Energy-contained shaped charge cover with micro-nano thermite as material

A liner and thermite technology, applied in the field of liner, to achieve the effects of simple molding process, enlarged perforation diameter, and enhanced damage or killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

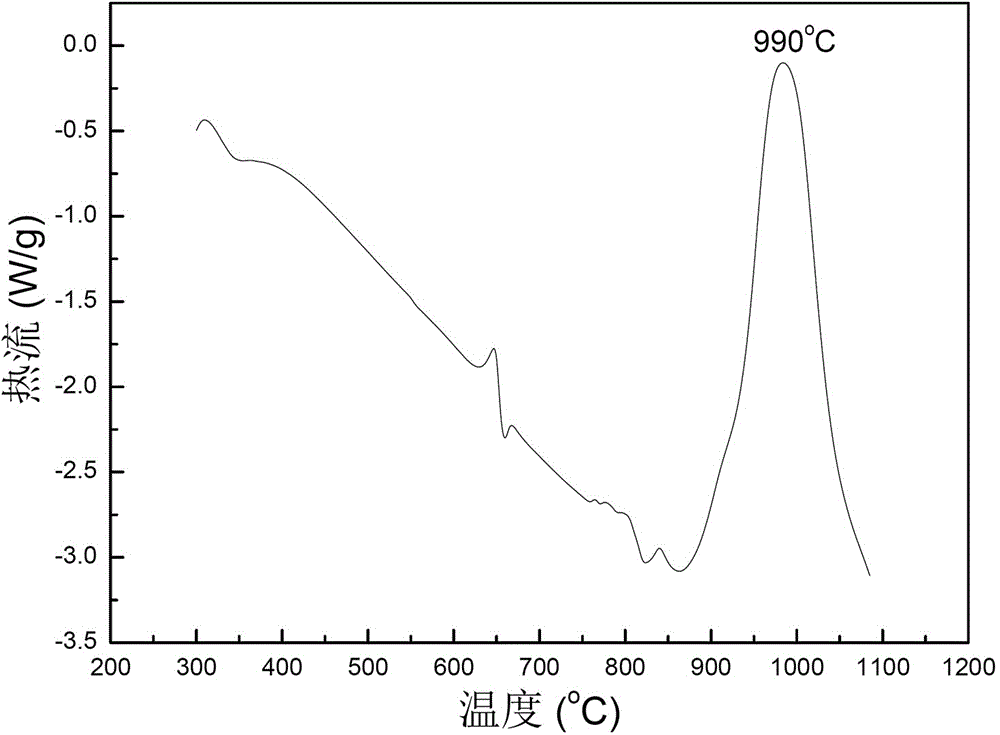

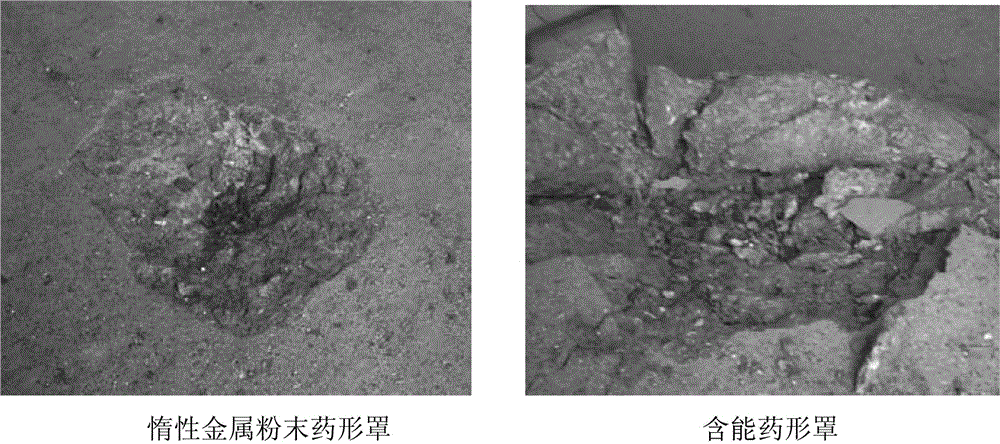

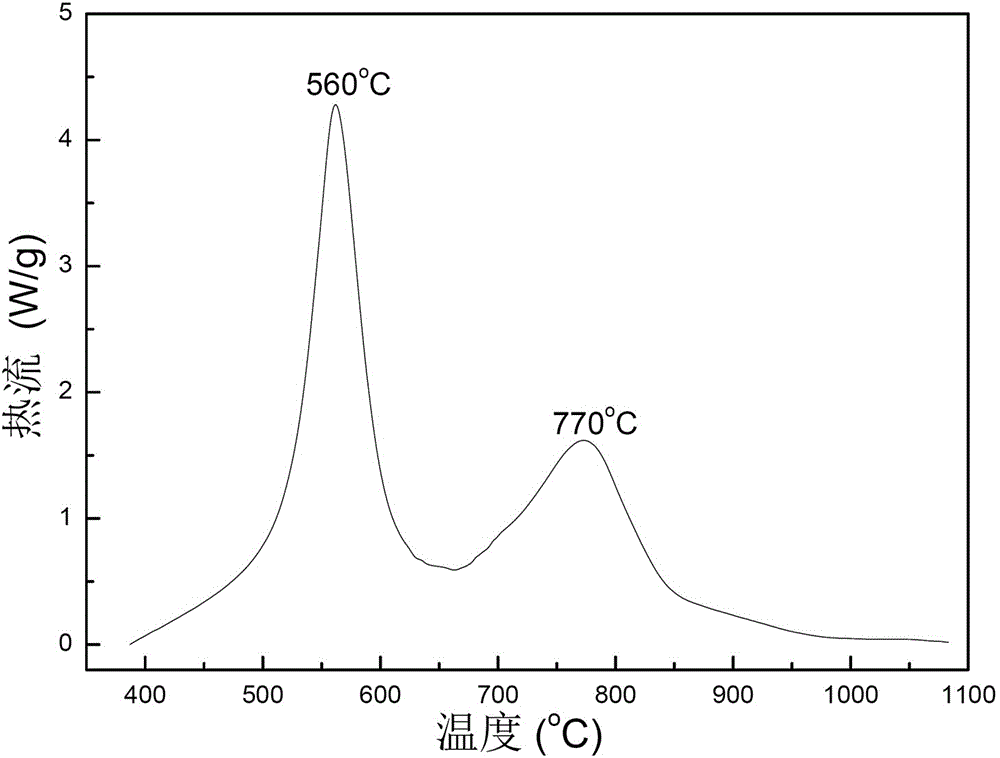

Method used

Image

Examples

Embodiment 1

[0043] 22.7g of aluminum powder with a particle size of about 5μm, 67.3g of α-Fe with a particle size of about 1μm 2 o 3 Put 4g of ferrocene into the ball mill, idle for 15 minutes without adding balls, then stop the machine, add about 40mL of absolute ethanol to the ball mill, add balls after the materials are completely wetted, stop the machine after 1 hour of ball milling, take out the wet materials, and put them at 50 °C drying to obtain the mixed thermite material.

[0044] 3.5gF 2641 and 2.5gPS were dissolved in 50mL ethyl acetate to form a binder solution.

[0045] The above binder solution and the thermite material are fully mixed and kneaded evenly, and granulated with a 12-mesh screen before the material is dry. The wet granules are uniformly dispersed in the tray and dried at 60°C to obtain the modeling powder.

[0046] The molding powder was added to the mold of the medicine-shaped mask, and cold-pressed at 30 MPa, and the formed medicine-shaped mask was kept a...

Embodiment 2

[0049] 26.9g of aluminum powder with a particle size of about 80nm, 65.1g of MnO with a particle size of about 0.8μm 2 Put 3g of ferrocene into the ball mill, idle for 15 minutes without adding balls, then stop the machine, add about 50mL of absolute ethanol to the ball mill, add balls after completely wetting the material, stop the machine after 1.5 hours of ball milling, take out the wet material, and put it at 60 °C drying to obtain the mixed thermite material.

[0050] 3gF 2641 and 2 g of PS were dissolved in 45 mL of ethyl acetate to form a binder solution.

[0051] The above binder solution and the thermite material are fully mixed and kneaded evenly, and granulated with a 12-mesh screen before the material is dry. The wet granules are uniformly dispersed in the tray and dried at 60°C to obtain the modeling powder.

[0052] The molding powder was added into the mold of the drug-type mask, and cold-pressed at 40 MPa, and the formed drug-type mask was kept at 60° C. for...

Embodiment 3

[0055] Put 17.6g of aluminum powder with a particle size of about 2μm, 77.9g of CuO with a particle size of about 1.5μm, and 2g of ferrocene into the ball mill, idle for 15 minutes without adding balls, then stop the machine, and add about 30mL of absolute ethanol to the ball mill , after completely wetting the material, add balls, stop the ball mill after 2 hours, take out the wet material, and dry it at 60°C to obtain the mixed thermite material.

[0056] 1.5gF 2641 and 1 g of PS were dissolved in 30 mL of tetrahydrofuran to form a binder solution.

[0057] The above binder solution and the thermite material are fully mixed and kneaded evenly, and granulated with a 12-mesh screen before the material is dry. The wet granules are uniformly dispersed in the tray and dried at 60°C to obtain the modeling powder.

[0058] The molding powder was added into the mold of the drug-type mask, and cold-pressed at 30 MPa, and the formed drug-type mask was kept at 50°C for 8 days to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com