Patents

Literature

333results about "Reaming devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perforating process of composite carbon fiber material product

ActiveCN1986145ASolve the hole layering problemGuarantee the quality of hole makingAutomatic control devicesTransportation and packagingAlloyCutting force

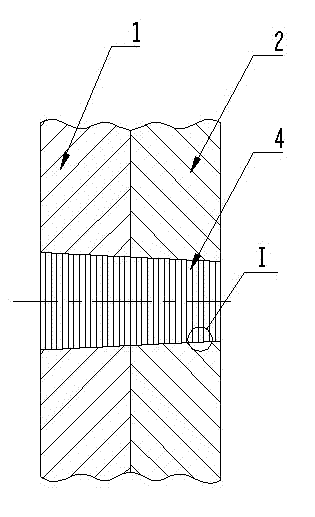

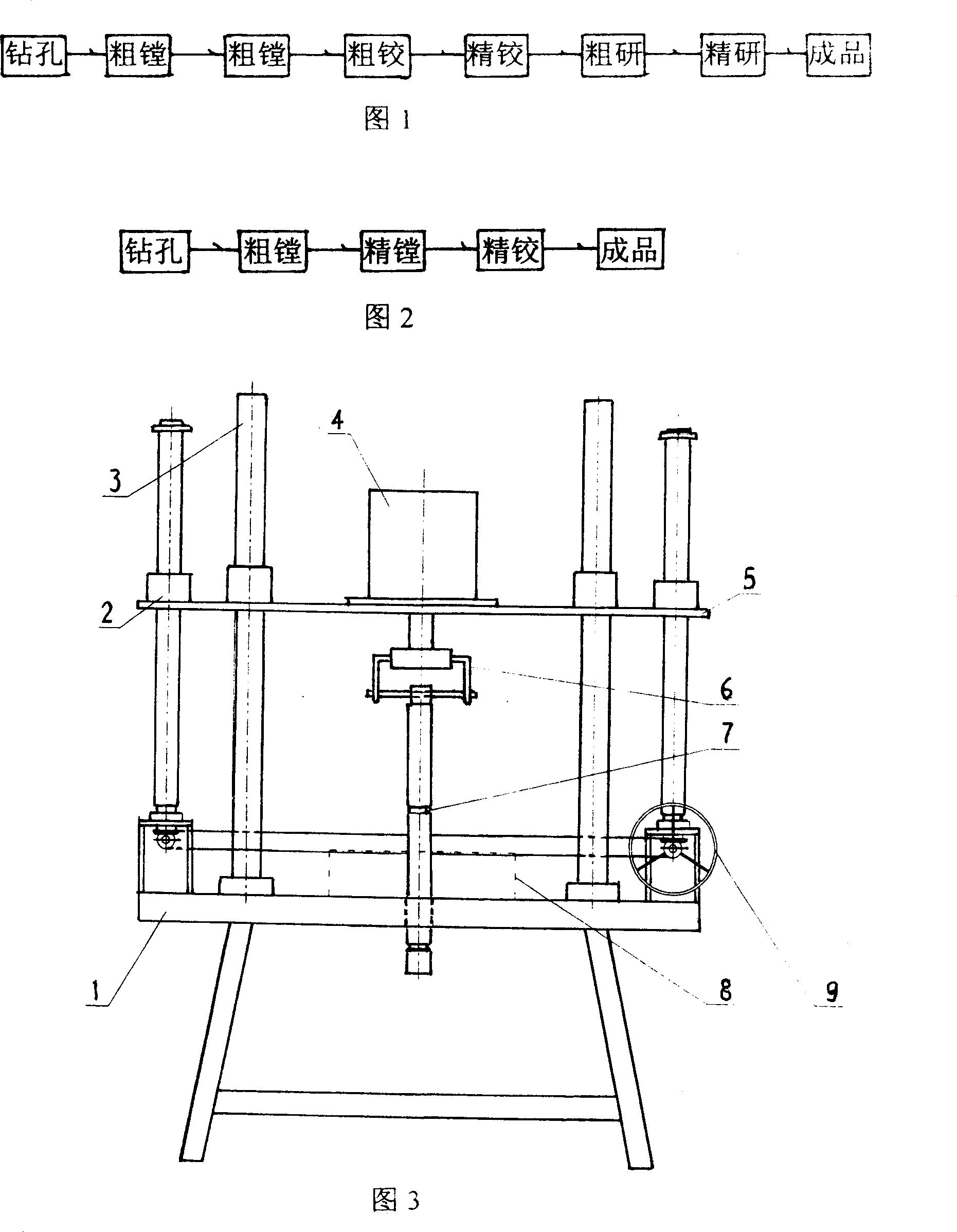

The perforating process of composite carbon fiber material product includes the following main steps: sorting hard alloy drilling bit with helix angle of 20 deg, vertex angle not smaller than 120 deg and chisel width of 0.06-0.1 D; drilling the guide hole based on the cutting force formula F=CFdxffYFvZFN; reaming at medium speed; and statically withdrawing the reamer. The improved perforating process has no delamination of the composite material, high production efficiency and high product quality.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

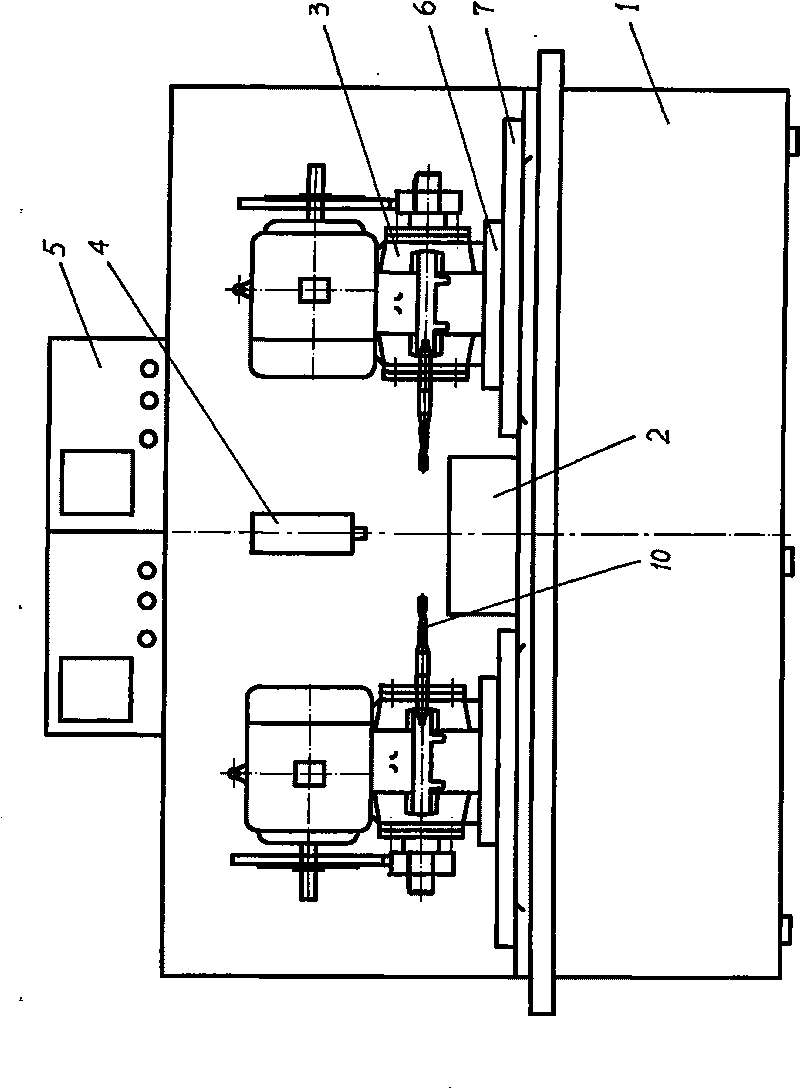

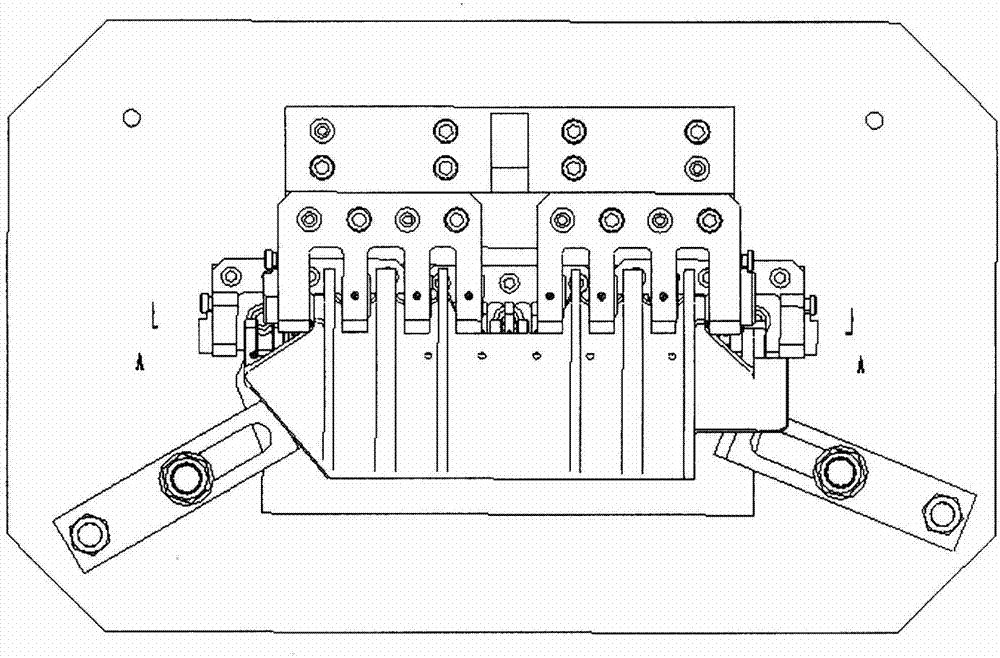

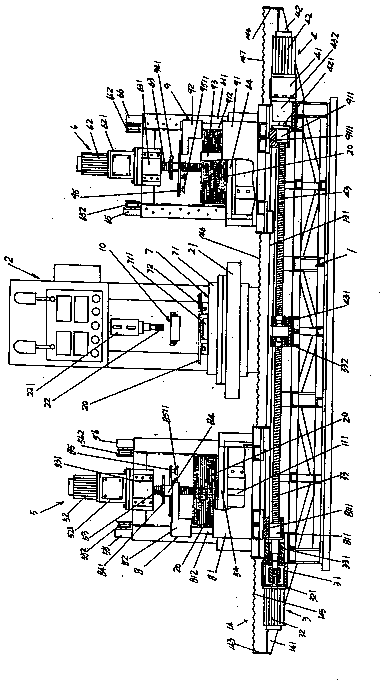

Automatic tapping equipment of wide-angle numerical-control uniflow meter

ActiveCN101695767AEnsure consistencyImprove processing efficiencyReaming devicesBoring/drilling machinesNumerical controlAutomatic test equipment

The invention relates to automatic tapping equipment of a wide-angle numerical-control uniflow meter. The automatic tapping equipment is structurally characterized in that a worktable, power heads and a controller are mounted on a lathe bed, wherein the worktable is arranged in the middle of the lathe bed; a uniflow meter shell-bearing groove is arranged on the upper surface of the worktable; a pneumatic clamping device is arranged above the worktable; the two power heads are respectively arranged at both sides of the worktable; a transversal slide rail and a longitudinal slide rail which are overlapped vertically in a cross way are arranged at the lower parts of the power heads; and an angular disk fixed on the lathe bed is arranged at the lower part of the longitudinal slide rail. The invention can punch and mold both sides of a uniflow meter shell in one step, ensure the shell-machining consistency and improve the machining efficiency. The invention is suitable for drilling and machining a uniflow heat meter shell and can machine and mold other similar working pieces needing bidirectional symmetrical or asymmetry drilling and machining in one step.

Owner:河北丰源智控科技股份有限公司

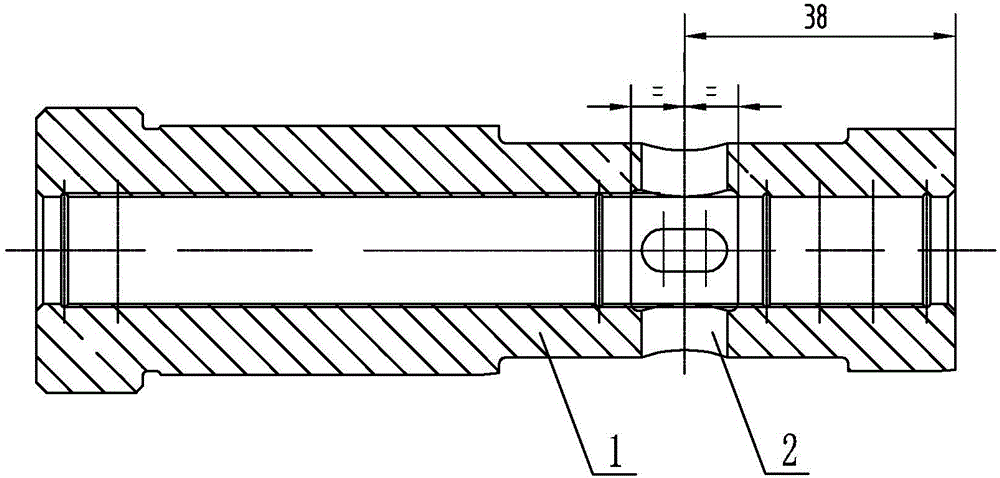

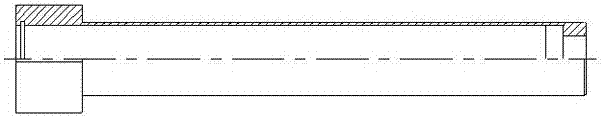

Method for processing deep hole of sleeve of steam turbine by using stepped reamer

InactiveCN103949857AGood chip removal and lubrication conditionsNot easy to leadReaming toolsReaming devicesEngineeringReamer

The invention relates to a method for processing a deep hole of a sleeve of a steam turbine by using a stepped reamer, and relates to a processing method for a deep hole of a sleeve. The method solves the problems that the sleeve has high possibility of deviation and vibration, the cutting elimination is difficult, the processed surface can be scratched and a cutter has high possibility of tipping when the deep hole of the sleeve of the existing steam turbine is processed. The method comprises the following steps: 1, discharging; 2, roughly turning an inner hole, an outer circle and both end surfaces of the sleeve for the first time; 3, quenching the sleeve; 4, roughly turning the inner hole, the outer circle and the both end surfaces of the sleeve for the second time; 5, tempering the sleeve; 6, finely turning the inner hole, the outer circle and the both end surfaces of the sleeve; 7, processing the inner hole of the sleeve on a lathe by using the stepped reamer; 8, grinding the inner hole of the sleeve; 9, drawing a hole line on the processing position of a radial hole; 10, drilling the radial hole; 11, milling the radial hole; 12, nitriding; 13, finely grinding the inner hole of the sleeve; 14, finely grinding the outer circle of the sleeve to complete the process of the deep hole of the sleeve of the steam turbine. The method is used for processing the deep hole of the sleeve of the steam turbine.

Owner:HARBIN TURBINE

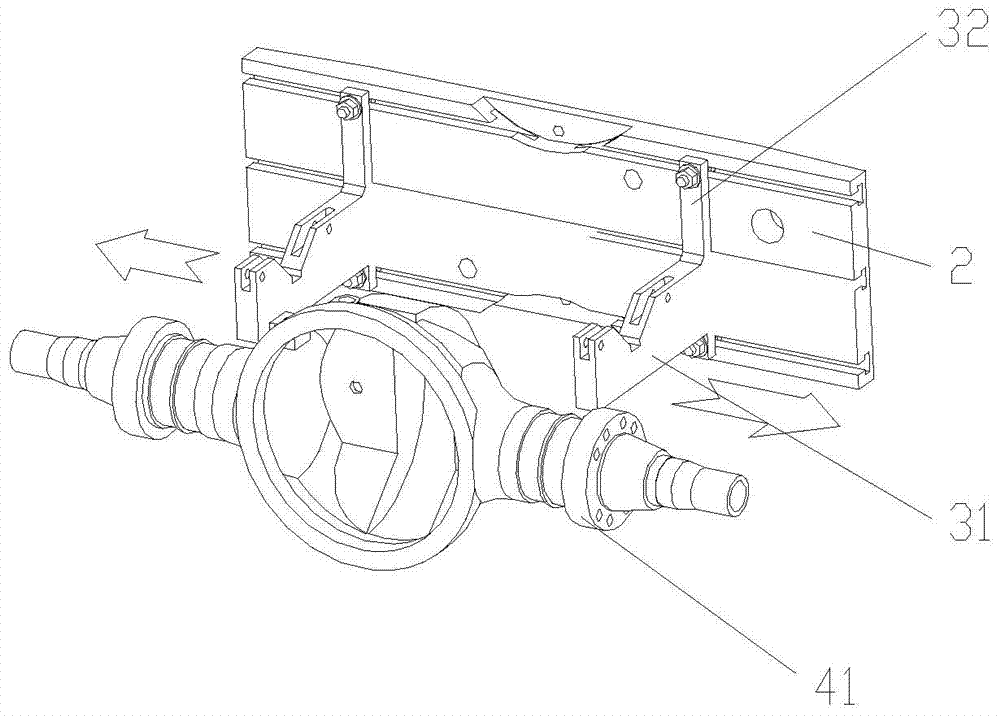

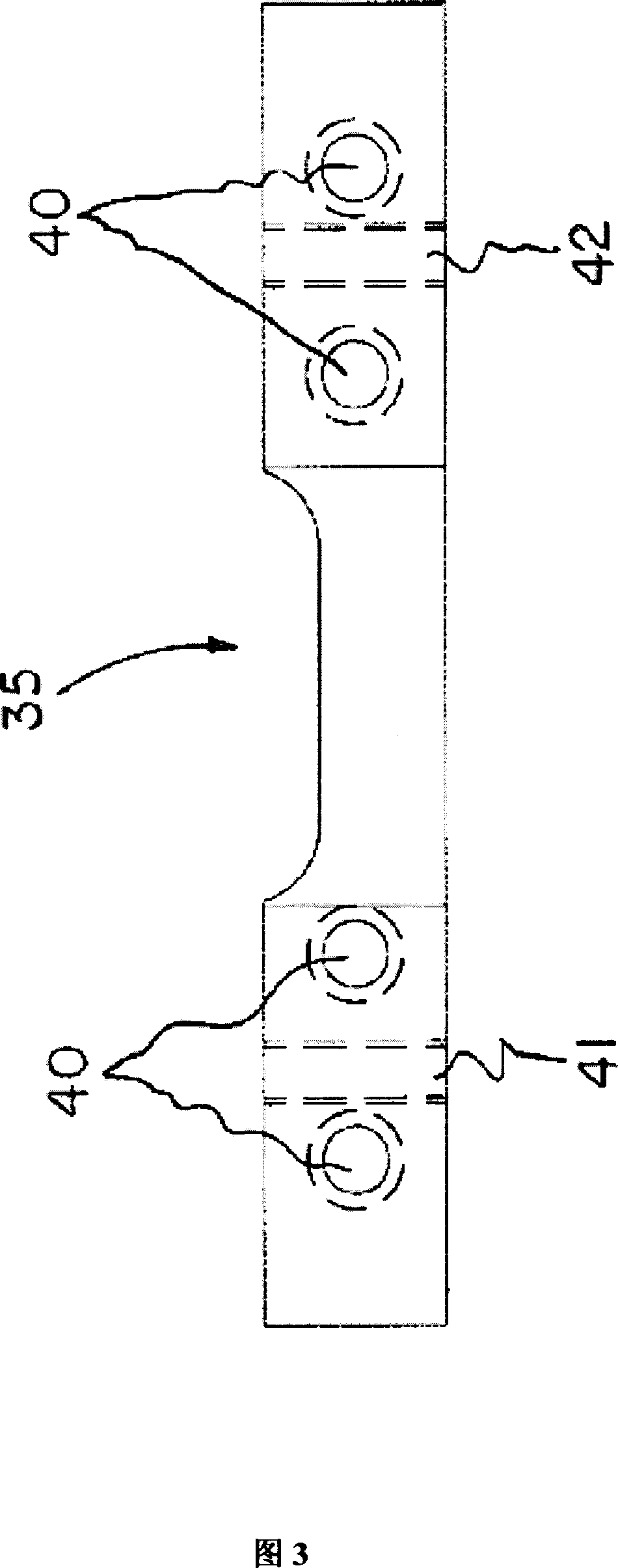

Machining device and machining technology for holes of driving axle housing of industrial vehicle

ActiveCN104325291AReduce the number of clampingReduce labor intensityThread cutting machinesOther manufacturing equipments/toolsMachining processFlange

The invention discloses a machining device and a machining technology for holes of a driving axle housing of an industrial vehicle. The machining device comprises a gyratory base and a gyratory frame, wherein one face of the gyratory frame is rotatably supported on the gyratory base; the other face of the gyratory frame is provided with a driving axle housing installation fixture; the driving axle housing installation fixture comprises clamping seats and drilling fixtures; the clamping seats are symmetrically arranged at the inner side of a flange disc of the driving axle housing in a clamping manner; the drilling fixtures symmetrically sleeve the flange disc of the driving axle housing. The machining process comprises the following steps of drilling / tapping an oil feeding hole and a vent hole in the upper part of the driving axle housing, drilling / tapping an observation hole in the front of the driving axle housing, drilling / tapping an oil discharging hole in the lower part of the driving axle housing, drilling / tapping / reaming a brake installation hole in one end of the driving axle housing, and drilling / tapping / reaming a brake installation hole in the other end of the driving axle housing. According to the machining device and the machining technology for the holes of the driving axle housing of the industrial vehicle, the requirements of brake holes in two ends of the driving axle housing on position degree, coaxiality and verticality of end surfaces can be met, and the machining efficiency for the holes of the driving axle housing can be effectively improved.

Owner:ANHUI ANHUANG MACHINERY

Single-disk reaming method of high-pressure rotor labyrinth disk

InactiveCN101733479AAvoid Scrap SituationsIncrease the frequency of maintenanceReaming toolsReaming devicesEngineeringHigh pressure

The invention discloses a single-disk reaming method of a high-pressure rotor labyrinth disk. A labyrinth disk is independently fixed on a clamp to ensure that the single labyrinth disk carries out single disk reaming when axial deformation is coincident to the assembly state; the labyrinth disk to be processed is independently assembled on the clamp and is tightly pressed by process bolts so as to ensure that the axial deformation of the labyrinth disk and the assembly state are coincident; the clamp in which the labyrinth disk is arranged is installed on a rock arm drilling machine, and then the process bolt on the labyrinth disk is removed every other process bolt; according to the size required to be processed, a proper cutter is chosen, installed on the drilling machine and fixed after centering; rough reaming is carried out on the loosened bolt hole of the labyrinth disk, and then fine reaming is carried out; manual feed is adopted for processing; the cutter rotation speed is 70-80 r / min; the process bolts are used for tightly pressing processed holes, other process blots which do not process holes are loosened, and the bolt holes which are not processed are processed; and a dial test indicator and a ring gauge are adopted for aperture measurement detection.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for processing large workpiece boring hole by using drilling machine

InactiveCN101628371AHigh precisionSimple structureReaming devicesDrill jigsEconomic benefitsProcessing cost

The invention discloses a method for processing large workpiece boring hole by using a drilling machine, comprising the following steps: 1. placing a processing workpiece on a supporting component, centering and fixing the processing workpiece, and reserving drilling machine base storing position below the processing workpiece; 2. lining out a hole line on the processing workpiece according to the position of a boring hole to be processed; 3. manufacturing a template according to the boring hole to be processed, and installing a drilling and reaming sheath on the template so as to manufacture a drilling and reaming sheath template; 4. fixing the drilling and reaming sheath template with the processing workpiece by a fixing component, and putting the drilling machine at a proper position, and then drilling and reaming the hole at different times. By using the method to process end face holes of large workpieces, the processing cost is low, the speed is high and the precision is high. For enterprises without large-sized boring machines, the method can be utilized to extend the business scope of general machine processing enterprises, reduce the cost and increase the economic benefits of the enterprises.

Owner:天津重钢机械装备股份有限公司

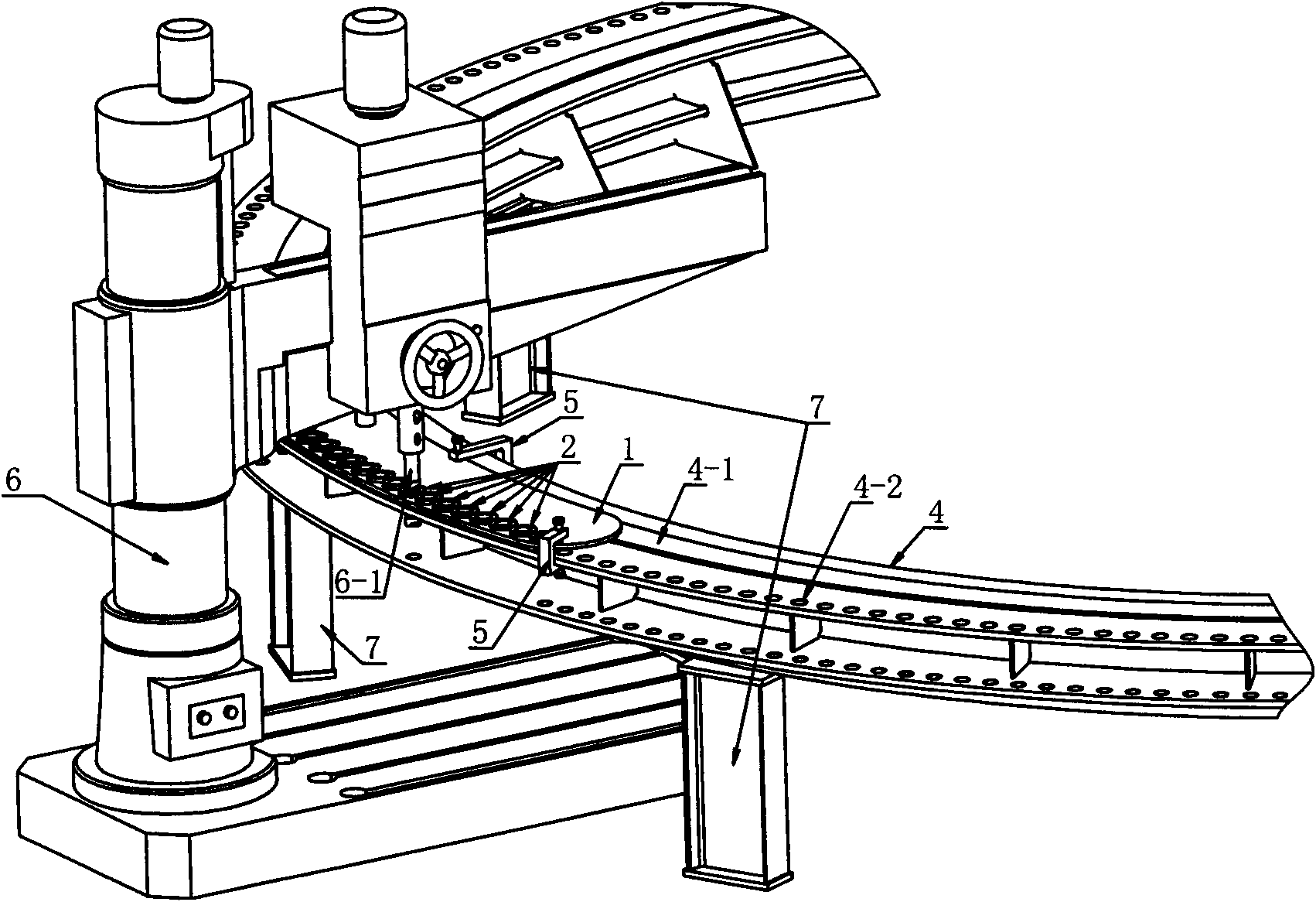

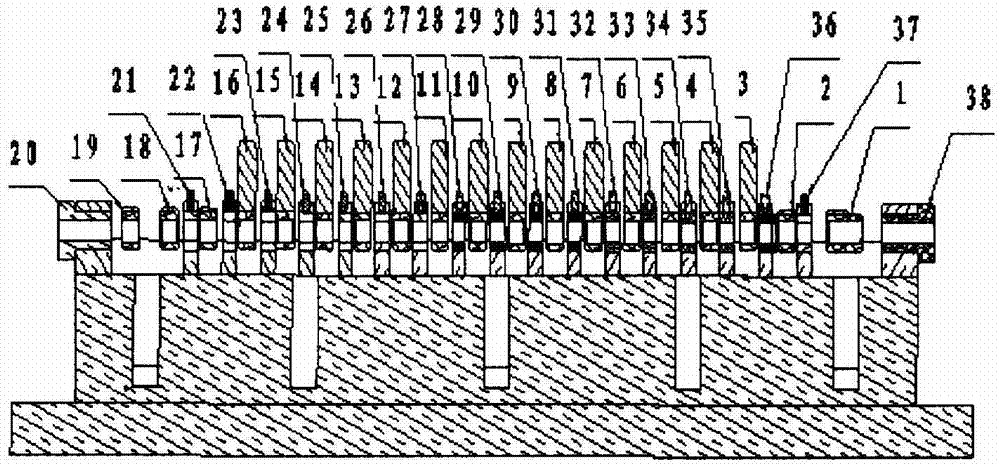

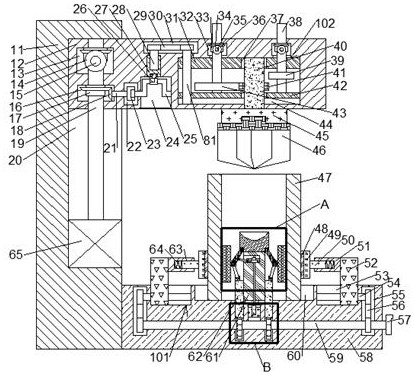

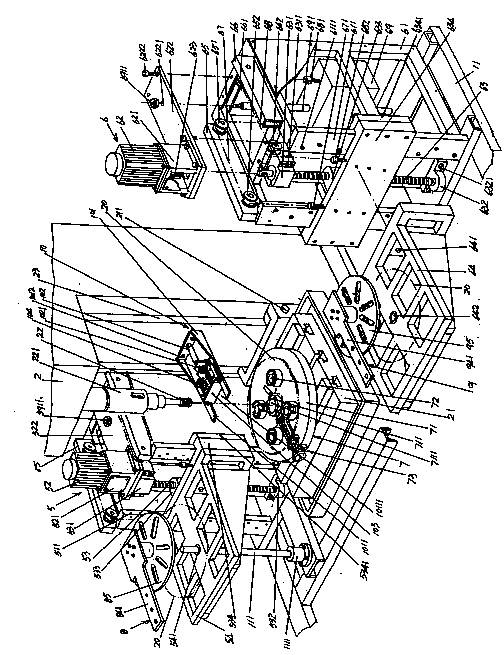

Automatic indexing reaming device

InactiveCN104289759AIncrease pressureFlexible adjustmentPrecision positioning equipmentReaming devicesAutomatic indexingEngineering

The invention discloses an automatic indexing reaming device which aims to meet the demand for reaming single cylinder workpieces efficiently. The automatic indexing reaming device comprises an indexing disk which is connected to a machine frame in a rotating mode. A pawl is arranged at one end of the cylindrical indexing disk. An oscillating rod is hinged to the indexing disk. The other end of the oscillating rod is provided with a strip hole and is connected with a crank as a driving link. A pawl abutting against a ratchet wheel is hinged to the oscillating rod. A feeding wheel is arranged at the other end, without the ratchet wheel, of the indexing disk. Charging holes are evenly formed in the circumferential edge of the feeding wheel. A sliding way is arranged above the feeding wheel. A reaming station is arranged on the side, in the forward rotation direction, of the charging holes, a pressing wheel is arranged on the reaming station and located outside the charging holes, a reamer which can axially move in a reciprocating mode is arranged at the position, on the side of the charging holes, of the reaming station, and a sliding way used for conveying the workpieces out is arranged above the feeding wheel. By the adoption of the automatic indexing reaming device, the procedure that the single cylinder workpieces are reamed in batches is completed, manual work is not needed basically, it is only required that the rotation speed of the crank and the action of the reamer are coordinated, and workpieces are reamed efficiently in batches.

Owner:CHONGQING SHANNENG INSTR

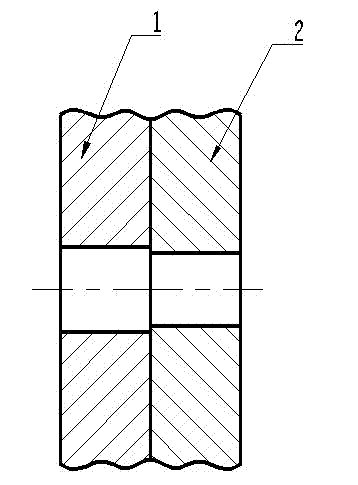

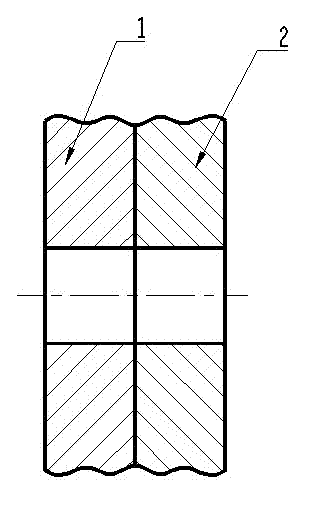

Large-diameter and high-precision taper hole processing method

The invention discloses a large-diameter and high-precision taper hole processing method, which comprises the following steps: A, aligning and tightening two parts constituting a taper hole; B, linearly pre-drilling a bottom hole on a drilling machine; C, enlarging the diameter of the bottom hole to be the same as the minimum diameter of the small end of a finished product taper hole and ensuring the position precision of the hole, D, pre-processing the bottom hole into a stepped hole (steps at all stages of the stepped hole are equidistant in the axial direction and have the same increment in the radial direction), and E, reaming the bottom hole into the finished product. The invention can effectively prevent a reamer from being damaged due to unstable cutting; since all parts of the reamer are consistent in degree of wear and uniformly stressed, the taper hole precision can be ensured stably; meanwhile, the reamer axially feeds at a step depth of the stepped hole formed through pre-processing the bottom hole, so that the reaming efficiency is improved greatly.

Owner:CHONGQING GEARBOX

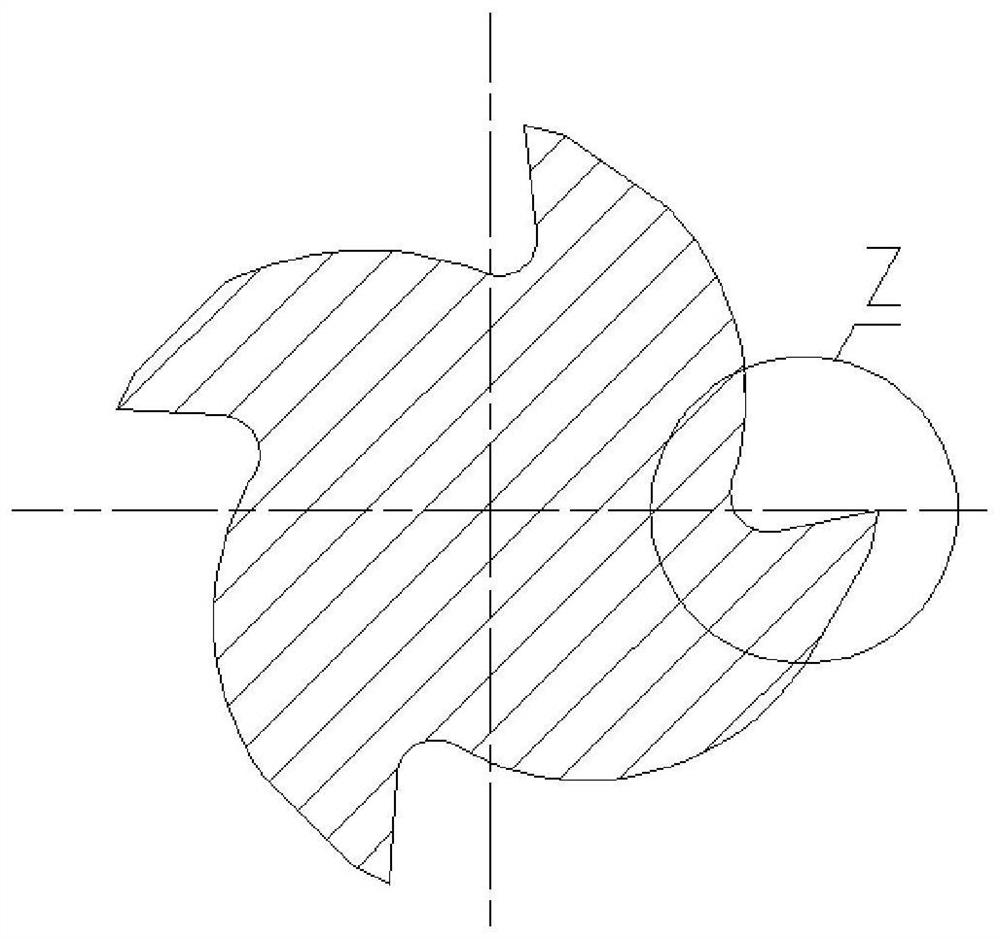

Special-shaped tube broacher

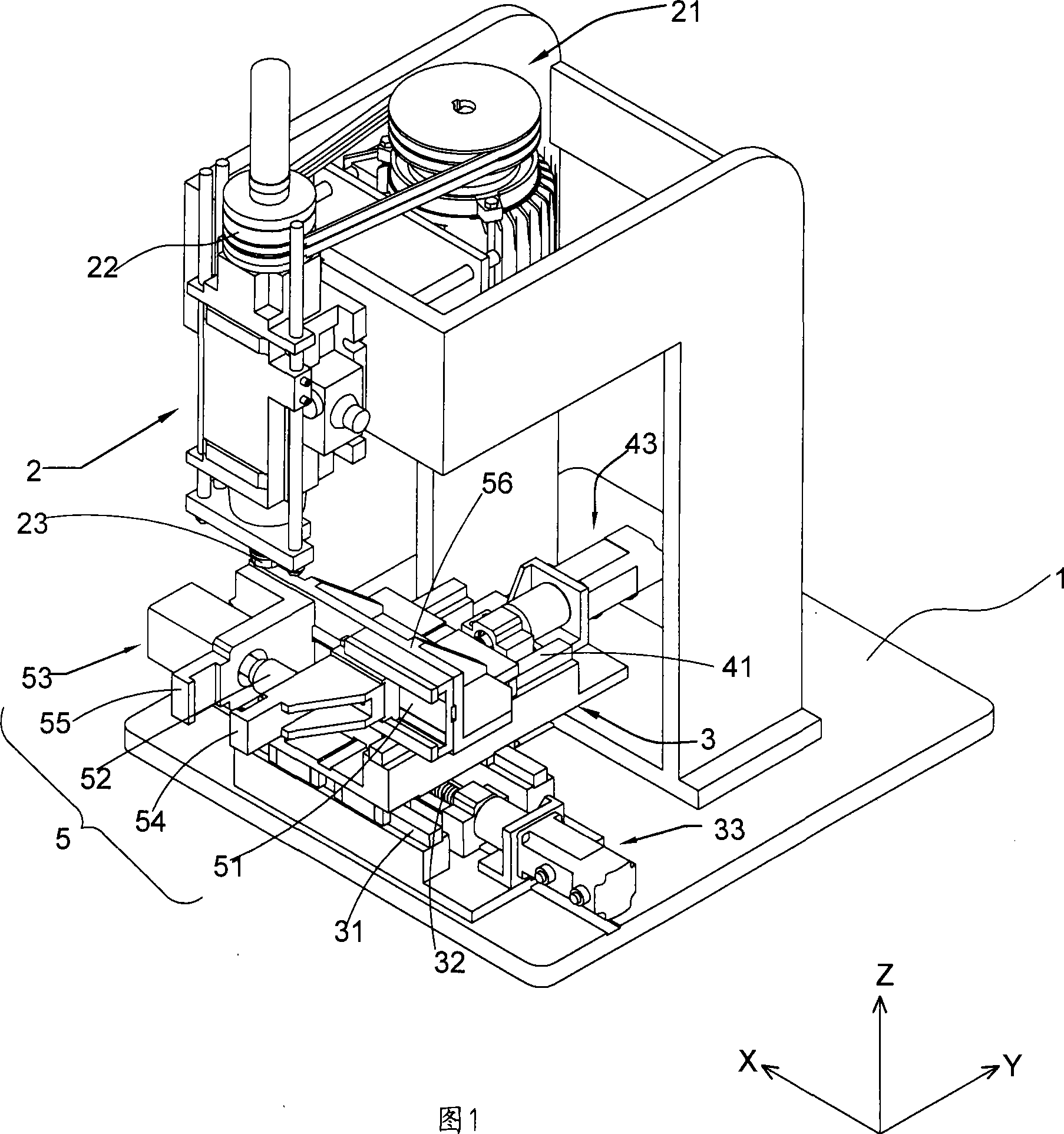

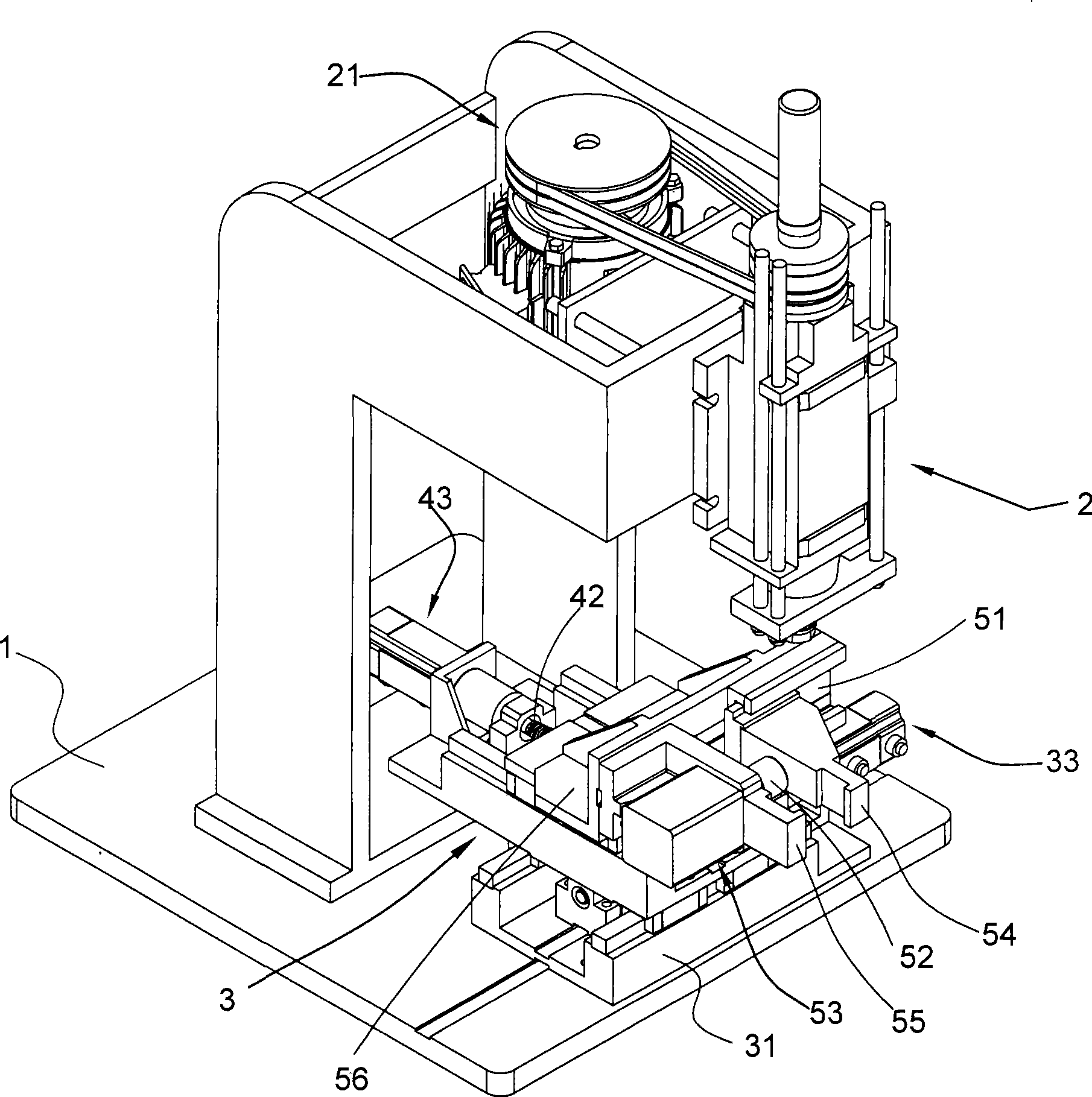

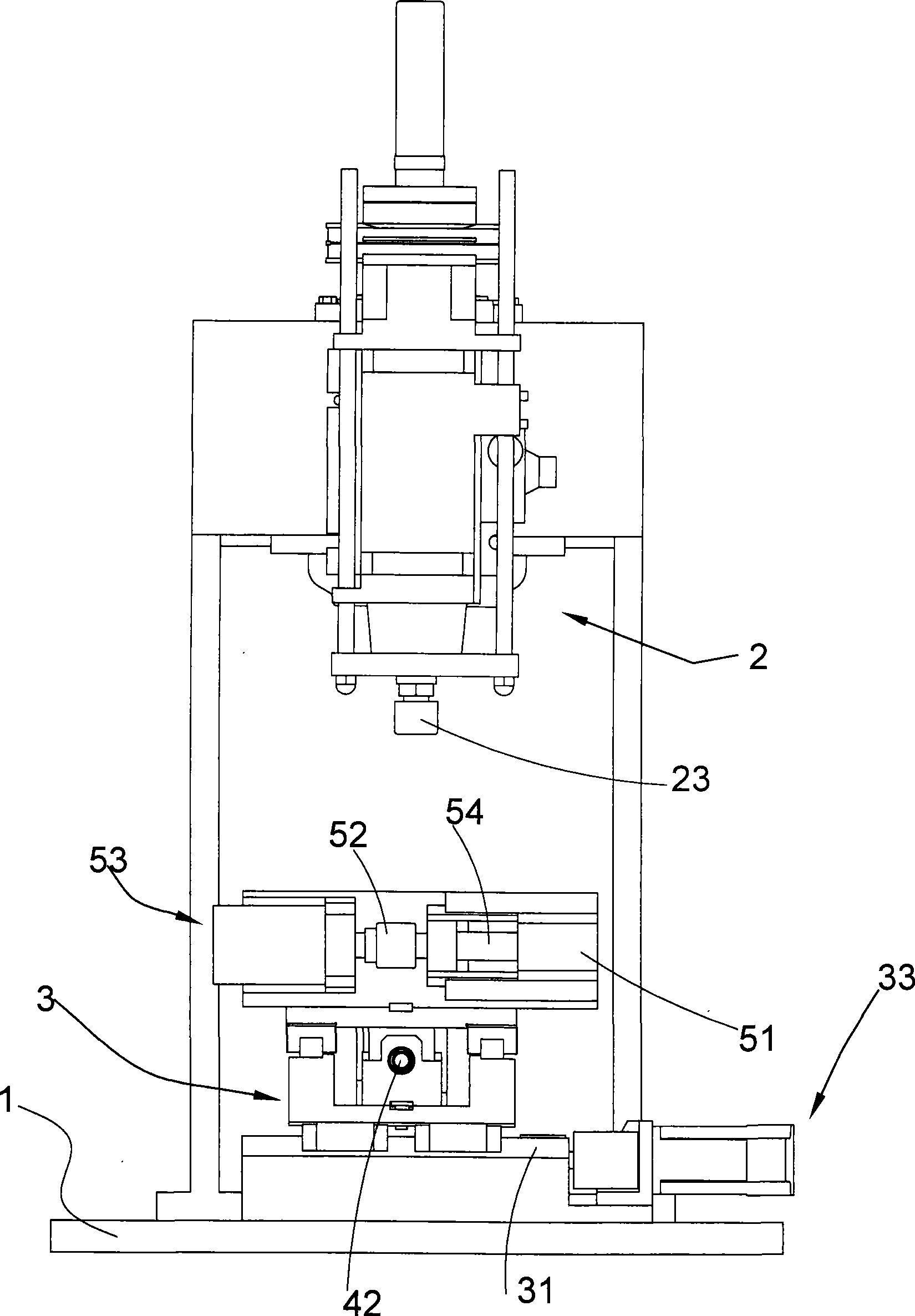

The invention relates to a special pipe reaming bench for processing a carboform pipe. The special pipe reaming bench comprises a stander, a tool apron which is fixedly arranged on the stander, a clamping device which is used for clamping a workpiece to be processed; wherein, the tool apron is rotatablely provided with a tool bit which can rotate along the self axial lead; the surface of the outer annulus of the tool bit is provided with carborundum; a seat body is provided with an X axis guide way which extends along the X direction; the X axis guide way is matched and connected with an X axis glide seat in a sliding way; the X axis glide seat is provided with a Y axis guide way which is perpendicular to the X axis guide way; the clamping device is arranged on the Y axis guide way in a sliding way; the axis lead direction of the tool bit is perpendicular to the X direction and the Y direction. By the technical proposal, the special pipe reaming bench can carry out reaming processing on the inner hole of the carboform pipe with various shapes.

Owner:庄添财

Ultrasonic stamping type cutting and extruding integrated machining method

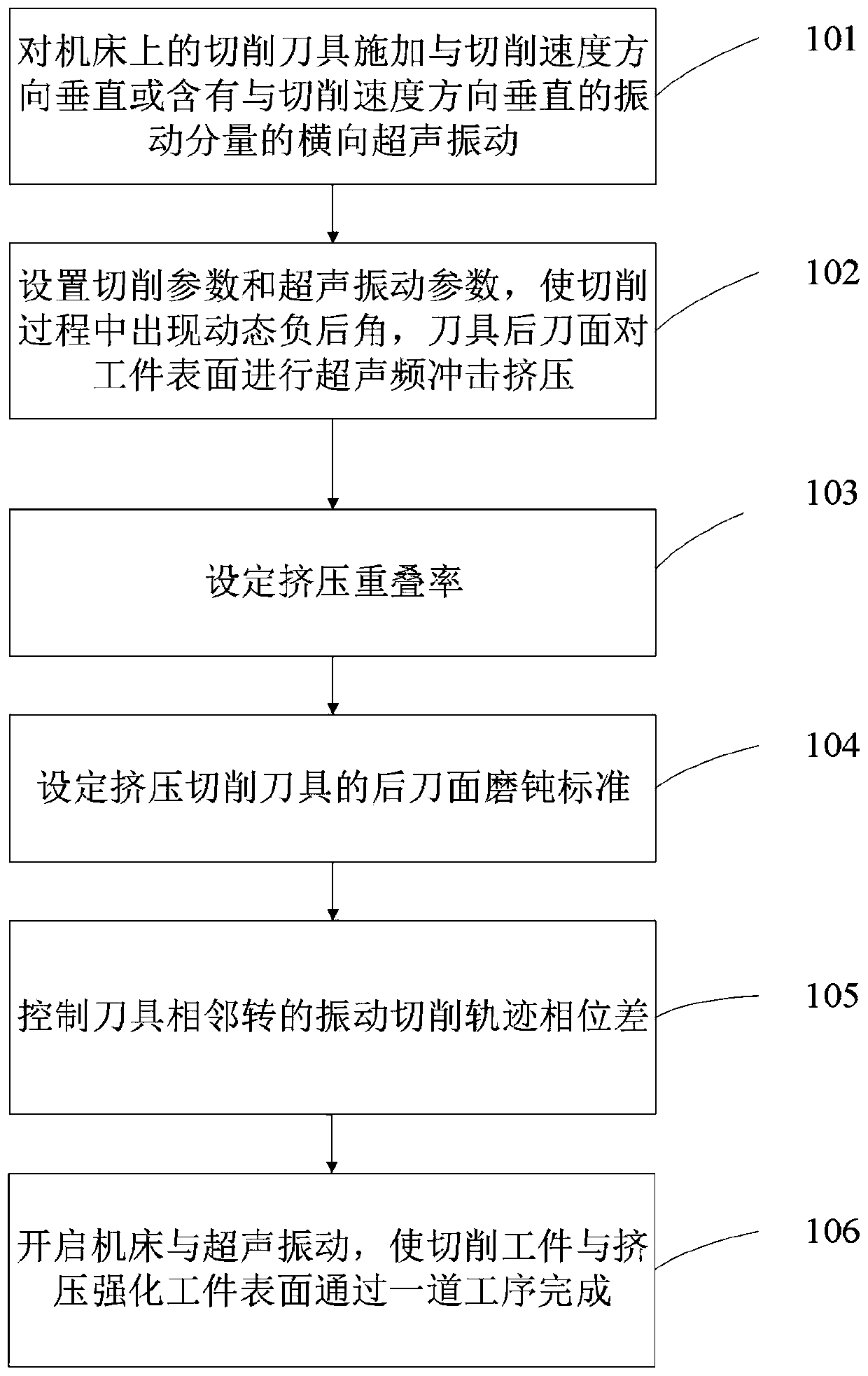

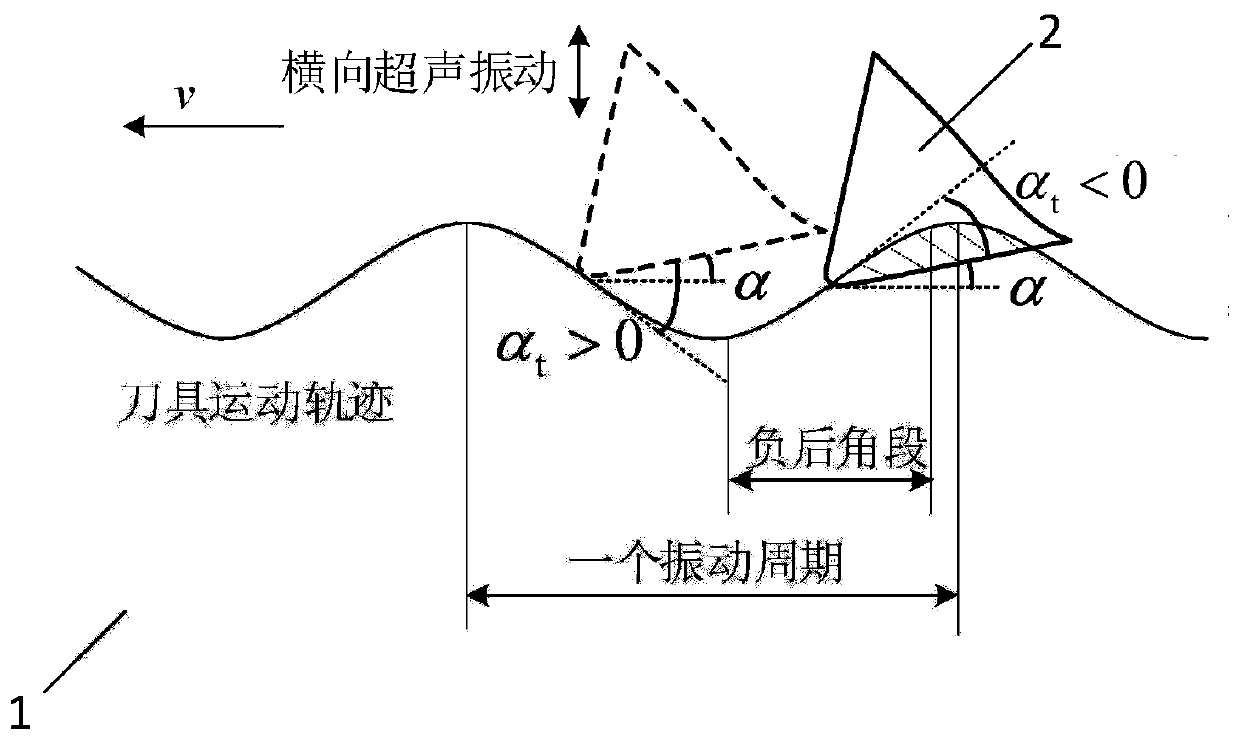

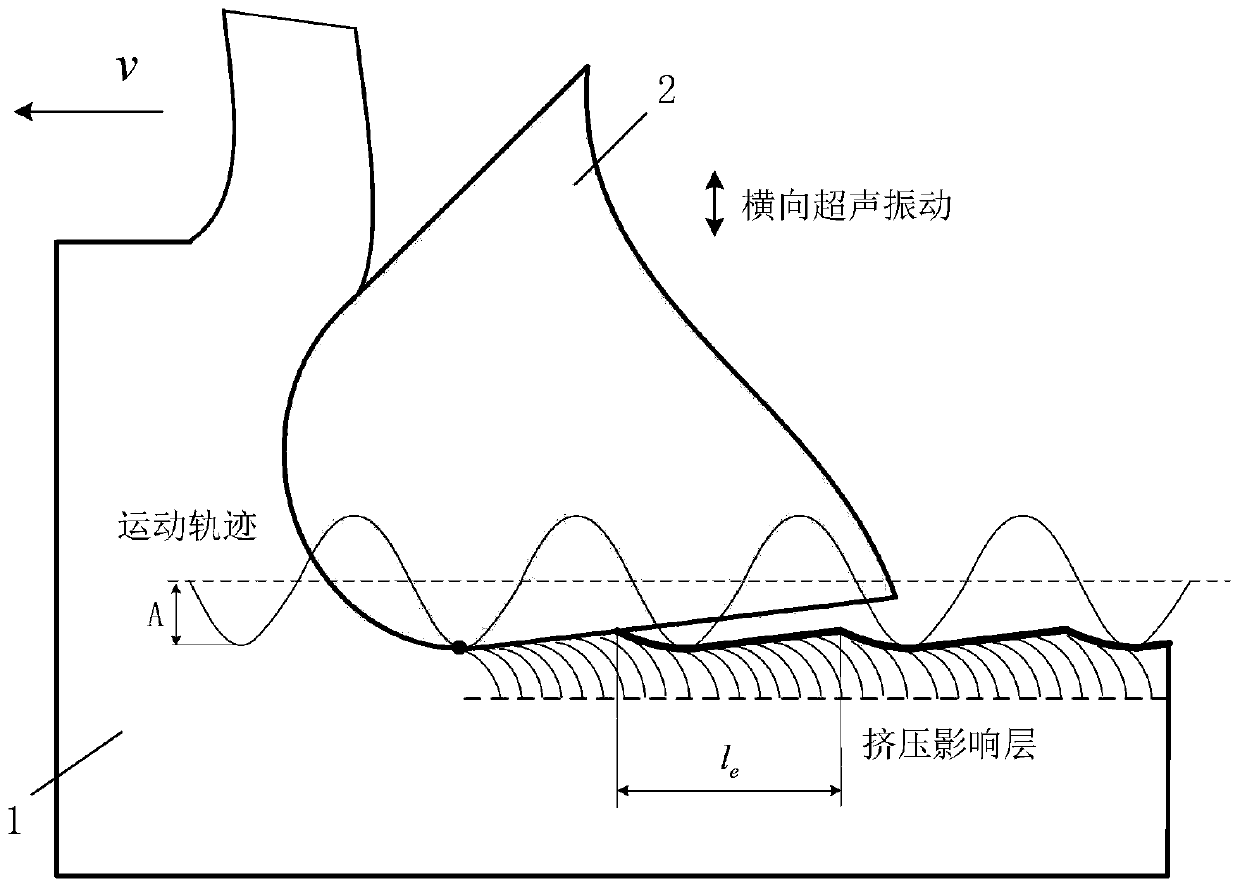

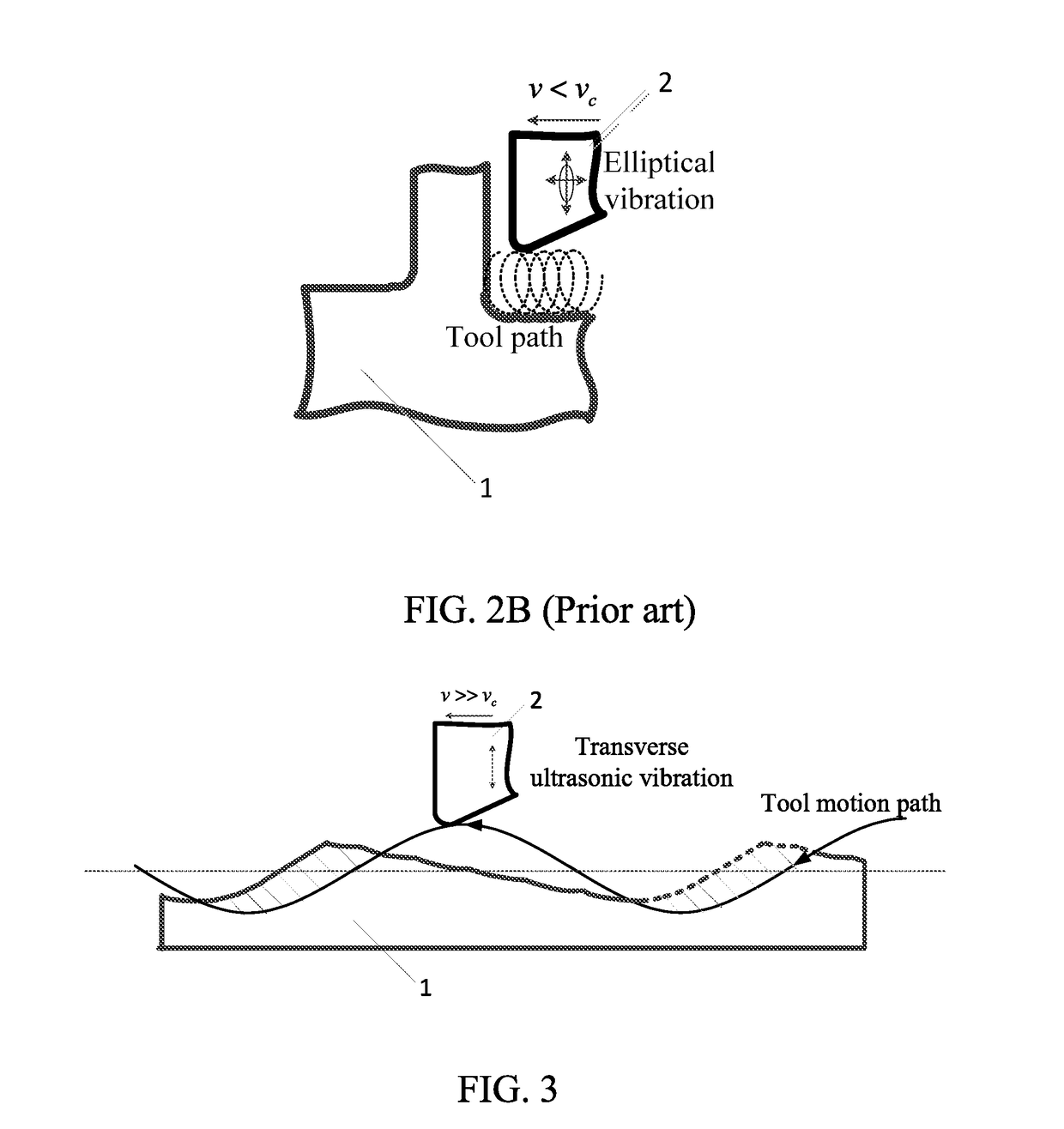

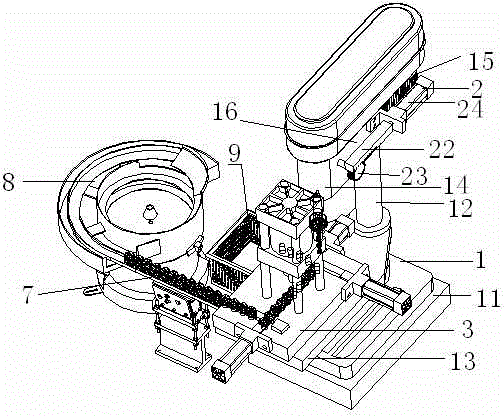

ActiveCN110076350AImprove fatigue lifeIncreased surface microhardnessTurning machine accessoriesBurnishing machinesPhase differenceUltrasonic vibration

The invention discloses an ultrasonic stamping type cutting and extruding integrated machining method. The ultrasonic stamping type cutting and extruding integrated machining method comprises the following steps that transverse ultrasonic vibration which is perpendicular to the cutting speed direction or contains a vibration component perpendicular to the cutting speed direction is applied to a cutting tool on a machine tool; cutting parameters and ultrasonic vibration parameters are set, so that a dynamic negative rear angle is generated in the cutting process, and ultrasonic-frequency impactextrusion is performed on the surface of a workpiece by a rear tool face of the tool; the extrusion overlap ratio is set; a grinding dulling standard of a rear tool face of an extruding and cutting tool is set; the vibrating and cutting track phase difference of adjacent rotation of the tool is controlled; the machine tool and ultrasonic vibration are started, so that workpiece cutting and extrusion reinforcement of the surface of the workpiece are completed through one working procedure. According to the ultrasonic stamping type cutting and extruding integrated machining method, a reinforcing working procedure is not needed to be additionally provided, and the surface of the workpiece can undergo extrusion reinforcement while the workpiece is cut.

Owner:BEIHANG UNIV

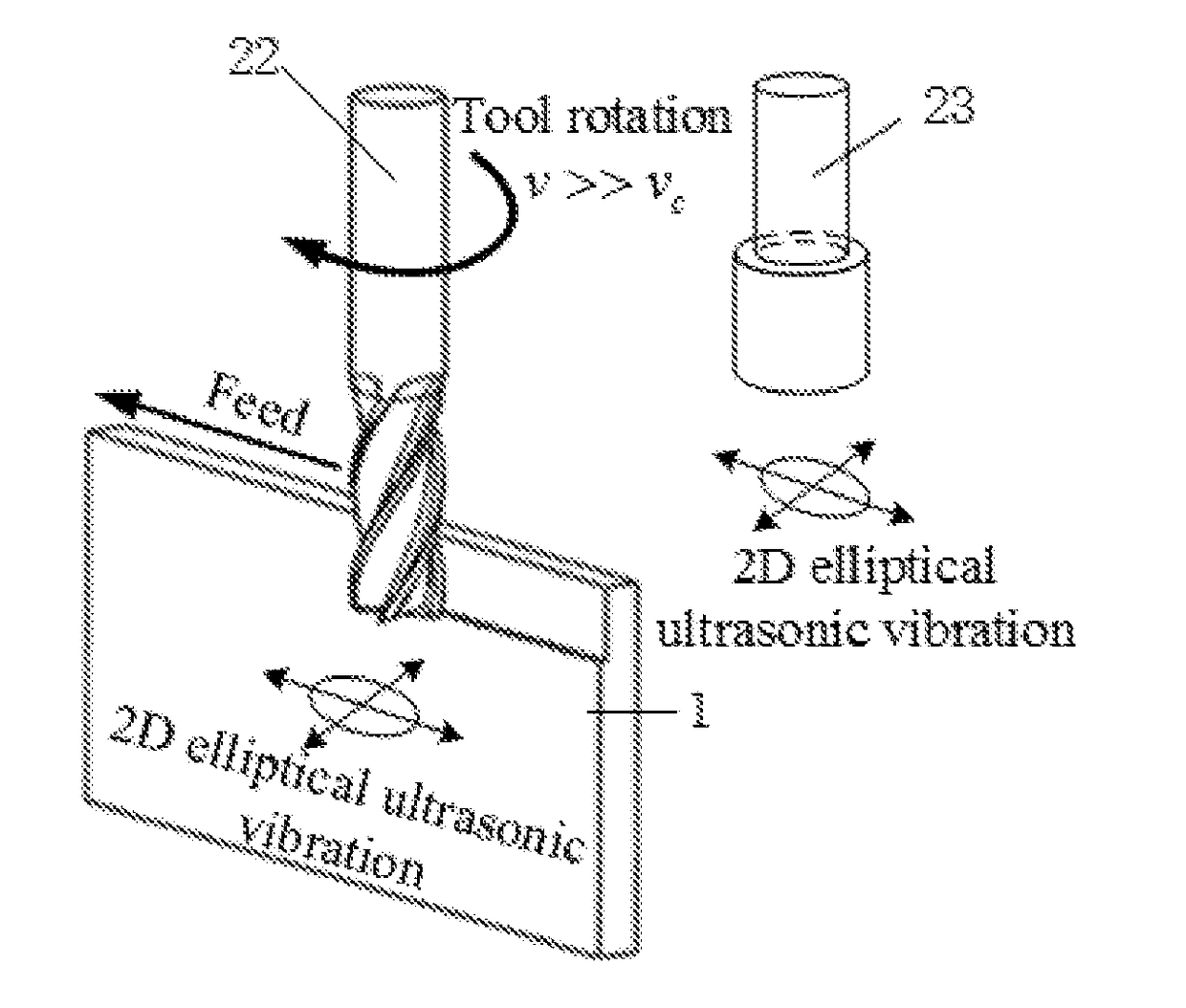

High-speed precision interrupted ultrasonic vibration cutting method

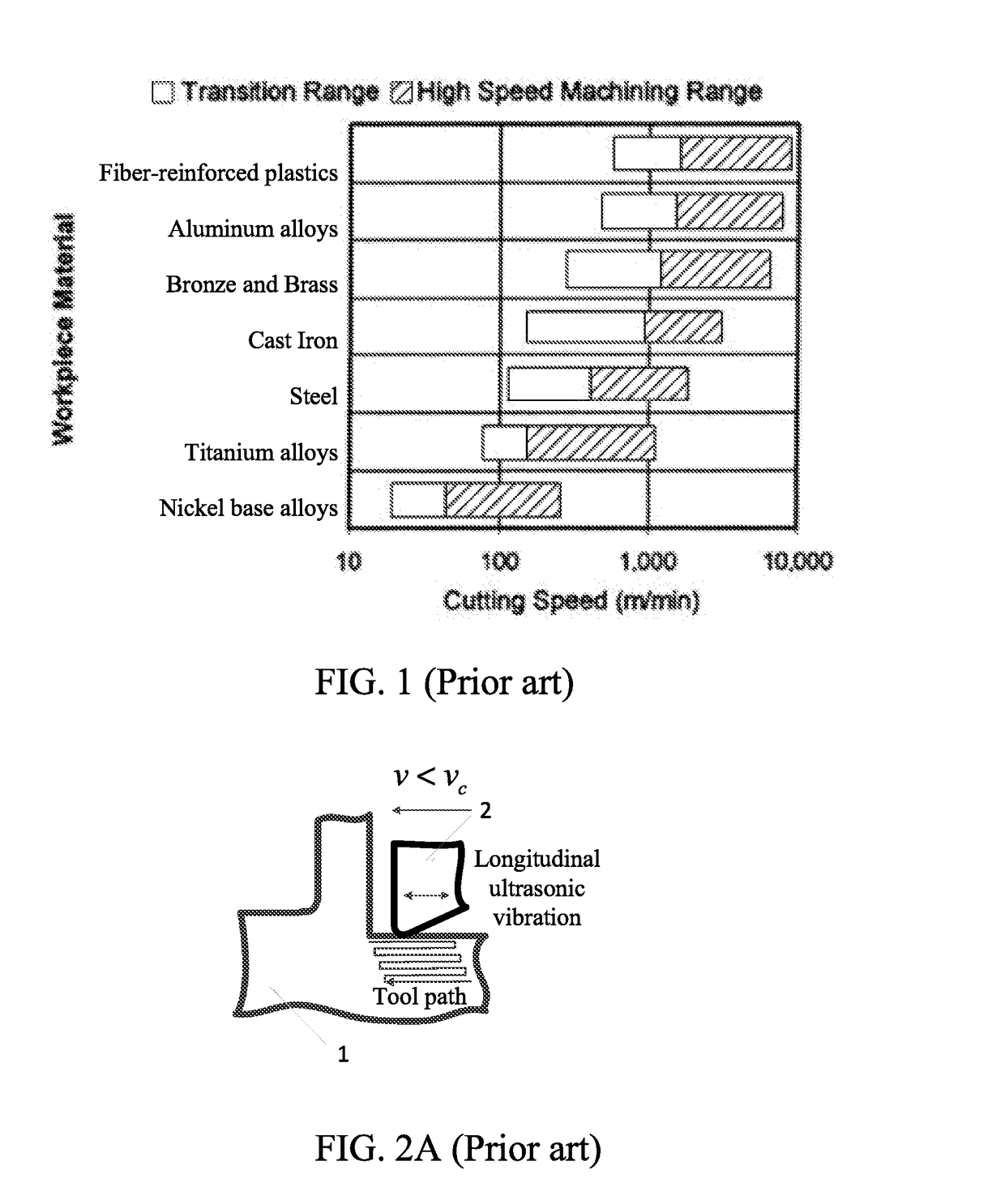

ActiveUS20170100781A1Low cutting speedMachining efficiency is limited largelyAircraft componentsWorkpiecesAviationEngineering

A high-speed precision interrupted ultrasonic vibration cutting method includes steps of: (1) installing an ultrasonic vibration apparatus on a machine tool, and stimulating a cutting tool to generate a transverse vibration, so as to realize varieties of machining processes; (2) realizing an interrupted cutting process by setting cutting parameters and vibration parameters to satisfy an interrupted cutting conditions; and (3) turning on the ultrasonic vibration apparatus and the machine tool, and starting a high-speed precision interrupted ultrasonic vibration cutting process. High-speed precision interrupted ultrasonic vibration cutting is able to be realized through the above steps during machining of difficult-to-machine materials in aviation and aerospace fields. A cutting speed is enhanced significantly, and exceeds a critical cutting speed of a conventional ultrasonic vibration cutting method and an elliptical ultrasonic vibration cutting method and even a high speed range of a traditional cutting method.

Owner:BEIHANG UNIV

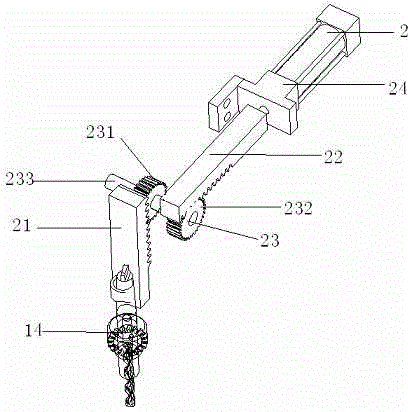

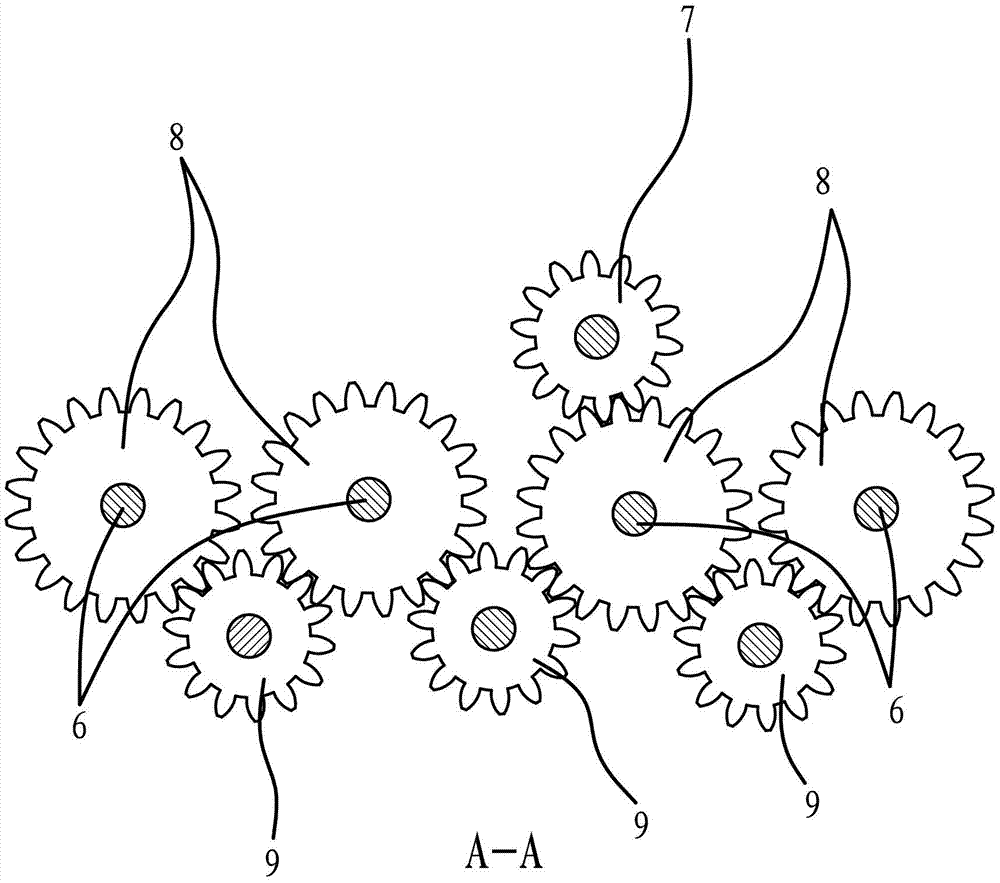

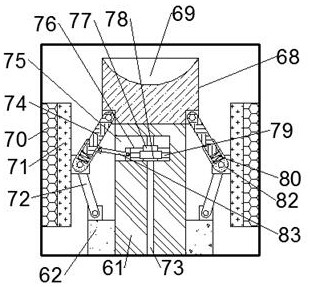

Cast-aluminum rotor processing device

ActiveCN104668625ASimple structureReasonable designFeeding apparatusReaming devicesEngineeringMaterial resources

The invention provides a bench drilling machine for a cast-aluminum rotor processing device. The bench drilling machine for the cast-aluminum rotor processing device is simple in structure and reasonable in design; by matching a drill telescopic cylinder, a first rack, a second rack and a gear set, the vertical motion of a drill is realized to perform inner bore reaming on a cast-aluminum rotor; the first rack, the gear set and the second rack are equal in linear speed, so the feed accuracy of the drill is ensured; meanwhile, the cost is low; a specially-made workbench is arranged on a saddle used as a drilling platform originally, so that the design cost is reduced; after started, the device can run autonomously, and is convenient and fast; meanwhile, two processes of projection spot pressing and inner bore reaming during cast-aluminum rotor processing are combined, and therefore process flows are optimized, manpower and material resources are saved, the production and processing efficiency is greatly increased, and the enterprise competitiveness is improved.

Owner:ZHENJIANG YUANDONG ELECTRIC MOTOR

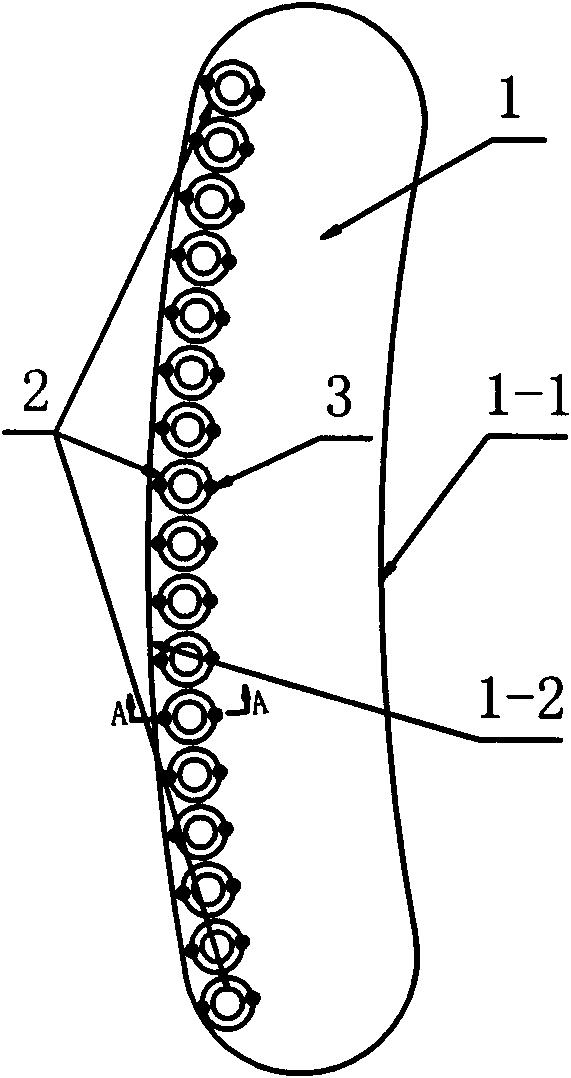

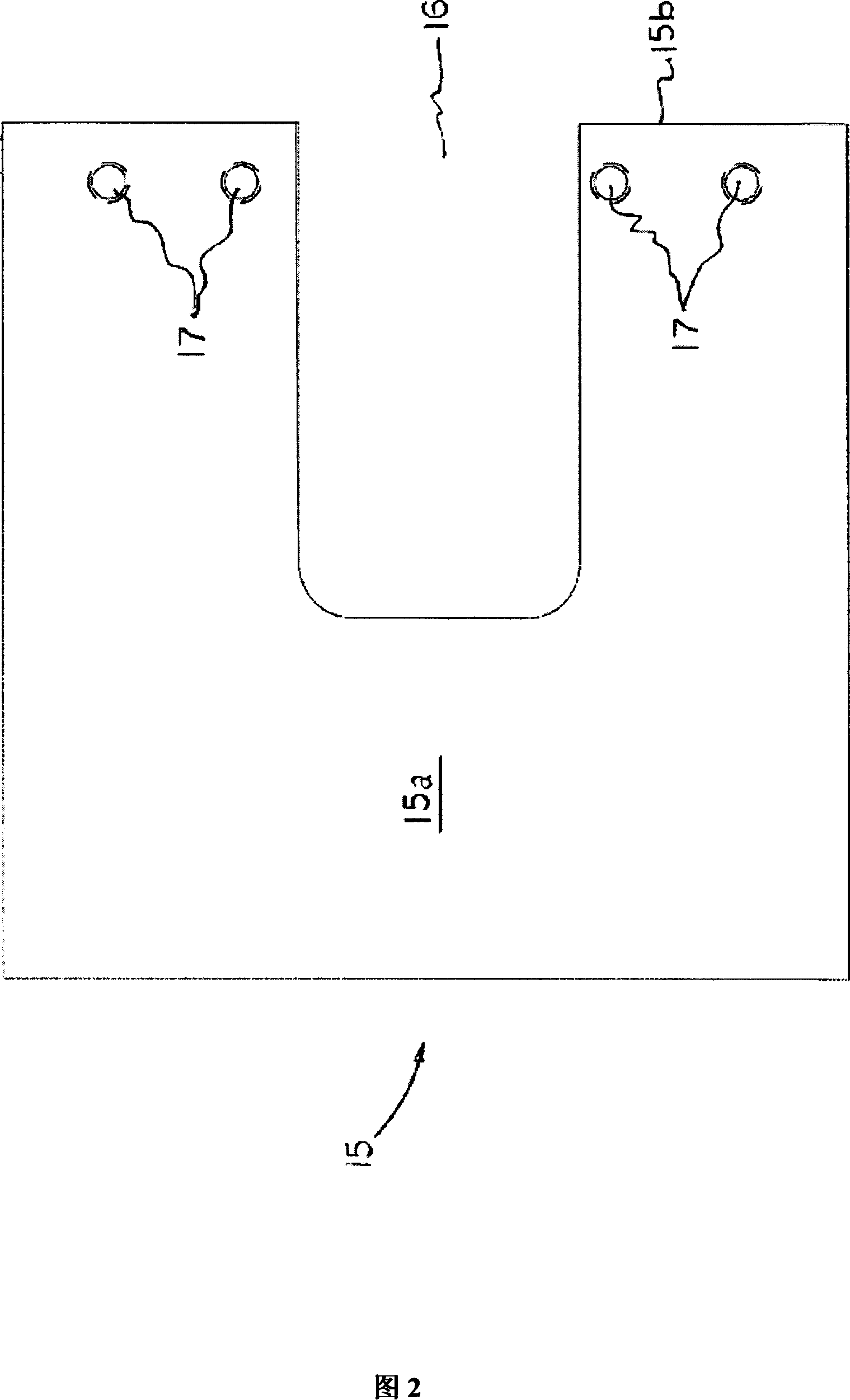

Processing method for holes in multi-lug-plate parts with dense spaces

ActiveCN102728994AQuality improvementGuaranteed coaxiality requirementsReaming devicesEngineeringMechanical engineering

The invention provides a processing method for holes in multi-lug-plate parts with dense spaces. The processing method comprises the following steps of: firstly, mounting a drilling template reaming guide sleeve on a drilling template; secondly, fixing the parts on a drilling jig; thirdly, mounting a drilling template front guide sleeve and a drilling template rear guide sleeve on the drilling template; fourthly, drilling and retaining machining allowance; fifthly, reaming; and sixthly, finishing the processing of the holes in the multi-lug-plate parts. According to the processing method, the production efficiency is increased, the production cost is reduced and the coaxiality of the holes is effectively ensured.

Owner:SHENYANG AIRCRAFT CORP

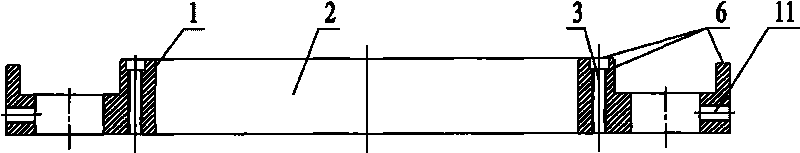

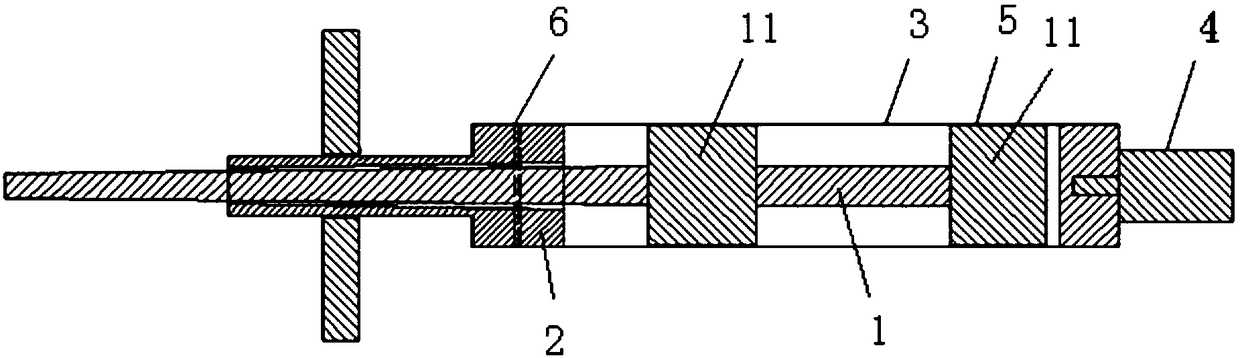

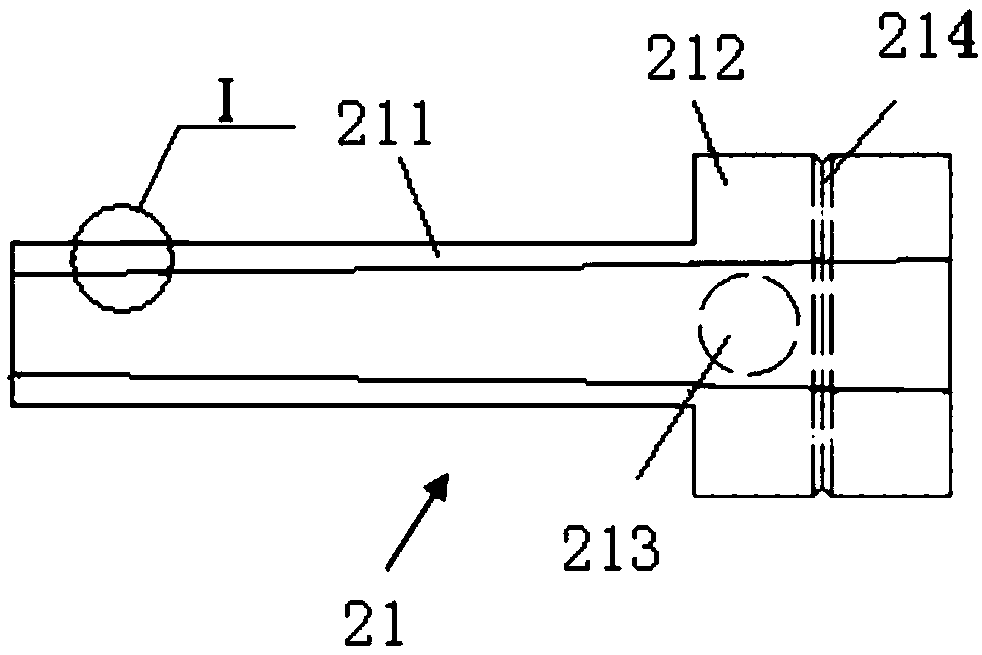

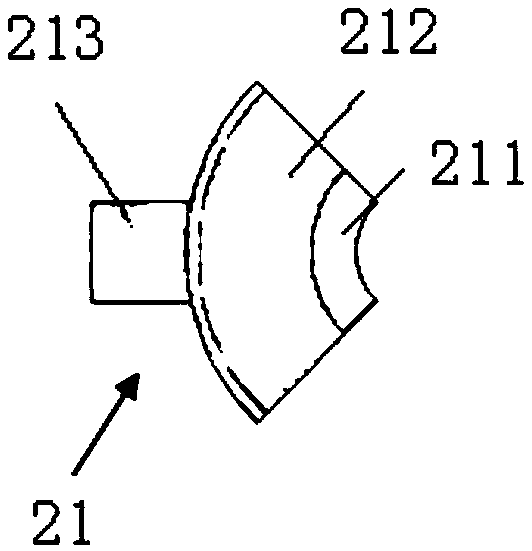

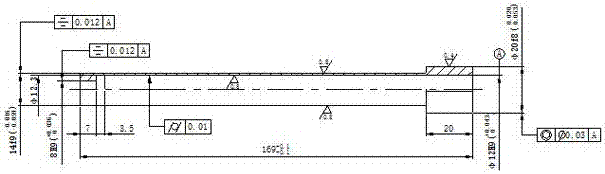

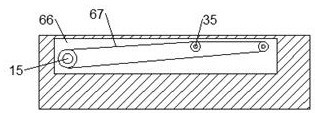

Reducing rotary cold extrusion strengthening process device

ActiveCN109304619AAvoid influenceEliminate the effects ofOther manufacturing equipments/toolsReaming devicesEngineeringProcessing accuracy

The invention provides a reducing rotary cold extrusion strengthening process device. The reducing rotary cold extrusion strengthening process device comprises a mandrel, as well as a lining and a fixed drum that are arranged on the mandrel in a sliding and sleeving manner and are fixedly connected with each other, wherein the lining consists of a plurality of fan-shaped lining blocks in circumferential arrangement; the other end of the fixed drum, away from the lining, is connected to a motor and a pipeline system; the mandrel comprises a conical cylinder and a constant-diameter cylinder; a conical through hole is formed in the lining; each fan-shaped lining block comprises a body and a lug boss; and spherical bulges in close and regular arrangement are formed on the outer surface of thebody. Owing to the spherical bulges in close arrangement on the surface of the lining, the fatigue life of a processed inner hole is favorably prolonged. The mandrel is designed into a conical cylinder, so that an adverse effect on the extrusion accuracy from abrasion of a square mandrel is avoided. Moreover, hole extrusion and the reaming process are combined to improve the degree of finish of the surface of the processed inner hole, so that the processing continuity is guaranteed, and the processing accuracy and the processing efficiency are improved.

Owner:EAST CHINA UNIV OF SCI & TECH +1

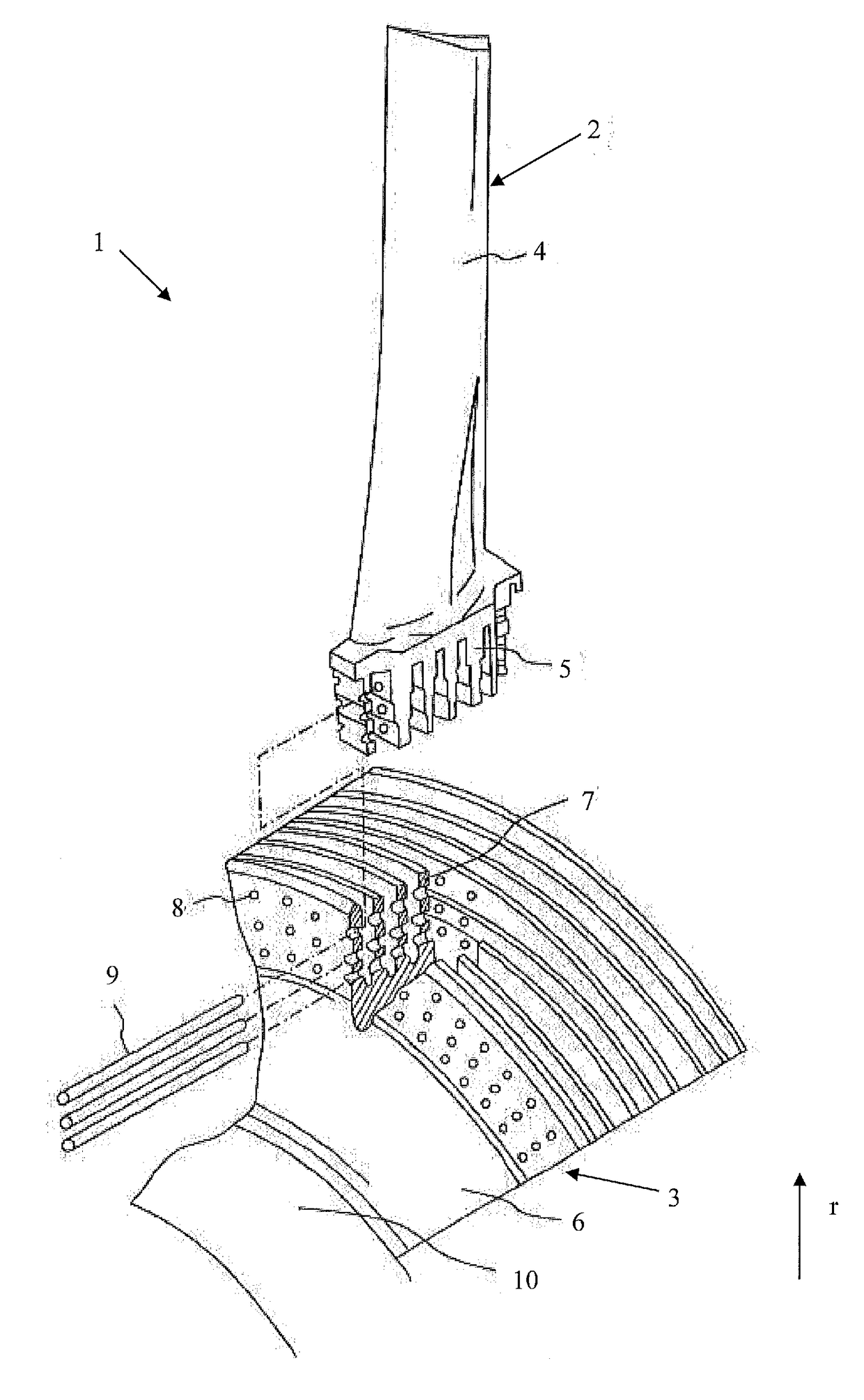

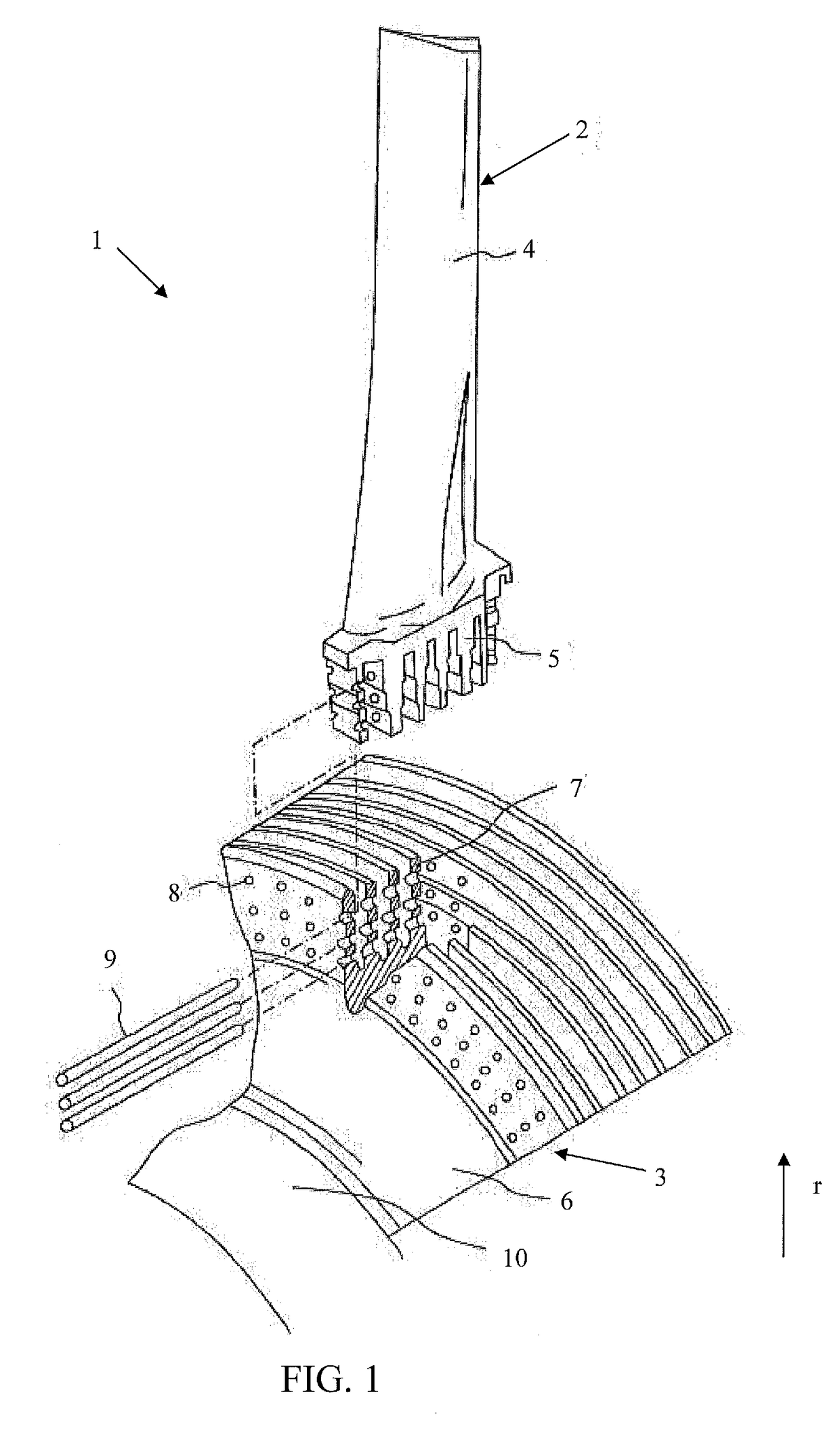

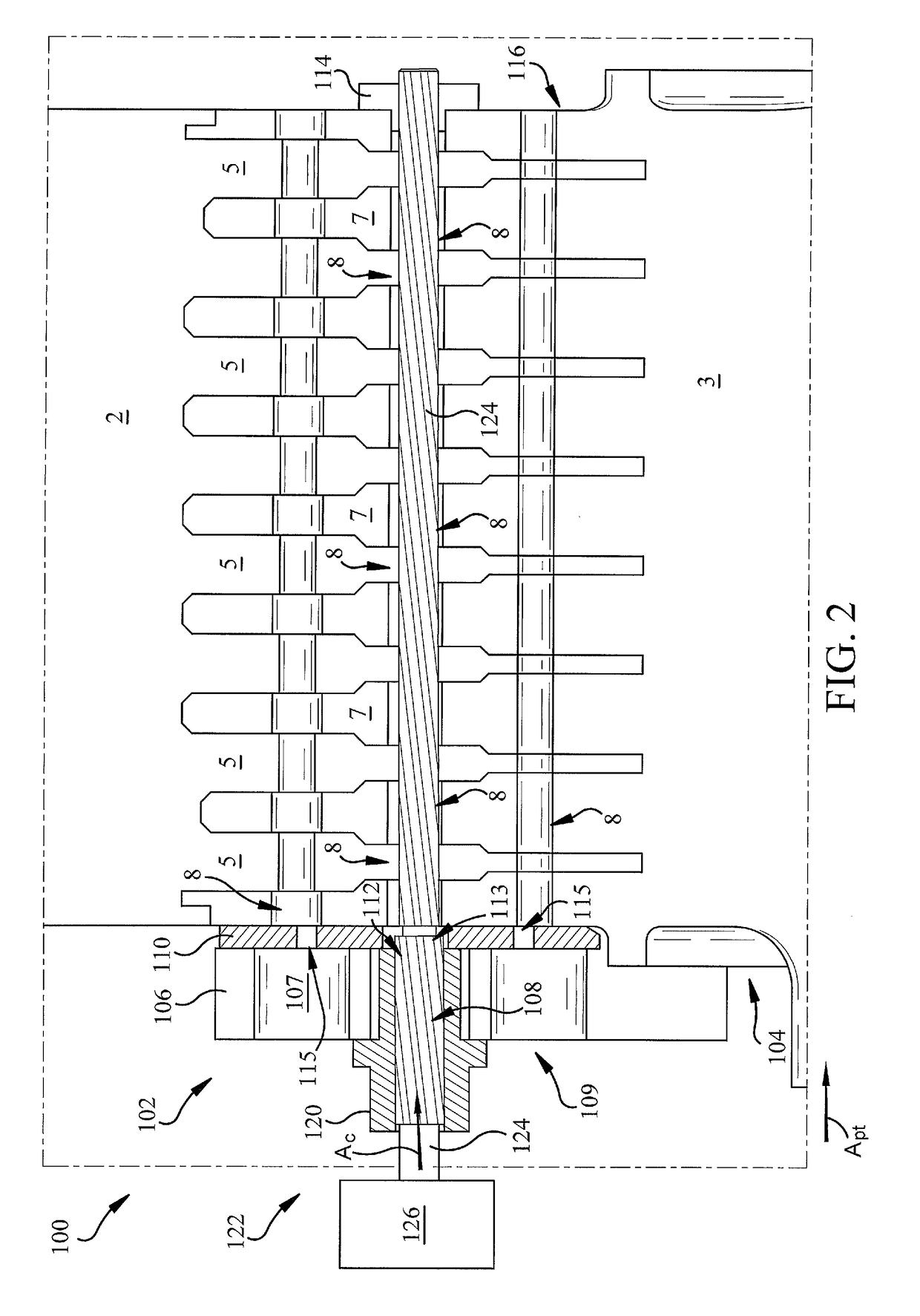

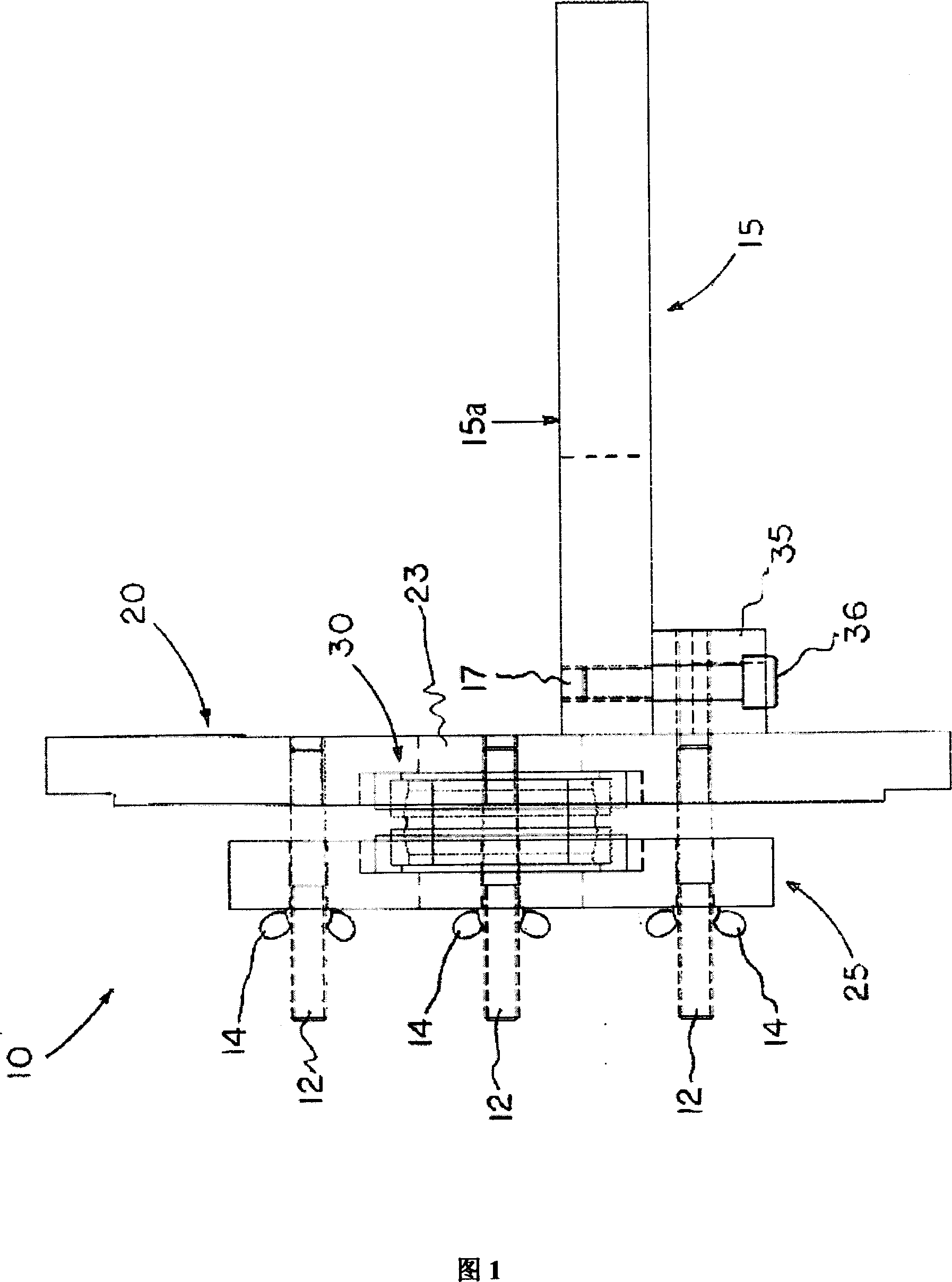

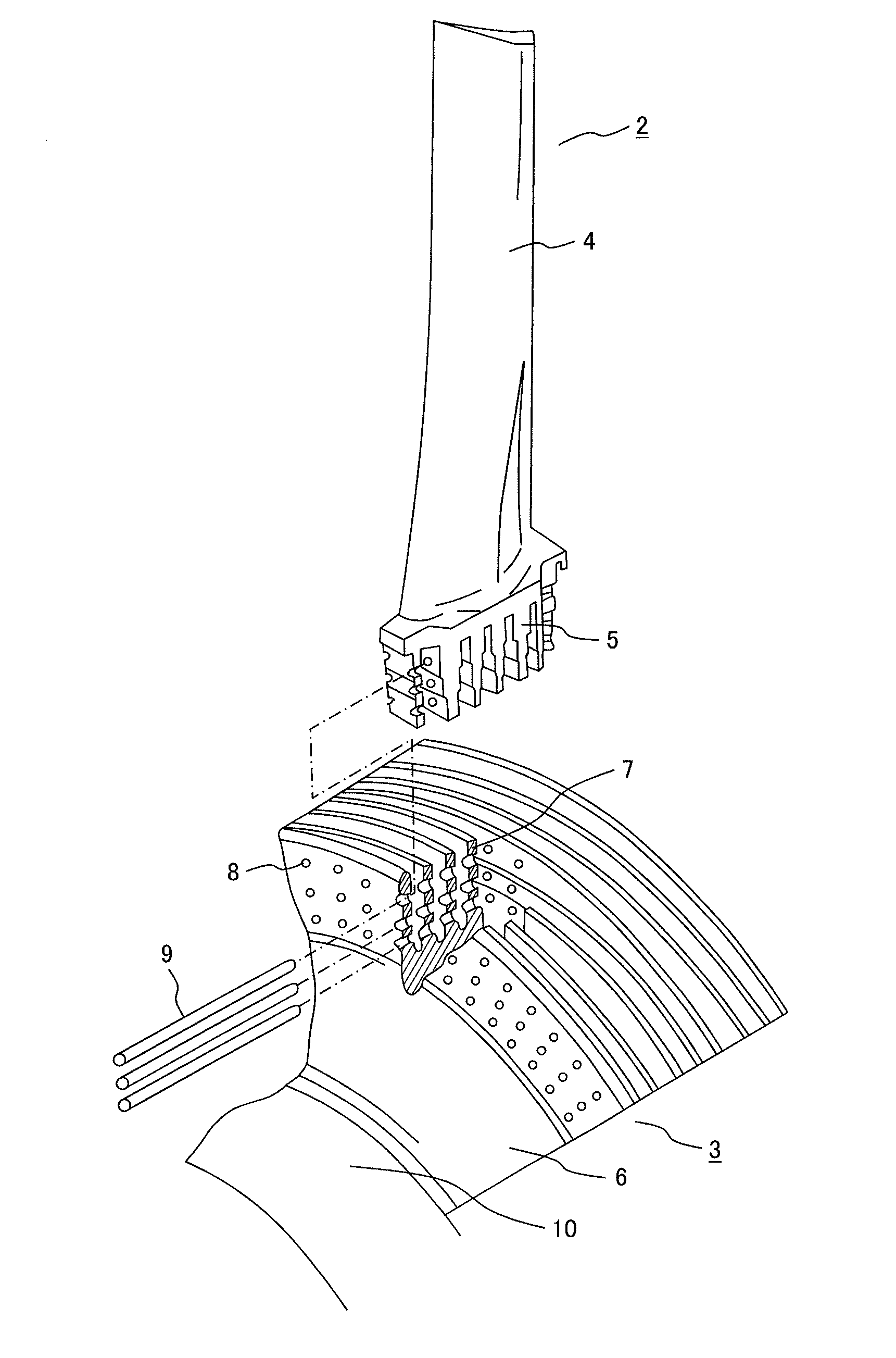

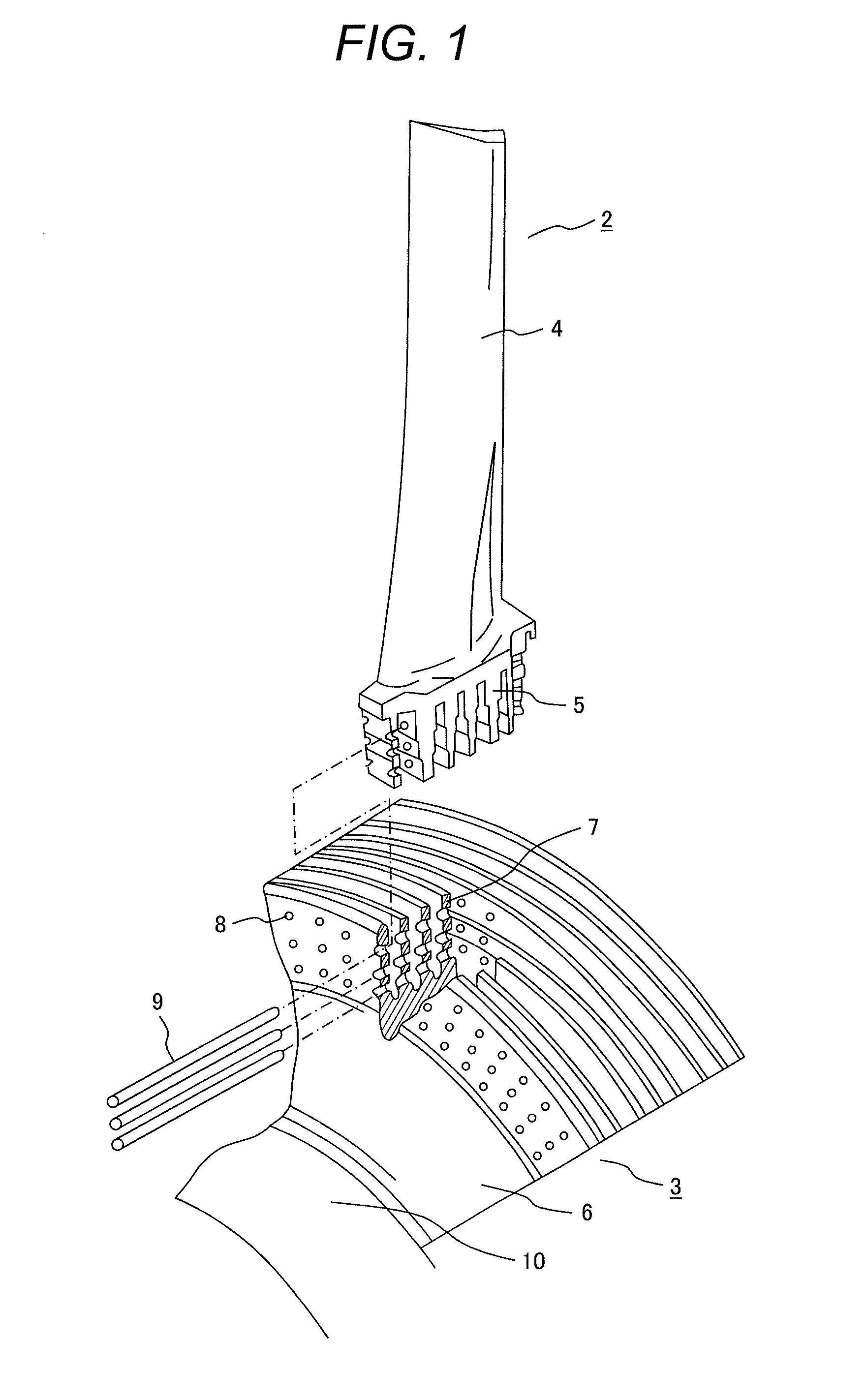

Machining system for turbomachine dovetail

Various embodiments include a system for machining a hole in a turbine blade. The system can include: a mount for engaging a first side of a turbine rotor, the mount including: a drill plate for coupling with the first side of the turbine rotor, the drill plate having: a body; a feed opening on a first side of the body; a passage extending from the feed opening through the body; and a second opening on a second side of the body, the second opening coupled with the passage and positioned to align with the pre-formed hole in the turbine rotor; an alignment bushing for engaging the pre-formed hole in the rotor at a second side of the rotor; and a cutting device for extending through the body and alignment bushing, the cutting device for machining the hole in the blade, the cutting device aligned along a chamfer axis relative to a primary axis of the turbine rotor.

Owner:GENERAL ELECTRIC CO

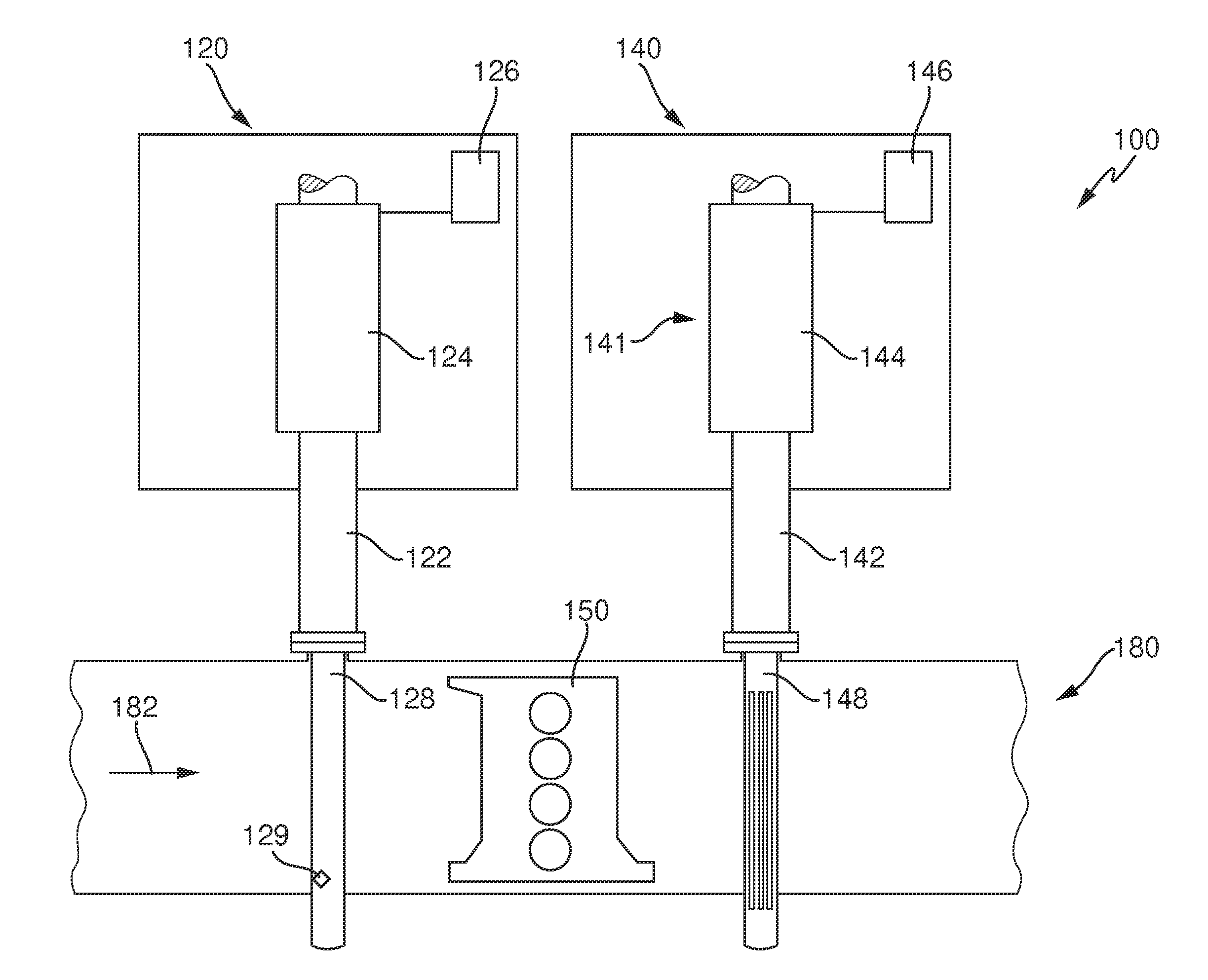

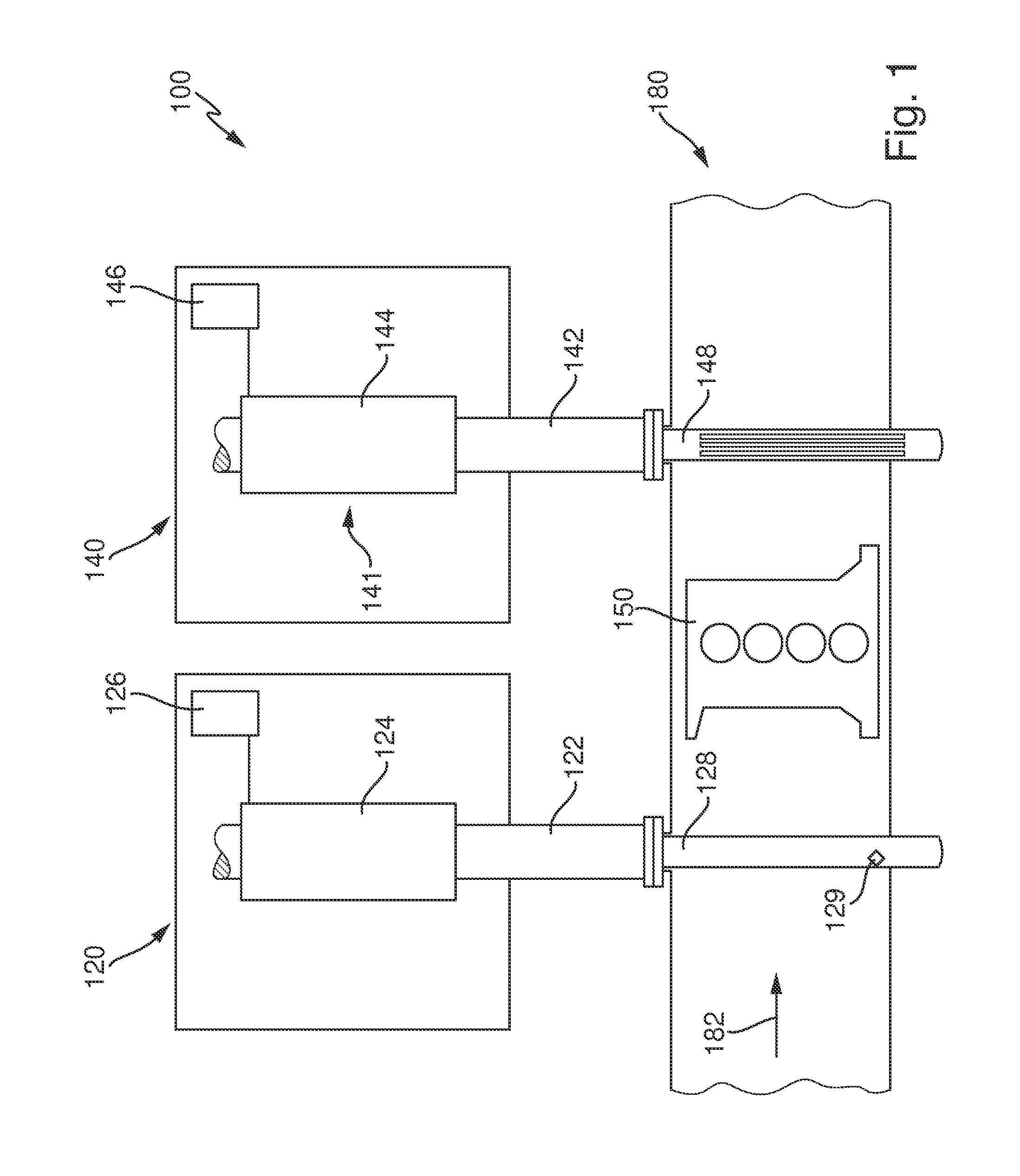

Method and Machining Installation for the Finishing of a Crankshaft Bearing Bore

In a method for the finishing of a crankshaft bearing bore in a cylinder crankcase of an internal combustion engine, starting from a prepared crankshaft bearing bore, a finished crankshaft bearing bore is produced with a prescribable desired size, a prescribable desired structure of the bore inner surface and a prescribable desired position of the bore axis. The prepared crankshaft bearing bore is first finished with at least one finishing tool with a geometrically defined cutting edge and then the honing of the crankshaft bearing bore is carried out. In a final finishing operation with a geometrically defined cutting edge immediately preceding the honing, an allowance of at least 0.4 mm is removed, and the honing tool is introduced into the bore coaxially in relation to the desired position of the bore axis and moved within the bore, an allowance of at least 0.08 mm being removed during the honing.

Owner:NAGEL MASCHEN UND WERKZEUGFAB +1

Hydraulic through-hole processing method and apparatus

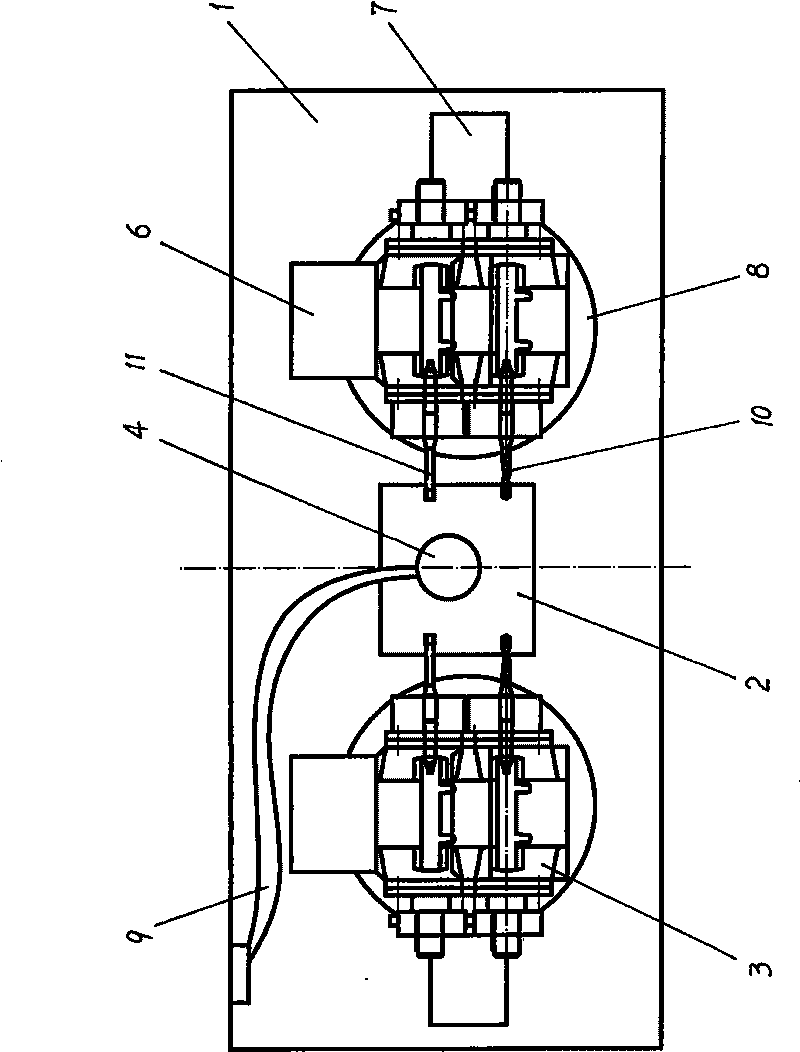

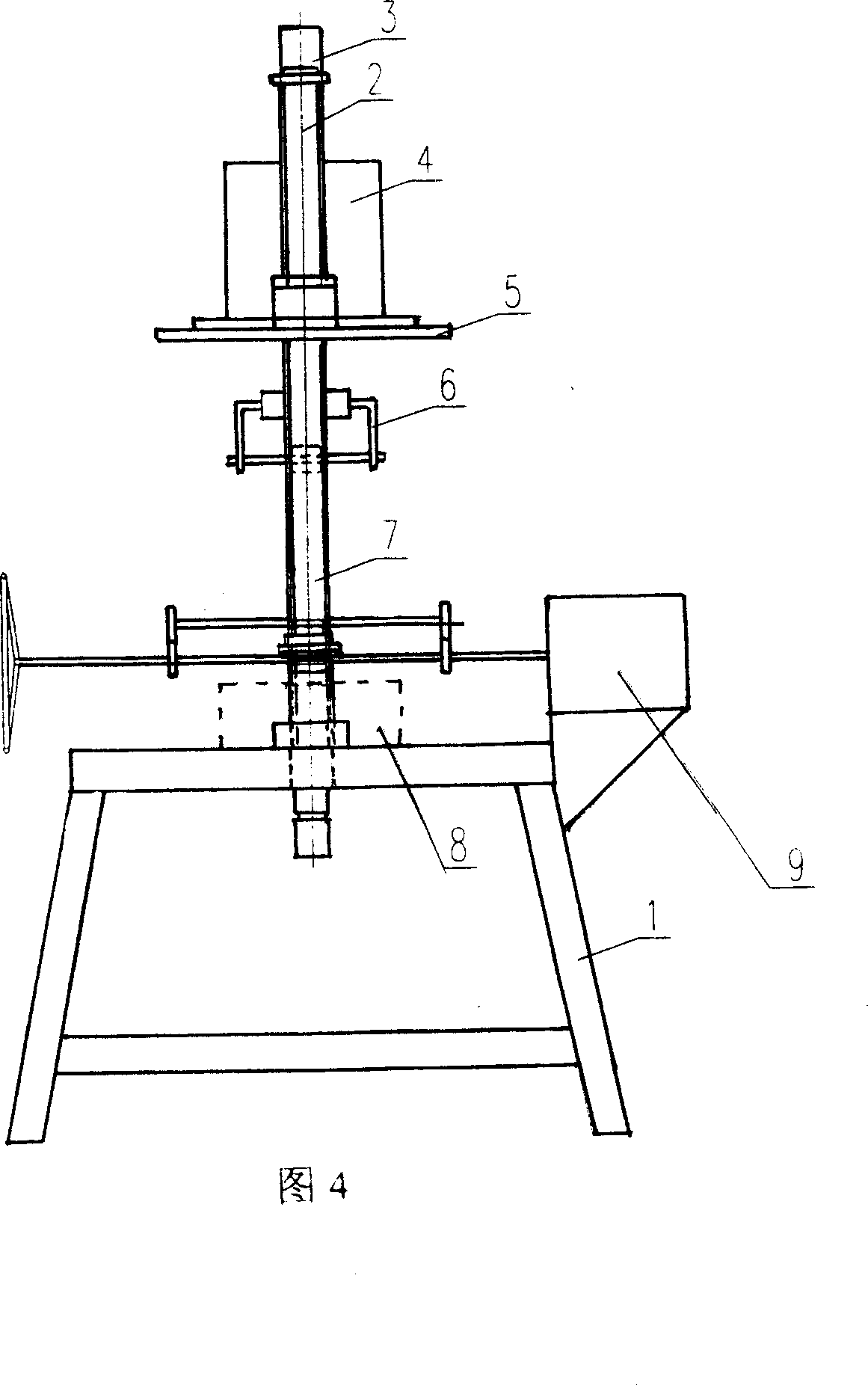

InactiveCN101024266ASmall and compact process stepsLess investmentFeeding apparatusOther manufacturing equipments/toolsEngineeringReamer

The invention discloses a hydraulic part through hole processing method and device. The method includes steps that drilling, rough boring, finish boring, finish ream. The device is formed by drilling machine, boring machine, finish ream special machine. The finish ream special machine includes work bench, shifting electric machine, spiral type forming gold steel reamer, feed screw nut set, guide post, mounting plate, self centering rotating shaft poking fork, feeding power transmission system. The work bench is symmetrically set a pair of guide posts and feed screw nut sets and fixed by the mounting plate of which middle the shifting electric machine is set and connected with the self centering rotating shaft poking fork and spiral type forming gold steel reamer. The feeding power transmission system is connected with the feed screw nut set which can make the mounting plate elevate along the guide post. The invention has the advantages of minor technology step, simple and reliable device, saving investment, low cost etc.

Owner:吉瑞龙(福建)工程机械有限公司

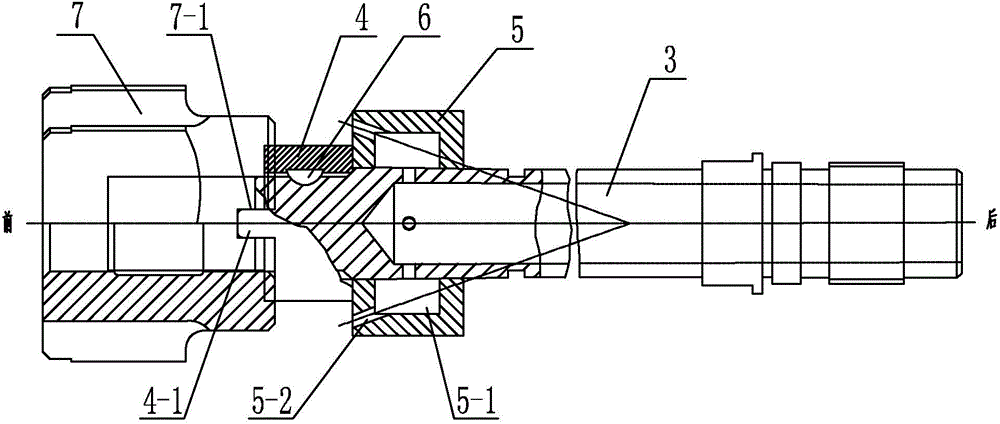

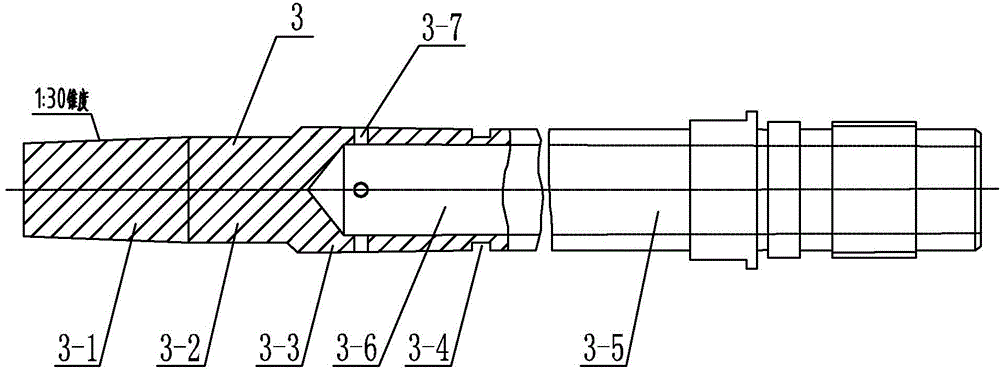

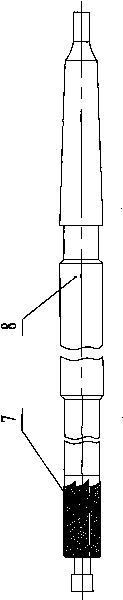

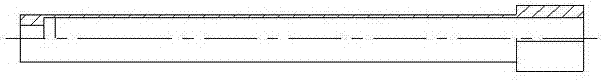

Machining tool and machining method for deep taper hole of liquid rocket engine cavitation pipe

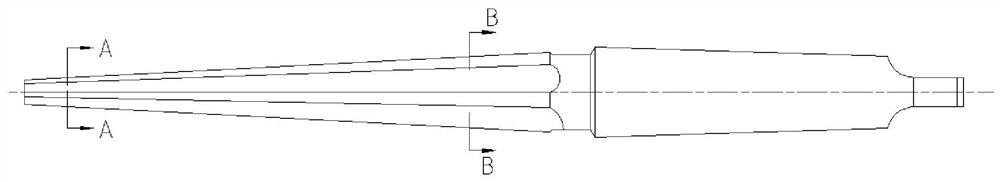

The invention relates to a machining tool and a machining method for a deep taper hole of a liquid rocket engine cavitation pipe. The machining tool comprises a conical head and a reamer handle part,the conical head is of a 6-degree + / -5'conical structure, the molded surface is an arc tooth back, four cutting edges are evenly distributed on the molded surface, and each cutting edge has a 2-degreeedge inclination angle. The machining method of the deep taper hole comprises the steps that a reamer is adopted on a general lathe, the reaming procedure is divided into rough reaming, semi-finish reaming and finish reaming, the machining process is conducted in a pecking mode, and soybean oil is brushed for cooling. The reaming technology is adopted for machining the deep taper hole, compared with a traditional boring technology, the taper hole is good in roundness, tool vibration is little, the machining quality and consistency are good, each cutting edge of the conical finish reamer is ground into a special front-back angle and a special edge inclination angle, batch machining of deep taper holes in an expansion section of one liquid rocket engine cavitation pipe is achieved in cooperation with the machining method, abrasion of the reamer for machining the cavitation pipe taper hole is effectively reduced, the roughness of the inner surface of the hole is reduced, the machining efficiency of the cavitation pipe is improved, and the effect is remarkable in batch production.

Owner:XIAN SPACE ENGINE CO LTD

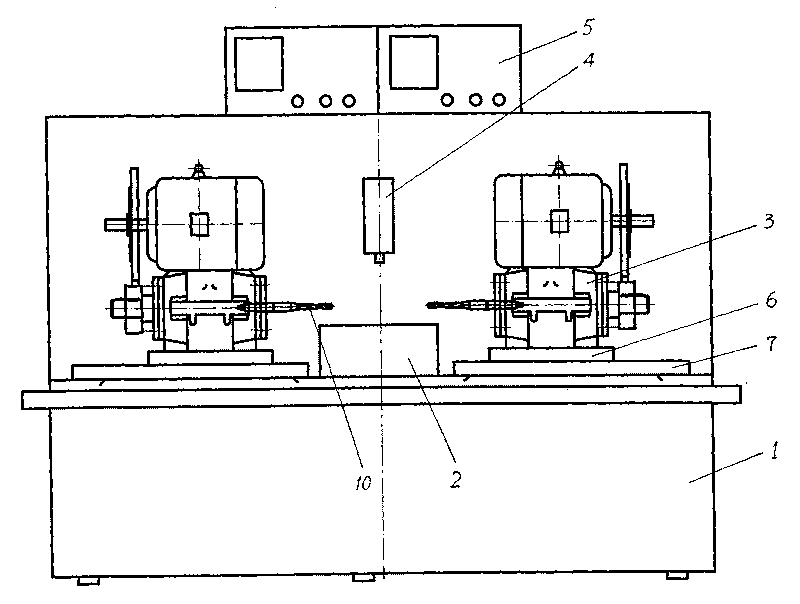

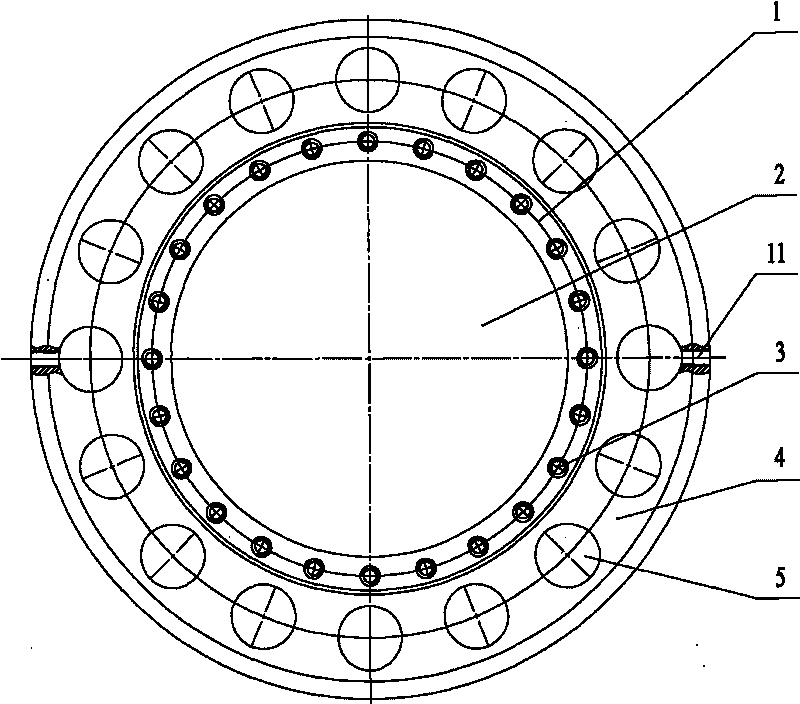

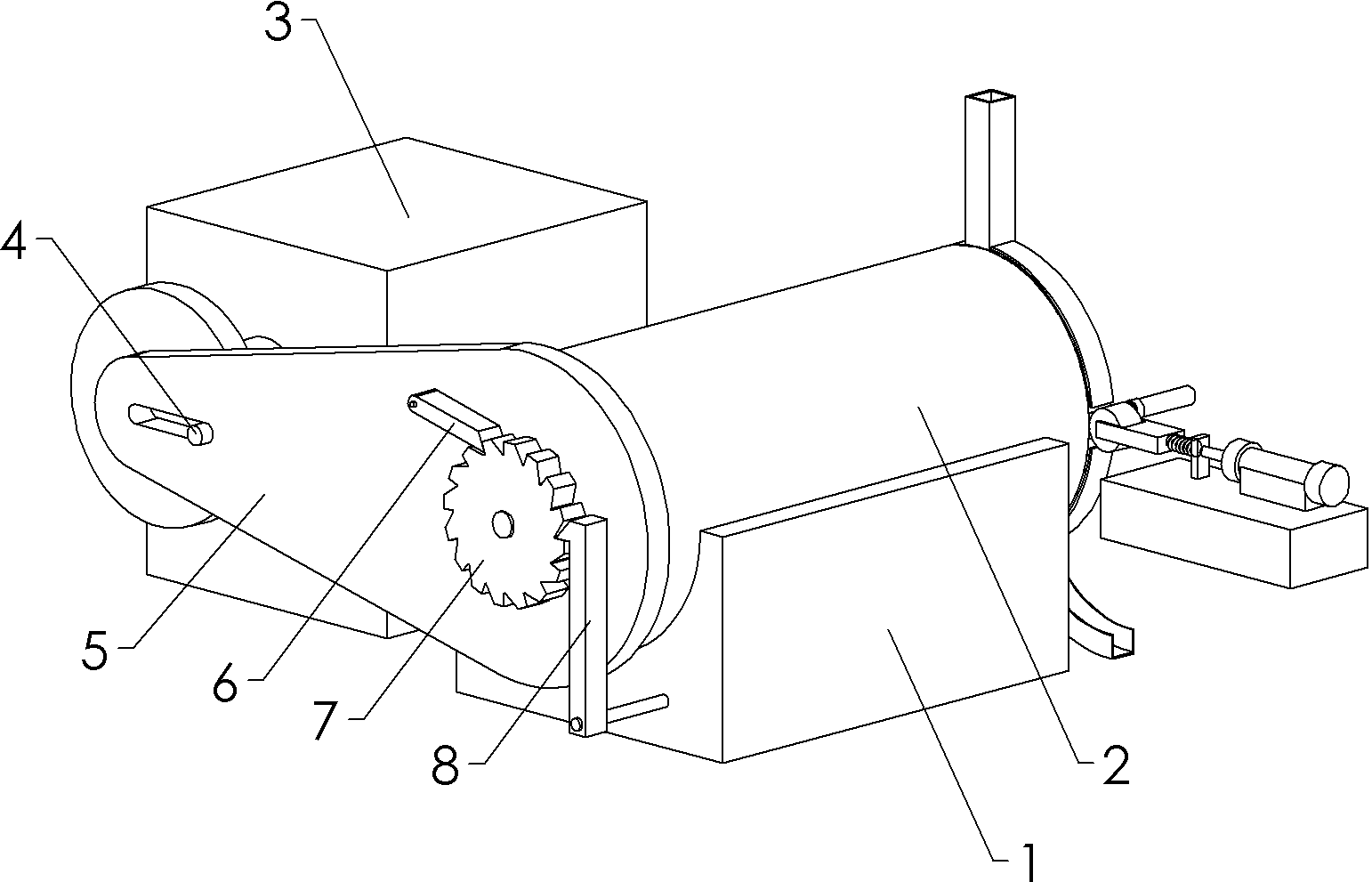

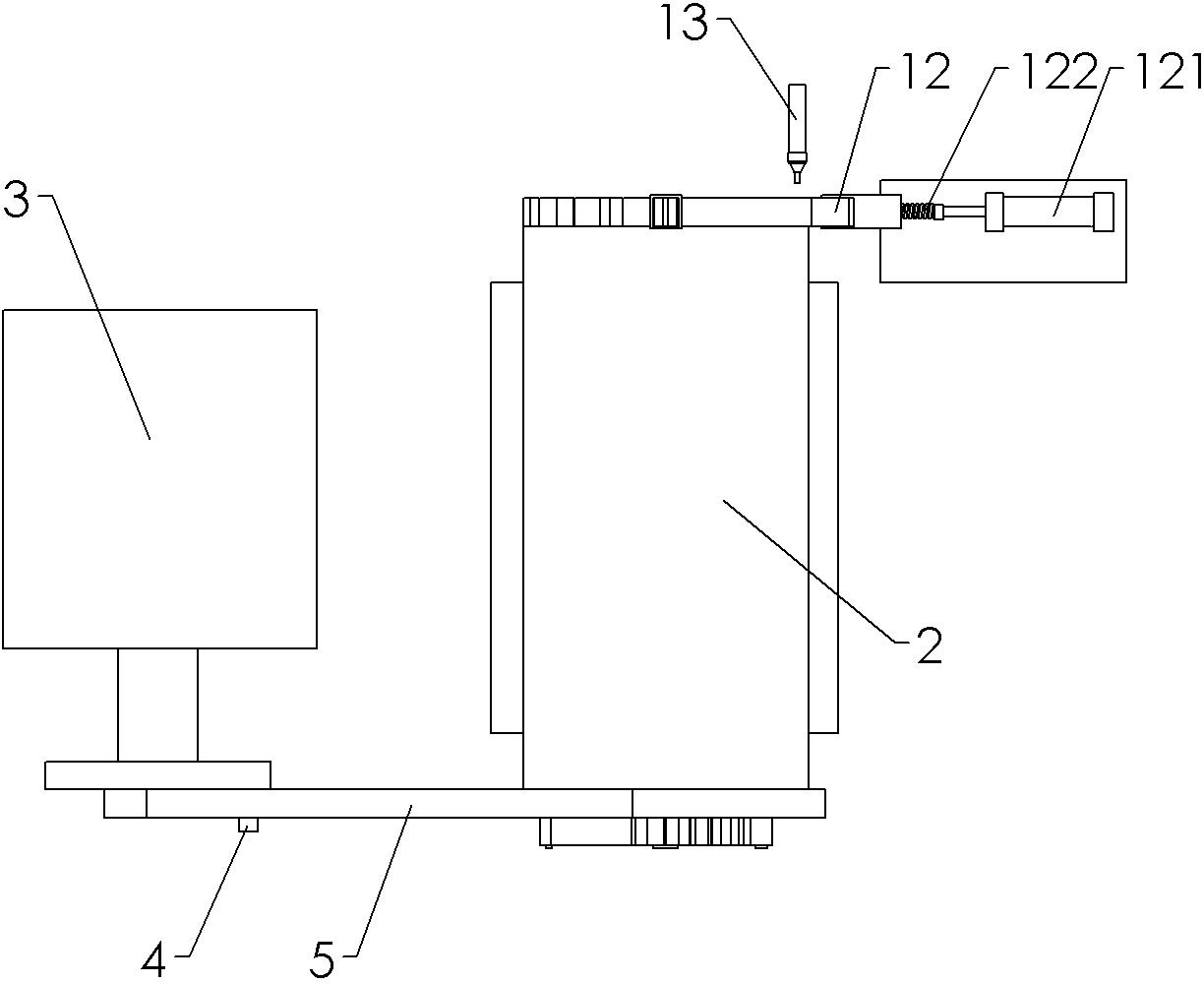

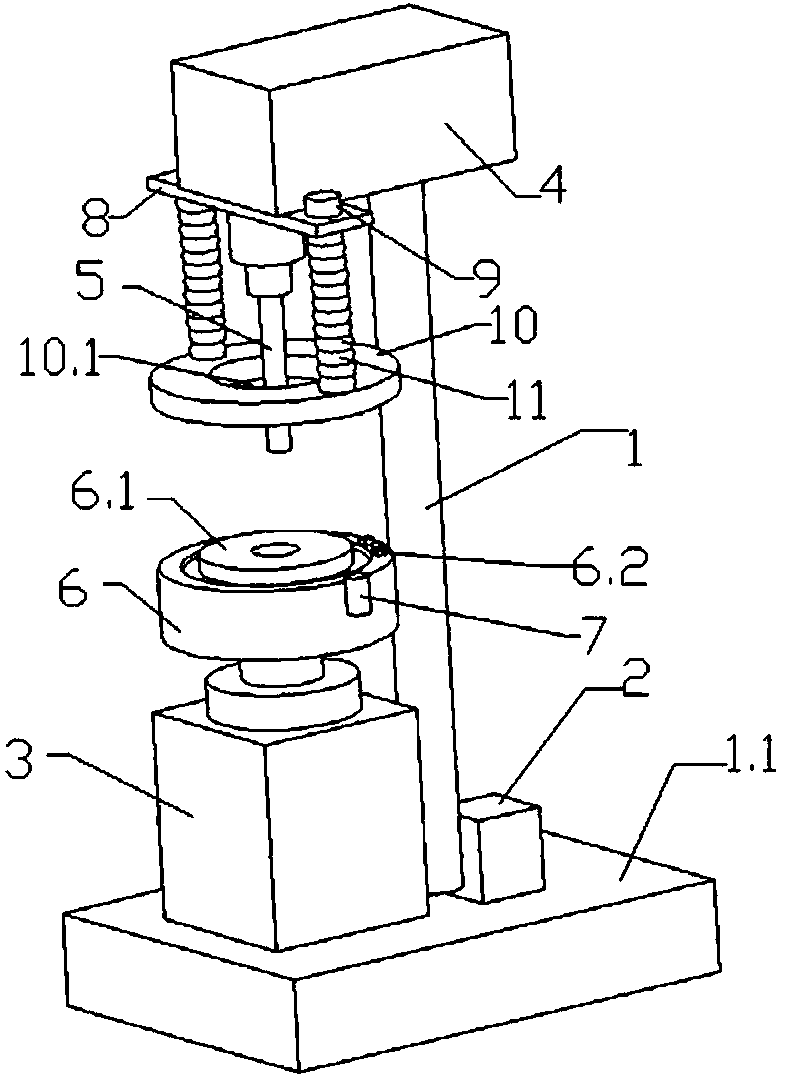

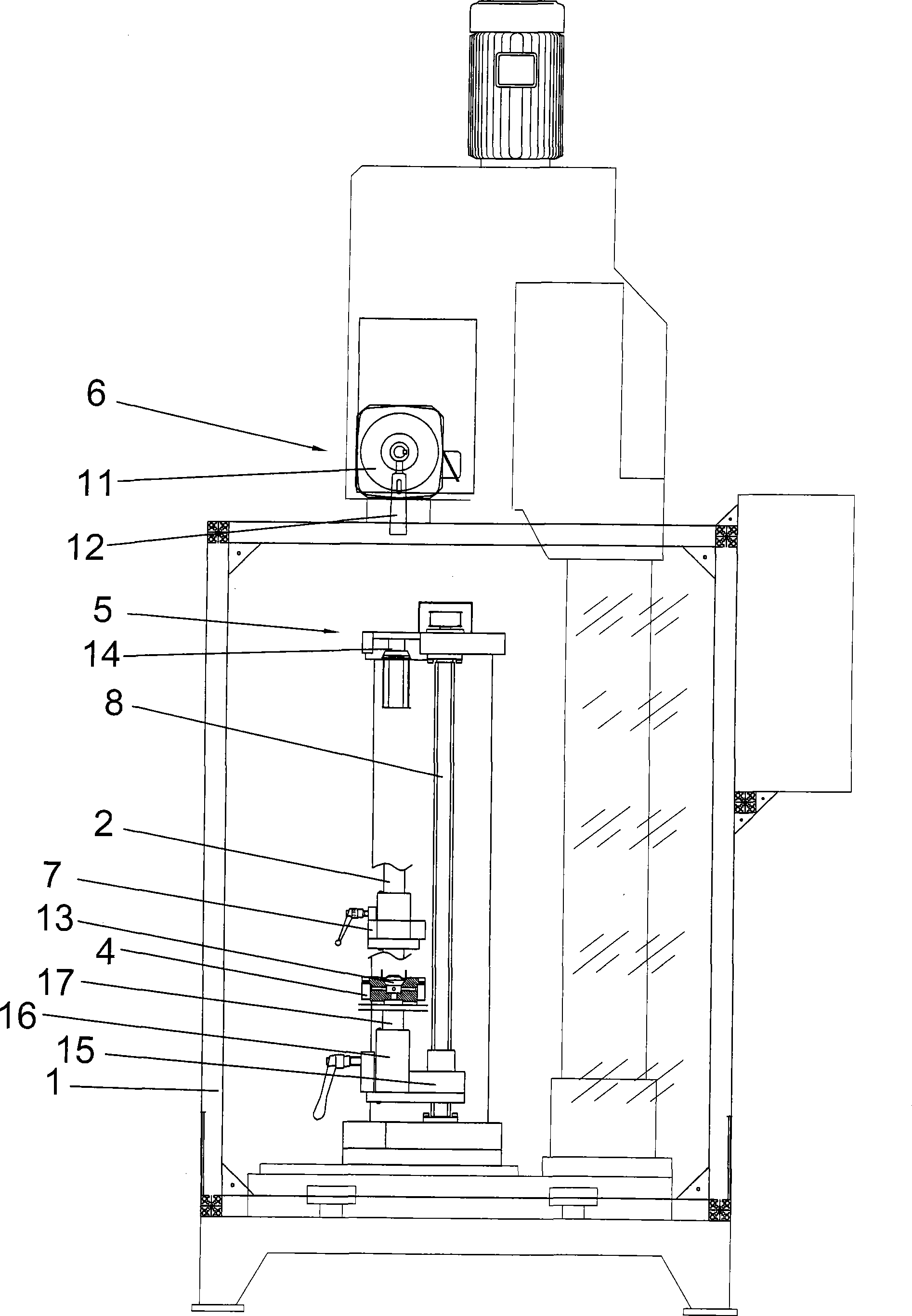

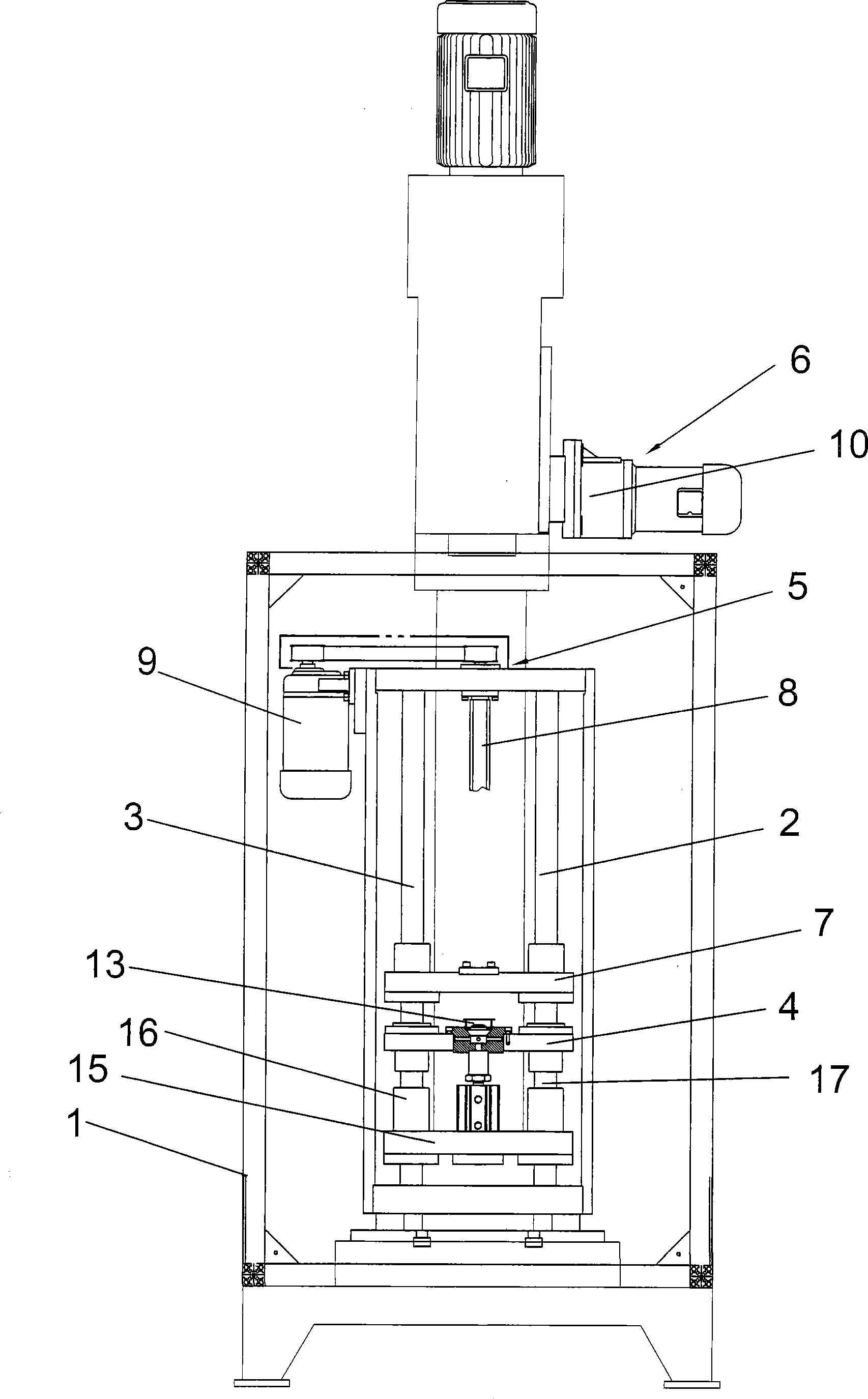

Automatic reaming machine

InactiveCN104070234ANo wasteAvoid compromising reaming qualityFeeding apparatusReaming devicesInductorEngineering

The invention discloses an automatic reaming machine. The automatic reaming machine comprises a rack (1), a controller (2), a cylinder (3) and a motor (4), wherein a reamer (5) is installed on a motor output shaft; a location seat (6) is installed on a cylinder piston rod; a location boss (6.1) is formed on the location seat (6); a limit block (6.2) is further arranged on the location seat (6); an inductor (7) used for inducting an aluminium freezing motor shell, and clamped and located on the location seat (6) is further installed on the location seat (6); the cylinder piston rod, the location seat (6), the motor output shaft and the reamer (5) are coaxially arranged; the cylinder (3), the motor (4) and the inductor (7) are electrically connected with the controller (2). The automatic reaming machine is high in automation degree, fast in reaming speed, high in efficiency, high in reaming quality, and relatively low in cost.

Owner:NINGBO LIONBALL VENTILATOR

Rocker shaft bore-deburring machine

ActiveCN103028781AEasy to operateImprove efficiencyFeeding apparatusReaming devicesElectric machineryMechanical equipment

The invention provides a rocker shaft bore-deburring machine, which belongs to the technical field of mechanical equipment. The invention solves the problems of the conventional deburring method, i.e. low deburring efficiency and high cost. The rocker shaft bore-deburring machine comprises a base, clamping mechanisms which can clamp rocker shafts are arranged on the base, a tool holder is also arranged on the base, tool chucks and a motor capable of driving the tool chucks to rotate are axially and fixedly connected with the tool holder, one end of each tool chuck is fixedly connected with a tool, the tools are aligned with the bores of the rocker shafts when the rocker shafts are clamped by the clamping mechanism, the motor is connected with the other ends of the tool chucks in a transmission way, and a driving mechanism which can drive the tool holder to move to cause the tools to reciprocate in a manner relative to the rocker shafts is also arranged on the base. The rocker shaft bore-deburring machine has the advantages of high machining efficiency, high stability and the like.

Owner:ZHEJIANG QIANGNENG MOTIVITY

Guide sleeve broacher

InactiveCN101412127AGuaranteed coincidenceReaming devicesPositioning apparatusElectric machineryEngineering

The invention relates to a guide sleeve reaming machine, which comprises a base body and a reamer mechanism arranged on the base body, wherein the reamer mechanism comprises a motor and a cutter permanent seat fixedly connected to a rotor of the motor; the cutter permanent seat is fixedly provided with a reamer of which the axial lead is vertical to a horizontal plane, and the base body is fixedly provided with a pair of guide posts of which the axial leads are vertical to the horizontal plane; the pair of the guide posts is sleeved with a positioning mold in a sliding mode respectively, and the positioning mold is provided with a first taper positioning hole; the tops of the pair of the guide posts are provided with an upper mould respectively, and the upper mould is provided with a second taper positioning hole; and when a guide sleeve is processed, the guide sleeve to be processed is fixedly placed between the first positioning hole and the second positioning hole; because the central lines of the first positioning hole and the second positioning hole are superposed with the axial lead of the reamer respectively, when the reamer of the reamer mechanism is fed to ream on the guide posts, the axial lead of the central hole of the guide sleeve can be ensured to be superposed with the axial leads of an inner pipe and an outer pipe.

Owner:庄添财

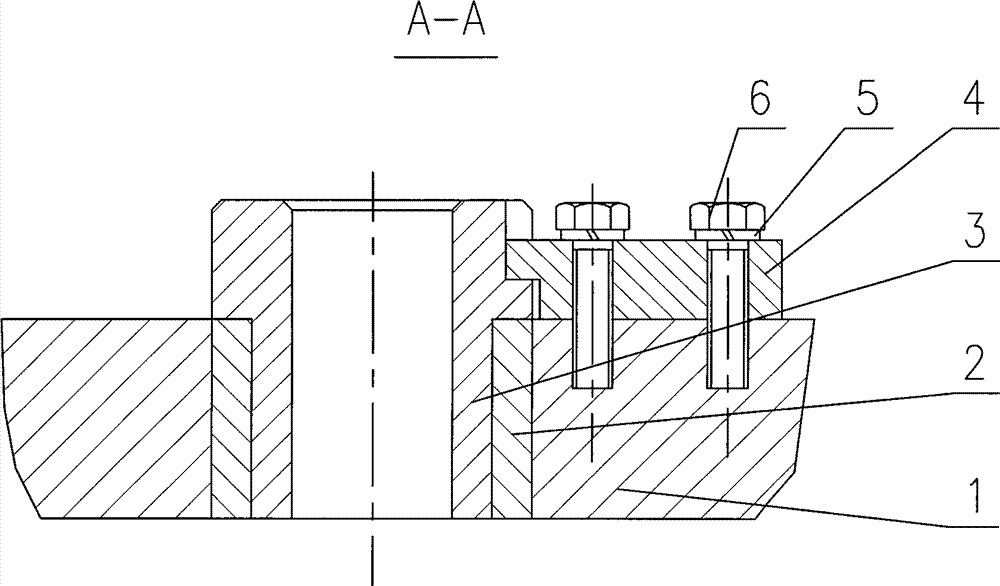

Drilling, expanding and hinge guiding device

InactiveCN103111662AHigh positioning accuracyHigh dimensional accuracyDrilling/boring measurement devicesReaming devicesReamerIndustrial engineering

The invention discloses a drilling, expanding and hinge guiding device which is fixedly arranged in a hole of a drilling template in a sleeved mode. A positioning board is fixed on the drilling template through a spring washer and a bolt, and a quick change sleeve is arranged in a hole of a fixed sleeve through the outer circle of the quick change sleeve and a groove. A vertical face of the quick change sleeve is contacted with a corresponding face of the positioning board through rotation. The outer circle of the fixed sleeve is matched with the hole of the drilling template by H7 / n6, and the outer circle of the quick change sleeve is matched with the hole of the fixed sleeve by H7 / g6. The fixed sleeve, the quick change sleeve and the positioning board undergo heat treatment by 58-62HRC. The drilling, expanding and hinge guiding device has the advantages of being capable of rapidly changing mold sleeves used for a drill, a hole expanding cutter and a reamer, and therefore holes with high-precision positions and sizes can be machined. The drilling, expanding and hinge guiding device is low in manufacture cost and high in economic benefit.

Owner:陈硕

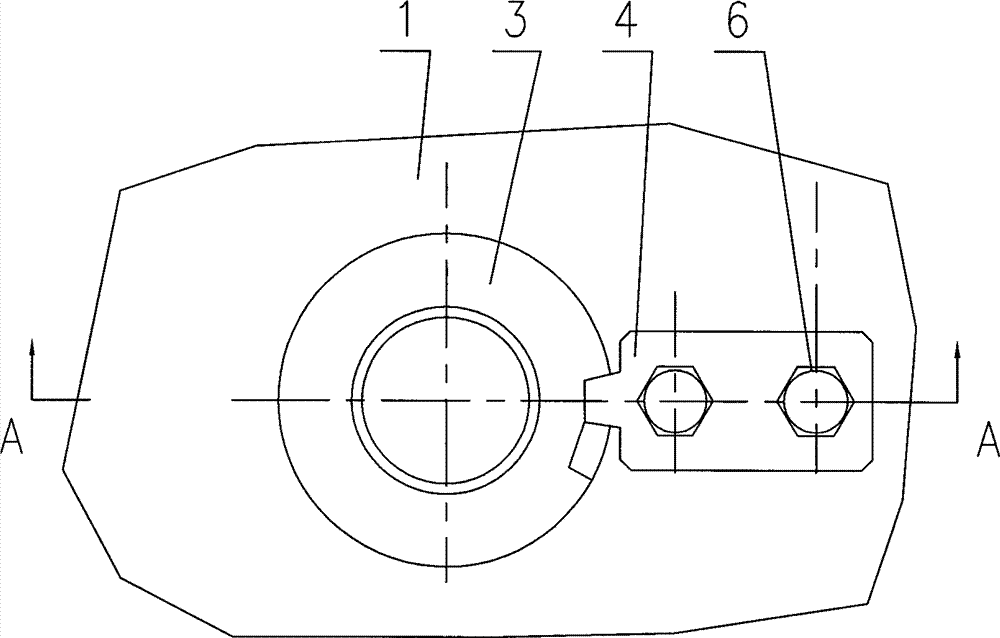

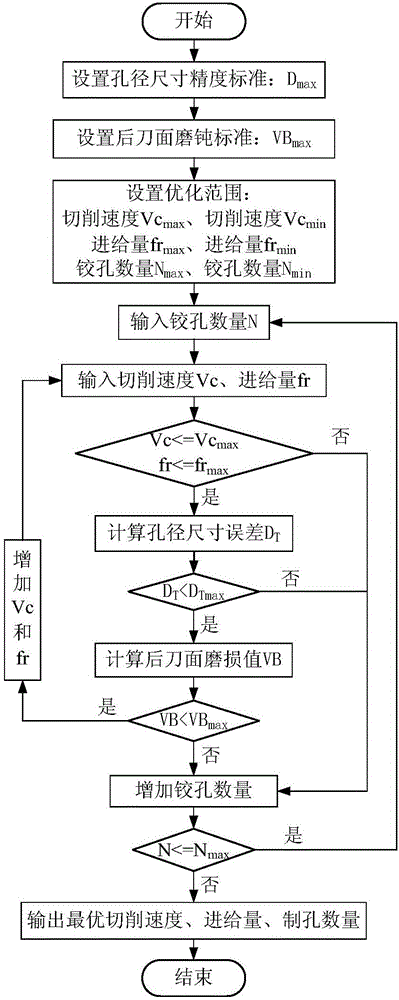

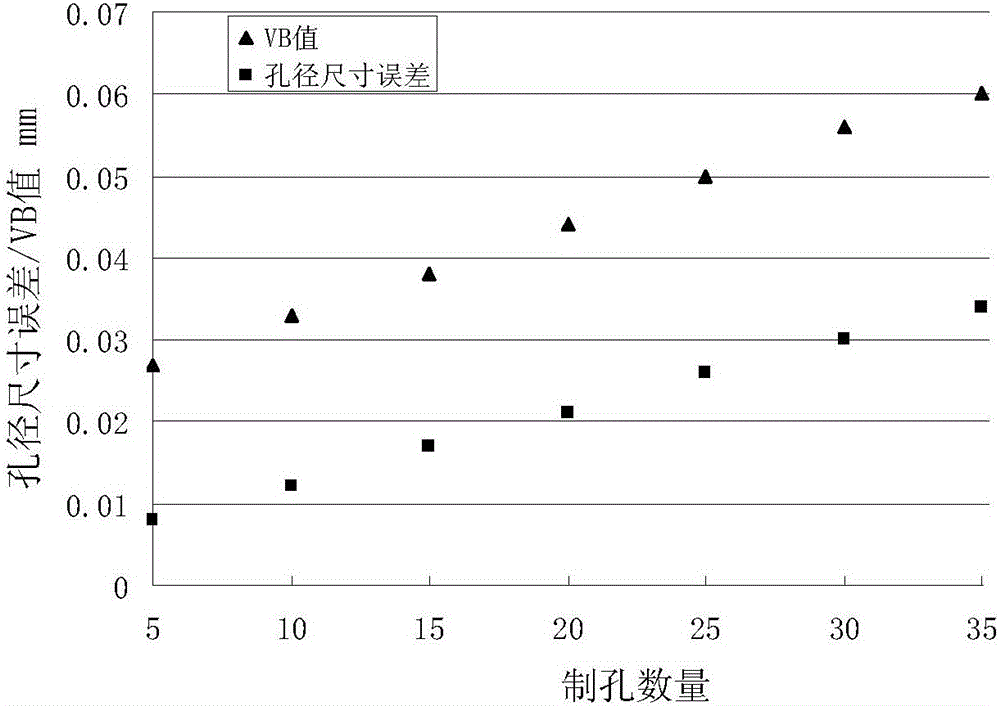

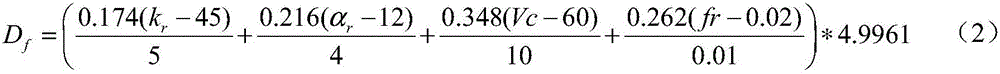

Optimization method for CFRP (carbon fiber reinforced plastics) and titanium alloy laminated structure reaming process

ActiveCN106624166AImprove structural reaming efficiencyReduce the failure rateReaming devicesPore diameterReamer

The invention provides an optimization method for a CFRP (carbon fiber reinforced plastics) and titanium alloy laminated structure reaming process and relates to the technical field of CFRP and titanium alloy laminated assembly. According to the optimization method for the CFRP and titanium alloy laminated structure reaming process, the constraints such as pore diameter size errors, rear knife face wear of a reaming tool, the service life of the reaming tool and the like are comprehensively considered, and the cutting speed and feed of the reamed hole are optimized according to the existing reamer structure parameter, pore diameter size accuracy standard and quantity of the formed pores. According to the method disclosed by the invention, the laminated structure reaming process is optimized by adopting multiple constraints, the reaming efficiency of the CFRP and titanium alloy laminated structure is effectively improved, and the reject rate and scrap rate of the parts are reduced, so that the reaming tool has the maximum reaming capacity.

Owner:沈阳航远航空技术有限公司

Machining methods for inner walls of cylinders with thin-walled small half-blind deep holes and thin-walled small full-blind deep holes

ActiveCN107243719AEfficient processingProcessing from difficult to easyMilling equipment detailsReaming devicesAlloyEngineering

The invention discloses machining methods for the inner walls of cylinders with thin-walled small half-blind holes and thin-walled small full-blind deep holes, and belongs to the technical field of machining for small-hole-diameter large-draw-ratio thin-walled half-blind inner holes and full-blind inner holes of structural elements in the field of machining. The process methods can be used for stably and effectively machining the cylinders with the thin-walled small half-blind deep holes and the thin-walled small full-blind deep holes. According to the adopted technical scheme, the machining method for the inner wall of the cylinder with the thin-walled small half-blind deep holes comprises the following steps that firstly, centering and aligning are conducted through a machining center; secondly, a bottom hole is formed through machining by adoption of a non-standard hard alloy inner cooling drill; thirdly, the holes are formed through machining by adoption of a non-standard hard alloy inner cooling reamer; fourthly, the lower end surface of the workpiece is machined; and fifthly, the walls of the holes are subjected to ultrasonic rolling finishing machining. Compared with the machining method for the inner wall of the cylinder with the thin-walled small half-blind deep holes, the fourth step is omitted according to the machining method for the inner wall of the cylinder with the thin-walled small full-blind deep holes. The machining methods provided by the invention are used for machining of the small-hole-diameter large-draw-ratio thin-walled half-blind and full-blind inner holes.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

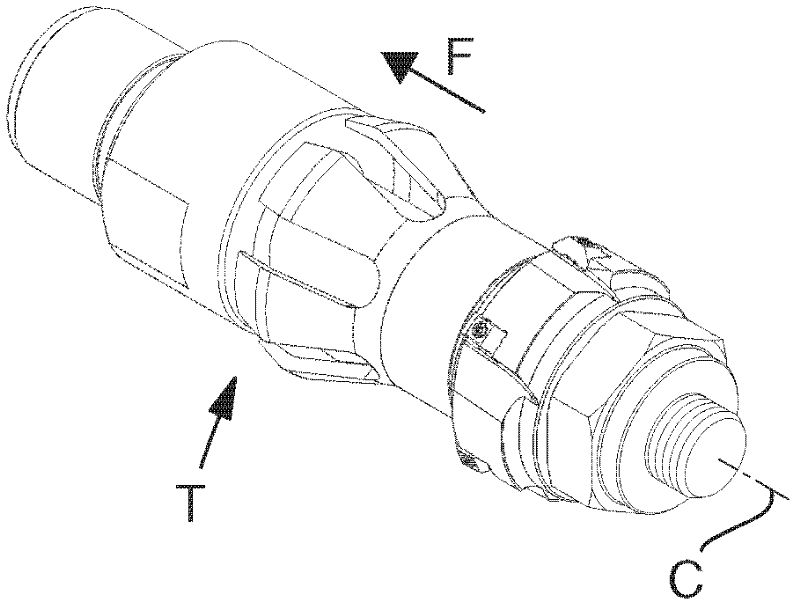

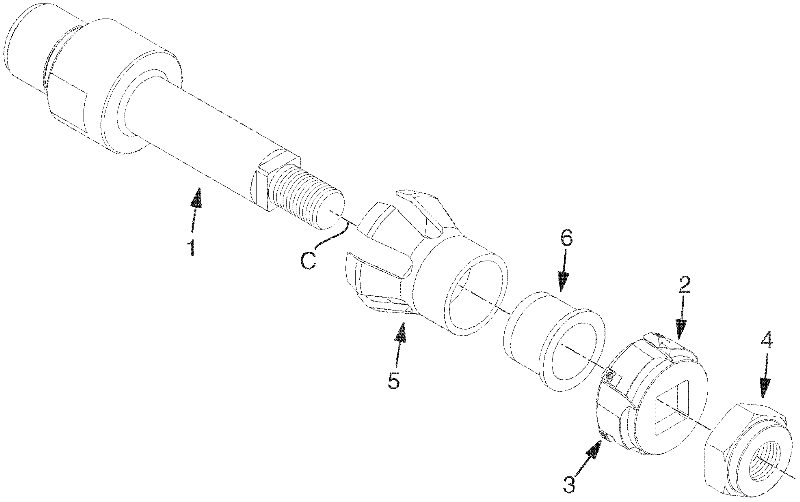

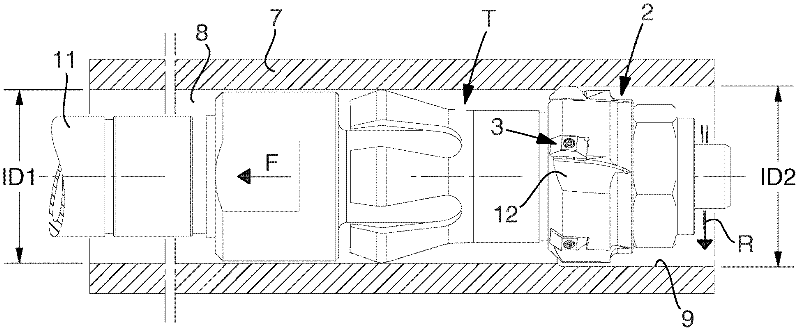

Turning reaming machine with high applicability

InactiveCN111906384AEasy to processAutomatic adjustment of rotation speedFeeding apparatusReaming devicesStructural engineeringMachine

The invention discloses a turning reaming machine. The turning reaming machine comprises a lifting table, a base and a supporting body, wherein a lifting cavity with a rightward opening is formed in the lifting table, the left side face of the supporting body is slidably connected with the left wall of the lifting cavity, and the base is fixedly arranged on the right side face of the lifting table; and a clamping mechanism used for clamping and fixing a hollow pipe is arranged in the base, the clamping mechanism comprises a stand column, a containing cavity with an upward opening is formed inthe base, the stand column is fixedly arranged on the bottom wall of the stand column, and the hollow pipe can be placed on the bottom wall of the containing cavity. According to the turning reaming machine, hollow pipes with different diameters can be clamped, installed and fixed, and in the clamping, installing and fixing state, the clamping force can be automatically adjusted through the diameters of the hollow pipes, so that the risk probability that when the hollow pipes are in the clamped state, the hollow pipes are clamped and damaged and deformed is reduced.

Owner:磐安字根电子科技有限公司

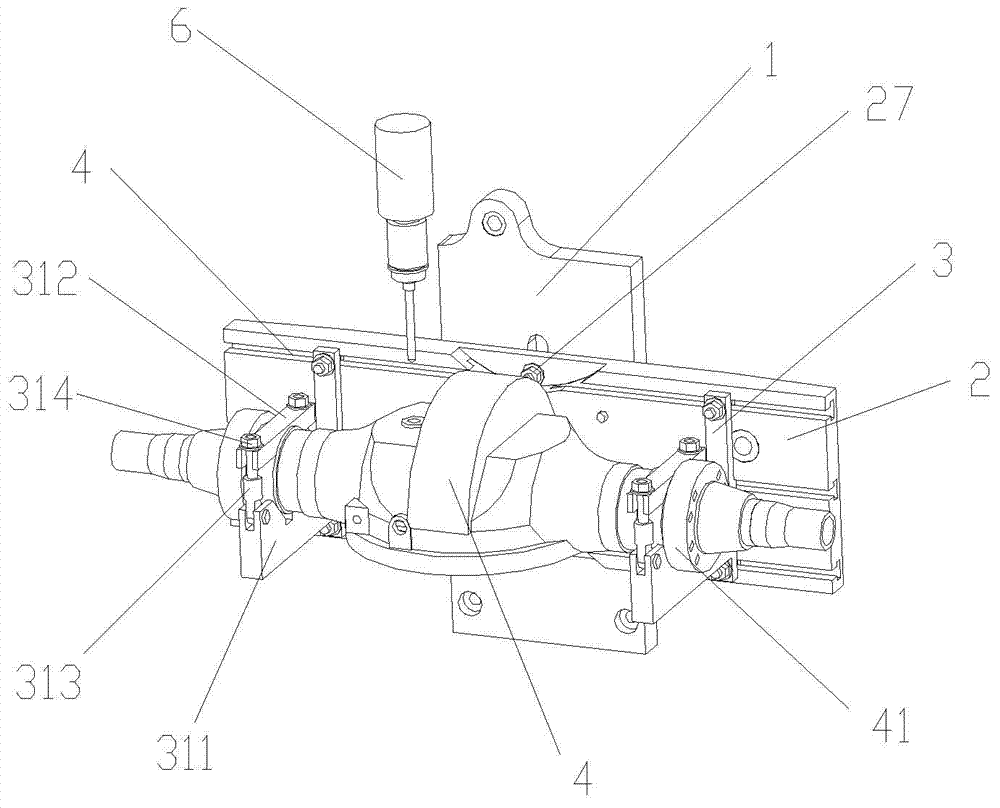

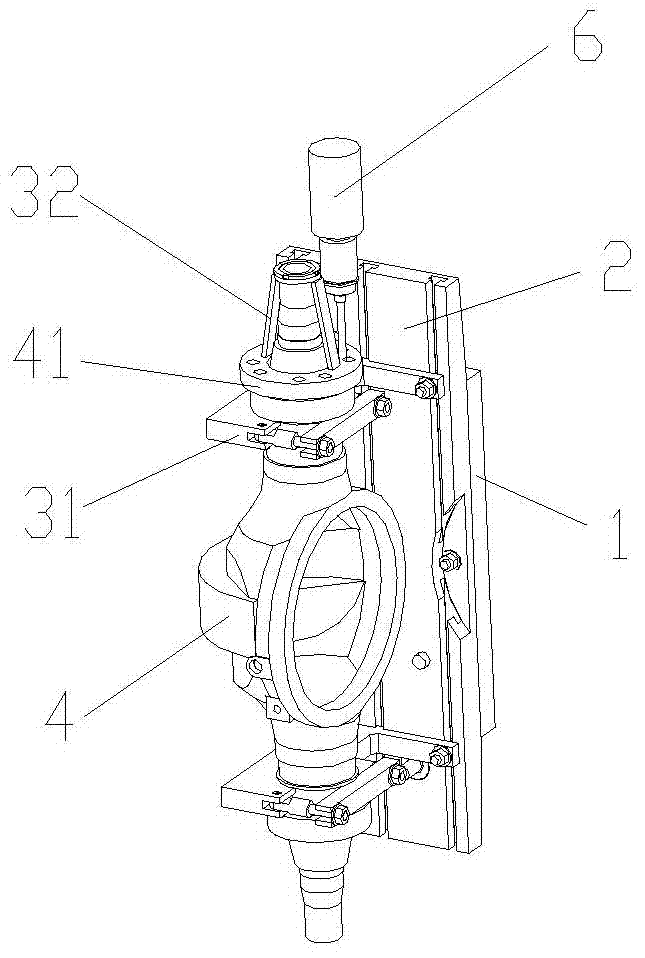

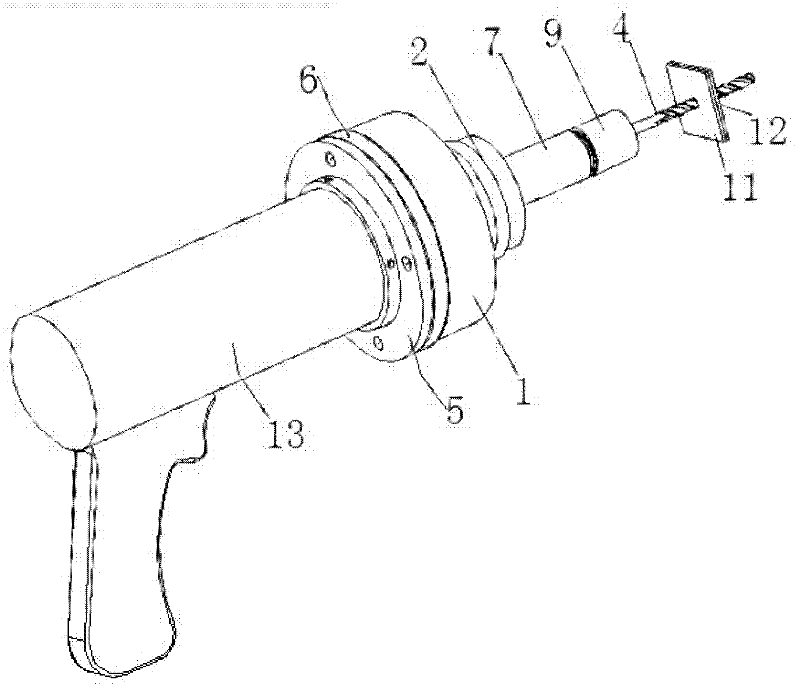

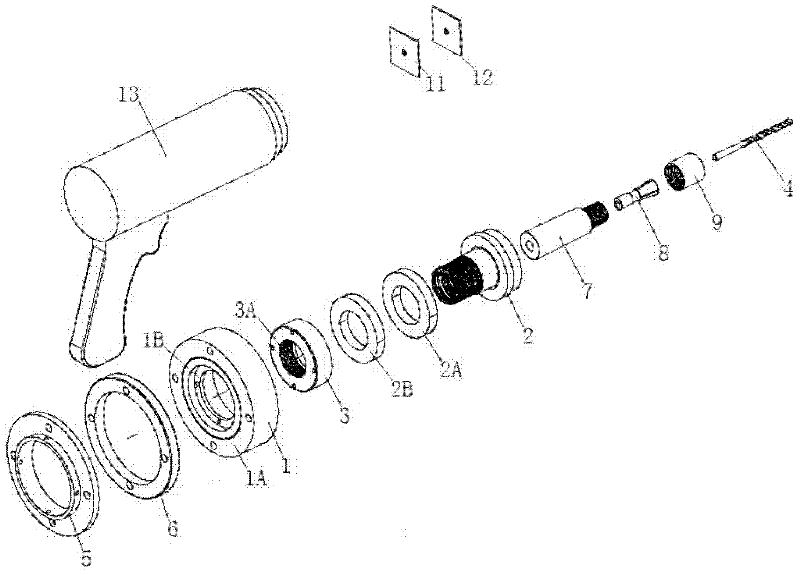

Ultrasonic vibration sleeve reaming machining device applied to air drill

ActiveCN102229001ASimple structural designRealize rotating power supplyReaming devicesTransducerUltrasonic vibration

The invention discloses an ultrasonic vibration sleeve reaming machining device applied to an air drill. The device comprises a slip ring, a front cover plate, a ceramic plate A, a ceramic plate B, a rear cover plate, a flange plate, a retainer ring, a manual air drill, a drill shaft sleeve, a spring chuck and a fastening cap; the main shaft of the manual air drill is connected into an internal thread hole of the front cover plate; after the ceramic plate A and the ceramic plate B are sequentially sleeved at the external thread section of the front cover plate, the front cover plate is in threaded connection into an internal thread hole of the rear cover plate; an inner ring of the slip ring is arranged on the rear cover plate, and an outer ring of the slip ring is connected with the retainer ring and the flange plate through bolts; and the inner conical section of one end of the drill shaft sleeve is connected with the outer cylindrical section of the spring chuck, the outer cylindrical section of the other end of the drill shaft sleeve is thermally fed into the inner cylindrical section of the front cover plate, and the chuck section of the spring chuck chucks a reamer or a coredrill and is finally locked through the fastening cap. By assembly design of the spring chuck, the clamped tool bit form is varied, a transducer, the main shaft of a common air drill and a cutter aredetached conveniently, and the rotary precision of the whole air drill tool is ensured.

Owner:BEIHANG UNIV

A reaming tool as well as a head and a cutting insert therefor

The invention relates to a reaming tool as well as a head and a cutting insert therefor. The reaming tool includes a head and a detachable cutting insert that is fixed in a seat in the head. The seat includes a radial support surface, a tangential support surface, and an axial support surface, while the cutting insert has the shape of a mirror-symmetrical polyhedron comprising six limiting surfaces, viz. two chip surfaces and at least two clearance surfaces, a number of alternately usable, identical cutting edges being formed in transitions between the chip and clearance surfaces. According to the invention, in at least one of the three limiting surfaces of the cutting insert, there is formed a female- or male-like securing means that co-operates with a complementary, male- or female-like securing means in the seat, more precisely in an inactive, contactless state as long as the cutting insert is held pressed by the cutting forces against the axial support surface of the seat, the securing means being potentially activatable by being brought into contact with each other in case the cutting insert would unintentionally be distanced from the axial support surface against the action of a clamping member.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

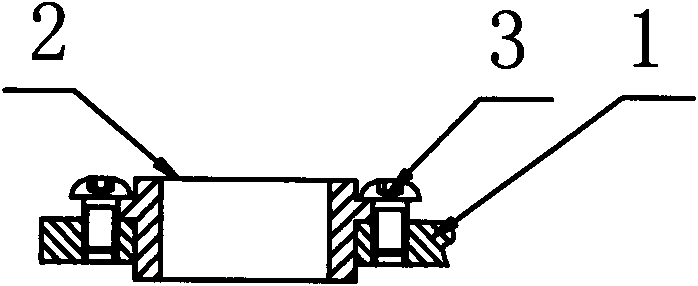

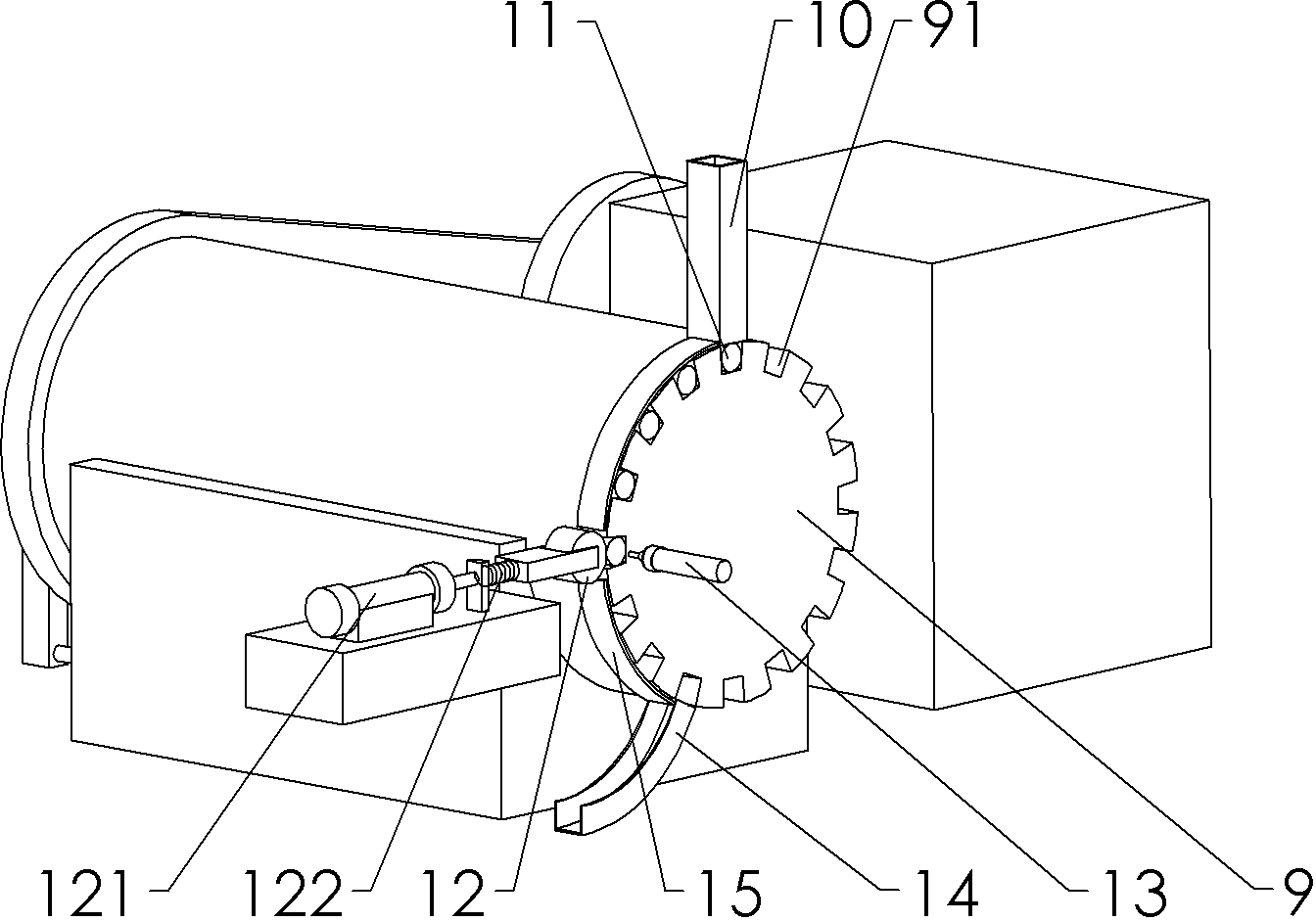

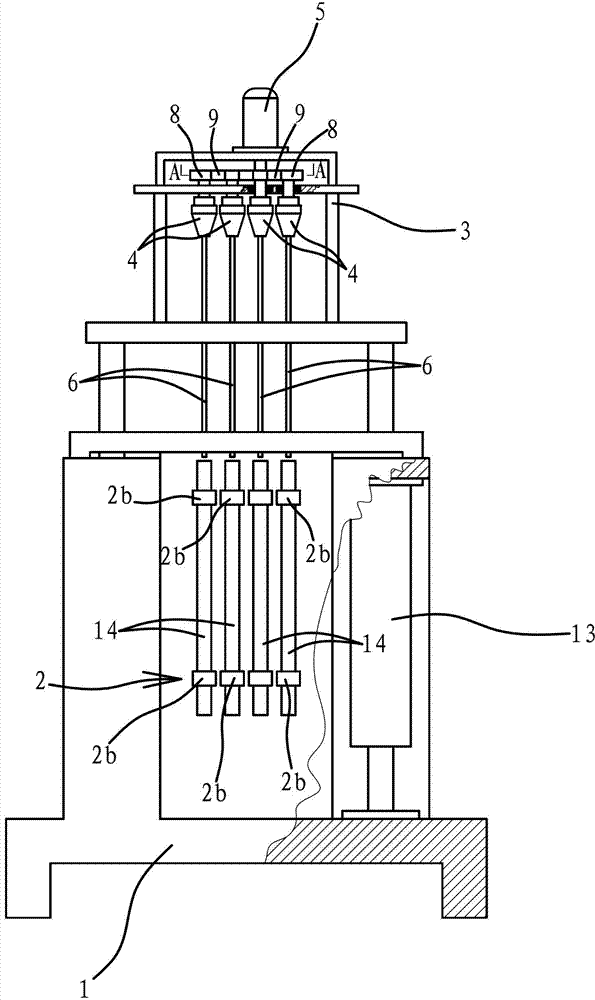

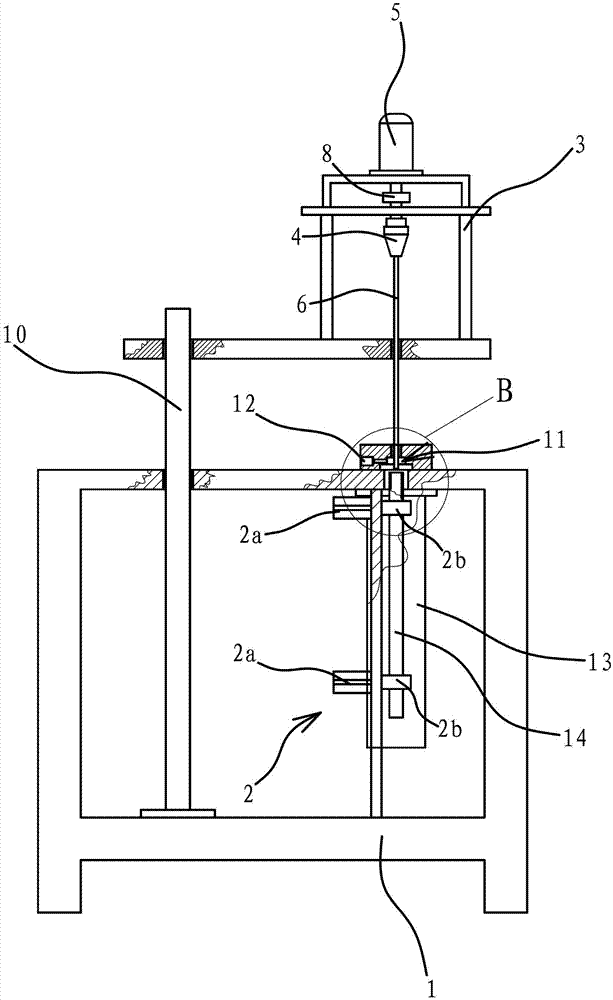

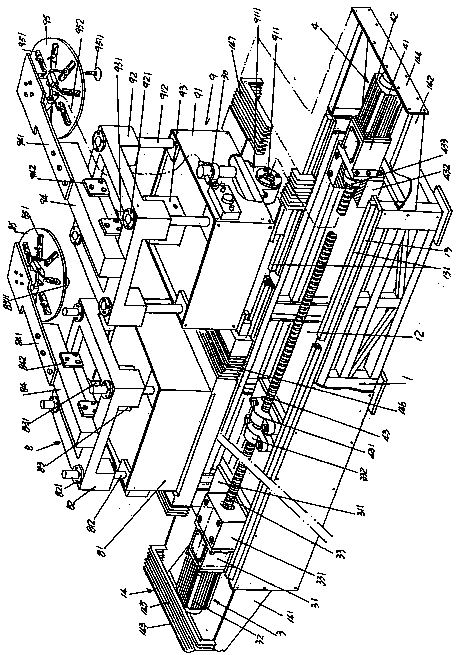

Disk saw blade feeding and receiving device of automatic reaming device for disk saw blade center hole

InactiveCN104289962AReduce work intensityImprove adaptabilityReaming devicesMetal working apparatusManipulatorUltimate tensile strength

The invention discloses a disk saw blade feeding and receiving device of and an automatic reaming device for a disk saw blade center hole, and belongs to the technical field of metal saw blade processing machinery. The automatic reaming device for the disk saw blade center hole comprises a base, a vertical drill, a receiving manipulator translating and driving mechanism, a feeding and receiving manipulator; the disk saw blade feeding and receiving device comprises a feeding and lifting gear and a receiving and lifting gear, the feeding and lifting gear comprises a feeding rack, a feeding motor, a feeding screw, a feeding and lifting gear, a left chain wheel seat of a feeding frame, a chain seat of the feeding mechanism, a first chain, a second chain and a balance block; the receiving and lifting gear comprises a receiving frame, a receiving motor, a receiving screw, a receiving and lifting platform, a left chain wheel seat of a receiving frame, a chain block of the receiving frame, a first lifting chain, a second lifting chain and a balance hammer. The disk saw blade feeding and receiving device is good in automation effect, working strength can be alleviated, safety can be ensured, the applicability to an operation place can be improved, human input can be reduced, and labor resource can be saved.

Owner:SUZHOU VOCATIONAL UNIV

Universal-purpose fixing clamp and universal-purpose reamer end method of using the same

InactiveCN101003129APrecise Position CalibrationPrecision Restoration WorkWork holdersReaming devicesLocking mechanismEngineering

A universal fixture, a universal reaming unit and a method using them for manually repairing the valve opening of OE valve or oil pump with high accuracy are disclosed. Said universal fixture has a cutting tool fixer or a rotary mechanical clamp, whose position can be accurately regulated. A locking unit is also disclosed.

Owner:SONNAX INDS

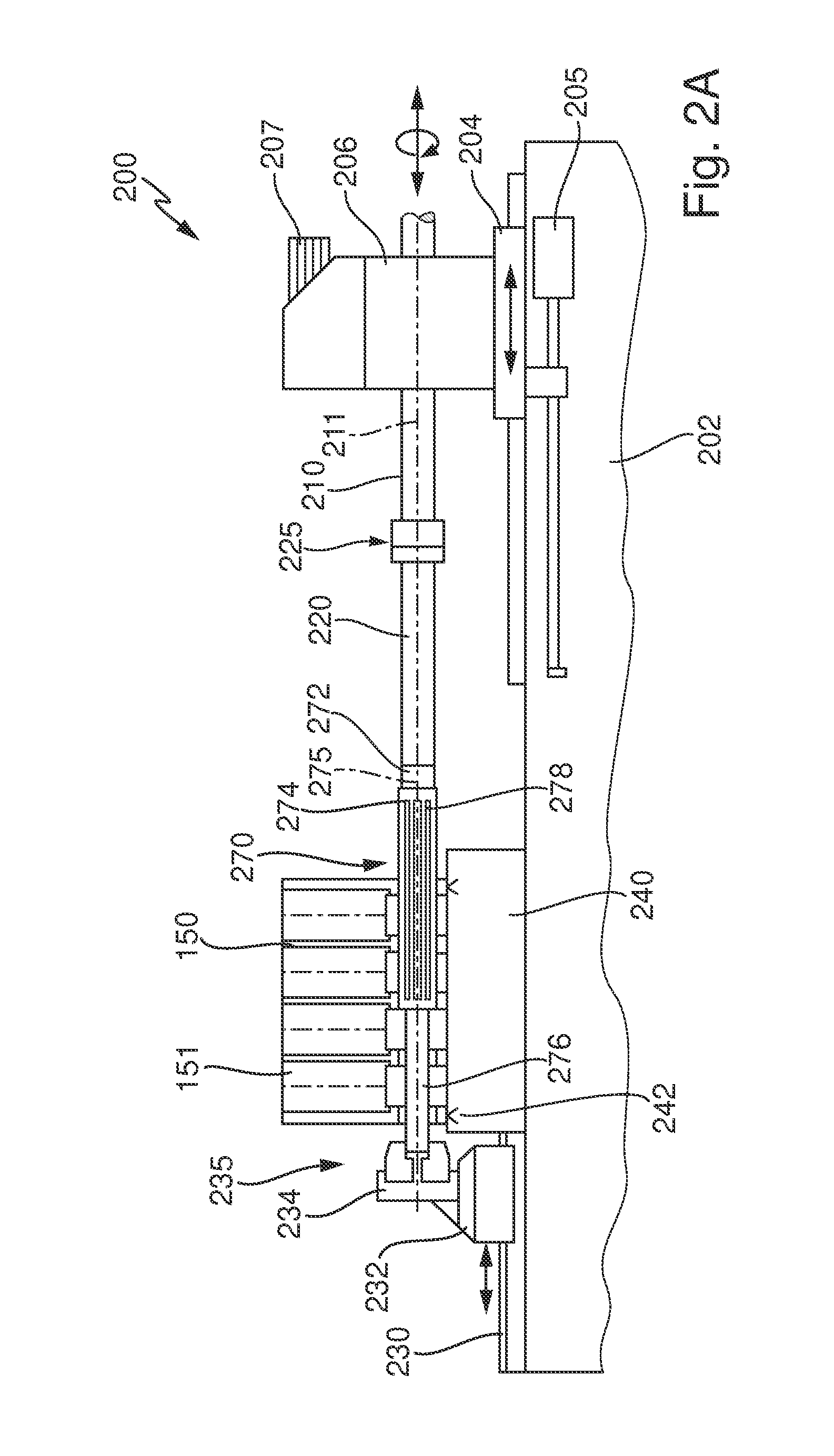

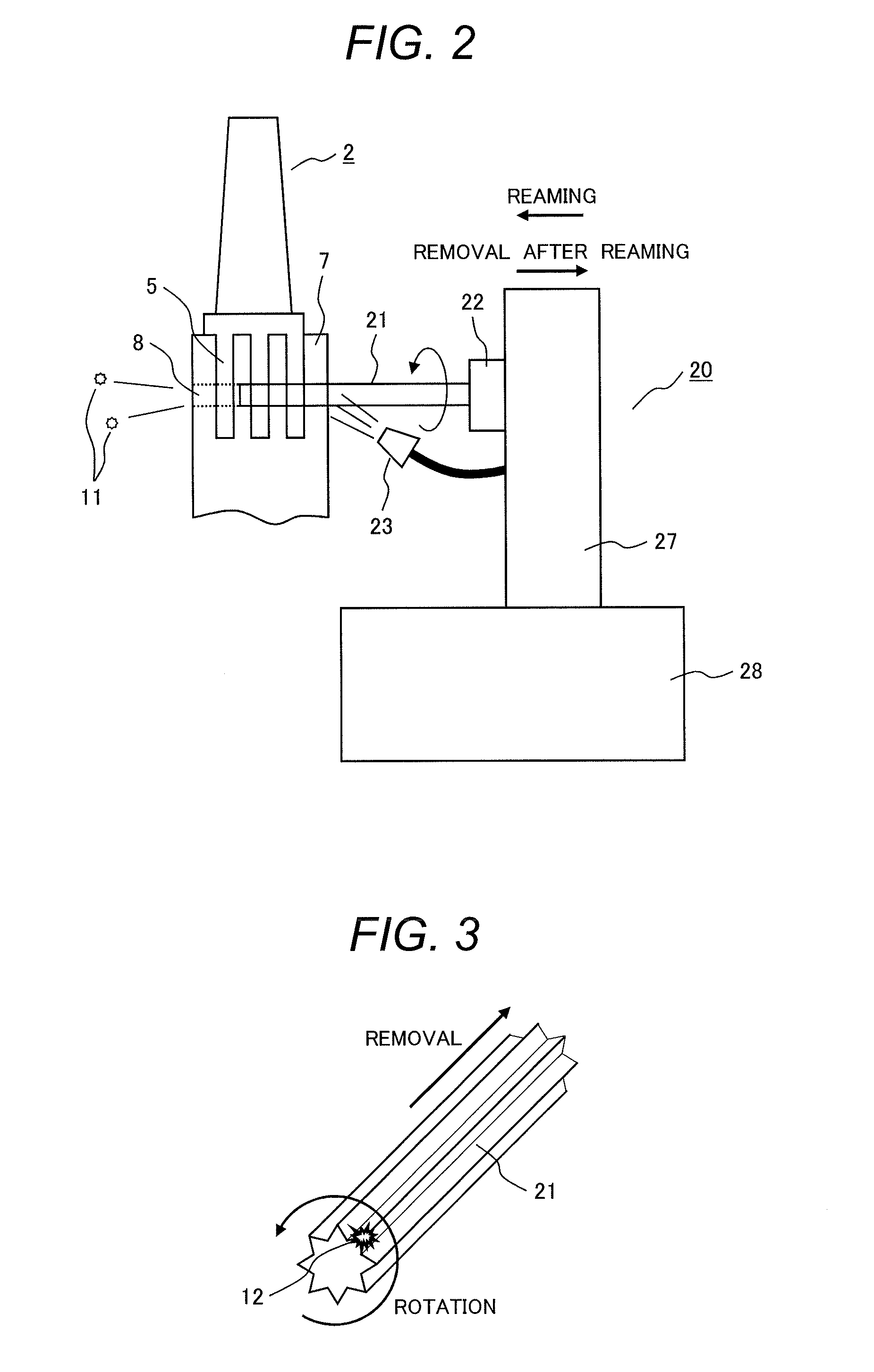

Method for Manufacturing Multi-Finger Pinned Root for Turbine Blade Attached to Turbine Rotor and Turbine Blade

In manufacturing a multi-finger pinned root pin-coupling a turbine blade made of a high-strength material and a rotor disc, a reamer used to ream a pin insertion hole formed through a turbine blade attachment base is removed from the pin insertion hole while being rotated so as to cause a scratch formed by a chip on the inner surface of the pin insertion hole to be inclined with respect to the axial direction of the pin insertion hole. This brings the direction of the scratch on the inner surface of the pin insertion hole and the direction of tensile stress generated on the inner surface of the pin insertion hole adequately close to be parallel to each other. As a result, the fatigue strength reduction caused by the scratch can be inhibited.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com