Method for processing deep hole of sleeve of steam turbine by using stepped reamer

A step type, steam turbine technology, applied in the direction of reamers, reaming devices, metal processing equipment, etc., can solve the problems of cutting and removing difficulties, easy deflection and vibration of the sleeve, and scratches on the processed surface, etc., to prevent The effect of scratching the processed surface, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

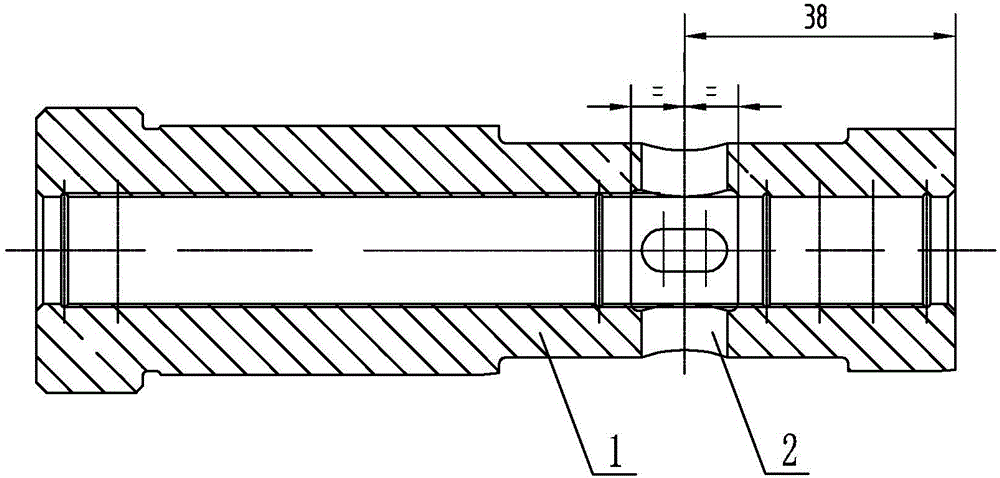

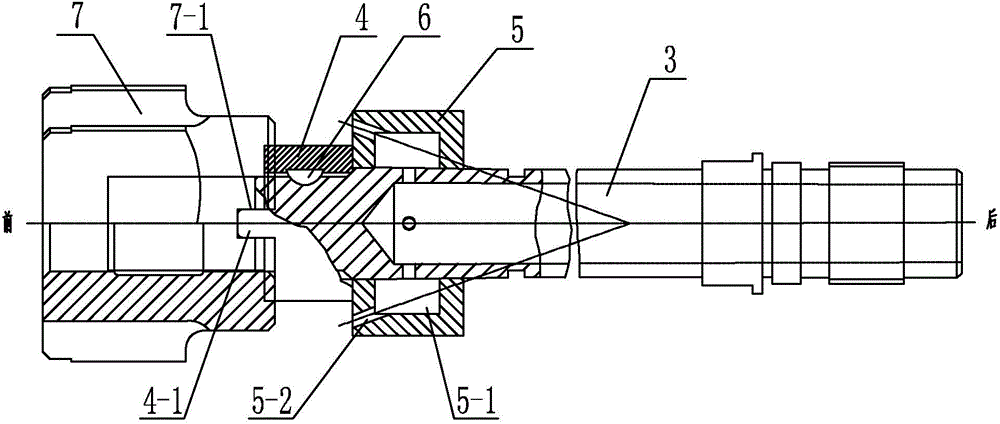

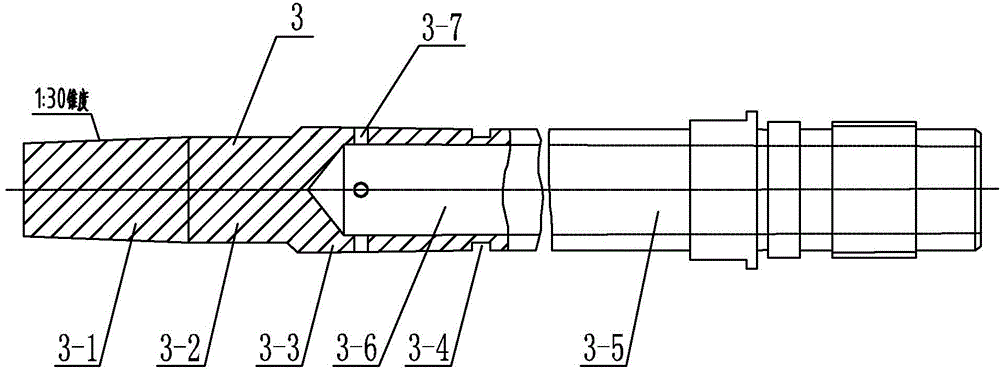

[0030] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this implementation mode, this implementation mode is realized through the following steps:

[0031] Step 1, blanking: select profile alloy steel round bar, length 398mm, diameter Ф95mm;

[0032] Step 2. The inner hole, outer circle and both ends of the first rough turning sleeve 1: leave 3mm allowance on the radius of the inner hole; leave 3mm allowance on the radius of each section of the outer circle; turn the two ends, Leave a margin of 3mm for each;

[0033] Step 3, Quenching and tempering: Carry out quenching and tempering treatment on the sleeve 1; Quenching and tempering treatment refers to high-temperature tempering treatment after quenching, and the high-temperature tempering temperature is between 500°C and 650°C;

[0034] Step 4. The inner hole, outer circle and both ends of the sleeve 1 for the second rough turning: leave 1.5mm allowance on the radius of the inner hole; leave 1.5mm a...

specific Embodiment approach 2

[0046] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, this embodiment is that in step seven, the reamer starts to move the knife from the end face of the end of the inner hole, and first reams out a length of 12mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, this embodiment is the feed speed s=0.16mm / r of the reamer in step 7. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com