Drum drill for drilling anchor rod

A technology for barrel drilling and bolting, which is applied to drill bits, drill pipes, drill pipes, etc., can solve the problems of unreliable action, complex overall structure, and single function of the drill bit, and achieve the effect of reliable action and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

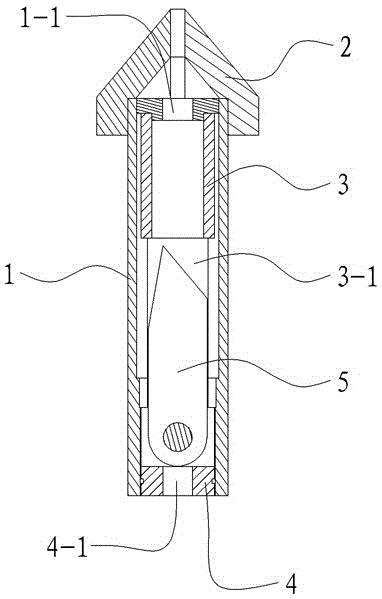

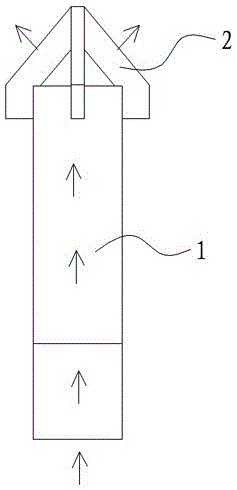

[0027] The anchor rod drilling of the present embodiment uses the barrel drill, as figure 1 , figure 2 and image 3 As shown, it includes a barrel drill body 1 and a drill tip 2 located at one end of the barrel drill body. The barrel drill body 1 is formed with a first through hole 1-1 axially through, and a slidable casing 3 is arranged in the first through hole 1-1, and a base 4 that can be externally connected to a drill pipe is formed at one end of the casing 3. The base 4 is provided with a second through hole 4-1, the casing 3 is provided with a reaming blade 5, and the side wall of the casing 3 is provided with an opening 3-1 for the reaming blade 5 to enter and exit the casing.

[0028] The drill tip 2 may be composed of a plurality of blades which are arranged on the outer wall of the barrel drill body 1 and whose upper ends converge in one place. The blades are evenly spaced three blades or four blades and five blades and more blades, etc. The upper ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com