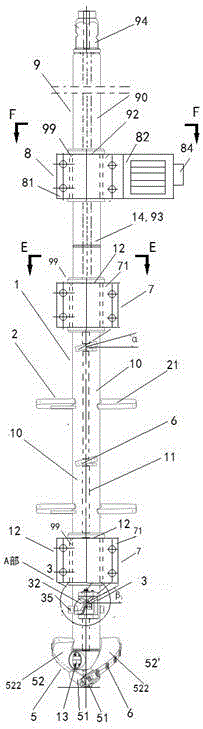

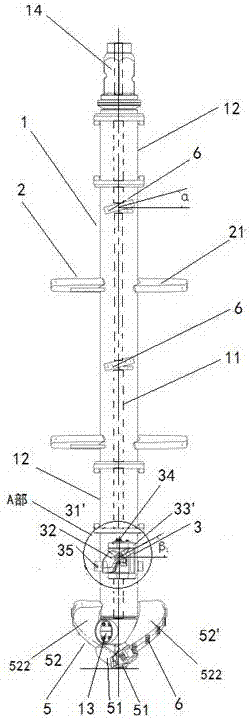

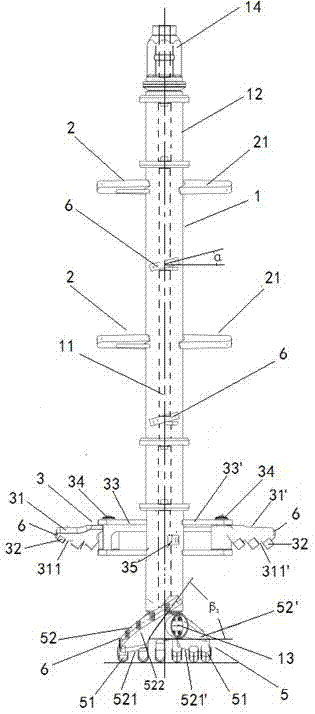

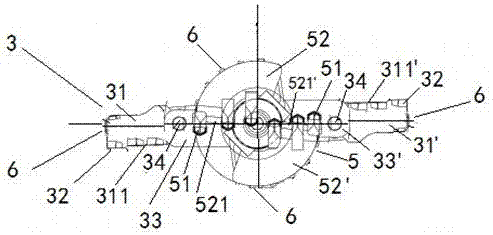

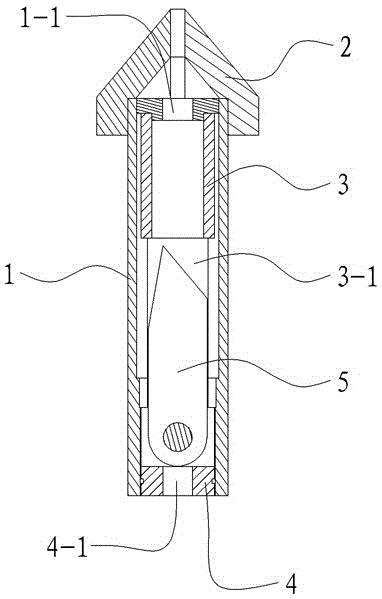

Self-expanded body anti-floating anchor rod

PendingCN110004928ALarge apertureEasy to operateProtective foundationBulkheads/pilesEngineeringDeep hole

The invention discloses a self-expanded body anti-floating anchor rod, and relates to the technical field of construction engineering. The self-expanded body anti-floating anchor rod is a pressure-bearing type self-expanded body anchor rod and includes a main rod, an expanded body anchoring mechanism and a driving piece, wherein the expanded body anchoring mechanism is arranged on the main rod, the driving piece sleeves the expanded body anchoring mechanism, and the driving piece drives the expanded body anchoring mechanism to expand in the radial direction and to move along the main rod in the axial direction so as to perform hole expanding movements. According to the self-expanded body anti-floating anchor rod, the driving piece drives the expanded body anchoring mechanism to expand in the radial direction and to move along the main rod in the axial direction to perform the hole expanding movements, thus a hole diameter of a deep hole is widened, hole expanding positioning is accurate, and the shape is fixed; and the self-expanded body anti-floating anchor rod is simple in structure, convenient to operate and good in anti-floating effect.

Owner:CHINA JINGYE ENG TECH CO LTD

Reaming drilling tool

Disclosed is a reaming drilling tool. The reaming drilling tool comprises a hollow tube body, an enlarged cutting wing, a first cutting wing, a second cutting wing, multiple groups of stirring blades, and wear-resisting plates, the stirring blades are arranged in the outer wall of the hollow tube in an up-and-down spaced mode, and an included angle of 90 degrees is formed between the two relative groups in the radial direction; the first cutting wing and the second cutting wing are both in a two-head form and arranged on the outer wall of the hollow tube body in a radial mode around the hollow tube body, and an included angle of a certain angles is formed in the radial direction of the hollow tube body; the wear-resisting plates are fixedly arranged on the stirring blades, the enlarging cutting wing, the first cutting wing, the second cutting wing and the free end arc surface which has the same axis with the hollow tube body respectively; an included angle of a certain degree is formed between a first wing blade and a second wing blade in the radial direction of the tube body of a drilling tool; an enlarged cutter body, a first cutter body and a second cutter body are made of cemented carbide blocks. The reaming drilling tool has the advantages that the reaming is simple, the strength of the cutter bodies is high, the wear resistance of spiral blades is high, the drilling capacity is high and the stirring is sufficient, and therefore the drilling efficiency and construction quality are effectively improved.

Owner:上海工程机械厂有限公司

Simple hand-operated puncher

InactiveCN102974863AEasy to punchEasy to reamPortable drilling machinesStone-like material working toolsFixation timeElectric power

The invention discloses a simple hand-operated puncher and relates to the technical field of portable drilling machines. The simple hand-operated puncher comprises a drill rod and a drill bit and is characterized in that the middle of the drill rod is provided with a U-shaped rocking arm; the rocking arm is provided with a sleeve; one end of the drill rod is provided with a chuck, the drill bit is fixedly connected with the drill rod by virtue of the chuck; and the other end of the drill rod is provided with a grab handle. The simple hand-operated puncher is simple in structure, convenient to carry and use, and convenient in bit replacement, especially can be used for conveniently and easily punching and broaching an ammeter box and a wall under the condition of no power supply in the power construction process, is rapid and accurate, and can be used for greatly shortening the installation and fixation time of the ammeter box and improving the overall working efficiency; and the chuck is convenient to use, and the drill bit can be firmly chucked.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD

Chambering drilling machine

ActiveCN106761416AEasy to reamHigh strengthDrill bitsDrilling machines and methodsWear resistanceUltimate tensile strength

A chambering drilling machine comprises chambering drilling tools, an expanding cutting wing, a second cutting wing, a protection frame, a guide frame, hollow polished drilling rods, multiple sets of stirring blades and wear-resisting plates. The second cutting wing is in a double-head type and is arranged on the outer wall of a hollow pipe in the mode of surrounding the hollow pipe in a radial mode, and an included angle of a certain degree is formed in the radial direction. The wear-resisting plates are fixedly mounted on the free end arc faces, coaxial with the hollow pipe, of the stirring blades, the expanding cutting wing and the second cutting wing; a second wing sheet forms an included angle of a certain degree in the radial direction of a drilling tool pipe; the left chambering drilling tool, the right chambering drilling tool and the hollow polished drilling rods are sleeved with the protection frame and the guide frame; an expanding cutter and a second cutting cutter are made from hard alloy blocks. The chambering drilling machine has the advantages that chamfering is easy and convenient, the cutting cutter is high in strength, a spiral sheet is high in wear resistance, drilling and excavating capacity is high, and stirring is full, and drilling and excavating efficiency and construction quality are effectively improved.

Owner:SHANGHAI GUANGDA FOUND ENG

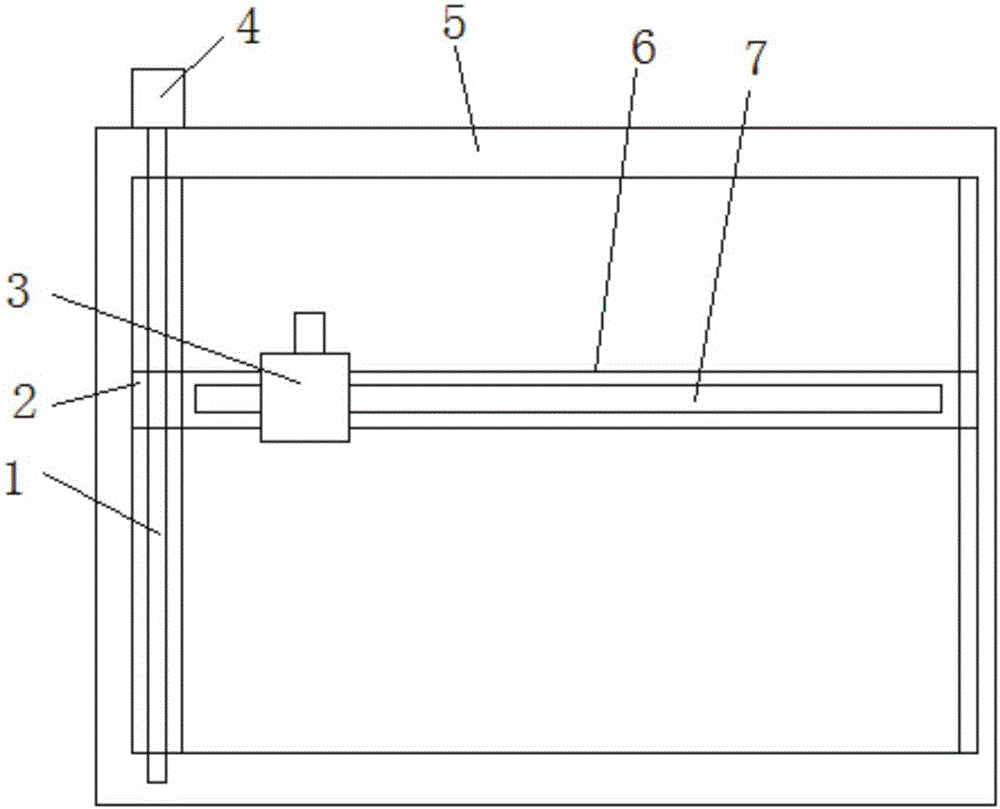

Automatic feeding mechanism of boring tool

The invention discloses an automatic feeding mechanism of a boring tool. The mechanism comprises a fixed frame; a cross bar is slidingly connected into the fixed frame; slide blocks are respectively arranged at the two ends of the cross bar; chutes are respectively formed in two side inner walls of the fixed frame; the slide blocks are slidingly connected into the chutes; a first motor is fixed on one side outer wall of the fixed frame through screws; an output shaft of the first motor is connected with a thread rod; the thread rod is rotationally connected into one chute; the thread rod is in threaded connection with the slide blocks in the chutes; a rack is mounted on the top end side wall of the cross bar; a movable frame sleeves the cross bar; a second motor is fixed on one side wall of the movable frame through screws; an output shaft of the second motor is connected with a gear; and the gear is positioned in the movable frame. The mechanism can realize movement in all directions, can realize adjustment of the machining angle, brings convenience to machining of round holes or arcs with different sizes, has no need to repeatedly adjust the positions of objects to be machined, and is high in machining efficiency.

Owner:JINGYIHENGZHUN TIANJIN CNC EQUIP CO LTD

Reaming tool

A reaming tool for use in reaming a bore includes a body adapted for location in a bore. The body defines a rotor of a rotary drive arrangement. A shaft adapted for location is disposed in the body. The shaft defines a stator of the rotary drive arrangement. A seal element is disposed between the shaft and the body. The seal element defines a bearing surface for permitting sealed relative rotation of the rotary drive arrangement. The tool includes a reaming member, wherein relative rotation between the body and the shaft facilitates reaming of the bore by the reaming member.

Owner:DEEP CASING TOOLS LTD

Broaching drilling tool

A broaching drilling tool comprises a hollow pipe body, an enlarging cutting wing, a second cutting wing, a plurality of stirring blades and wear-resisting plates; the multiple stirring blades are arranged on the outer wall of the hollow pipe body in a vertically-spaced mode, and every two opposite stirring blades form an inclined angle of 90 degrees in the radial direction; the second cutting wing is in a double-head shape and arranged on the outer wall of the hollow pipe body in the mode that the hollow pipe body is enclosed in a radial mode, and an inclined angle of a certain degree is formed in the radial direction of the second cutting wing; the wear-resisting plates are fixedly installed on the free end arc surfaces, which are with the same axle center as the hollow pipe body, of the stirring blades, the enlarging cutting wing and the second cutting wing correspondingly; and second wing pieces from an inclined angle of a certain degree in the radial direction of a drilling tool pipe body, and an enlarging knife body and a second cutting knife body are each made of hard alloy blocks. The broaching drilling tool has the characteristics of being easy and convenient to broach, high in cutting knife strength and spiral piece wear-resisting property, large in drilling and excavating capacity, sufficient in stirring and the like; and drilling and excavating efficiency and the construction quality are effectively improved.

Owner:SHANGHAI GUANGDA FOUND ENG

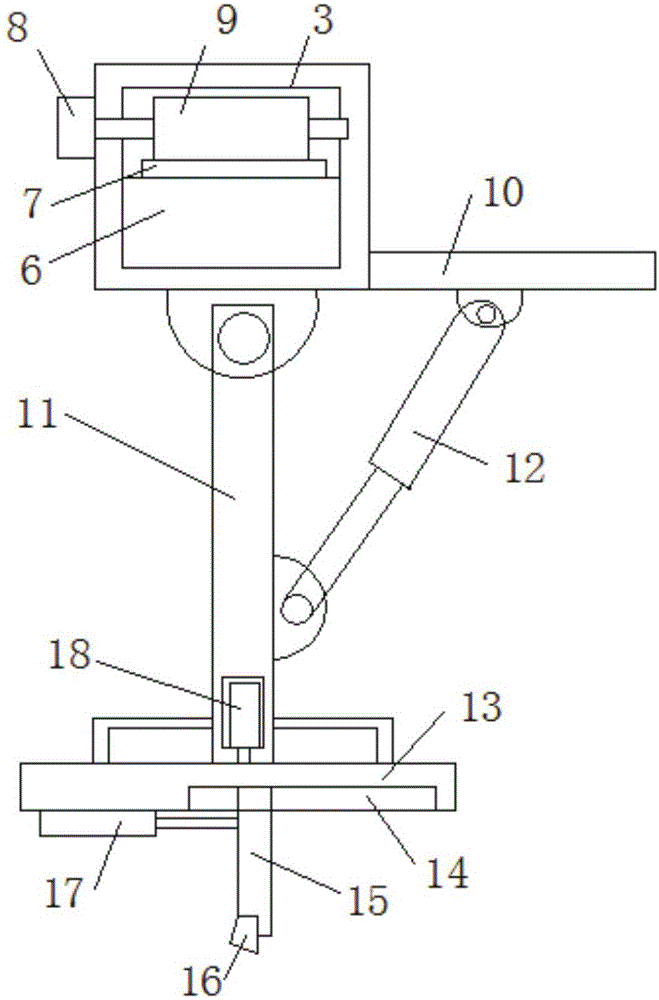

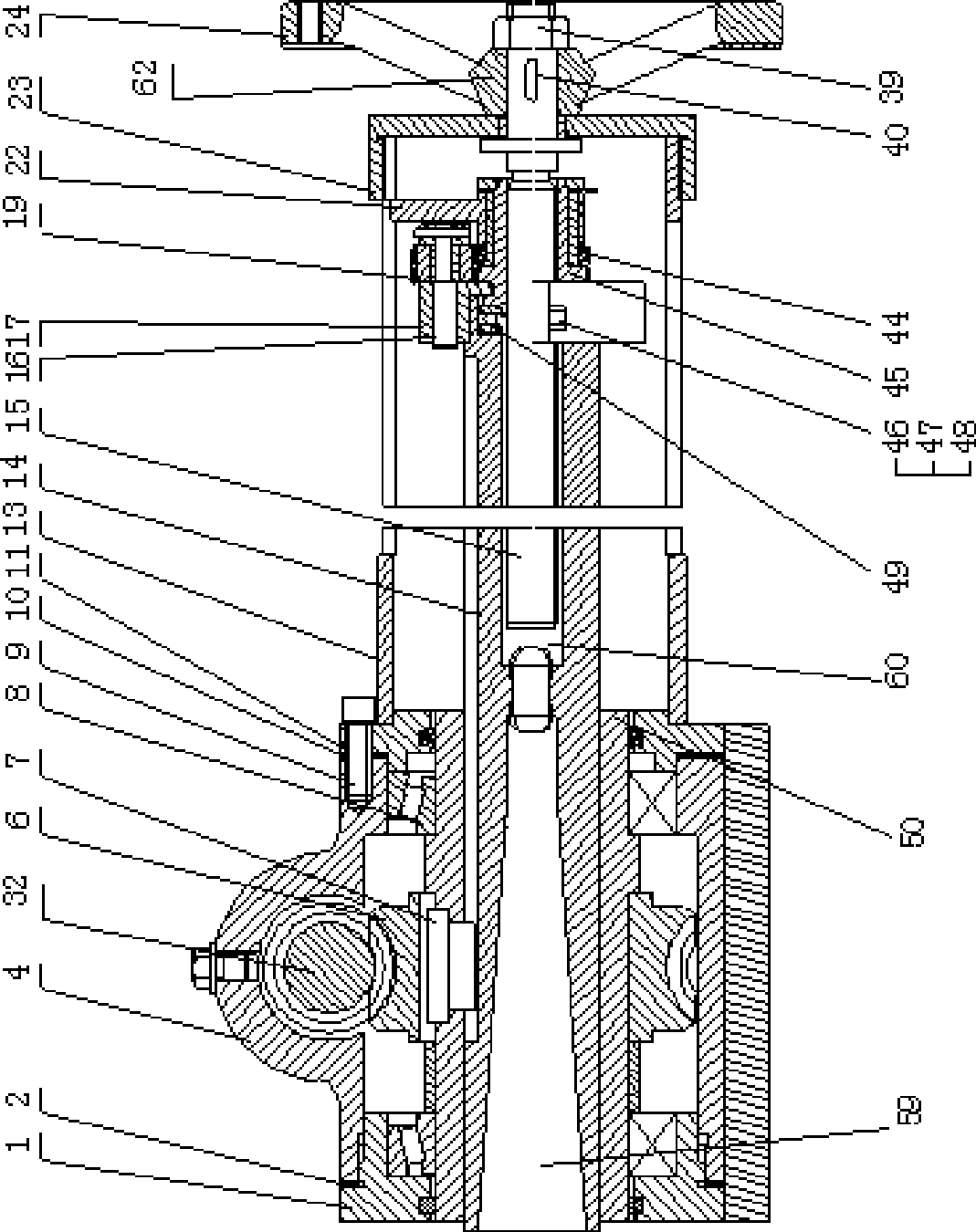

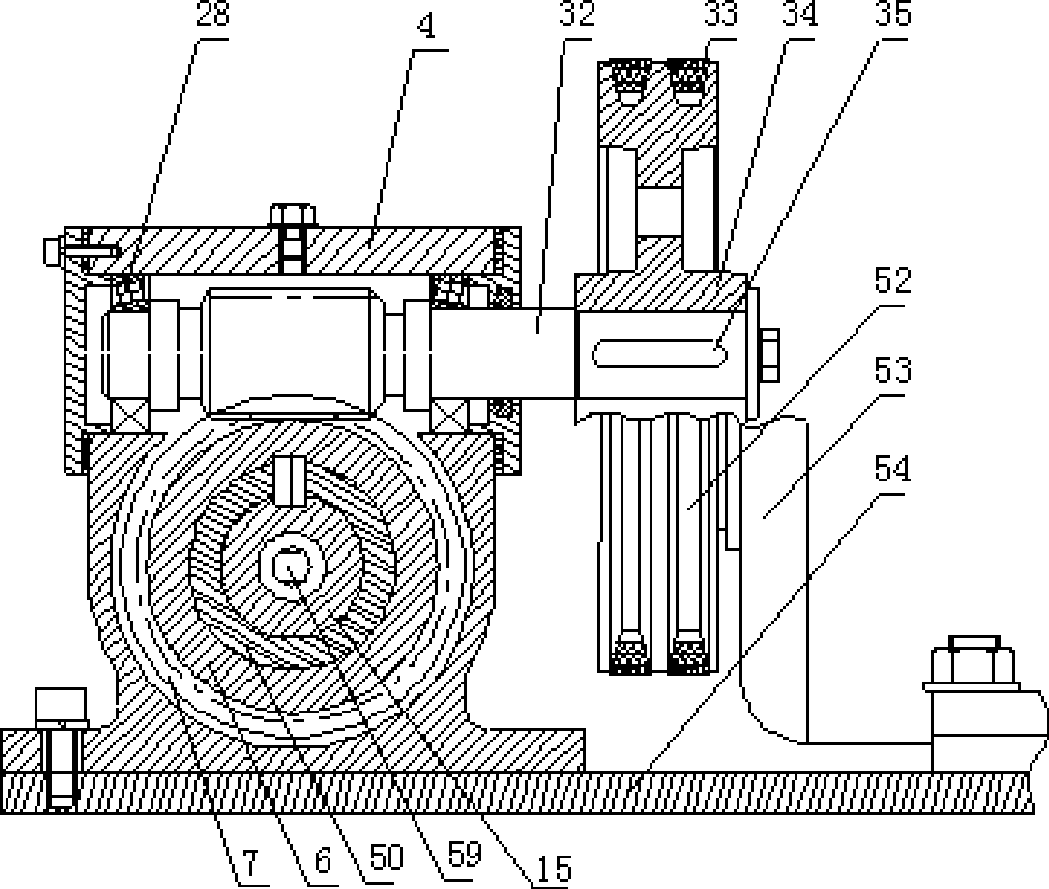

Reaming machine

InactiveCN101518839ACompact structureReduce labor intensityAutomatic control devicesFeeding apparatusThrust bearingEconomic benefits

The invention relates to a large screw hole reaming device, in particular to a reaming machine. A motor is used for providing power; a belt is connected with a worm; a worm wheel is used for providing transmission to drive a reamer bar; a lead screw is arranged in the reamer bar; and a Huff clip, a planet gear, a transmission nut, a plane thrust bearing and a hand wheel are arranged on the reamer bar. The reaming machine is provided with compact transmission and feeding components which are convenient for the drilling and reaming operations in the narrow space, and has two working modes of electric operation and manual operation, thereby having high efficiency and easy control of precision, reducing the construction period and improving the economic benefit. Meanwhile, each of the power, transmission and feeding components utilizes a dismountable connection, thereby being convenient for the transport, assembly and disassembly of the device and greatly reducing the labor intensity of workers.

Owner:WUCHANG SHIPBUILDING IND

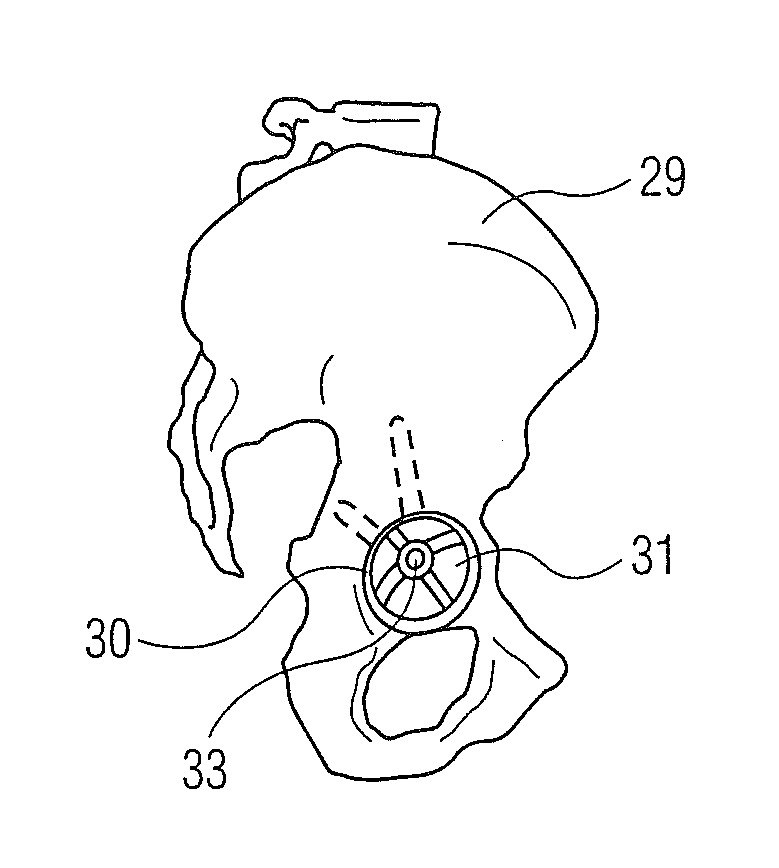

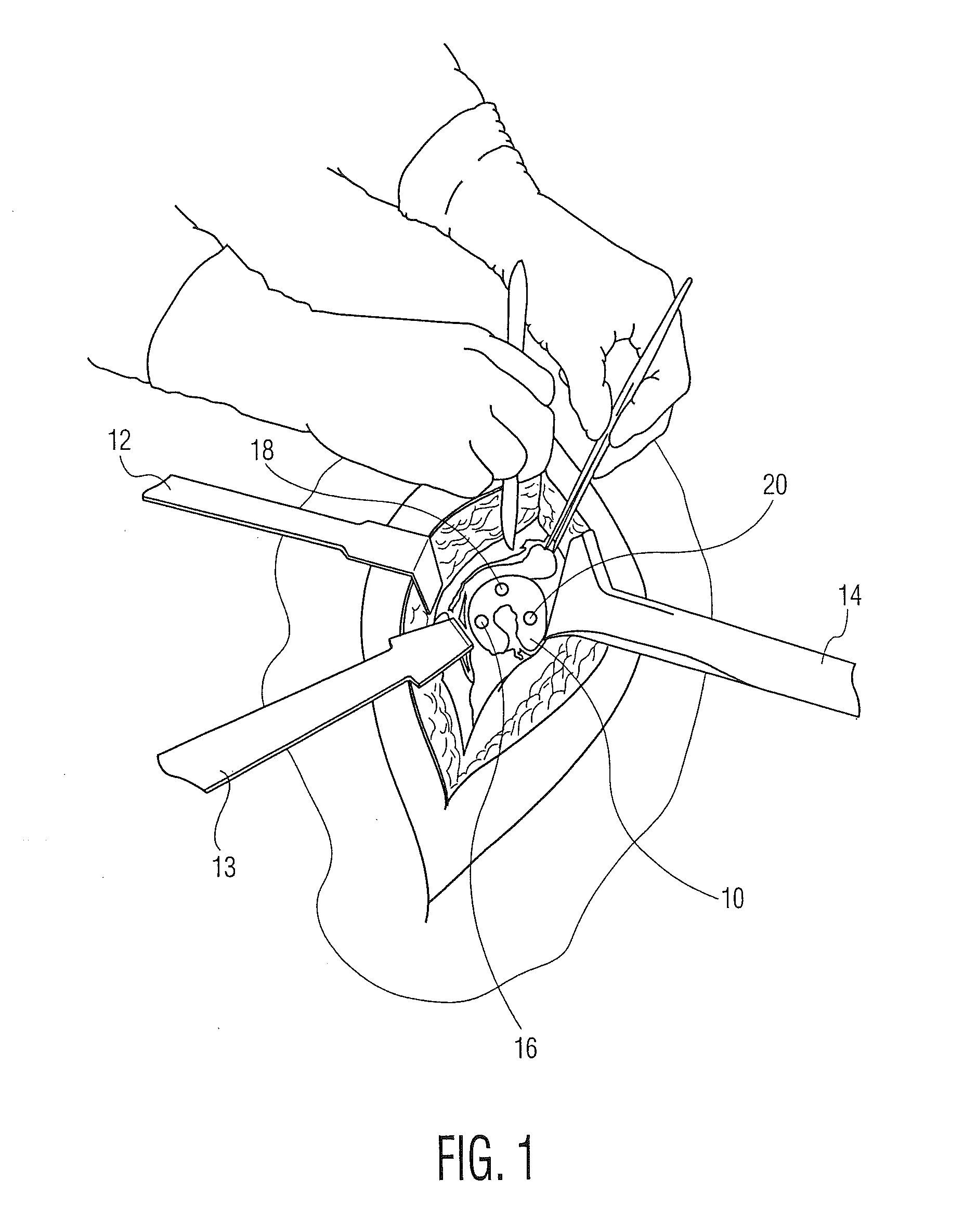

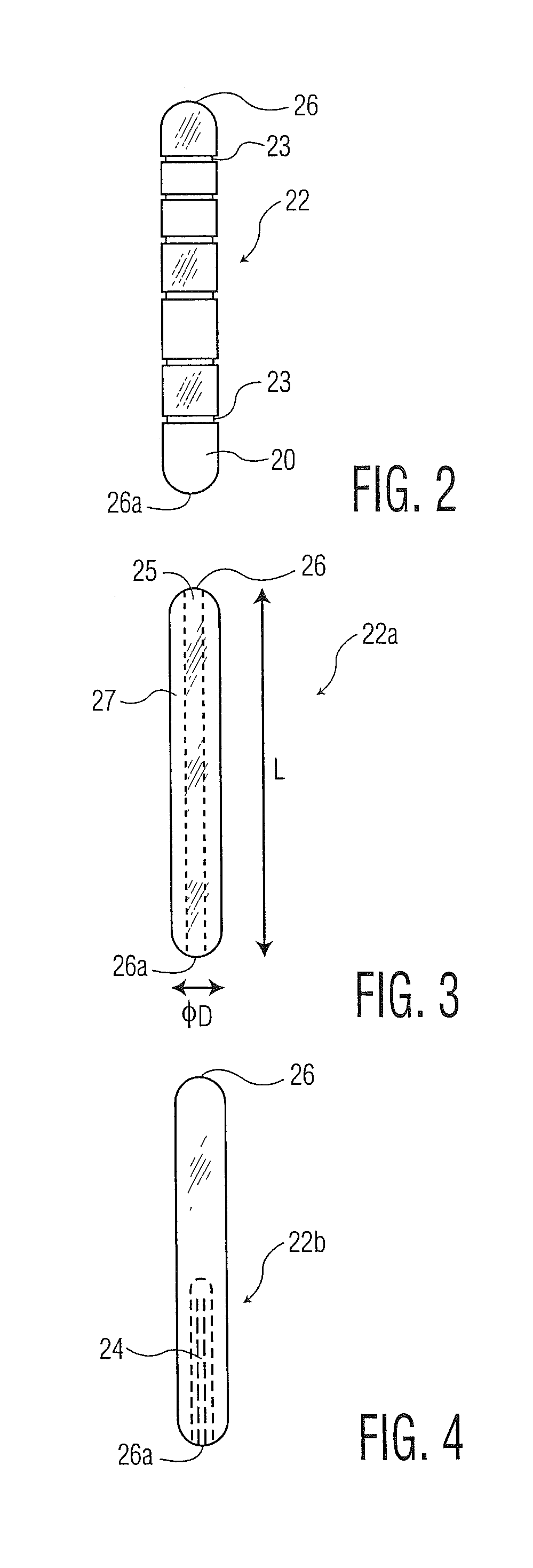

Porous bone reinforcements

ActiveUS20140012390A1Easy to reamFor full exposureInternal osteosythesisJoint implantsProsthesisBiomedical engineering

A method of reinforcing the bone in an acetabulum for receiving a prosthetic acetabular implant includes preparing a surface of the acetabulum to receive an acetabular implant. At least one porous generally cylindrical bone reinforcement element is provided. At least one bore is drilled in an area of the acetabulum receiving the prosthetic acetabular implant for receiving at least one and preferably more reinforcement elements in the form of cylindrical pilings. The cylindrical porous bone reinforcement element is inserted in the bore such that an exposed surface of the porous bone reinforcement element is adjacent the surface of the acetabulum. The acetabular implant is then implanted with an outer surface of the acetabular implant supported by the reinforcement members.

Owner:HOWMEDICA OSTEONICS CORP

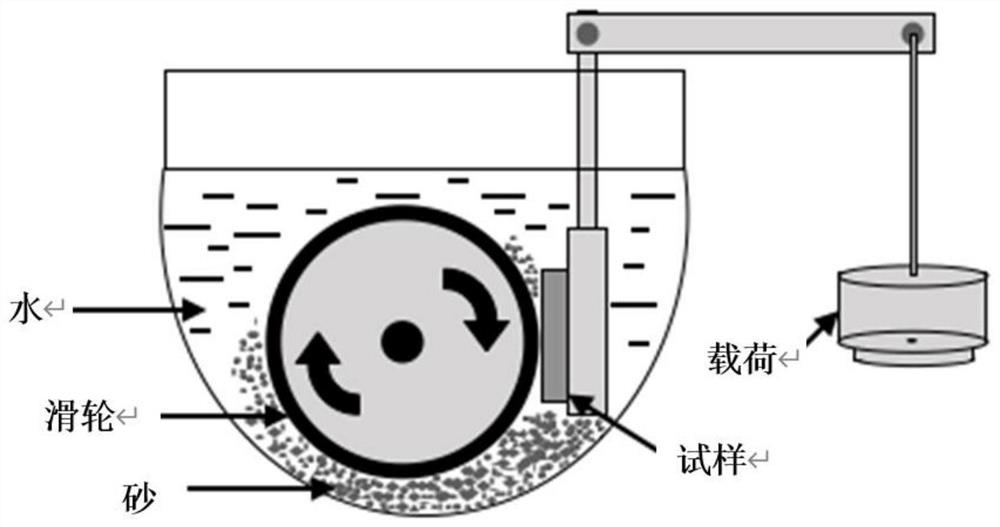

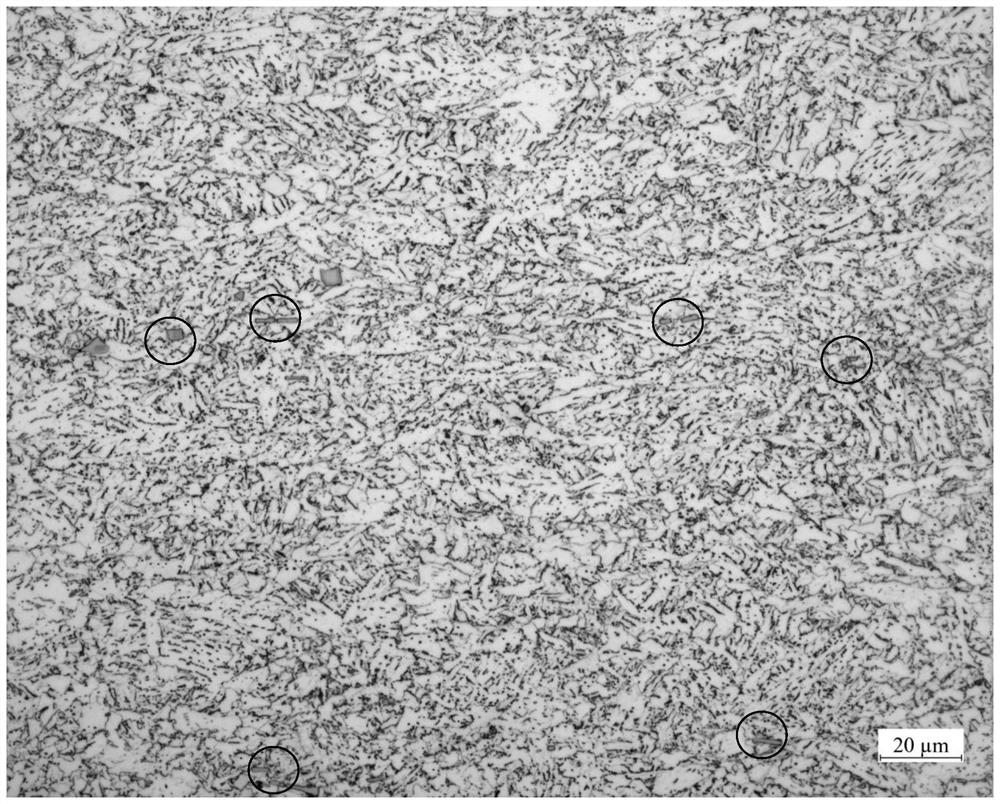

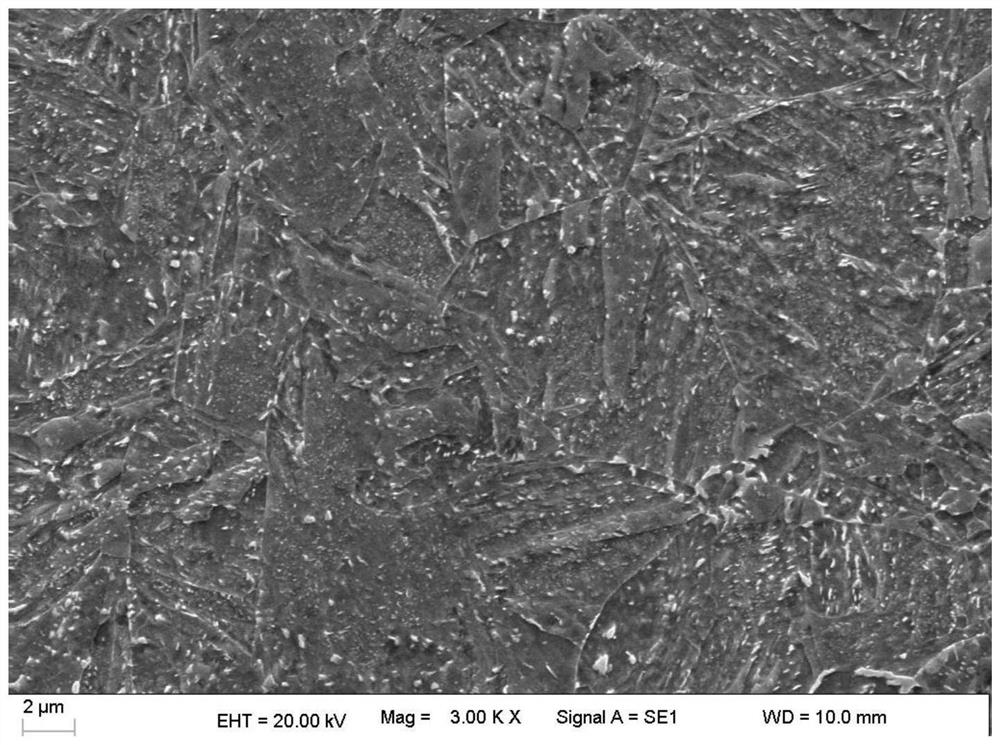

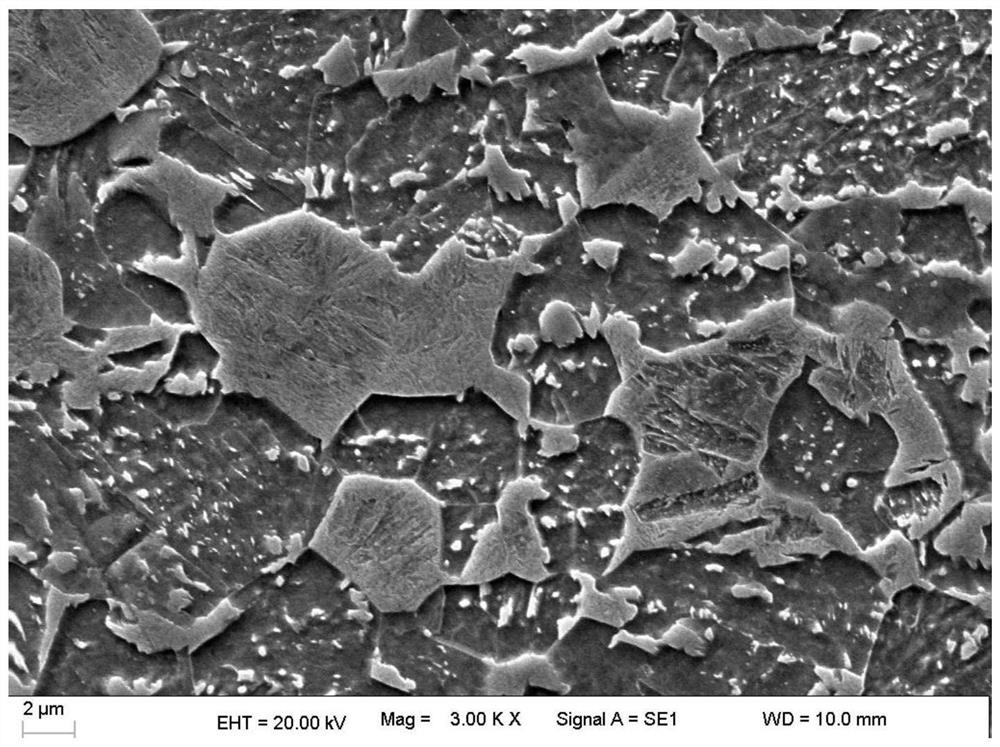

Bainite-based wear-resistant steel and production method thereof

The invention belongs to the technical field of hot continuous rolling plate strips, and particularly relates to bainite-based wear-resistant steel and a production method thereof. The technical problem to be solved by the invention is to provide the bainite-based wear-resistant steel which comprises the following chemical components in percentage by mass: 0.15 to 0.25 percent of C, 0.35 to 0.50 percent of Ti, 0 to 0.05 percent of Nb, 0 to 0.5 percent of Cr, 0.1 to 0.3 percent of Mo and the balance of Fe and inevitable impurities. According to the bainite-based wear-resistant steel and the production method thereof provided by the invention, micron-nano double-scale Ti (C, N) is separated out to serve as a hard phase, so that the wear-resistant service life is prolonged; and through controlling the matrix structure to be granular bainite and a small amount of acicular ferrite, the material is ensured to have an excellent performance.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Kipah-level bainite steel with ultrahigh yield ratio and manufacturing method of Kipah-level bainite steel

ActiveCN114107785AReduce consumptionRapid return temperature controlFurnace typesHeat treatment furnacesChemical elementStrip steel

The invention discloses a Gigaba-grade bainite steel with an ultrahigh yield ratio. The Gigaba-grade bainite steel comprises the following chemical elements in percentage by mass besides Fe: 0.12-0.24% of C, 0.12-0.24% of Si, 0.12-0.12% of Cr, 0.12-0.12% of Mo, 0.2 to 0.5 percent of Si; 1.3 to 2.0 percent of Mn; b: 0.001 to 0.004 percent of the total weight of the raw materials; cr is less than or equal to 0.4%, Nb is less than or equal to 0.06%, Ti is less than or equal to 0.1%, and Mo is less than or equal to 0.4%. In addition, the invention further discloses a manufacturing method and an annealing process for the steel. The annealing process comprises the following steps: (a) heating to a soaking temperature Ts of 840-900 DEG C at a heating rate of less than or equal to 50 DEG C / s in a heating section; (b) preserving heat for less than 5 minutes at a temperature Ts in a soaking section; (c) cooling to (Ts-80)-(Ts-140) DEG C at a first cooling rate of less than or equal to 15 DEG C / s in a slow cooling section; (d) cooling to (Ts-490)-(Ts-440) DEG C at a second cooling rate of more than or equal to (130-Q) DEG C / s in a rapid cooling section, Q = C * 180 + Si * 10 + Mn * 30 + Ni * 50 + Cr * 15 + Mo * 15 + B * 2000; the third cooling speed is larger than or equal to [(Q-80) / 12] and smaller than or equal to [(Q-80) / 8]; and (f) the strip steel is air-cooled to the room temperature in the air cooling section.

Owner:BAOSHAN IRON & STEEL CO LTD

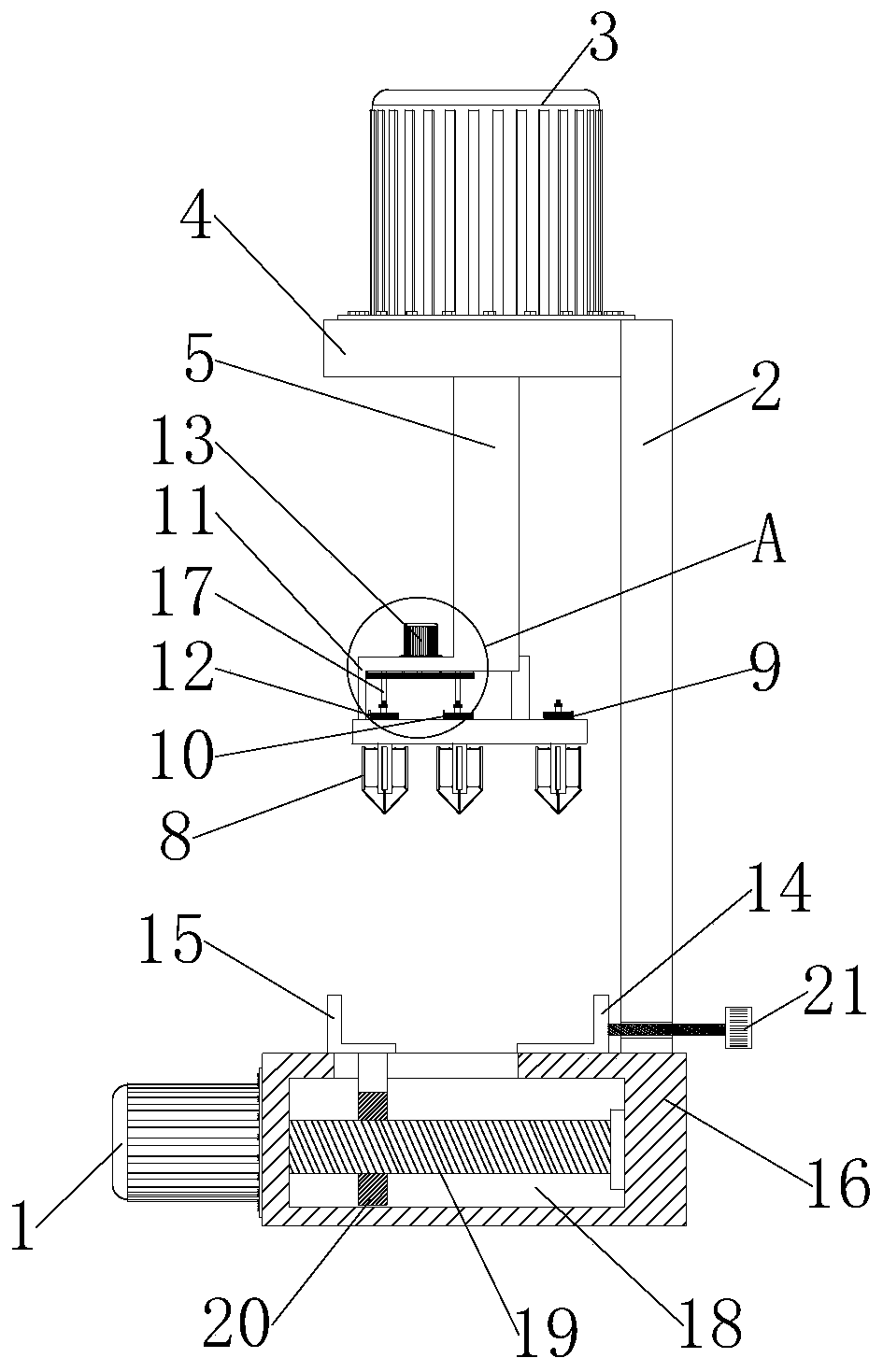

Drilling equipment with hole expanding function

ActiveCN111376054AEasy to drillEasy to reamOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine

The invention discloses drilling equipment with a hole expanding function. The drilling equipment comprises a machine body, a clamping cavity is formed in the machine body, supporting bases are fixedly arranged on the left side and the right side of the clamping cavity correspondingly, supporting columns are slidably connected in the supporting bases, supporting springs are connected between the supporting columns and the supporting bases, a main body is fixedly arranged between the supporting columns, and a clamping device for clamping a workpiece is arranged in the machine body. According tothe drilling equipment, the accuracy of drilling in position and vertical direction can be guaranteed, hole expanding machining can be carried out during drilling, tool replacement is avoided, and the machining speed and the machining efficiency are improved.

Owner:徐州鸿祥机械制造有限公司

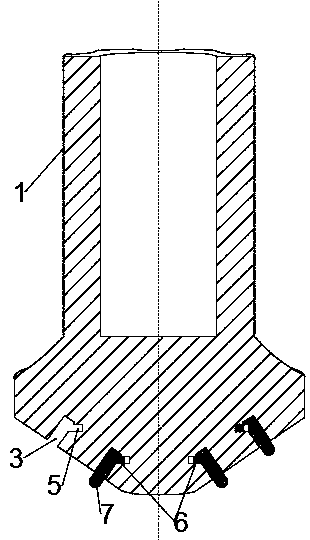

Multifunctional drill bit

The invention discloses a multifunctional drill bit and belongs to the field of drill bit rock drilling and reaming tools. The multifunctional drill bit comprises a columnar connecting body connectedwith a drill rod, a conical impact surface is arranged at one end of the columnar connecting body, alloy tooth mounting holes are formed in the conical impact surface, and a circular-arc-shaped notchis formed in the side wall of the columnar connecting body. The multifunctional drill bit is characterized in that clamping pin holes are formed in the inner walls of the alloy tooth mounting holes; clamping pins in clearance fit with the clamping pin holes are arranged in the clamping pin holes; alloy teeth are mounted in the alloy tooth mounting holes; clamping openings corresponding to the clamping pin holes are formed in the side walls of the alloy teeth; and the columnar connecting body is sleeved with a detachable reaming device. According to the multifunctional drill bit, the advantagesof existing drill bit equipment can be fully utilized while metal teeth are prevented from falling off, the utilizing value of an existing drill bit is explored, efficient reaming can be conducted, and the production cost is saved.

Owner:贵州新生恒创工业设计有限公司

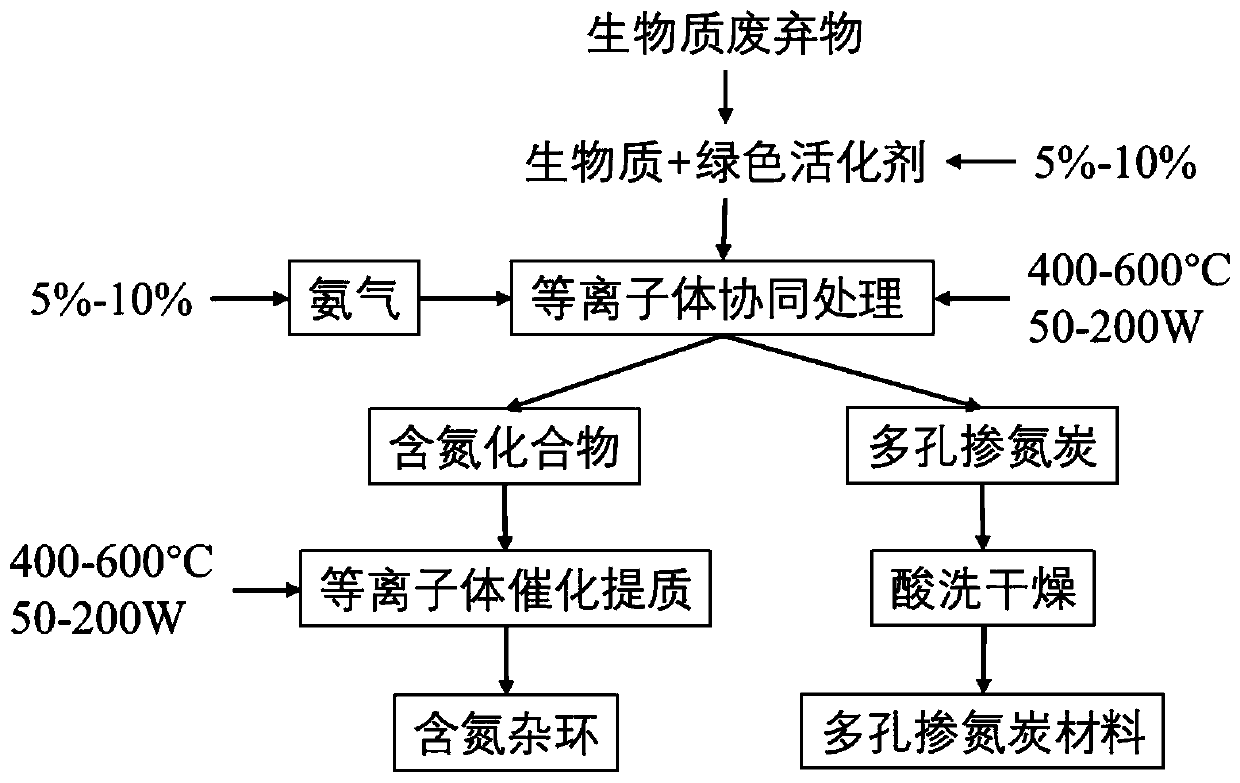

Method for preparing nitrogen-doped carbon and nitrogen-containing heterocyclic ring by using plasma

The invention belongs to the field of biomass utilization, and discloses a method for preparing nitrogen-doped carbon and a nitrogen-containing heterocyclic ring by using plasma. The method comprisesthe following steps: S1, mixing biomass with an activator; S2, reacting under the conditions of ammonia gas and plasma to obtain pyrolysis volatile matter; S3, carrying out a cyclization upgrading reaction on the pyrolysis volatile matter under the action of a catalyst to obtain a solid product and a nitrogen-containing heterocyclic ring volatile matter; and S4, cooling the nitrogen-containing heterocyclic ring volatile matter to obtain liquid oil enriched with the nitrogen-containing heterocyclic ring product, and carrying out acid washing, water washing and drying treatment on the solid product to obtain the porous nitrogen-doped carbon material. Plasma is introduced in the reaction process, the ammonia gas is promoted to be decomposed into nitrogen-containing free radical groups by utilizing plasmas, the reaction of the free radical groups and a biomass pyrolysis intermediate is enhanced, and the synergistic effect of the free radical groups and the activator is enhanced, so that the formation of the nitrogen-containing product is promoted, and the purpose of preparing the high-selectivity nitrogen-containing heterocyclic ring and the high-performance nitrogen-doped carbon by utilizing biomass is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

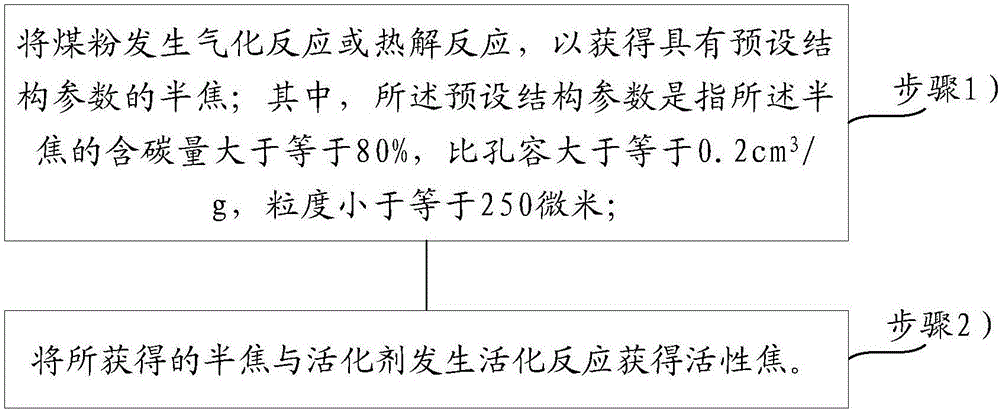

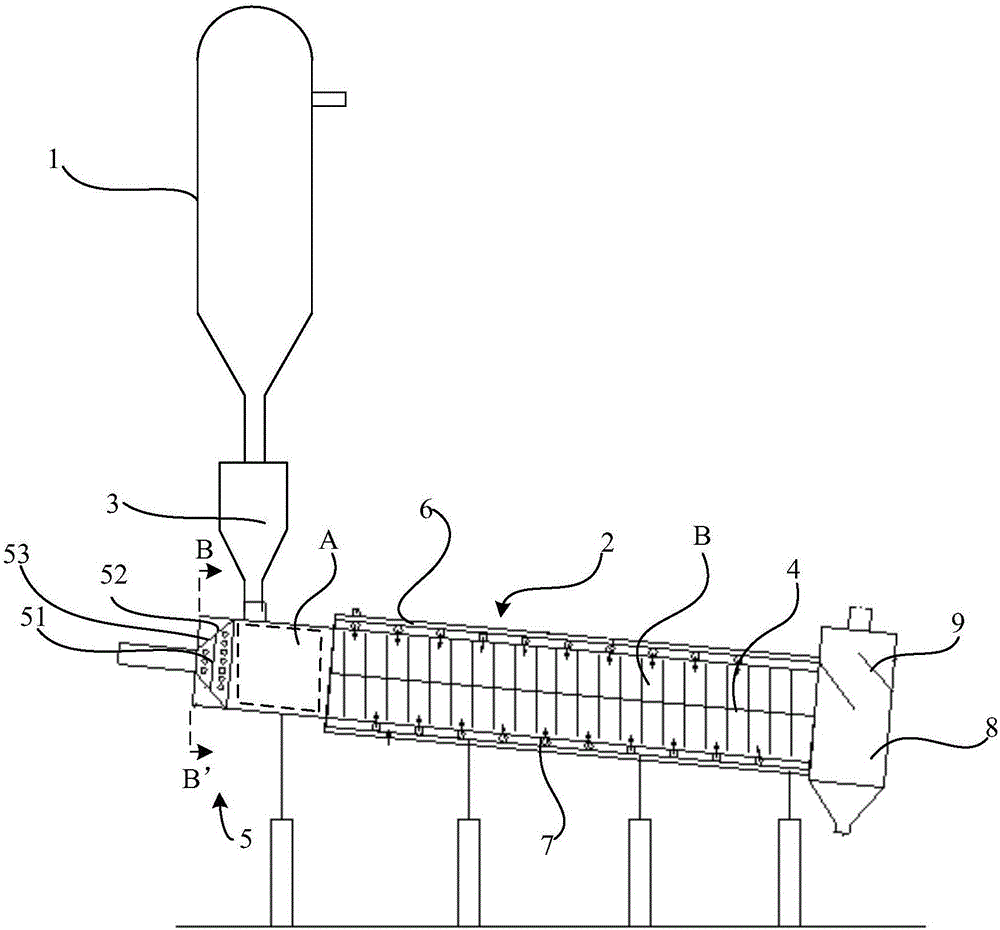

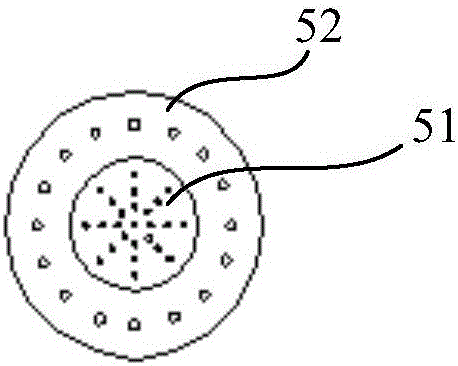

Active coke preparation method and preparation device

ActiveCN106744942AHigh specific pore volumeSpecific pore volumeCarbon compoundsGranularityMicrometer

The invention relates to the technical field of active coke, in particular to an active coke preparation method and preparation device. The active coke with large specific pore volume, high specific surface area and good adsorption performance can be obtained. The active coke preparation method includes the steps: 1) performing gasification reaction or pyrolysis reaction on pulverized coal to obtain semi-coke with preset structural parameters; 2) performing activating reaction of the semi-coke and activators to obtain the active coke. The preset structural parameters indicate that the carbon content of the semi-coke is larger than or equal to 80%, the specific pore volume is larger than or equal to 0.2cm<3> / g, and granularity is smaller than or equal to 250 micrometers. The active coke preparation method is used for preparing the active coke.

Owner:ENN SCI & TECH DEV

Drum drill for drilling anchor rod

The invention relates to a drum drill for drilling an anchor rod, and belongs to the technical field of a foundation fixation building in soil layer drilling. The drum drill comprises a drum drill body and a drill bit, wherein a first through hole which passes through in the axial direction is formed in the drum drill body; a sliding casing is arranged inside the first through hole; a hole expanding blade is arranged on the casing; a base is manufactured at one end of the casing; a second through hole is formed in the base; an opening is formed in a side wall of the casing. During use, the casing slides and is completely fed into the first through hole, one end of the casing is in sealed meshing with the other end of the drum drill body, then the casing and the drum drill body can rotate synchronously; meanwhile water flows through the second through hole and the first through hole in sequence and is ejected out from the first through hole; when the base and the opening completely slide off the first through hole, the hole expansion blade extends outside the sleeve from the opening, and at the same time the water flows through the second through hole and the opening in sequence and is ejected out from the opening. The drum drill is simple in overall structure and reliable in action, and drilling, hole expansion, grouting and drill bit withdrawing can be completed at one time.

Owner:SUZHOU NG FOUND ENG

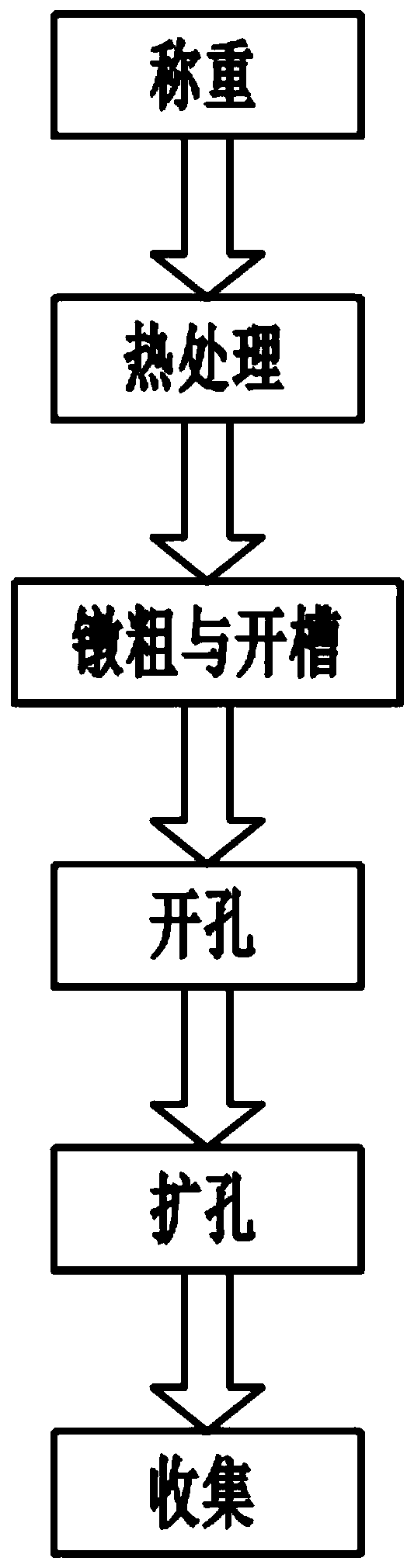

Rolling ring production process

InactiveCN111531329AImprove plastic processing propertiesImprove mechanical propertiesPunchingBroaching

The invention belongs to the technical field of machining of seamless metal rings, and particularly discloses a rolling ring production process. The rolling ring production process comprises the following steps that blanks are weighed, specifically, the blanks and a blank loading device are prepared, and the blanks are sequentially weighed; heat treatment is conducted, specifically, a blank heating device is prepared, and the blank is placed in the blank heating device for heating; upsetting and slotting are conducted, specifically, a blank upsetting device is prepared, and and the blank is put into the blank upsetting device for upsetting and slotting; punching is conducted, specifically, a blank punching device is prepared, and the blank is put into the blank punching device to be punched; broaching is conducted, specifically, a ring rolling machine is prepared, and the blank is put into the ring rolling machine for broaching; and collecting is conducted, specifically, a ring rollingmachine conveying device is prepared, and the blank is put into the ring rolling machine conveying device for recycling. The invention aims to provide a ring rolling production process to solve the problem of difficult hole opening caused by large blank thickness.

Owner:重庆市璧山区茂渝机械制造有限公司

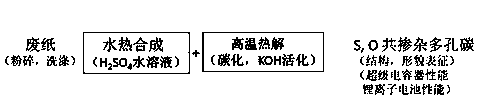

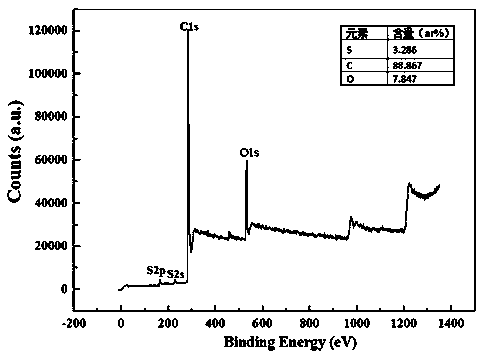

Method for preparing sulfur-oxygen co-doped porous carbon based on paper

PendingCN110902678AReduce lossesReduce collapseCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention belongs to a method for preparing sulfur-oxygen co-doped porous carbon from paper, particularly waste paper. The sulfur doping content of a porous carbon material is regulated and controlled through hydrothermal synthesis of a sulfuric acid solution by utilizing hydrothermal synthesis and high-temperature pyrolysis technologies on the basis of inherent structural characteristics of the paper; and the S and O co-doped porous carbon material is prepared through KOH assisted pyrolysis. The sulfur element doping amount of the prepared porous carbon material can be regulated to 0.3 at%-4at%, and the material presents a reticular hierarchical pore structure. A symmetrical capacitor assembled by taking the material as an electrode has the specific capacitance retention rate of 96% after 10000 times of circulation, has good electric circulation stability, and is worthy of market popularization and application.

Owner:NINGXIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com