Reaming machine

A technology of reaming machine and electric motor, which is applied in the direction of reaming device, reaming device, boring/drilling, etc. It can solve the problems of heavy weight, large size, and difficult transportation, so as to achieve high operating efficiency, reduce labor intensity, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

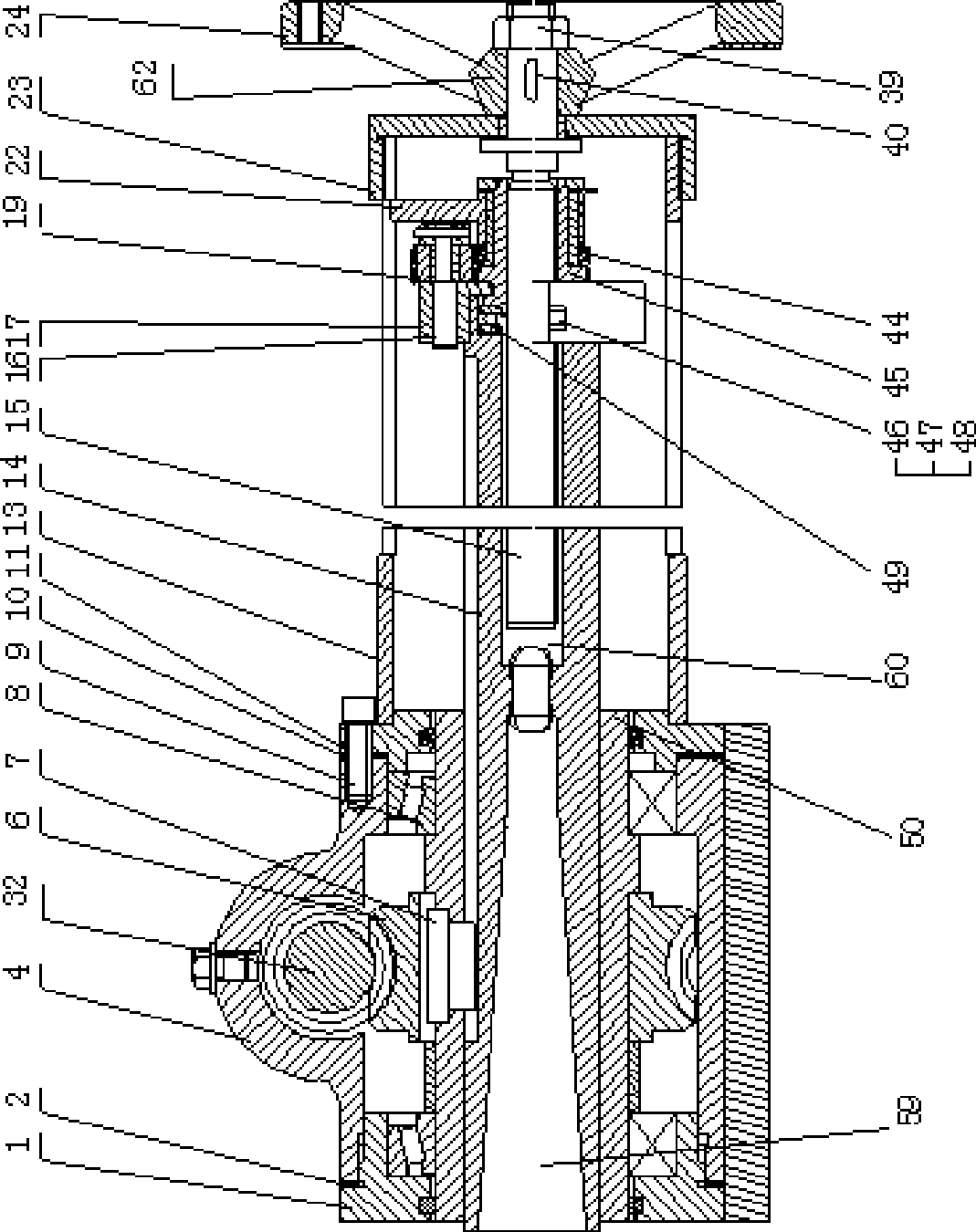

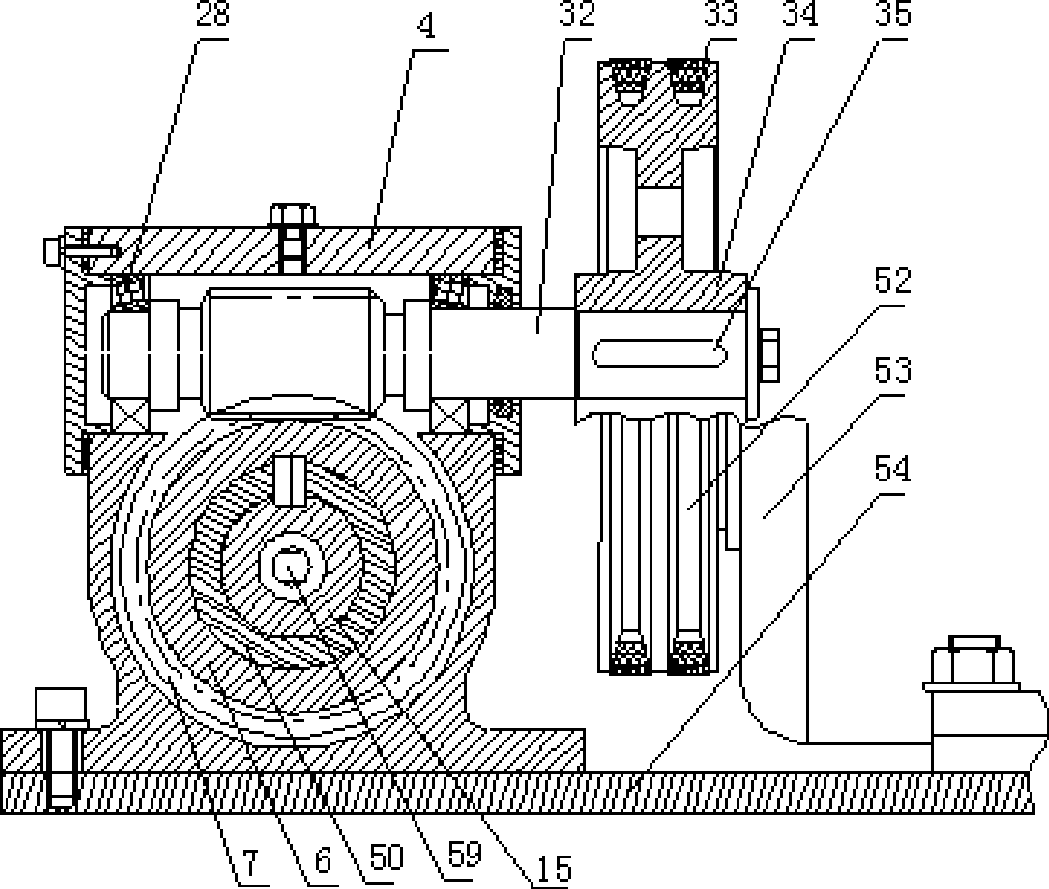

[0009] Such as figure 1 As shown, the upper casing 4 is riveted with the bearing end caps 1, 11 on the cylinder body 13 through screws 9, and the upper casing 4 and the bearing end caps 1, 11 are respectively connected by sealing rings 2, 10, and the worm 32 is installed on the Inside the upper housing 4 , it is connected with the turbine 6 at the opening between the bearing end covers 1 and 11 , the turbine 6 cooperates with the combination key 7 , and the combination key 7 is installed on the transmission shaft 50 . The inner wall of transmission shaft 50 cooperates with the left end of reamer bar 14, and the right end of reamer bar 14 is installed in cylinder body 13 by guide sleeve bar 22; Cavity 60, plane thrust bearing 49, screw mandrel 15 are installed in the cavity 60, plane thrust bearing 49 is installed on the screw mandrel 15, nut bolt spacer 46, 47, 48 Huff clamp ring 17 is installed in cavity 60 On the outer wall, a small shaft 16 is installed in the half clamp r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com