Automatic indexing reaming device

An automatic indexing and hinge pin technology, applied in the direction of reaming device, reaming device, precision positioning equipment, etc., can solve the problem that the work efficiency cannot meet the actual demand and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

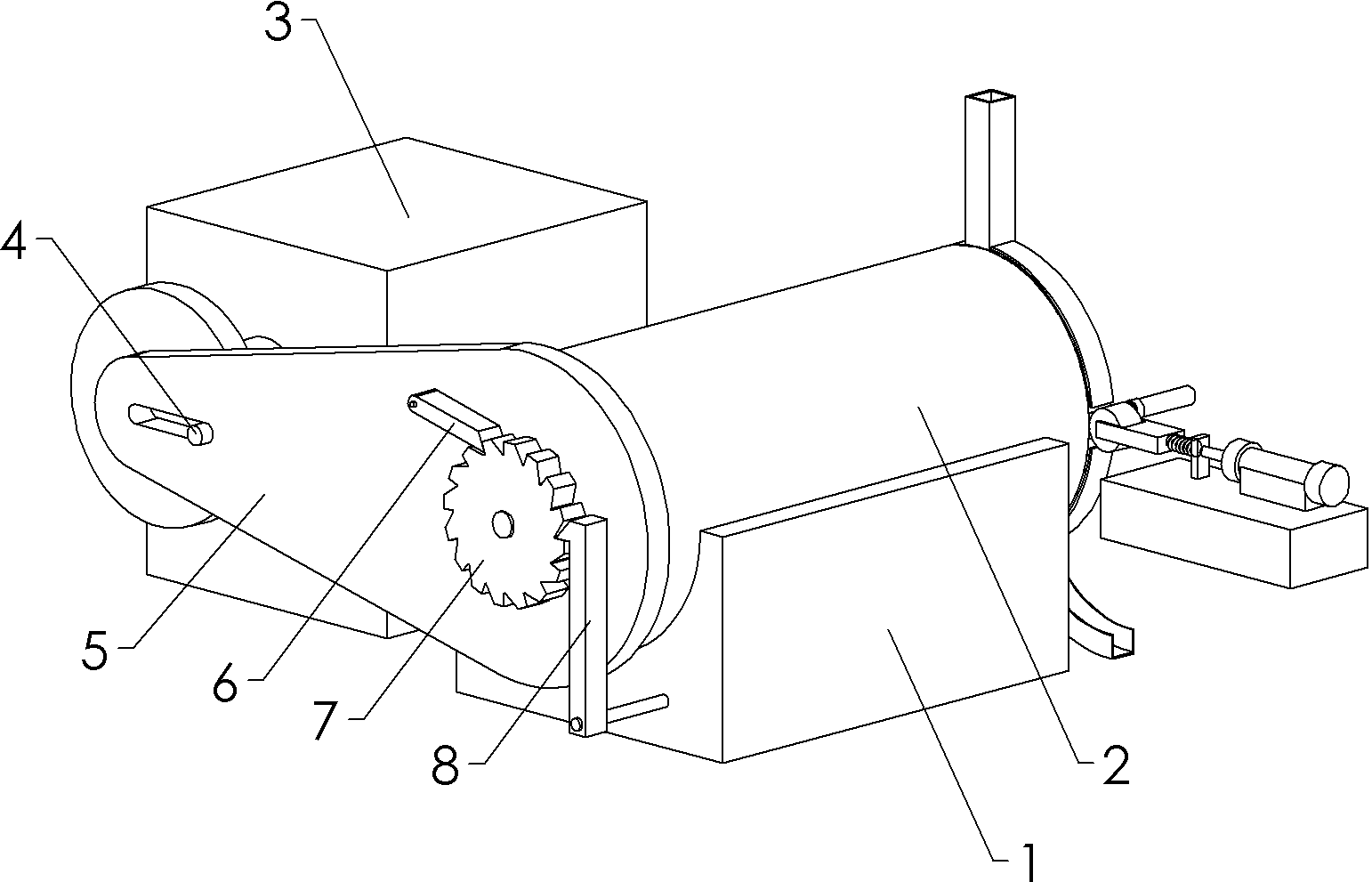

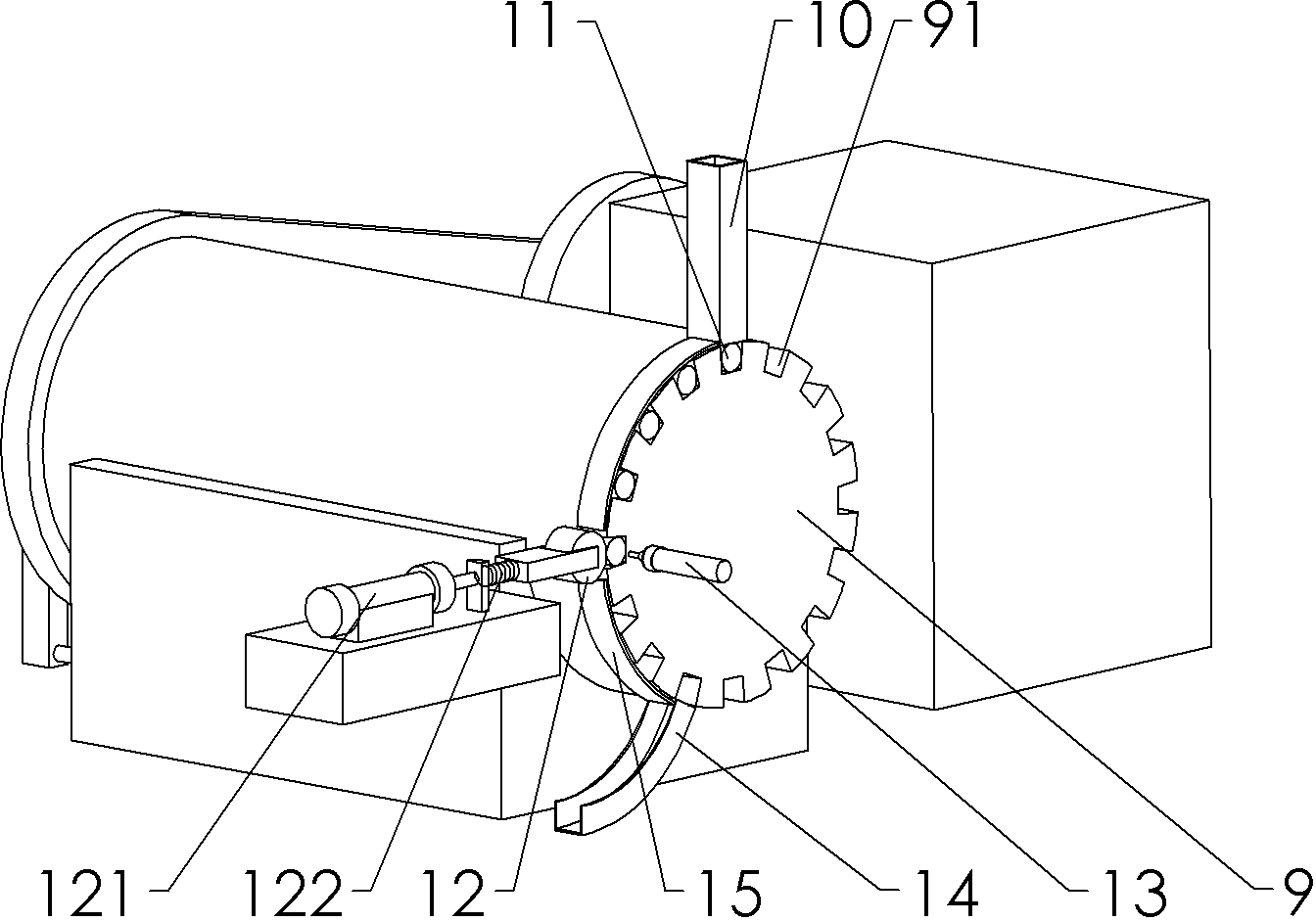

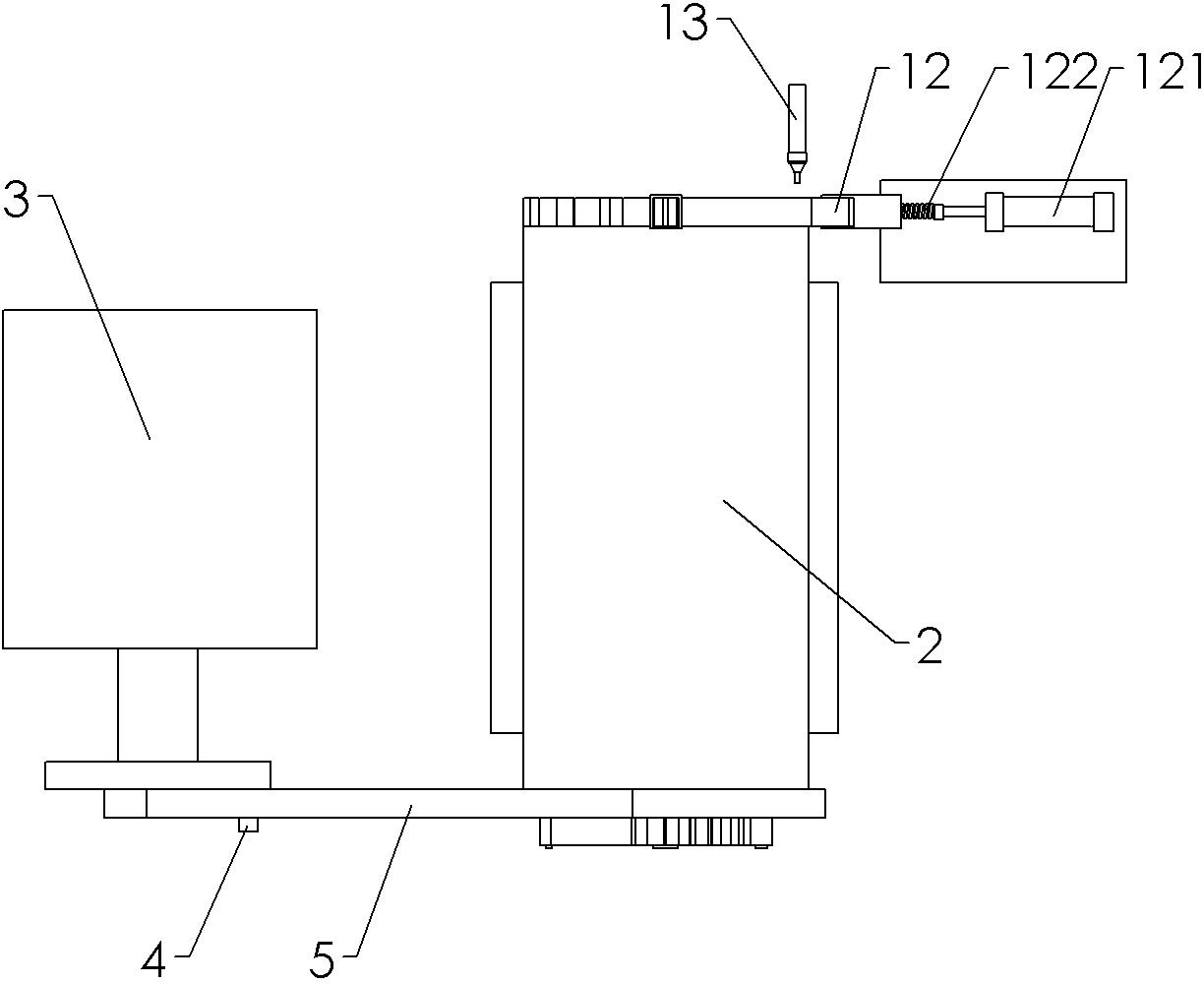

[0014] The reference signs in the drawings of the description include: frame 1, main shaft 2, casing 3, crank 4, swing lever 5, pawl 6, ratchet 7, reverse pawl 8, feeding wheel 9, charging port 91, Upper slideway 10, workpiece 11, hold-down wheel 12, cylinder 121, stage clip 122, reamer 13, glideway 14, baffle plate 15.

[0015] The embodiment is basically as all appended Figure 1~3 As shown: the main shaft 2 of the indexing plate is connected to the frame 1 in rotation, a stepping motor and a reducer are installed in the casing 3, the output shaft of the reducer is extended and connected to the crank 4, and a swing rod 5 is hinged on the main shaft 2. The other end of the swing rod 5 is provided with a bar-shaped hole that is hinged to the crank 4, and the rotation of the crank 4 drives the swing rod 5 to swing back and forth. The torsion spring on the crank 4 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com