Multifunctional drill bit

A technology of drill bits and drill rods, which is applied to drill bits, drilling equipment, earthwork drilling, etc. It can solve the problems of increased construction costs, looseness of the drill bit body, and easy collusion, etc., to save manufacturing costs, prolong service life, and achieve high efficiency. The effect of reaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

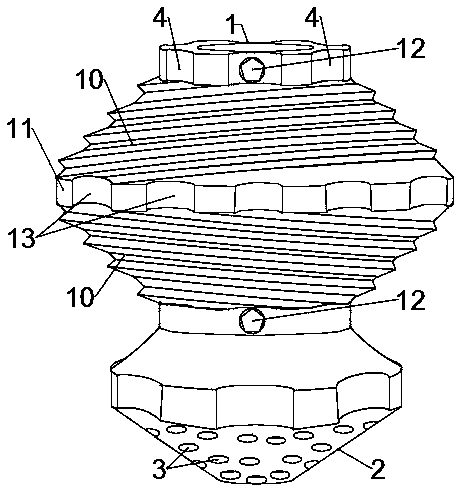

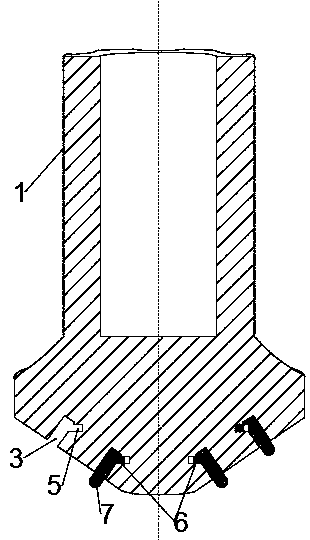

[0021] Example 1. If figure 1 As shown, a multi-functional drill bit, which includes a columnar connector 1 connected to the drill rod, is provided with a conical impact surface 2 at one end of the columnar connector 1, and is provided with an alloy tooth mounting hole on the conical impact surface 2 3. An arc-shaped slot 4 is provided on the side wall of the columnar connecting body 1, a pin hole 5 is provided on the inner wall of the alloy tooth installation hole 3, and a pin 6 with clearance fit is provided in the pin hole 5, The opening direction of the pin hole 5 is perpendicular to the axial direction of the conical impact surface 2, and is located on the inner wall of the alloy tooth installation hole 3 on the side closer to the axis of the conical impact surface 2; The metal block put into the tooth installation hole 3 is cylindrical or arc-shaped; the alloy tooth 7 is installed in the alloy tooth installation hole 3, and the side wall of the alloy tooth 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com