Injection moulded phenolic moulding plastic for communtator

A phenolic molding compound and injection molding technology, applied in the field of phenolic molding compound, can solve the problems of easy cracking of reaming holes, inability to produce, low compression molding efficiency, etc., and achieve easy control of process parameters, environmentally friendly production process, and good product consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

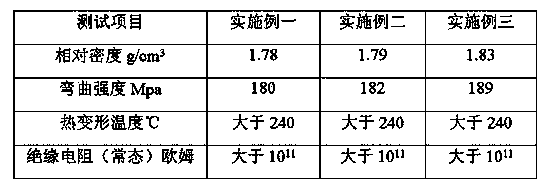

Examples

Embodiment 1

[0021] By weight, 24 parts of phenolic resin (softening point is 90-100 °C GB / T8146-2003, free phenol content is 0.5%-8% ISO8974-2002), 8 parts of hexamethylenetetramine, 2 parts of magnesium oxide , 26 parts of alkali-free glass fiber (average diameter of 8-9μm, average length of 2-6mm), 1 part of stearic acid, 36 parts of wollastonite and 3 parts of polyurethane (model MH-T80, granular, mesh number 75 -300 mesh) After the ingredients are mixed, enter the single-screw extruder (the machine model is WF100, the temperature zone is divided into three sections, the first section feeds preheating, the second section kneads and plasticizes, the third section kneads and homogenizes and discharges ) extrusion, wherein the three-stage temperature of the screw extruder is respectively set to: 45°C for the first stage, 98°C for the second stage, and 85°C for the third stage. Injection molding phenolic molding compound for commutators.

Embodiment 2

[0023] By weight, 20 parts of phenolic resin, 7 parts of hexamethylenetetramine, 1 part of magnesium oxide, 1 part of calcium oxide, 30 parts of alkali-free glass fiber, 0.5 part of stearic acid, 1 part of calcium stearate, 36.5 Part of mica powder and 3 parts of polyurethane batching mix, production process is identical with embodiment one.

Embodiment 3

[0025] By weight, 15 parts of phenolic resin, 6 parts of hexamethylenetetramine, 2 parts of magnesium oxide, 33 parts of alkali-free glass fiber, 1 part of zinc stearate, 36 parts of talcum powder, and 3 parts of polyurethane ingredients are mixed to produce The process is the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com