Automatic feeding mechanism of boring tool

An automatic feeding and boring tool technology, which is applied to metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of low processing efficiency and few feeding directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

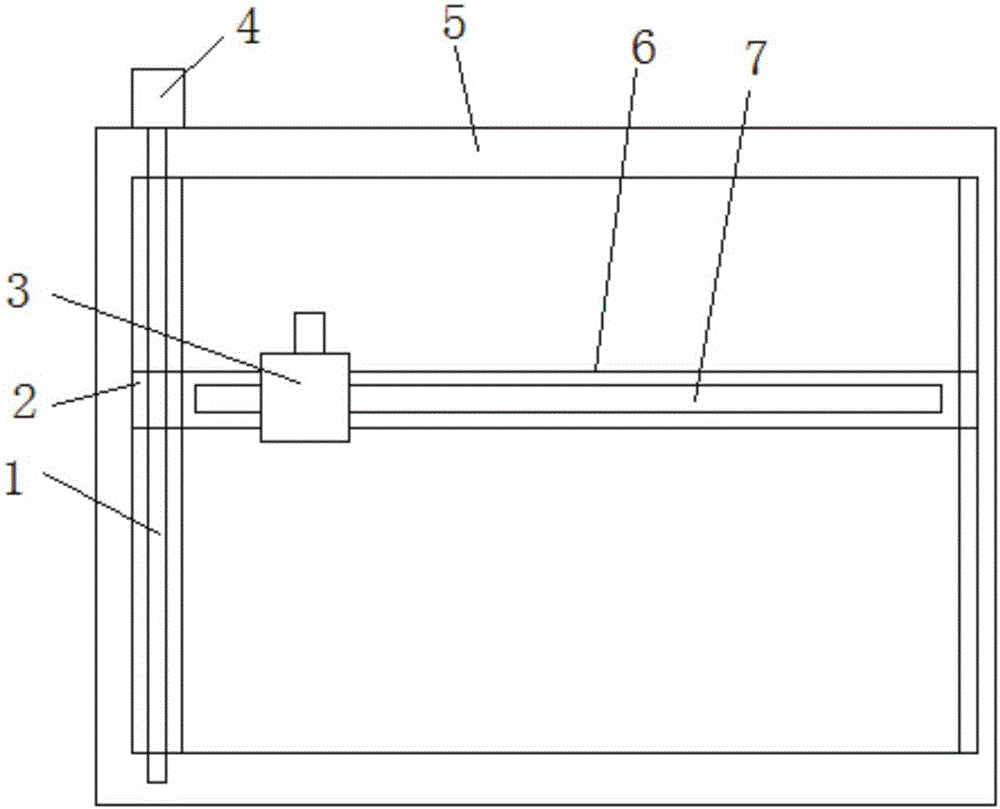

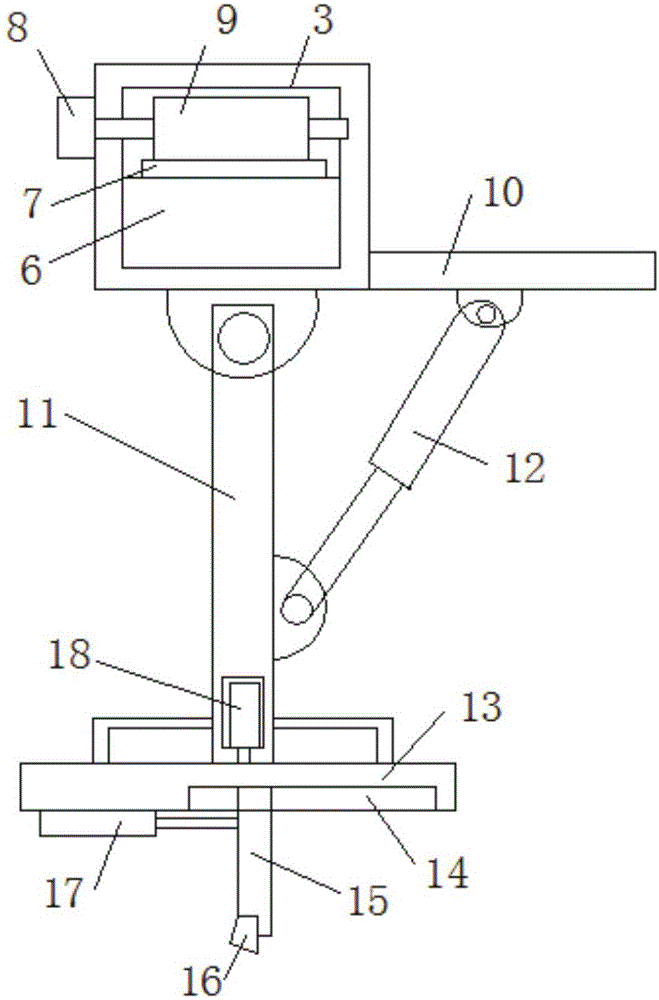

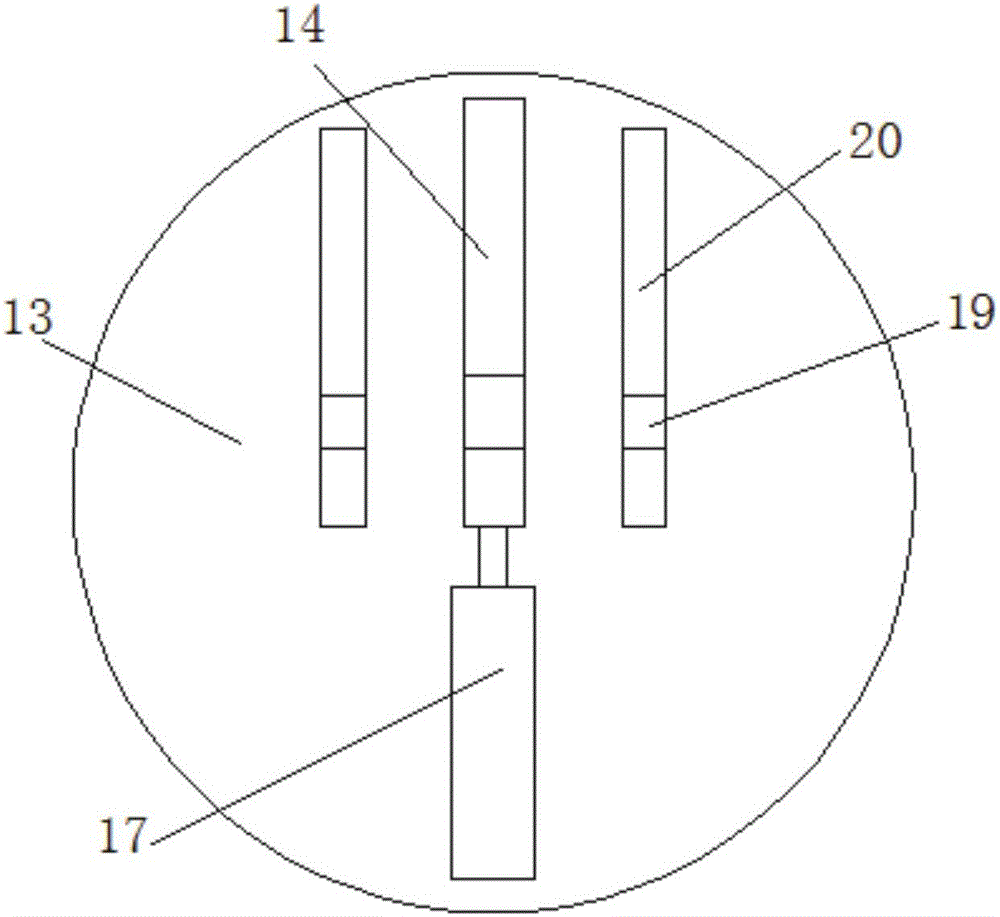

[0018] Embodiment: When in use, the fixed frame 5 is fixed on the machine tool through the fixed plate and screws, the first motor 4 drives the threaded rod 1 to rotate, the threaded rod 1 is threadedly connected with the slide block 2, and drives the cross bar 6 to move back and forth, and the second The motor 8 drives the gear 9 to rotate, the gear 9 and the rack 7 mesh with each other, and drives the movable frame 3 to move left and right on the cross bar 6. The third motor 18 drives the rotating plate 13 to rotate, and the rotating plate 13 drives the cutter head 16 to rotate for cutting and drilling. When reaming is required, the push rod motor 17 drives the connecting rod 15 in the movable groove 14 Inner movement makes the cutter head 16 continuously deviate from the circle to ream the hole. At the same time, the connecting rod 15 drives the limit rod 19 to slide in the limit groove 20, so that the cutter head 16 is more stable. The device can realize left and right forw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com